2SHB 3 | Version 1.02

Imprint

Product identification

Scissor lift Item number

SHB 3 6240030

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

Internet: www.unicraft.de

Indications regarding the operating instructions

Original instructions

Edition: 12.06.2020

Version: 1.02

Language: English

Author: FL

Indications regarding the copyright

Copyright © 2020 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company Stuermer. Passing on as well

as copying of this document, the use and distribution of

its content are prohibited if not explicitly permitted. Con-

traventions are liable to compensation.

Subject to technical modifications and error.

Contents

1 Einführung ...............................................................3

1.1 Urheberrecht ...................................................... 3

1.2 Kundenservice.................................................... 3

1.3 Haftungsbeschränkung...................................... 3

2 Sicherheit .................................................................3

2.1 Symbolerklärung................................................. 3

2.2 Verantwortung des Betreibers............................ 4

2.3 Personalanforderungen...................................... 5

2.4 Persönliche Schutzausrüstung.......................... 5

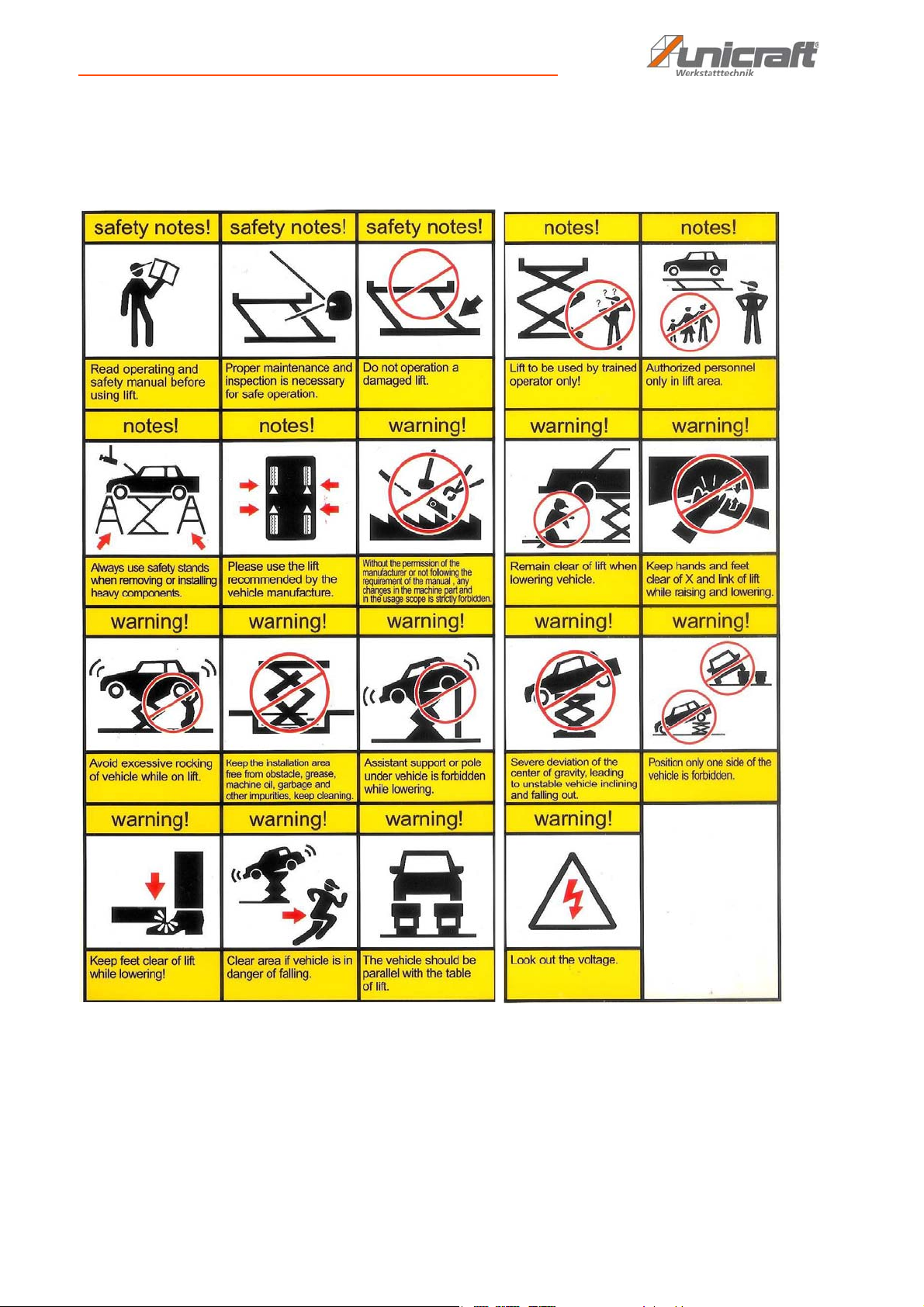

2.5 Sicherheitskennzeichnung an der Hebebühne.. 5

2.6 Warnhinweise an der Hebebühne...................... 6

2.7 Allgemeine Sicherheitsvorschriften .................... 7

2.8 Sicherheitsvorrichtungen.................................... 7

3 Bestimmungsgemäße Verwendung ......................8

3.1 Vorhersehbarer Fehlgebrauch ........................... 8

