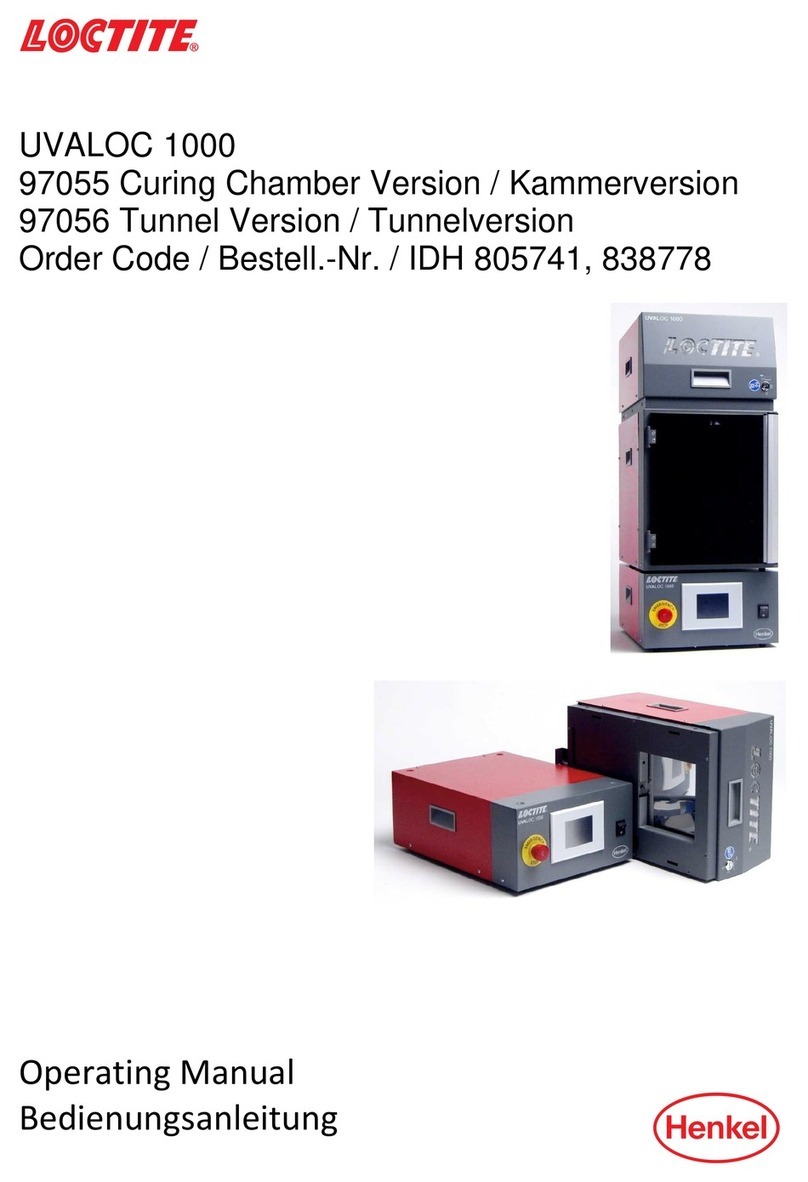

Henkel LOCTITE ZETA 7760A User manual

EQUIPMENT

Operation Manual

7760A

Exposure Time

Timed

Manual

Lamp Hours

TIMER LT4H

RESET

LOCK

NiS

UP

DOWN

CURTIS

HOURS

1

10

UV

Lamp & Reflector

DescriptionP/N

98451

97328

98543

97326

Spare Components

Item No. 1329221

Warning: UV Energy is transmitted from the end of the

are required that meet ANSI Z80.3 & Z87.1 Certification.

light guide. Protective eyewear equipped with side shields

Dual Light Guide, 1M

Single Light Guide, 1.5M

Single Light Guide, 1M

Lamp On

Loctite® Zeta® 7760A UV Curing Wand System

Part Number: 1329221

TABLE OF CONTENTS

1. PLEASE OBSERVE THE FOLLOWING............................................................................3

1.1 EMPHASIZED SECTIONS...............................................................................................................................3

1.2 ITEMS SUPPLIED ..........................................................................................................................................3

1.3 FOR YOUR SAFETY......................................................................................................................................3

1.4 FIELD OF APPLICATION,(INTENDED USAGE)...............................................................................................4

2. DESCRIPTION.........................................................................................................................................4

2.1 THEORY OF OPERATION ..............................................................................................................................4

2.2 OPERATING ELEMENTS AND CONNECTIONS,REFERS TO FIGURE 1..............................................................5

3. TECHNICAL DATA.............................................................................................................................7

3.1 ENERGY REQUIREMENTS.............................................................................................................................7

3.2 DIMENSIONS...............................................................................................................................................7

3.3 UV OUTPUT CHARACTERISTICS .................................................................................................................7

4. INSTALLATION....................................................................................................................................7

4.1 SPACE REQUIREMENTS................................................................................................................................7

4.2 CONNECTIONS.............................................................................................................................................9

5. OPERATING THE UNIT..................................................................................................................9

5.1 INSERTING AND REMOVING THE LIGHT GUIDES..........................................................................................9

5.2 POWERING UP...........................................................................................................................................10

5.3 ADJUSTING DUAL WAND FOR MAXIMUM OUTPUT....................................................................................11

