Hernon Ultracure 7 User manual

Hernon Manufacturing

®

107-028 Ultracure 7

1 | P a g e

Ultracure 7

LED UV Curing System

107-028

121 Tech Drive

Sanford, FL 32771

www.Hernon.com

Phone: (407) 322-4000 Fax: (407) 321-9700

September 2015

Hernon Manufacturing

®

107-028 Ultracure 7

2 | P a g e

About This Manual

Thank you for selecting Hernon's Ultracure 7 for your application. The Ultracure 7 was developed with

your needs in mind. Your Ultracure 7 has been calibrated and tested to ensure optimal performance and

long life.

To ensure safe and trouble-free operation, please review the procedures and warnings contained in this

manual before setting up or operating your Ultracure 7. While safety is paramount, proper handling and

operation of Ultracure 7 will also serve to produce quality product yield.

Hernon Manufacturing designs and builds a wide range of custom manufacturing and packaging

machines. Hernon Manufacturing machines are built only with high quality components of proven

reliability.

This Manual is published by Hernon solely as a guide for Operators, Design Engineers, OEM Customers,

and Maintenance Personnel. Liability for difficulties arising from unknown or unforeseen technical

limitations is disclaimed, and Hernon makes no representation as to the thoroughness of this manual.

Hernon reserves the right to revise this manual at any time without notice, for any reason.

If you have any problems or concerns, please contact Hernon Technical Support at (407) 322-4000.

Trained Hernon professionals are standing by to serve you.

IMPORTANT

These instructions are general. Specific cure times should be evaluated and

recommended by Hernon’s Lab. Please contact Hernon’s Technical Department

(407)322-4000 for specific instructions.

Hernon Manufacturing

®

107-028 Ultracure 7

3 | P a g e

Table of Contents

Ultracure 7 .................................................................................................................................................... 1

About This Manual........................................................................................................................................ 2

Table of Contents.......................................................................................................................................... 3

Unpacking and Inspection............................................................................................................................. 4

Safety ............................................................................................................................................................ 5

Features/Specifications.................................................................................. Error! Bookmark not defined.

Power Requirements ................................................................................................................................ 6

Status Indicator......................................................................................................................................... 6

Errors/Fault Conditions.............................................................................. Error! Bookmark not defined.

Thermal...................................................................................................... Error! Bookmark not defined.

UV Curve/ UV Output Curve ...................................................................... Error! Bookmark not defined.

Installation ..................................................................................................... Error! Bookmark not defined.

Mounting................................................................................................................................................... 7

Wiring Configurations .................................................................................... Error! Bookmark not defined.

Quick Install –No Feedback........................................................................ Error! Bookmark not defined.

Single Unit Wiring with Feedback Status I/O......................................... Error! Bookmark not defined.

LED Failure .............................................................................................................................................. 12

Multi-Unit Wiring with Feedback Status I/O.......................................... Error! Bookmark not defined.

External I/O Signals ........................................................................................ Error! Bookmark not defined.

Maintenance ...............................................................................................................................................12

Frequently Asked Questions .......................................................................................................................12

Warranty .....................................................................................................................................................14

Notes...........................................................................................................................................................15

Hernon Manufacturing

®

107-028 Ultracure 7

4 | P a g e

Unpacking and Inspection

Upon receipt of the unit, carefully remove the contents from the boxes and check for damage. Hernon

is not responsible for damage from shipping –all claims for shipping damage should be made with

carrier.

Check all boxes for contents and document any serial numbers for further reference. You may wish to

retain original shipping cartons in case you need to repackage any item for return.

If you observe or experience any problem with your equipment, notify Hernon Customer Support, your

authorized distributor, or your Hernon representative immediately.

NOTE: REPORT ANY SHORTAGE TO HERNON CUSTOMER SERVICE

Before continuing with unpacking and installation, please read the following chapters of this manual for

safety recommendations and installation, running, and troubleshooting instructions.

CAUTION! Always wear proper (High Intensity UV Blocking) protective goggles or face shield

when working near the front of the unit which emits Ultraviolet light! Note: Reflected UV

light may be harmful.

WARNING! Always observe safety requirements!

CAUTION! Risk of Electrical Shock when cover is removed!

