Instructions manual KM 775 - 785

1Introduction:........................................................................................................ 1

1.1 Purpose of the operating manual:.................................................................. 1

1.2 Presentation:.................................................................................................. 1

1.3 Reference standards:..................................................................................... 1

1.4 General warnings and recommendations:...................................................... 1

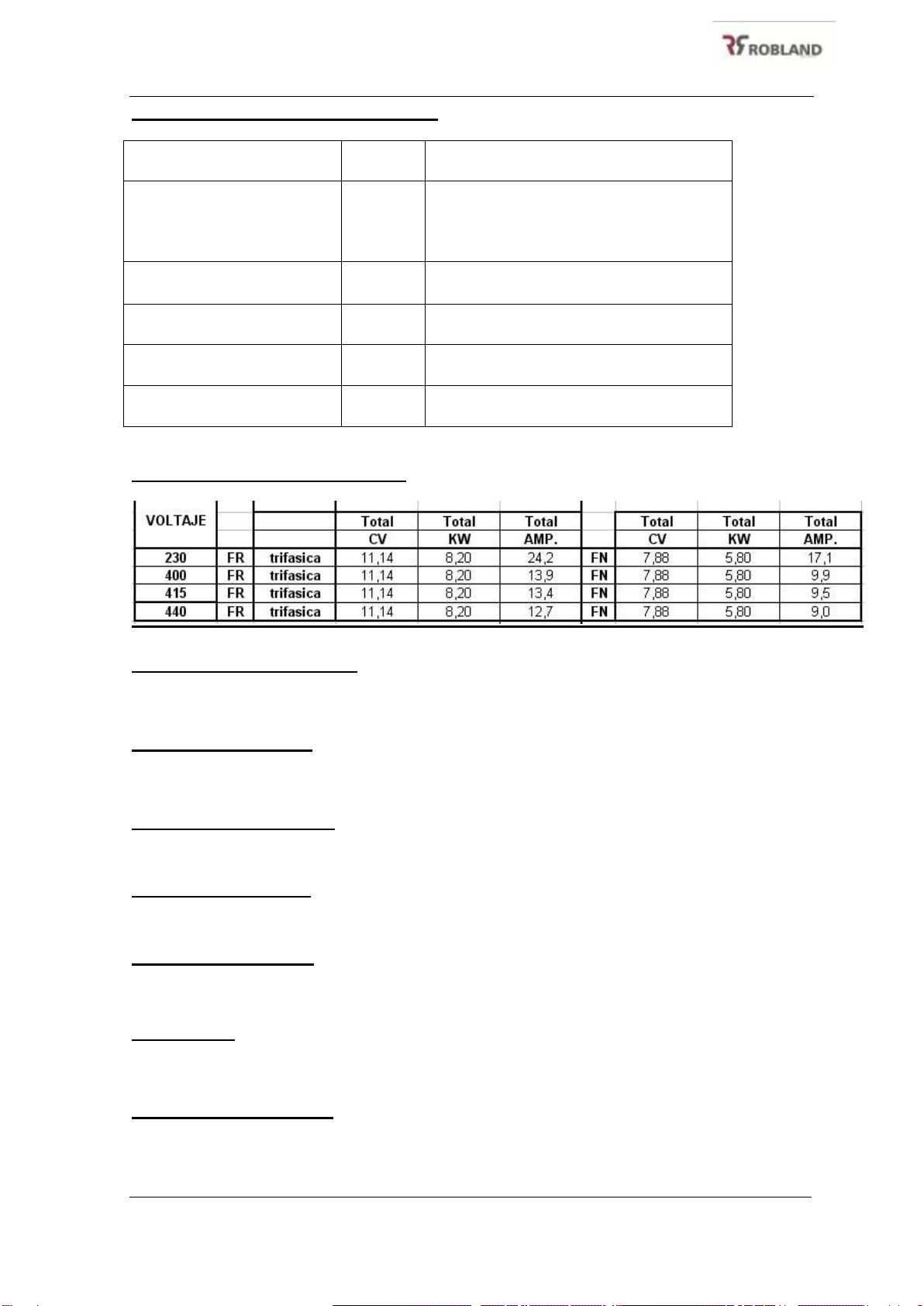

1.5 Technical specifications:................................................................................ 2

2MACHINE Installation: ........................................................................................ 3