5.4 USING FOOT SWITCH /REMOTE DEVICE ...................................................................................................12

6. CARE AND MAINTENANCE.....................................................................................................13

6.1 REPLACING THE LAMP MODULE ...............................................................................................................13

6.2 CHANGING THE OPTICAL FILTER ..............................................................................................................15

REPLACEMENT PROCEDURE............................................................................................................................15

7. TROUBLESHOOTING....................................................................................................................16

8. DOCUMENTATION...........................................................................................................................17

8.1 WIRING DIAGRAM.....................................................................................................................................17

8.2 PIN CONNECTIONS.....................................................................................................................................18

8.3 REPLACEMENT PARTS AND ACCESSORIES.................................................................................................18

9. WARRANTY............................................................................................................................................19

1. Please Observe the Following

1.1 Emphasized Sections

WARNING!

Refers to safety regulations and required measures that protect the operator or other persons

from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

Notice:

Gives recommendations for better handling of the unit during operation or adjustment, as

well as for service activities.

1.2 Items Supplied

1 ZETA® 7760A UV Curing Wand System

1 UV lamp/reflector assembly (Customer to Install)

1 Pair of UV protective glasses

1 Ballast jumper wire (input voltage selection)

1 Foot switch

1 Users manual

1 Power cord

1.3 For Your Safety

For safe and successful operation of the unit, read these instructions completely. If the

instructions are not observed, the manufacturer can assume no responsibility. Be sure to

retain this manual for future reference.

WARNING!

Always wear the included UV safety glasses or glasses that conform to ANSI Z87.1/CSA

Z94.3 when operating the unit.

WARNING!

Always cover hands, face and other parts of the body that may be exposed to UV light.

WARNING!

Never look into the end of the light guide.

WARNING!

Never open the shutter mechanism without the light guide installed.

WARNING!

Never remove the cover of the unit without first switching the power off and unplugging

the power cord.

WARNING!

Damage to the power cord or the housing can result in contact with live electrical parts.

Check the power cord and housing before each use. If the power cord or unit is damaged,

do not operate.

The unit may be repaired only by a Loctite authorized service technician.

1. Please Observe the Following (continued)

Caution!

Never turn the unit on without the lamp connected to the power supply.

Caution!

The energy emitted from the end of the light guide can heat any surface that it is directed

at. Care must be taken to determine the proper offset distance and exposure time.

Caution!

Turning the lamp on and off frequently will cause the UV output of the lamp to decline at

a faster rate. It is recommended that the unit be left on during breaks and short down

times.

Caution!

Avoid making sharp bends in the light guide, as this will cause a loss of UV energy or

possibly cause permanent damage. To prevent permanent damage, the minimum bend

radii are 2.4 inches for a single light guide and 1.6 inches for a dual light guide.

Caution!

The AC requirements for the Zeta 7760A are as follows;

88 to 136 VAC and 176 to 264 VAC. When operating between 88 to 136 VAC the

enclosed jumper must be installed across pins ST4 and ST5 on the ballast.

1.4 Field of Application, (Intended Usage)

This Loctite® ZETA® 7760A UV Curing Wand System is designed for use with

Loctite® products that cure when exposed to ultraviolet light produced by the unit. The

UV energy is directed towards the product through a liquid filled light guide that is

ordered separately. Several configurations of light guides are available from Loctite,

including single and dual ended types. The unit is also capable of interfacing with an

external relay or PLC circuit.

2. Description

2.1 Theory of Operation

When the unit is switched on, electrical power is immediately supplied to the lamp and ignition

should occur within several seconds. As soon as the lamp ignites, the green “Lamp On”

indicator, located on the front panel, will come on. Also, an internal relay will change state,

making a closure across pins three and four of the footswitch connector located on the rear panel

of the unit. It will take several minutes for the lamp to reach full power. Curing takes place when

the shutter is opened, allowing UV light to be directed from the end of the liquid filled light

guide to the adhesive. The curing parameters, (UV irradiance and exposure time) must be

determined before use. The UV irradiance, (the strength of the UV light), at the adhesive surface

can be varied by adjusting the distance of the light guide from the bond. If the light guide is

moved to within ½ inch of the adhesive surface, vapors from the curing process may build up on

the end of the light guide, reducing the UV intensity. The UV exposure time required to

complete the curing process depends primarily on the UV irradiance and the properties of the

adhesive product.

The timed exposure cycle starts by momentarily engaging the footswitch or when an externally

operated device such as a PLC makes a relay closure across pins 1 and 9 of the nine pin foot

switch connection on the rear panel. In the manual operating mode, the shutter remains open for

as long as the footswitch or alternate external device maintains contact between pins 1 and 9.

The hour meter, located on the front panel, records the total hours of operation accumulated by

the lamp. UV lamps undergo a gradual reduction in UV output over time and it is recommended

that the lamp output be monitored on a regular basis. Frequently turning the power on and off

will increase the rate that the lamp degrades, therefore, it is recommended that the unit be left on

during short work breaks such as lunch and other idle periods.

Notice: The hour meter should only be reset when a new lamp is installed.