CAUTION! Cover is warm to the touch when unit is in operation!

WARNING: DANGEROUS ULTRAVIOLET EMMISSION

Hernon Manufacturing

®

107-028 Ultracure 7

5 | P a g e

Safety

Please, read all safety specifications before performing any procedures such as checking products on

delivery, storage and transportation, installation, wiring, operation and inspection, or disposal. Be sure

to observe these precautions thoroughly.

GENERAL WARNINGS

All operators and maintenance personnel are required to read this safety

instruction list before attempting to operate, adjust or repair.

Never operate with electrical enclosure open.

Do not operate this or any other machine without all protective guards and

covers in place.

Do not operate this device before reading and understanding the operator’s

procedures in this manual.

Any electrical servicing or adjustments requiring access to electrical enclosures on

the machine should be performed only by qualified personnel with electrical

power disconnected and locked out.

Safety glasses must be worn by the operator and any one in the area of

operation. W/ #5 Green Shade Goggles.

Hands should never be placed near moving or illuminated areas.

Disconnect and lock out electrical power, hydraulic power, air pressure and water

before performing machine or tooling adjustment and or maintenance.

Keep area around device/s clear of all debris, water, oil, etc.

Use only genuine OEM Hernon replacement parts when servicing this machine

tool. Ignoring this warning could cause unintended operation and possible injury.

WARNING: DANGEROUS ULTRAVIOLET EMMISSION

Recommended #5 Green shade goggles for eye protection

This equipment is designed to be used properly, set up with components correctly connected, and

operated in accordance with relevant instructions. Its design was developed to maximize operator

safety.

Hernon Manufacturing

®

107-028 Ultracure 7

6 | P a g e

General

The Ultracure 7 carries the same functionality as the Ultracure 6, but is more optimized for tight spaces

with its two-piece design. A 90° cable connector is available upon request.

Figure 1- The Ultracure 7 shown as both straight and 90°.

Features

Ultra Violet Energy (UVA) Curing

Liquid-cooled

365nm High Output LED

Built-in power regulation and overheating protection

Two-piece design

Specifications

Part Number

107-022

Power Requirements

24VDC, 700 mA

UV Output

2.5 /W cm² (max) @ 365nm

I/O Port

5 pin

Cooling

Liquid (Two M5 x 0.8 holes)

Head Dimensions (approx.)

2.13”x 1.50”x 1.25”

Control Box Dimensions (approx.)

3.5” x 2” x 1.5”

Cable Length

12ft (4m)

System Warranty

1 year from purchase

NOTE: Power Supply not included.

Hernon Manufacturing

®

107-028 Ultracure 7

7 | P a g e

Figure 2- Ultracure 7 LED unit dimensions and mounting.

