S&C Instruction Sheet 711-590 9

Inspection Recommendations

Recommended Inspection Procedures

The Mark V Circuit-Switcher inspection procedures to be

followed are summarized in Table 2. The applicable S&C

instruction sheets for the circuit-switcher, switch operator,

pre-insertion inductor, grounding switch, etc., should be

referenced for further details.

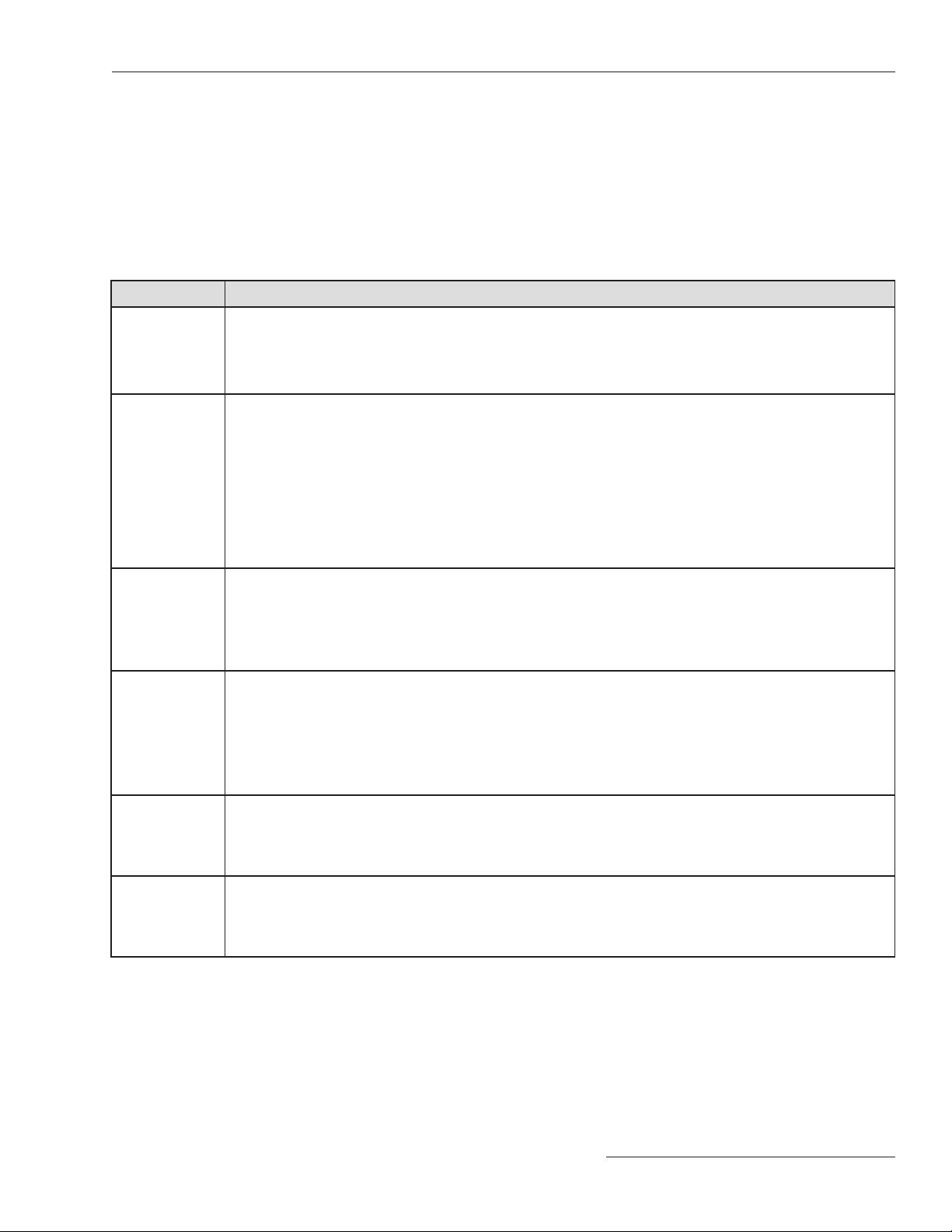

Table 2� Recommended Inspection Procedures for S&C Mark V Circuit-Switcher Components

Component Inspection Procedures

General

1� Check with the nearest S&C Sales Office to determine whether there are any outstanding field notifications involving inspection,

maintenance, or retrofit�

2� Check the overall cleanliness of the insulators, live parts, and exterior of the operator� If there is severe contamination, power wash

with water or clean using a non-abrasive cleaning method� After washing, reapply an appropriate contact lubricant,to the disconnect

live parts�①

Switch operator

1� Check for evidence of water ingress, damage, excessive corrosion, or wear�

2� Check the ease of operation during slow, manual cranking using the switch operator manual operating handle� Listen for

simultaneity of tripping of the interrupters� From the point at which one interrupter trips, no more than 40° of rotation should be

required before the other two interrupters trip� If excessive rotation is required, contact the nearest S&C Sales Office�

3� Simulate a fault by activating the protective relay circuit (if applicable)� Check electrical operation, coupled and decoupled�

4� Check for loose wiring inside the enclosure and proper functioning of the position-indicating lamps, operation counter, convenience

lamp, etc�

5� Check brake operation and adjust, if necessary�

6� Check the key interlocks, if furnished, mechanically and electrically�

Power train

1� Check for evidence of damage, excessive corrosion, or wear�

2� Check the fastener tightness�

3� Observe operation during slow, manual cranking using the switch operator manual operating handle� Check for complete stroking

of the various drive levers against their stops and for attainment of over toggle positions, as required�

4� Check seal conditions�

Brain

1� Remove the brain cover and check for evidence of water ingress, damage, excessive corrosion, or wear�

2� Check for tightness of shunt-cable fasteners and for evidence of excessive fraying of the shunt cable�

3� Check the seal conditions�

4� Replace the brain cover� Observe operation during slow, manual cranking using the switch operator manual operating handle�

Listen for the tripping action of the interrupter on opening and observe operation of the interrupter targets�

5� Check for proper clearances at the brain adjustment-holding device and at the blade crank-arm stop�

Shunt-trip device

1� Remove the shunt-trip solenoid-housing cover and check for evidence of water ingress, damage, excessive corrosion, or wear�

2� Check the seal conditions�

3� Replace the shunt-trip solenoid-housing cover� Simulate a fault by activating the protective-relay circuit� Verify all three shunt-trip

solenoids function and the switch operator motor follows through to open the disconnect�

Interrupter

1� Check for low gas pressure (red indicator)�

2� Check the fastener tightness on current-carrying parts�

3� (Optional) Check the resistance using the resistance values in Table 3 on page 11 for a vertical-break or integer style circuit-switcher

or Table 4 on page12 for a center-break style circuit-switcher