3.2 Restrisiken .......................................................... 8

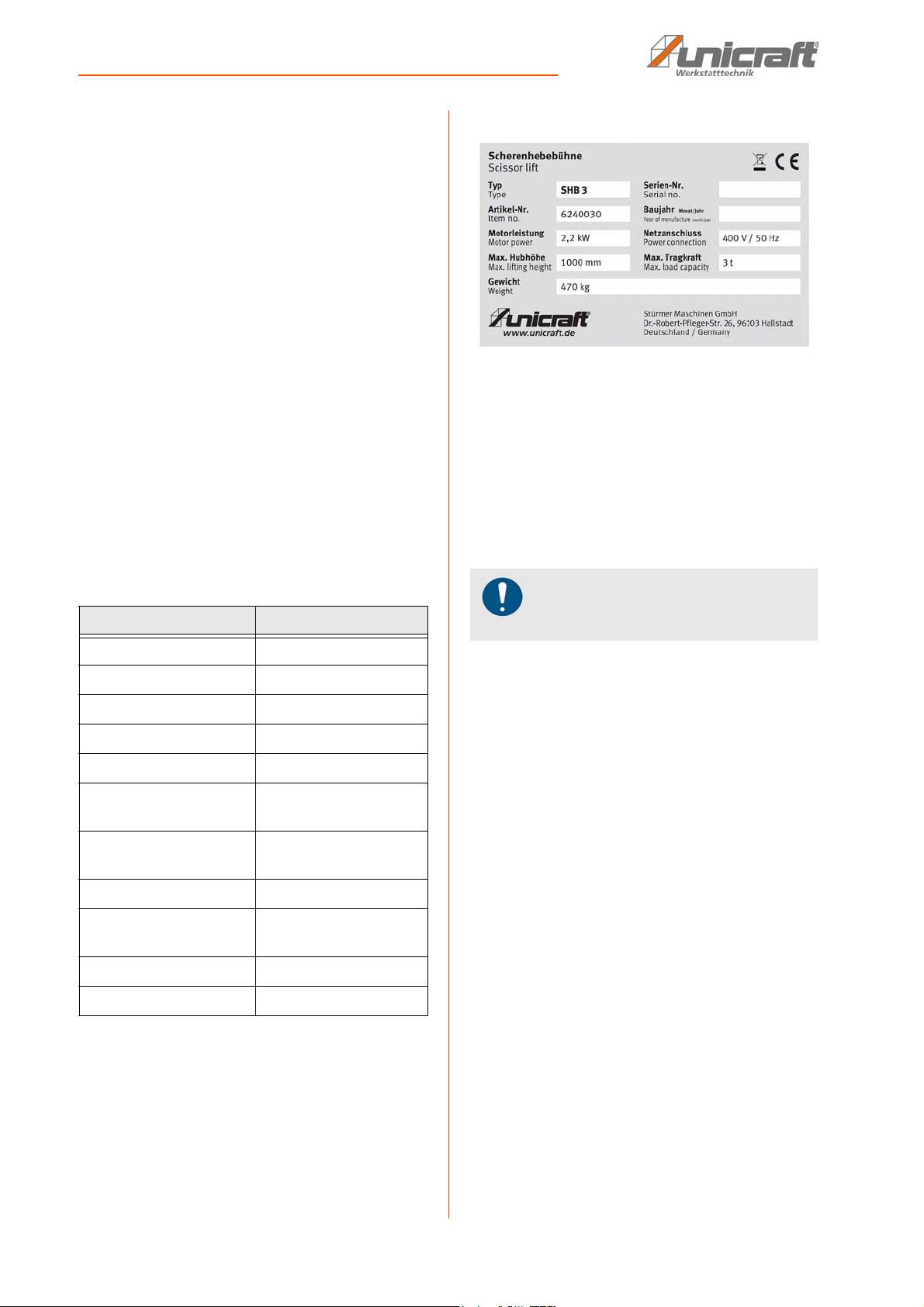

4 Technische Daten....................................................8

4.1 Typenschild ........................................................ 8

5 Transport, Verpackung und Lagerung ..................8

5.1 Transport ............................................................ 8

5.2 Verpackung ........................................................ 9

5.3 Lagerung ............................................................ 9

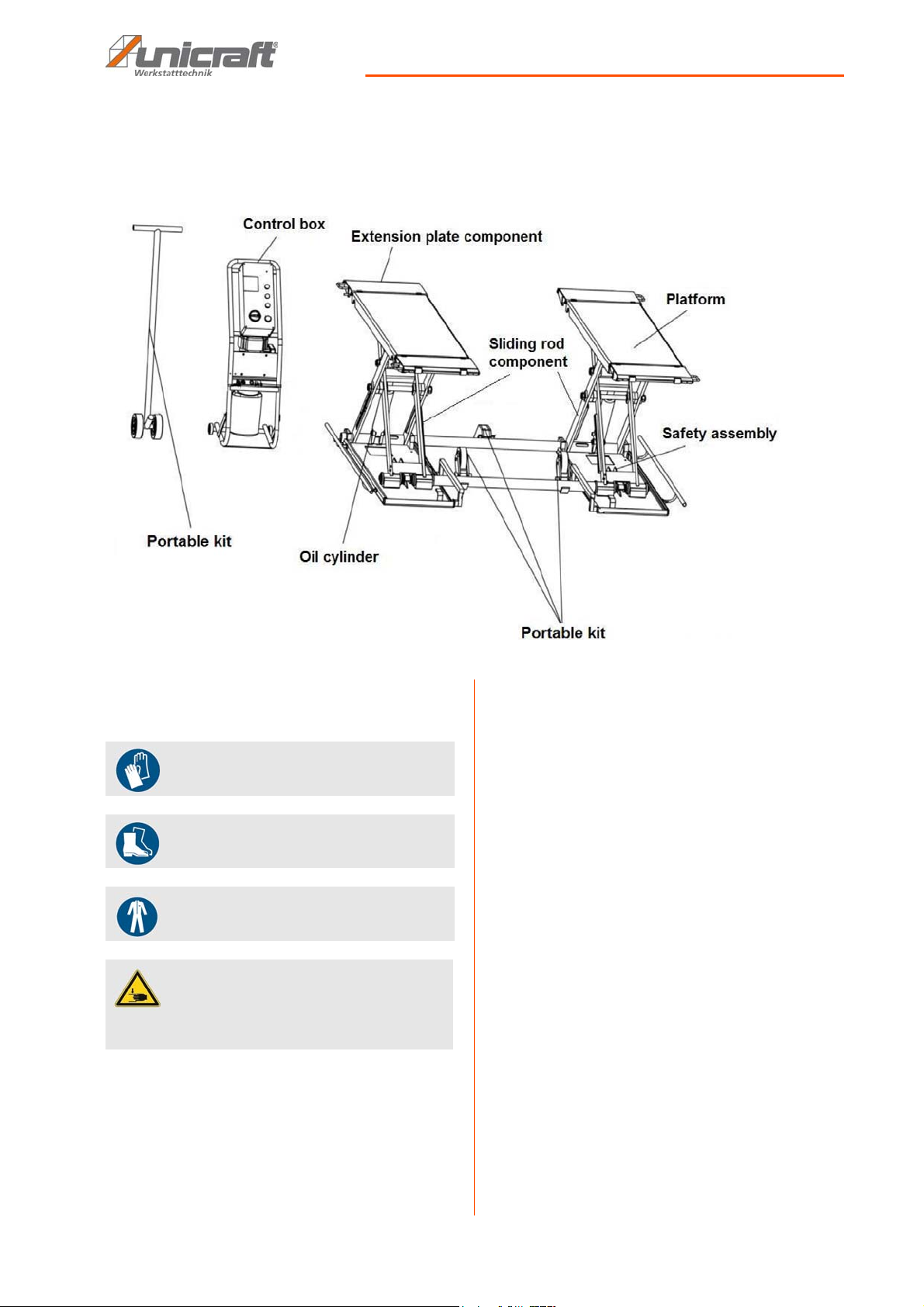

6 Gerätebeschreibung ...............................................9

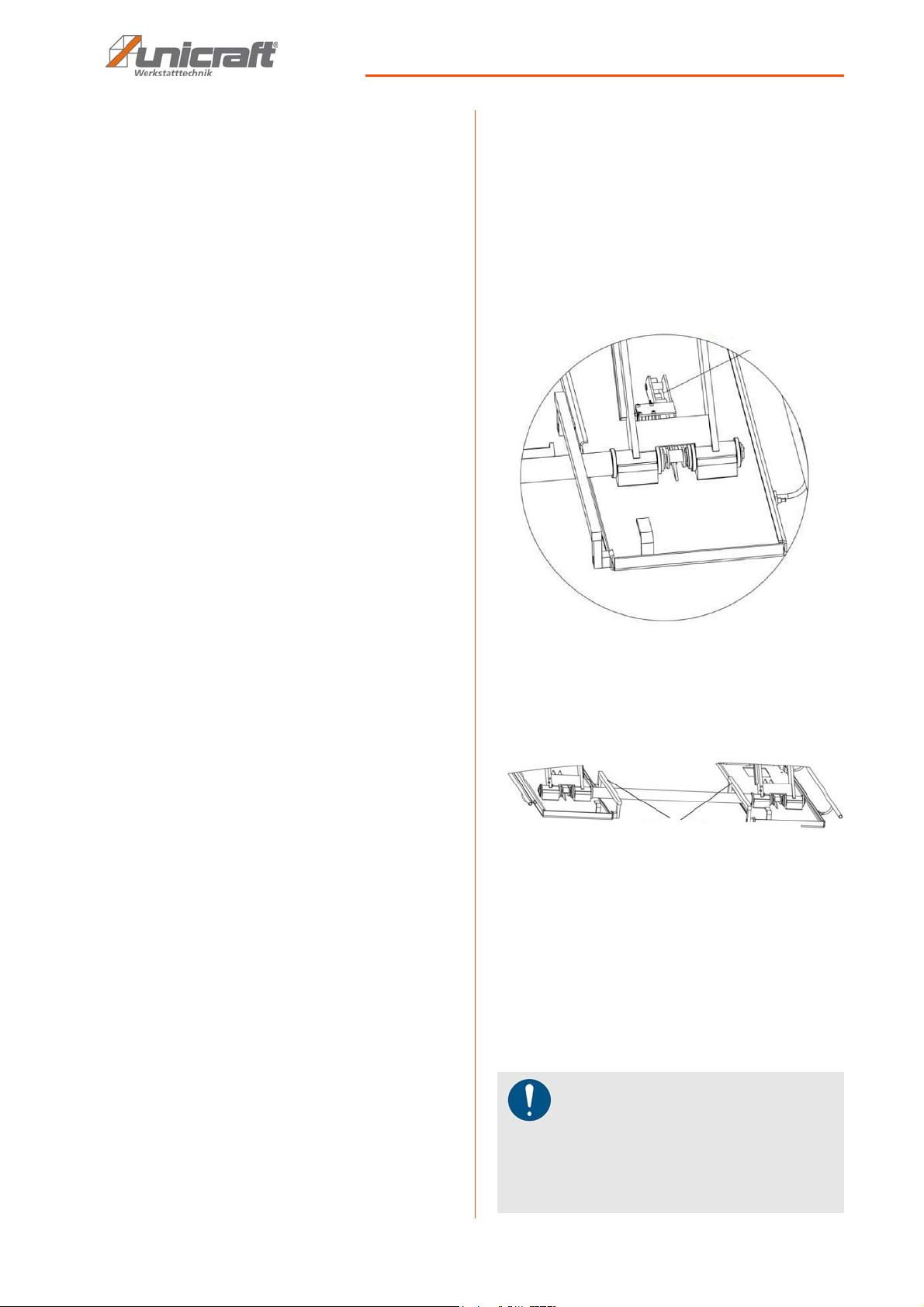

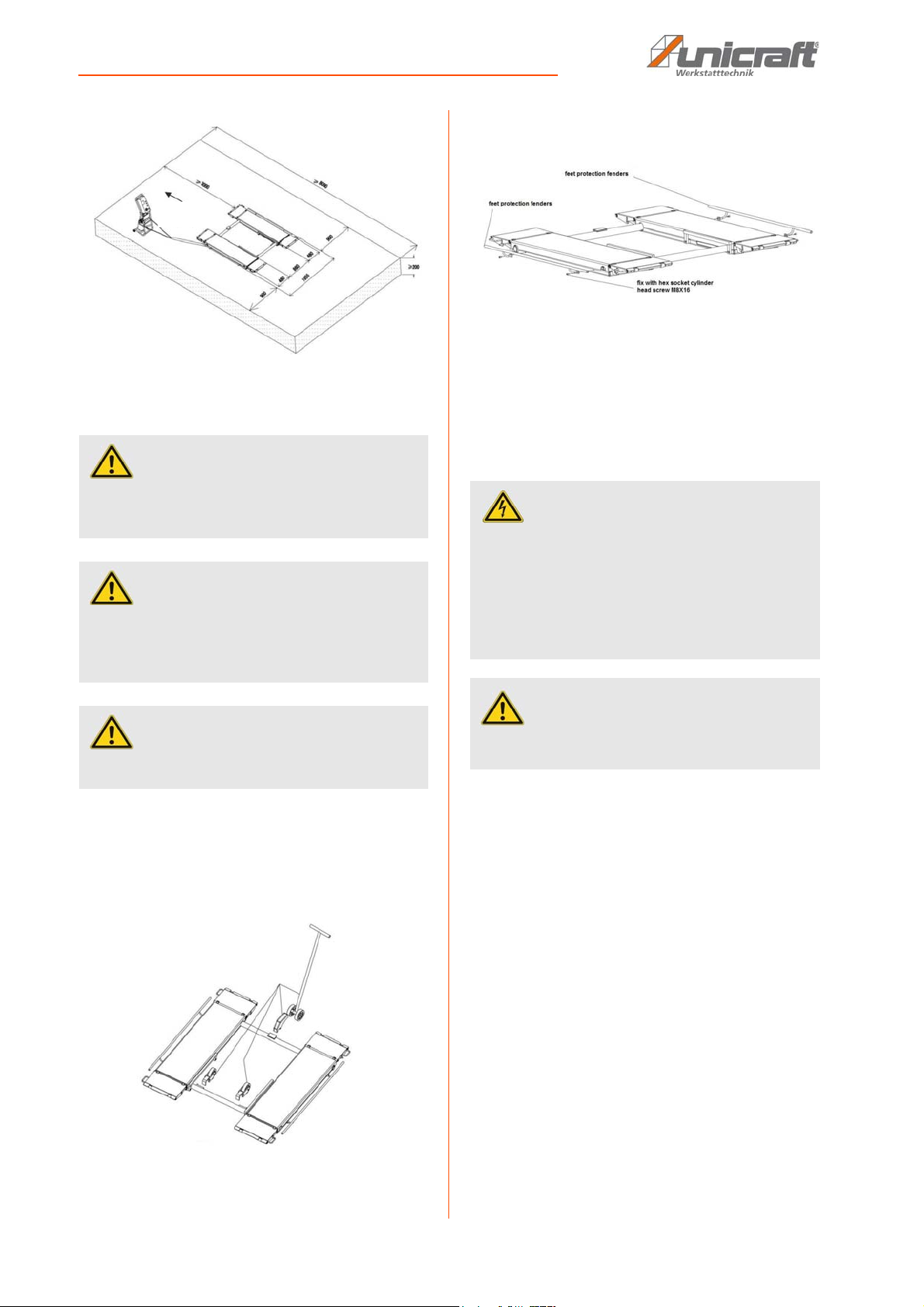

7 Montage..................................................................10

7.1 Anforderungen an den Aufstellort .................... 10