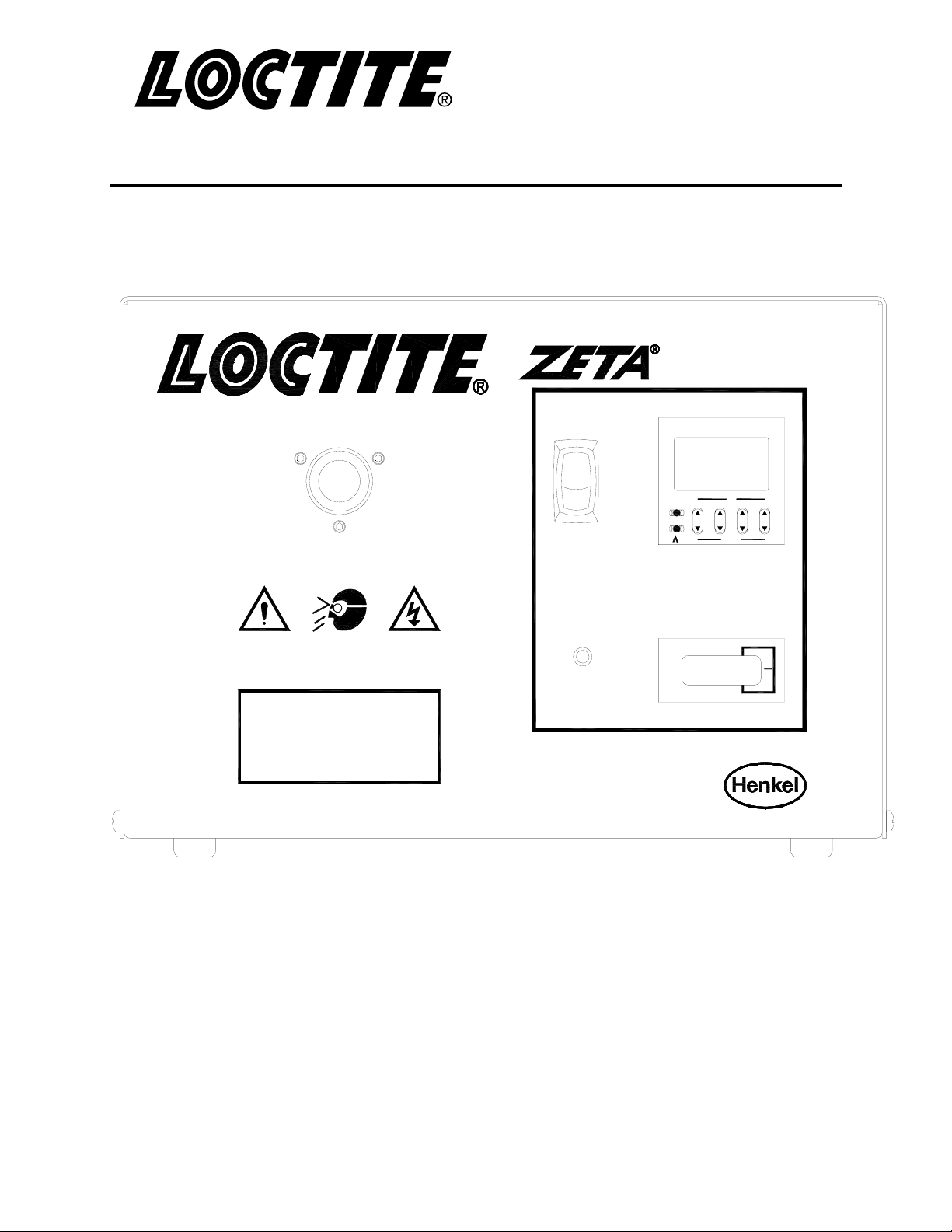

2.2 Operating Elements and Connections, refers to Figure 1

1. Power Inlet Module

Connect line cord to power inlet module.

2. Power Fuse Holder

Fuse is located in the power module.

3. Power Switch

4. Foot Switch Connection

Standard 9 pin “D” connector for foot switch or other external switch.

5. Light Guide Receptacle

Is used to retain the light guide.

6. Digital Exposure Timer

Controls the period of time the shutter is opened. The UV time is set by pressing the

buttons located directly under the LCD, which indicates seconds. The manual/timed

selector switch must be set to "timed.” When the foot switch is pressed the shutter

mechanism will open for the indicated time and the timer will begin counting down.

When the unit times out the shutter will close and the LCD will indicate the original

pre-set time interval.

7. Lamp Hour Meter

The hour meter indicates the cumulative time that the lamp has been ON.

8. Mode Selector – Manual/Timed

When set to “manual” the UV light is passed through the light guide for as long as the

foot switch is depressed. In the “timed” mode, the timer’s LCD display indicates

exposure time and the cycle is initiated when the foot switch is momentarily engaged.

9. Hour Meter Reset

Use switch to reset the hour meter to zero after installing a new lamp module.

10. Lamp On Indicator

The lamp will ignite when the main power is switched on. The green lamp on

indicator located on the front panel will light to confirm that the lamp is operating.