Mounting

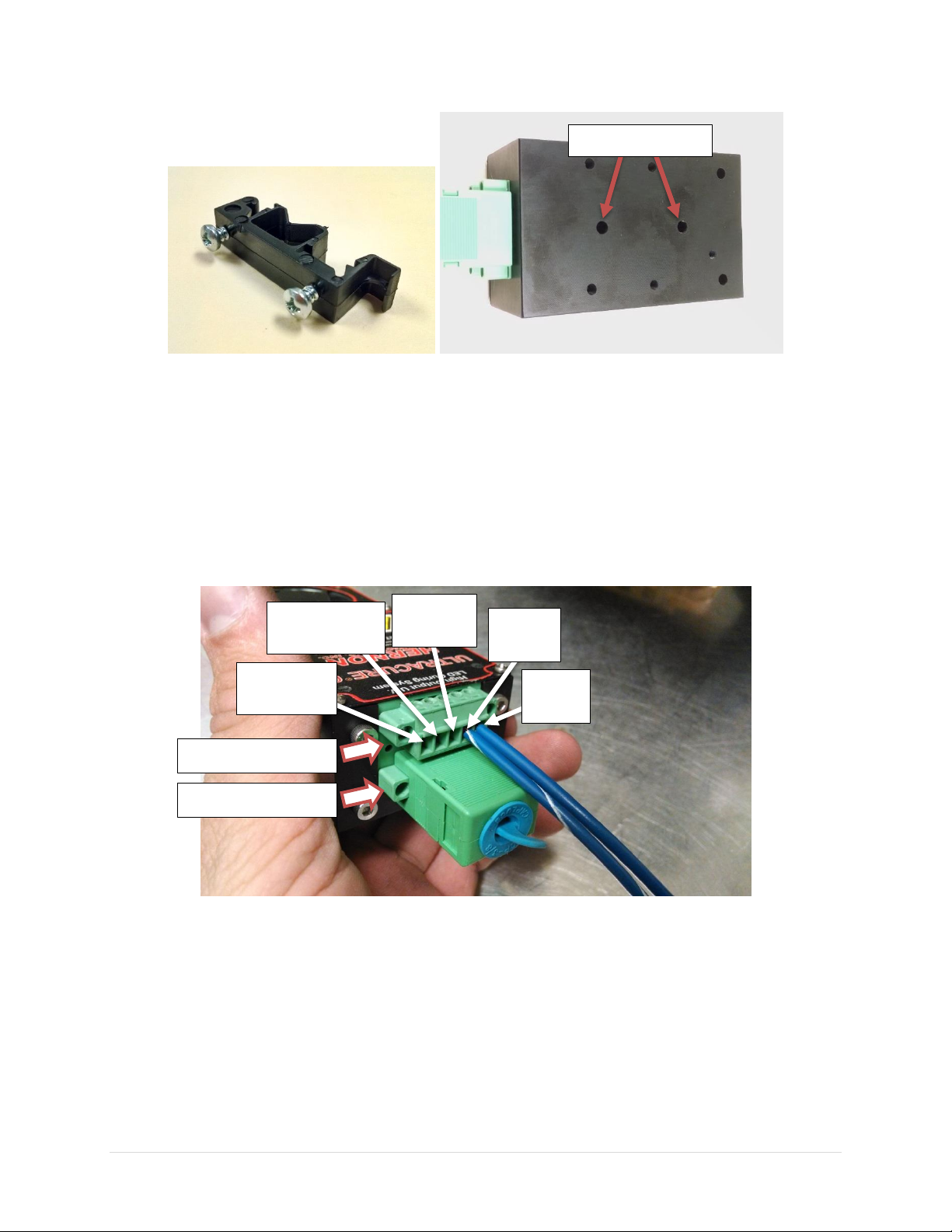

The Ultracure 7 has three mounting options on the LED unit: Four M4 x 0.8 on electrical connector end,

two M4 x 0.8 on the bottom face of the device, and two M4 x 0.8 on both sides of the LED. Refer to

Figure 2.

The control box has two M3 thru-holes for mounting. A DIN Rail adapter, or “Dinclip”, can be used, and

is included along with required mounting screws. The control box must be opened in order to install the

DIN Rail adapter.

Figure 3- Control box, with mounting holes and cover screws shown.

Hernon Manufacturing

®

107-028 Ultracure 7

8 | P a g e

Figure 4- The included "Dinclip" and hardware, shown next to mounting holes on bottom face of the control box.

Operation Guidelines

Wiring Configurations

The Ultracure 7 can be wired with or without status feedback.

Quick Install –No Feedback

Connect 24VDC as shown for quick install with no feedback.

Figure 5 - Ultracure 7 pin connectors, with pins labelled. Shown wired in no-feedback configuration.