7.2 Aufstellen der Hebebühne................................ 10

8 Hydraulischer und Elektrischer Anschluss ........11

8.1 Elektrischer Anschluss ..................................... 11

8.2 Hydraulischer Anschluss.................................. 11

9 Prüfpunkte nach der Installation .........................12

10 Bedienung............................................................12

10.1 Beschreibung des Steuerpults....................... 13

10.2 Last heben...................................................... 13

10.3 Last absenken ................................................ 13

11 Pflege, Wartung und Instandsetzung ................14

11.1 Pflege durch Reinigung.................................. 14

11.2 Wartung und Instandsetzung/Reparatur ....... 14

11.2.1 Prüfungsintervalle......................................14

11.3 Schmierstellen an der Hebebühne................. 15

12 Störungsbeseitigung ..........................................15

13 Entsorgung, Wiederverwertung von Altgeräten...16

13.1 Außer Betrieb nehmen.................................... 16

13.2 Entsorgung von Schmierstoffen/Ölen............. 16

13.3 Entsorgung über kommunale Sammelstellen .... 16

14 Ersatzteile ............................................................16

14.1 Ersatzteilbestellung ........................................ 16

14.2 Ersatzteilzeichnungen .................................... 17

15 Elektro-Schaltplan...............................................18

16 Hydraulik-Schaltplan...........................................19

17 Druckluft-Schaltplan ...........................................19

18 EU-Konformitätserklärung .................................20