2. Description (continued)

7760A

Exposure Time

Timed

Manual

Lamp Hours

TIMER LT4H

RESET

LOCK

NiS

UP

DOWN

CURTIS

HOURS

1

10

UV

Lamp & Reflector

DescriptionP/N

98451

97328

98543

97326

Spare Components

Item No. 1329221

Warning: UV Energy is transmitted from the end of the

are required that meet ANSI Z80.3 & Z87.1 Certification.

light guide. Protective eyewear equipped with side shields

Dual Light Guide, 1M

Single Light Guide, 1.5M

Single Light Guide, 1M

11 1/2

8 5/16

1

2

3

Power

Switch

Fuse

Holder

Power

Inlet

Module

4

Foot

Switch

Connection

5

Light

Guide

Receptacle

6

78

9

Hour Meter Reset

Lamp: 200 Watt

Made in U.S.A. Fuse: 4 Amp, 250 V

Input: 88-136; 176-264 VAC, 47 to 440 Hz.

3.0 A @ 120 VAC, 1.7 A @ 240 VAC

Rocky Hill, Connecticut 06067, U.S.A. Zeta 7760A Wand System

Loctite® Item No: 1329221

Serial No: 4CWA-01

FOR SPARE PARTS, MANUALS, REPAIRS,

OR TECHNICAL ASSISTANCE:

Visit us at equipment.loctite.com

or call Henkel Corp. at:

USA - (1) 860-571-5174

Germany - (49) 89-9268-0

Singapore - (65) 6482-3881 Label P/N: 988341

O

Lamp On

10

Warning Manual Before Servicing Unit.

Disconnect and Refer to

Warning

FOR 88-136 VAC,JUMPER REQUIRED ACROSS PINS ST4 AND ST5 ON BALLAST.

FOR 176-264 VAC, REMOVE JUMPER FROM PINS ST4 AND ST5 ON BALLAST.

(SEE MANUAL PAGE 9)

Figure 1.

3. Technical Data

3.1 Energy Requirements

Input Voltage Ranges: 88-136 and 176-264 VAC

Operating at 88 to 136 VAC requires that the enclosed jumper be installed on

pins ST4 and ST5 on the ballast.

Input frequency Range: 47 to 440 Hz

Auxiliary Output Voltage: 27 volts DC, nominal

Main fuse located in power module in rear of unit: 4A/250V, 5mm

3.2 Dimensions

Housing: Approximately 11.5 inch W x 13.5 inch D x 8.4 inch H

Weight: Approximately 18 pounds

3.3 UV Output Characteristics

Initial UV output: 14 to 18 W/cm² typical. Exact output measurement is dependent on

the brand and calibration method of the meter used, as well as the condition and

straightness of the light guide.

7760 UV OUTPUT SPECTRUM

240 265 290 315 340 365 390 415

Wavelength (nanometers)

4. Installation

4.1 Space Requirements

A space of 12" wide x 16" deep x 9" height is required. It is important to have at least 8

inches of space behind the unit to insure proper airflow.

Caution!

Do not block the intake and exhaust fans located on the back of the housing.

Caution!

The unit should always be operated with the rubber support feet resting on a flat

surface. Do not operate with the unit resting on its side or at an angle greater than 15

degrees, front to back.

4.1 Lamp Installation

IMPORTANT NOTICE

THE CURING LAMP MUST BE INSTALLED IN THE UNIT BEFORE TURNING THE POWER

ON. THE CURING LAMP IS PACKAGED INSIDE OF THE UNIT.

Lamp Retainer Wire

Lamp

Lamp Reflector

Ceramic Hub

Anode Connection

Cathode Connection

2

1

Caution!

Do not touch the inside surface of the lamp reflector or the lamp. Contaminants from

hands will create “hot spots” and cause the module to fail prematurely. If either surface

is accidentally touched, carefully wipe with a clean, soft cloth and isopropyl alcohol.

1. Make sure the unit is unplugged.

2. Remove the four screws from the sides of the housing and lift off the cover.

3. Remove the sheet metal shroud that encases the lamp.

4. Flip the swivel section of the lamp retainer wire forward.

5. Grasp the lamp assembly by the white ceramic hub and pull back on the wire

retainer until the reflector fits into the counter bore in the lamp holding plate.

6. Flip swivel retainer back over the lamp holder.

7. Connect the power leads.

8. The power lead attachment connected to the front of the reflector should be

approximately in the twelve o’clock position. If it is not, grasp the ceramic hub of

the lamp, pull back slightly and rotate until the lead is at twelve o’clock.

9. Replace the lamp shroud and the enclosure cover.

10. Press the lamp hour reset switch to set the hour meter to zero.

Notice: Step 10 should only be done when a new lamp is installed.

4.2 Electrical Connections

WARNING! Make sure the power switch is OFF and the unit is unplugged before

proceeding.

IMPORTANT NOTICE

The enclosed jumper wire must be installed on pins ST4 and ST5 if the unit is to

be operated on line voltage between 88 and 136 VAC. Do not install the jumper

if the line voltage is between 176 and 264 VAC.

+-

L (ST1)

N (ST2)

PE (ST3)

ST4 ST5 ST6 ST7

ST4 TO ST5 JUMPER

-Plug the power cord into the power module located at the bottom left of the rear

panel.

-Plug the cord into the electrical utility outlet.

-Insert the light guide into the receptacle located on the left side of the front panel until

it is fully engaged.

-Plug the footswitch into the nine pin D-sub connector located on the rear panel. Or, if

the unit is being operated from an external processor, a closure across pins one and

nine is required to actuate the shutter. An internal relay closure connected to pins

three and four of the footswitch connector provides conformation that the curing lamp

is on. When the lamp is not on, an open circuit exists across pins three and four.