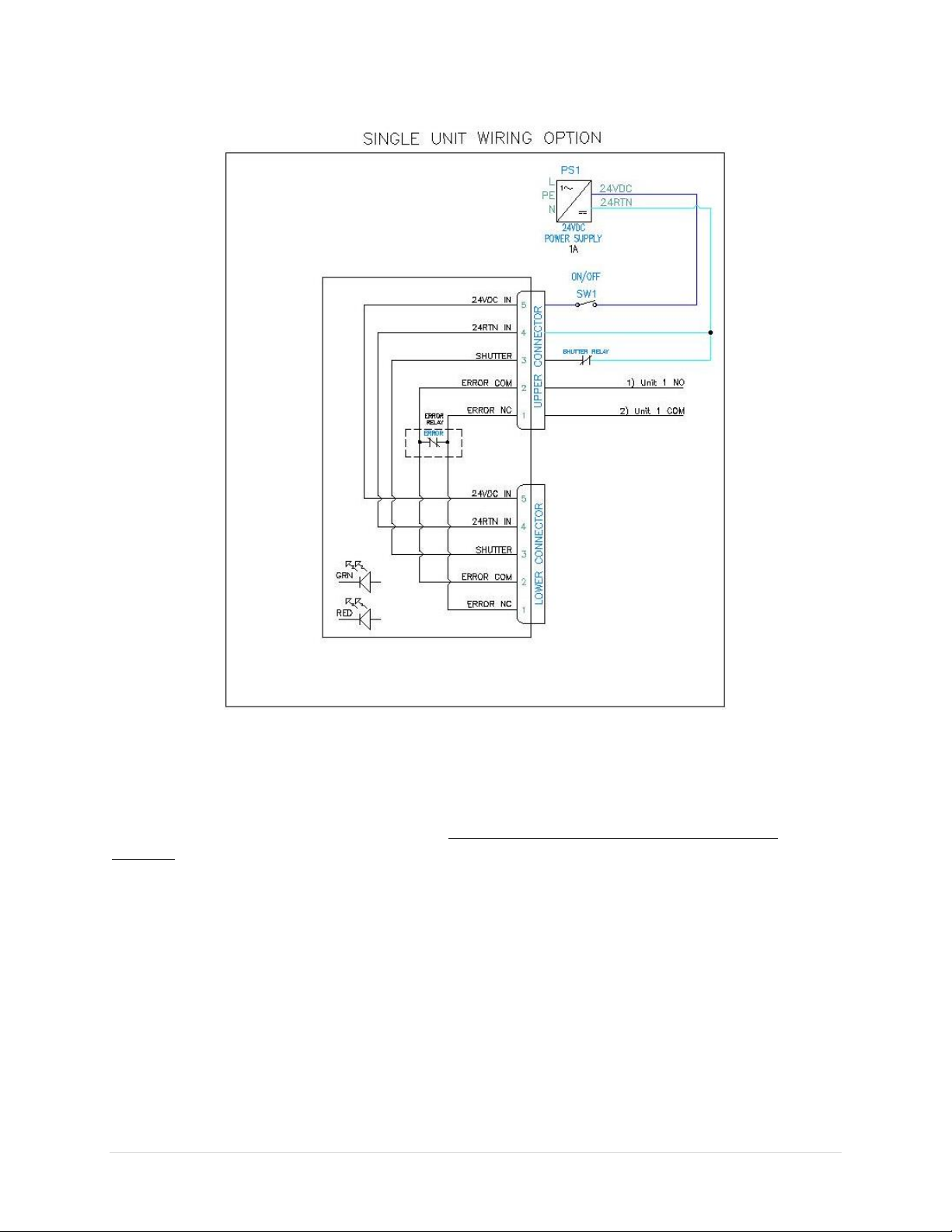

Single Unit Wiring with Feedback Status I/O

Reference Drawing on next page.

The Ultracure 7 unit will turn on under the following conditions: when the Power Supply (PS1) is on, the

Switch (SW1) is closed, and shutter relay contacts are open.

If the unit has an over temperature error or a burned out LED, the error relay will turn on, opening up

the NC contacts.

Pin #1

(Error NC)

Pin #2

(Error COM)

Pin #3

(Shutter)

Pin #4

(-)

Pin #5

(+)

Upper Connector

Lower Connector

“Dinclip” Mounts

Hernon Manufacturing

®

107-028 Ultracure 7

9 | P a g e

Figure 6- Single-Unit Wiring.

The Ultracure 7 unit will turn on/off quickly when the shutter relay contacts are opened/closed. If the

shutter relay is not used, leave Pin 3 disconnected and the unit will turn on and off with SW1 only. The

cooling fans will be turned off with SW1 as well. DO NOT connect Pin 3 to anything over than 24

RETURN! Status Relay Contacts in each unit are rated for 30VDC and 2A.

Multi-Unit Wiring with Feedback Status I/O

Reference Drawing on next page.