2.1 General safety rules at the KM 775 edge banding machine installation:........ 3

2.2 Limits of use:.................................................................................................. 3

2.3 Machine movement and sitting: ..................................................................... 4

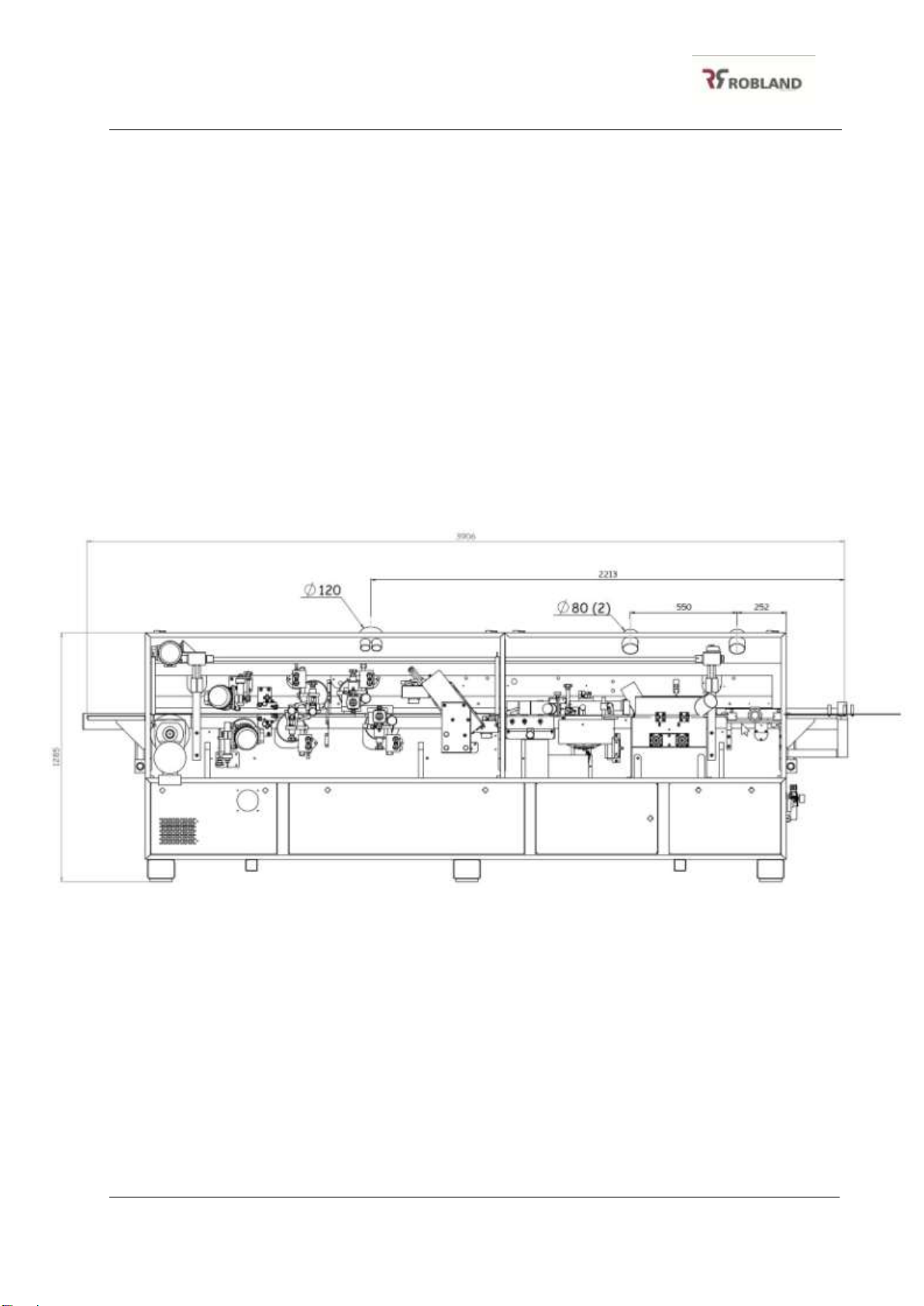

2.4 Dimensions and safety zones: ....................................................................... 5

2.5 Electrical installation:...................................................................................... 5

2.6 Pneumatic installation:................................................................................... 7

2.7 Fitting the roll-holder tray: .............................................................................. 7

2.8 Fitting the apron:............................................................................................ 8

3Setting up and starting the machine:................................................................ 8

3.1 Control devices on the button panel:.............................................................. 8

3.2 Start-up and stop the machine....................................................................... 9

3.3 Adjusting presser height:................................................................................ 9

3.4 Loading and regulating the band in roll form:................................................. 9

3.5 Regulating surplus strip:............................................................................... 10

4Working stations:.............................................................................................. 11

4.1 PREMILLING STATION PF-12.................................................................... 11

4.1.1 Depth regulation of the pre-trimming:.................................................... 11

4.1.2 Adjusting the motor’s premilling: ........................................................... 11

4.1.3 Adjustment of the first motor:................................................................ 11

4.1.4 Adjustment of the second motor: .......................................................... 11

5Working stations:.............................................................................................. 12

5.1 Glue pot station:........................................................................................... 12

5.1.1 Dispensing glue: ................................................................................... 12

5.1.2 Glue level in the tank: ........................................................................... 12

5.1.3 Setting up for correct gluing:................................................................. 13

5.1.4 Replacing heating resistances:............................................................. 13

5.1.5 Security:................................................................................................ 15

5.2 Roller base:.................................................................................................. 15

5.2.1 Security:................................................................................................ 16

5.3 V-7 end trimming station:............................................................................. 16

5.3.1 Pneumatic regulation:........................................................................... 16

5.3.2 Security................................................................................................. 17

5.3.3 Safety systems:..................................................................................... 17

5.3.4 Working limits:....................................................................................... 18

5.3.5 Mechanical regulation:.......................................................................... 18

5.3.6 Replacing the end trimmer discs:.......................................................... 18

5.4 Trimming station JC-5:................................................................................. 19

5.4.1 Adjustment with flat cutters:.................................................................. 19