5. Operating the Unit

5.1 Inserting and Removing the Light Guides

Caution!

Be sure to remove the plastic end caps before attempting to use the light guide.

Caution!

If the free end of the light guide is secured at a fixed location, sharp bends should be

avoided since this causes a decrease in UV power.

Caution!

Never pull on the jacketing portion of the light guide. During installation or removal,

grasp the light guide on the strain relief nearest the input end of the light guide.

•Installing single light guide - Insert the large end of single light guide into the

light guide receptacle located on the left side of the front panel. Push light guide

firmly until it is fully engaged.

•Installing dual light guide – Insert the dual wand light guide into the light

receptacle and rotate the collar assembly (951639) so that the scribed line on the

collar is in the 12 o’clock position. See section 5.3 “Adjusting Wand for

Maximum Output.”

Notice:

It is important that the rotational position of a dual light guide be set to maximize the

UV output for each wand. This setting is specific to each curing unit and light guide

(See section 5.3 - Adjusting Dual Wand).

5.2 Powering Up

1. Switch the main power ON. The power switch is on the lower left of the rear panel.

2. The green LED on the front panel will come on to confirm that the lamp has

ignited.

3. Allow approximately five minutes for the lamp to reach full power.

4. Set the operating mode selector switch to “timed” or “manual”.

5. For manual operation, engage the footswitch to start UV exposure and hold until the

curing cycle is complete. When the footswitch is released the exposure will end

immediately. For timed operation use the keys directly below the numbers on the

display to set the desired exposure time. Momentarily engage the footswitch to start

the cycle. The UV exposure will begin immediately and continue until the system

times out.

6. UV exposure cycles may be initiated by using an externally operated device, such

as a PLC controlled relay in place of the footswitch.

Notice:

Avoid shutting the main power off for brief periods of time. Frequent start-ups will

cause the lamp to decay at an accelerated rate. If the system is shut down, wait a

minimum of ten minutes before restarting. Once the lamp is ignited, allow it to operate

for a minimum of fifteen minutes before turning it off.