When PS1 is on, switch SW1 is closed and shutter relay contacts are open then all the Ultracure 7 units

in the Multiunit loop will turn on. The green LED on each unit will turn on when the units are on. If one

of the units has an over temperature error or a burned out LED then that units’ error relay will turn on

and the error loop will open. The red LED will turn on when an error is active. The Ultracure 7 units will

turn on/off quickly when the shutter relay contacts are opened/closed. If the shutter relay is not

used/required then leave Pin 3 disconnected and the units will turn on/off with SW1 only. The cooling

fans will be turned off with the SW1 as well. DO NOT connect Pin 3 to anything other than 24 RTN of

this multi-unit loop! Status Relay contacts in each unit are rated for 30VDC and 2A.

Hernon Manufacturing

®

107-028 Ultracure 7

10 | P a g e

Figure 7- Multi-Unit Wiring.

Hernon Manufacturing

®

107-028 Ultracure 7

11 | P a g e

System Status/Faults

Two status indicator LED’s are located on top of the

module.

Green lamp: Power on and working properly.

Red lamp: Indicates one of the following Fault Conditions:

LED failure open

LED short

Pink lamp: Over temperature

If the fan fails, or the ambient temperature gets too

high, an automatic shutdown will protect the LEDs. The

LEDs are forced off if the unit temperature reaches 60°C,

and will stay off until the substrate cools down to 55°c.

UV Output Curve

The Ultracure 7 has an optimal distance for ideal curing properties. The diagram below shows the UV

Intensity vs Distance Curve.

Figure 8- UV output curve.

Power LED

Fault LED

Hernon Manufacturing

®

107-028 Ultracure 7

12 | P a g e

External I/O Signals

The only output signal on the Ultracure 7 is an Error signal from port 2. Refer to Figure 5

LED Failure

The unit has experienced an LED failure; this is fixed by opening the driver enclosure and flipping

the corresponding dipswitches one at a time (from 1 to 5) until the unit turns back on. The unit

will operate properly with one or more inoperable LEDs.

Dip s/w 6 allows customer to bypass the closed led fault condition. (Note: red fault lamp will

stay illuminated). Once bypassed customer must manually inspect for led failures.

Maintenance

Verify the protective glass is clean.

Frequently Asked Questions

Q: Why is my unit turning off by itself?

A: LED failure, refer to next question for answer.

Q: The unit no longer turns on, but the unit is not hot what happened?

A: The unit has experienced an LED failure; this is fixed by opening the driver enclosure and flipping the

corresponding dipswitches one at a time (from 1 to 5) until the unit turns back on. The unit will operate

properly with one or more inoperable LEDs.

Hernon Manufacturing

®

107-028 Ultracure 7

13 | P a g e

Q: How often should the Ultracure 7 be cleaned?

A: The unit should be cleaned prior to every start up. This will ensure a long life of the LEDs.

Use a razorblade to clean glass of any cured sealant

Hernon Manufacturing

®

107-028 Ultracure 7

14 | P a g e

Warranty

CAUTION!

HERNON CORPORATION RESERVES THE RIGHT TO INVALIDATE ANY WARRANTIES, EXPRESSED OR

IMPLIED, DUE TO ANY REPAIRS PERFORMED OR ATTEMPTED ON HERNON EQUIPMENT WITHOUT

WRITTEN AUTHORIZATION FROM HERNON. THOSE CORRECTIVE ACTIONS LISTED BELOW ARE LIMITED

TO THIS AUTHORIZATION.

Hernon offers a one-year warranty against defects in material and workmanship on all system

components, except the LED, with proof of purchase date. Unauthorized repair, modification, or improper

use of equipment may void warranty. The use of aftermarket replacement parts not supplied or approved

by Hernon will void any effective warranties and may result in damage to the equipment.

The data contained in this bulletin is furnished for information only and is believed to be reliable. We cannot assume

responsibility for results obtained by others over whose methods we have no control. It is the user’s responsibility

to determine suitability for the user’s purpose of any product or methods mentioned herein and to adopt such

precautions as may be advisable for the protection of property and persons against any hazards that may be involved

in the handling and use thereof. Nothing in this bulletin is to be interpreted as a representation of freedom from

domination of patents owned by others or a license under a Hernon patent. We recommend that each prospective

user test his proposed application before repetitive use, using the data as a guide.

Hernon Manufacturing

®

107-028 Ultracure 7

15 | P a g e

Notes

This manual suits for next models

1

Table of contents

Other Hernon Industrial Equipment manuals