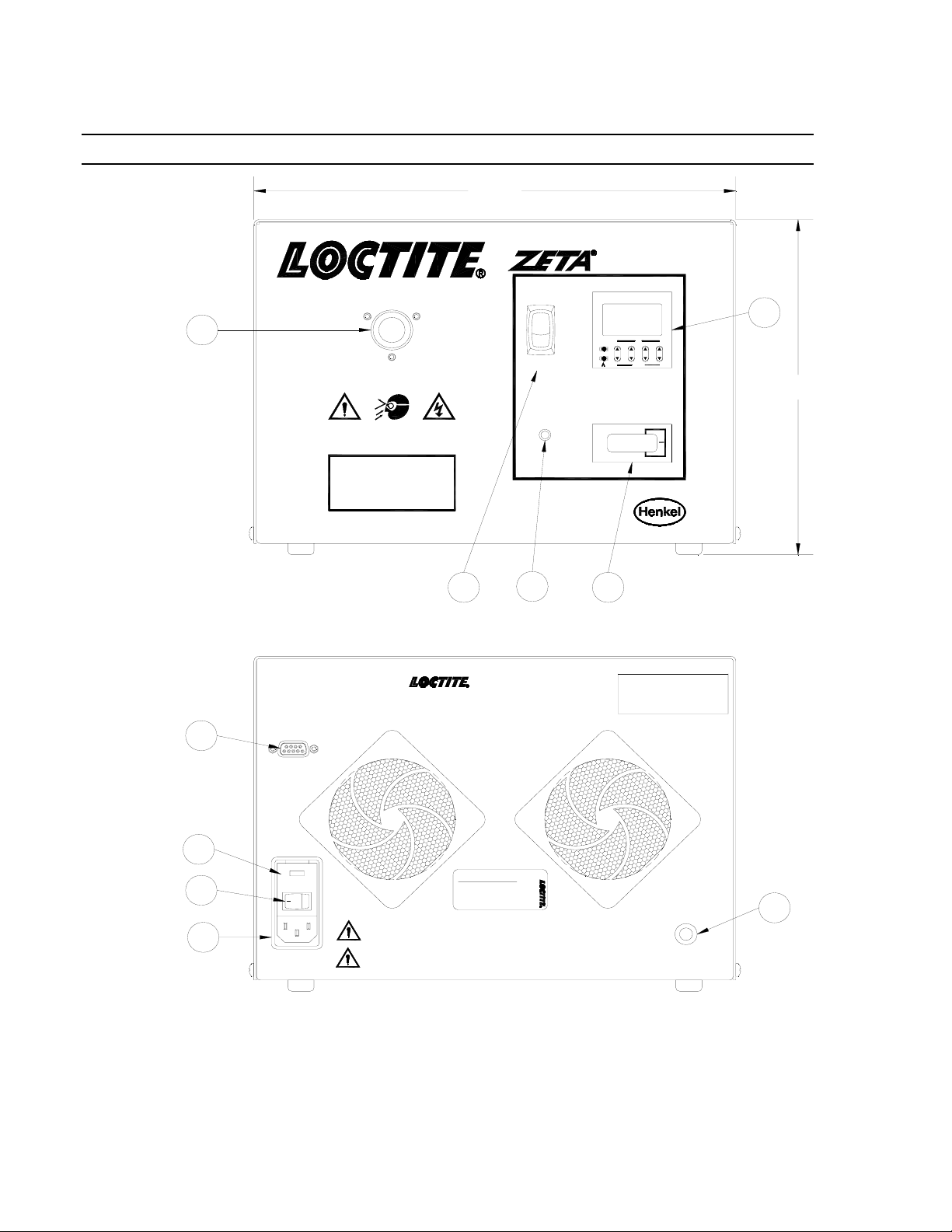

5.3 Adjusting Dual Wand for Maximum Output

7760A

Exposure Time

Timed

Manual

Lamp Hours

TIMER LT4H

RESET

LOCK

NiS

UP

DOWN

CURTIS

HOURS

1

10

UV

Lamp & Reflector

DescriptionP/N

98451

97328

98543

97326

Spare Components

Item No. 1329221

Warning: UV Energy is transmitted from the end of the

are required that meet ANSI Z80.3 & Z87.1 Certification.

light guide. Protective eyewear equipped with side shields

Dual Light Guide, 1M

Single Light Guide, 1.5M

Single Light Guide, 1M

Adapter Hub

Scribe Line This Set Screw Locks

The Balancing Adapter

To The Units Base

This Set Screw Locks

The Light Guide In

Position After Balancing

The Output Power

Lamp On

Objective

Balance the UV output from the two light guides of Loctite® P/N 97328.

Tools Needed

3/32 inch hex key

Loctite® 7020 UV Spot Radiometer P/N: 1406024

Setup

1. Install the collar assembly (951639) over the part of the light guide receptacle that

protrudes from the front of the unit. Rotate the collar assembly until the scribed line is

in the 12 o’clock position. Use the set screw to secure the collar in that position.

2. Insert the input end of the light guide into the light guide receptacle/collar assembly

pushing it as far forward as it will go. Tighten the set screw on to the light guide.

3. Turn on electric power to unit.

4. Set shutter timer to 2 seconds.

5. Insert one of the light guide ends into a Loctite® 7020 UV Spot Radiometer P/N:

1406024.

6. Press the radiometer start switch.

7. Actuate foot switch to open shutter.

8. Release the radiometer start switch while the shutter is still opened.

9. Read and record the radiometer reading.

10. Position the second light guide in the radiometer.

11. Press the radiometer start switch.

12. Actuate foot switch to open shutter.

13. Release the radiometer start switch while the shutter is still opened.

14. Read and record the radiometer reading.

15. Compare the two radiometer readings.

16. If the lower reading is equal to or greater than 90% of the higher reading, the dual

wand is balanced.

17. If the lower reading is less than 90% of the higher reading, loosen the set screw and

rotate the collar a small increment around the light guide receptacle. Use the set screw

to secure the collar in that position.

18. Take and compare another set of radiometer readings.

19. Continue until the lower reading is equal to or greater than 90% of the higher reading.

20. Tighten set screw to lock the input end of the dual wand in position.

Notice:

If a radiometer is not available, it is recommended that Loctite Service be contacted at

1-800-LOCTITE (1-800-562-8483) to insure optimum performance when installing a

new dual ended light guide.

5.4 Using Foot Switch / Remote Device

The ZETA® 7760A can also be actuated using a foot switch or by external devices. The

foot switch connection is made up of a 9 pin D connector. Making a dry-contact relay

closure across pins 1 and 9 can actuate the unit.

6. Care and Maintenance

Notice:

It is recommended that the UV output from the lamp be monitored regularly using a

Loctite® 7020 UV Spot Radiometer P/N: 1406024. If a radiometer is not used to

monitor the lamp, it is recommended that the lamp be replaced when the hour meter,

located on the front panel, indicates 1,000 hours of operating time has elapsed. It is

normal for the lamp output to slowly decline over operating time, however, the

effective life of the lamp will decrease significantly faster if it is turned on and off

frequently.

Caution!

It is recommended that the end of the light guide be positioned no closer than ½ inch

from the Loctite® product being cured. The heat transmitted by the lamp can adversely

affect the properties of the cured product or possibly cause damaged to the part surface.

Notice:

Vapors from some products may gradually accumulate on the end of the light guide,

reducing the UV output. It should be inspected regularly and cleaned as necessary using

isopropyl alcohol and a soft, clean cloth.

Caution!

Avoid placing sharp bends in the light guide. This reduces the UV output and may

permanently damage the light guide. If the light guide is mounted on a fixture, secure it

by the metal exit fitting and not the flexible plastic section.

Caution!

Be sure to remove the plastic end caps before attempting to use the lightguide.

Notice: The intake and exhaust fan filter elements should be replaced as needed to

insure proper cooling of the power supply and UV lamp assembly. They should be

inspected routinely.

6.1 Replacing the Lamp Module

Caution!

Do not touch the inside surface of the lamp reflector or the lamp. Contaminants from

hands will create “hot spots” and cause the module to fail prematurely. If either are

accidentally touched, carefully wipe them with a clean, soft cloth and isopropyl alcohol.

1. Switch the power off and unplug the unit.

2. Allow several minutes for the lamp to cool.

2. Remove the four screws from the sides of the housing and lift off the cover.

3. Remove the sheet metal shroud that encases the lamp.

4. Disconnect the lamp leads by separating the Male/Female connector.

6. Flip the wire retainer over the lamp holder.

7. To remove the lamp module grasp the white ceramic hub and carefully pull back

and lift up at the same time.

8. Install the new lamp module and flip retainer back over the lamp holder.

9. Reconnect the power leads.

6.1 Replacing the Lamp Module (continued)

10. The bare power lead attachment to the front of the reflector should be

approximately in the twelve o’clock position. If it is not, grasp the ceramic hub of

the lamp, pull back slightly and rotate until the lead is between the two white plastic

insulators.

11. Replace the lamp shroud and the enclosure cover.

12. Press the lamp hour reset switch to set the hour meter to zero.

Notice: Step 11 should only be done when a new lamp is installed.

WARNING!

The UV lamp used in this unit contains a very small amount of mercury. Disposal of

lamps should be done in accordance with state and local regulations.

Lamp Changeover Components

Lamp Retainer Wire

Lamp

Lamp Reflector

Ceramic Hub

Anode Connection

Cathode Connection

2

1

6.2 Changing The Optical Filter

The 7760A uses a special optical filter designed to reduce heat. It is retained by two clips

and thumbscrews in front of the light receiving end of the light guide. The filter that comes

with the unit, P/N 98599 is designed to allow the use of the standard light guides. This

arrangement will transmit the wavelengths needed to obtain excellent surface cure and cure

depth in most applications. In cases where it is difficult to achieve dry to the touch surfaces,

an alternate filter, P/N 98598, is designed to improve the surface cure ability. P/N 98598

must be used with the extended range light guides.

Replacement Procedure

1. Unplug the unit and remove the cover.

2. Remove the heat shroud, exposing the lamp and optical staging.

3. Remove the light guide from the unit and turn the unit onto its front side.

4. Looking down at the light guide entrance hole, loosen the two thumbscrews securing

the filter.

5. Swing the two retaining clips out of the grooves allowing removal of the filter.

6. Set the unit back onto its feet and the remove the filter from the unit.

7. Set the unit back on its front side and insert the new filter into the hole.

8. Replace the retaining clips and thumbscrews.

Caution! Avoid touching the surfaces of the filter by holding the edges only. If the

surfaces are touched or become dirty use a clean, soft wiper and isopropyl alcohol to

remove the contaminants.

7. Troubleshooting

Type of Malfunction Possible Causes Corrections

Power does not come on. - No voltage present. Check wall circuit.

- Defective fuse. Replace fuse.

- Defective line cord Replace.

Lamp does not light. - Lamp leads are not connected.

- Defective power supply Call 800-562-8483

for technical assistance

- Lamp failure. Replace lamp module.

Power comes on but light is - Footswitch is not plugged Check footswitch

not emitted from the light- in. connection.

guide. The shutter mechanism

makes no noise when the - Defective footswitch. Call 800-562-8483

footswitch is engaged. for technical assistance

- Defective shutter mechanism. Call 800-562-8483

for technical assistance

- Faulty power supply Call 800-562-8483

or supply connection. for technical assistance

All system functions appear to - UV output has declined Replace lamp module.

be operating, but the product due to normal lamp aging.

does not cure completely.

(If a radiometer - End of light guide has an Clean light guide with

is used to monitor the UV output, accumulation of product soft cloth and isopropyl

the power is low.) or other contaminants. alcohol.

- Light guide is not fully Check light guide

inserted in receptacle. connection.

- Light guide has exceeded its Replace light guide.

usefullife.

8. Documentation

8.1 Wiring Diagram

CHASSIS AND LID

CONNECTIONS

CURTIS

HOUR

METER

RESET

SWITCH

1

34

2

SOL.

FAN

ENCL.

FAN ENCL.

FAN LAMP

FAN

NAIS CYCLE

TIMER

9

10

11

NO 6

2

NC MANUAL

TIMED

560

ohms

1N5253

0.01uf

2N6039 24 VOLTS

MC7809ACT

10k/5%/1/4W

IRF-510

270/5%/1/4W

HONEYWELL

SDP-8405-003

CML

5102H5-5V

MOUNTED ON

FRONT PANEL

9.0 VOLTS

OMRON RELAY

G5SB-14-DC9

44.4mA COIL

TO REAR PANEL

9 PIN SUB-D

CONNECTOR

PIN 4PIN 3

1N4002

TO LED ANODE

TO LED CATHODE

MODE

SELECTOR

SWITCH

LAMP

ANODE

LAMP IGNITER

POWER ENTRY MODULE - CORCOM PS0S0SS60

250V/4A

E

N

L

N

EN/O

OUTPUT PS45-27

POWER

SUPPLY

CHASSIS GROUND

PARTITION

SWITCH

INPUT

LAMP

CATHODE ---

L

PE

LAMP BALLAST

+++ N

L

N/C

PE

L

N+ -

28V SOLENOID

LEDEX

195206-131

PIN 5

FOOT SWITCH

PIN 1

REAR PANEL

9 PIN SUB-D

PIN 9

68 ohms +/-1%;

1W

1N4005

2N6039

100k

ohms

100k

ohms 1N4005

1k

+

-

2.2uf

1M

10k

ohms

10k

470k

2.2k

20k

1N914

NC

NO

91+/-5%; 5W

LM311

DELAY ADJ.

OMRON RELAY

G5SB-14-24DC

16.7 mA

1N914 1

4

87

RED DOT

RED DOT

OUTPUT ST4

ST5

INSTALL JUMPER ACROSS ST4 AND ST5

IF UNIT IS OPERATED BETWEEN 88 AND

136 VAC.

DO NOT INSTALL JUMPER IF UNIT IS

OPERATED ON VOLTAGE BETWEEN 176

AND 264 VAC.

CHASSIS

GROUND

8.2 Pin Connections

8.3 Replacement Parts and Accessories

Loctite Part Number Description

98451 Replacement Lamp Module

97326 Single End Light Guide (5 mm x 1M)

97328 Dual Ended Light Guide (3 mm x 1M)

98543 Single Light Guide (5 mm x 1.5M)

984770 Fan Filter Element, Quantity 5

97210 UV Safety Glasses

986051 Foot Switch Assembly

1406024 Loctite® 7020 UV Spot Radiometer

951639 Dual Wand Adapter Kit

1332501 Lamp Igniter

1332503 Lamp Ballast

1116644 Switching Power Supply

9. Warranty

Henkel expressly warrants that all products referred to in this Instruction Manual for the UV Curing Wand

System, (hereafter called “Product”), shall be free from defects in materials and workmanship. Liability for

Henkel shall be limited, as its option, to replacing those Products which are shown to be defective in either

materials or workmanship or to credit the purchaser the amount of the purchase price thereof (plus freight

and insurance charges paid therefore by the user). The purchaser’s sole and exclusive remedy for breach of

warranty shall be such replacement or credit.

A claim of defect in materials or workmanship in any Product shall be allowed only when it is submitted in

writing within one month after discovery of the defect or after the time the defect should reasonably have

been discovered and in any event, within 2 years after the delivery of the Products to the purchaser. This

warranty does not apply to perishable items, such as fuses and fan filters. The lamp is also warranted to

produce 50% of the minimum rated initial output at 500 hours of operating time, when measured using an

in-calibration Loctite 98720 UV Spot Radiometer, and a new Loctite 5mm x 1000mm lightguide in a fully

straight orientation. No such claim shall be allowed in respect of products which have been neglected or

improperly stored, transported, handled, installed, connected, operated, used or maintained. In the event of

unauthorized modification of the Products including, where products, parts or attachments for use in

connection with the Products are available from Henkel, the use of products, parts or attachments which are

not manufactured by Henkel, no claim shall be allowed.

No Products shall be returned to Henkel for any reason without prior written approval from Henkel.

Products shall be returned freight prepaid, in accordance with instructions from Henkel.

NO WARRANTY IS EXTENDED TO ANY EQUIPMENT WHICH HAS BEEN ALTERED, MISUSED,

NEGLECTED, OR DAMAGED BY ACCIDENT, OR IF THE SYSTEM USED TO DISPENSE ANY

LIQUID MATERIAL OTHER THAN HENKEL PRODUCTS.

EXCEPT FOR THE EXPRESS WARRANTY CONTAINED IN THIS SECTION, HENKEL MAKES NO

WARRANTY OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, WITH RESPECT TO THE

PRODUCTS.

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND

OTHER WARRANTIES OF WHATEVER KIND (INCLUDING AGAINST PATENT OR

TRADEMARK INFRINGEMENT) ARE HEREBY DISCLAIMED BY HENKEL AND WAIVED BY

THE PURCHASER.

THIS SECTION SETS FORTH EXCLUSIVELY ALL OF LIABILITY FOR HENKEL TO THE

PURCHASER IN CONTRACT, IN TORT OR OTHERWISE IN THE EVENT OF DEFECTIVE

PRODUCTS.

WITHOUT LIMITATION OF THE FOREGOING, TO THE FULLEST EXTENT POSSIBLE UNDER

APPLICABLE LAWS, HENKEL EXPRESSLY DISCLAIMS ANY LIABILITY WHATSOEVER FOR

ANY DAMAGES INCURRED DIRECTLY OR INDIRECTLY IN CONNECTION WITH THE SALE

OR USE OF, OR OTHERWISE IN CONNECTION WITH, THE PRODUCTS, INCLUDING, WITHOUT

LIMITATION, LOSS OF PROFITS AND SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES,

WHETHER CAUSED BY NEGLIGENCE FROM HENKEL OR OTHERWISE.

Henkel Corporation

One Henkel Way

Rocky Hill, CT 06067-3910

Henkel Canada Corporation

2225 Meadowpine Boulevard

Mississauga, Ontario L5N 7P2

Henkel Capital, S.A. de C.V.

Calzada de la Viga s/n Fracc. Los Laureles

Loc. Tulpetlac, C.P. 55090

Ecatepac de Morelos, Edo. de México

Henkel Corporation

Automotive / Metals HQ

32100 Stephenson Hwy.

Madison Heights, MI 48071

Henkel Ltda.

Rua Karl Huller, 136 – Jd.

Canhema 09941-410

Diadema/SP, Brazil

www.loctite.com

Loctite is a trademark of Henkel Corporation, U.S.A. © Copyright 2009. Henkel Corporation

All rights reserved. Data in this operation manual is subject to change without notice.

Manual P/N: 8901957, Rev B, Date: 03/2010

Table of contents

Other Henkel Industrial Equipment manuals