XT-K 50-30/EN/REV 00

Installation and connections - Use and Maintenance

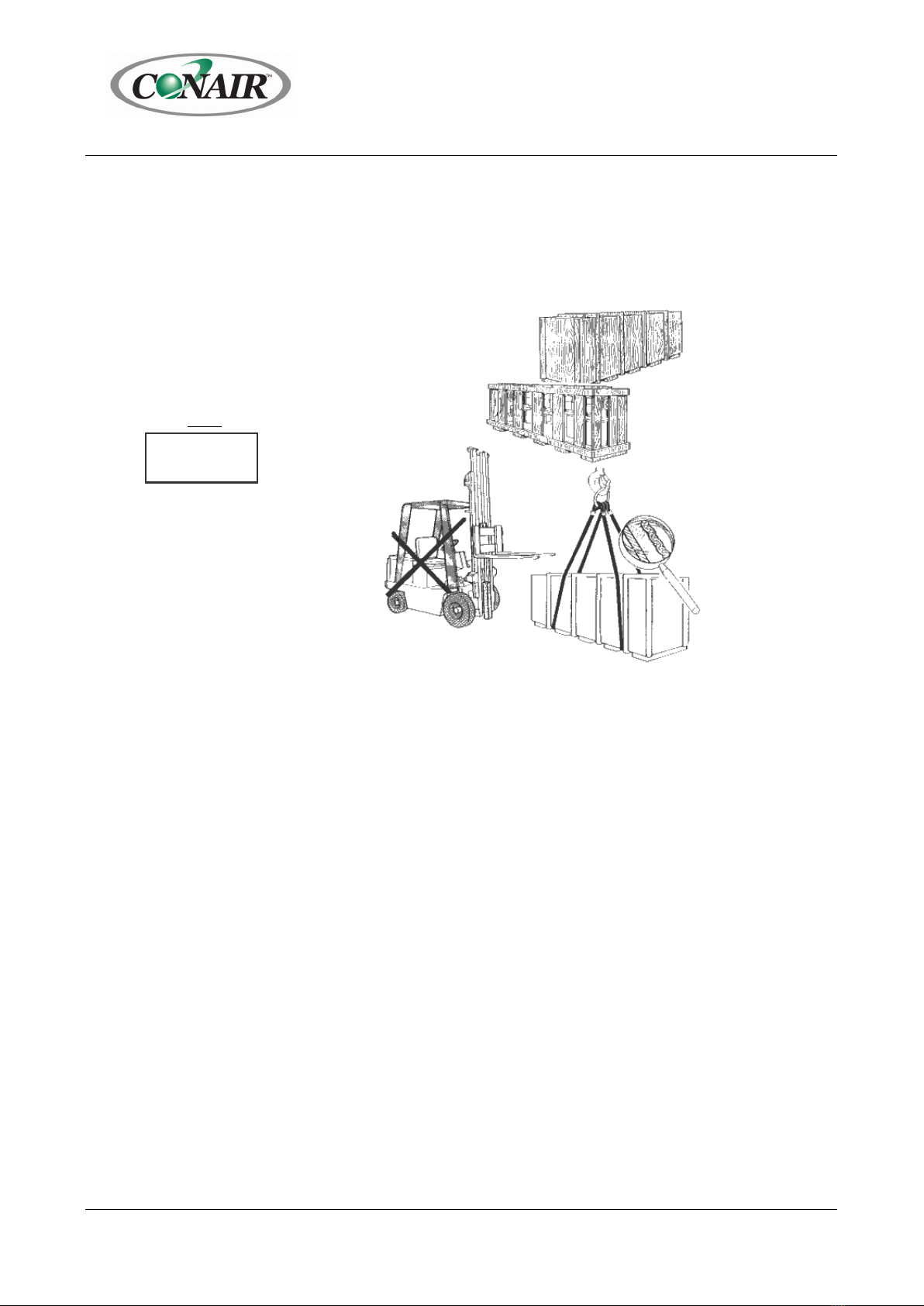

Packing inspection on delivery of machine

When goods are received, packing must be checked according to the following criteria:

boxes must be undamaged;

mechanical parts such as posts, guides, brackets, etc. must not be damaged.

In case of damaged goods, acceptance of hauled material is carried out with reservation as it is necessary to inspect the

intactness of the goods.

If anything is found to be damaged, before taking out parts of the system from the package, immediately contact Conair.

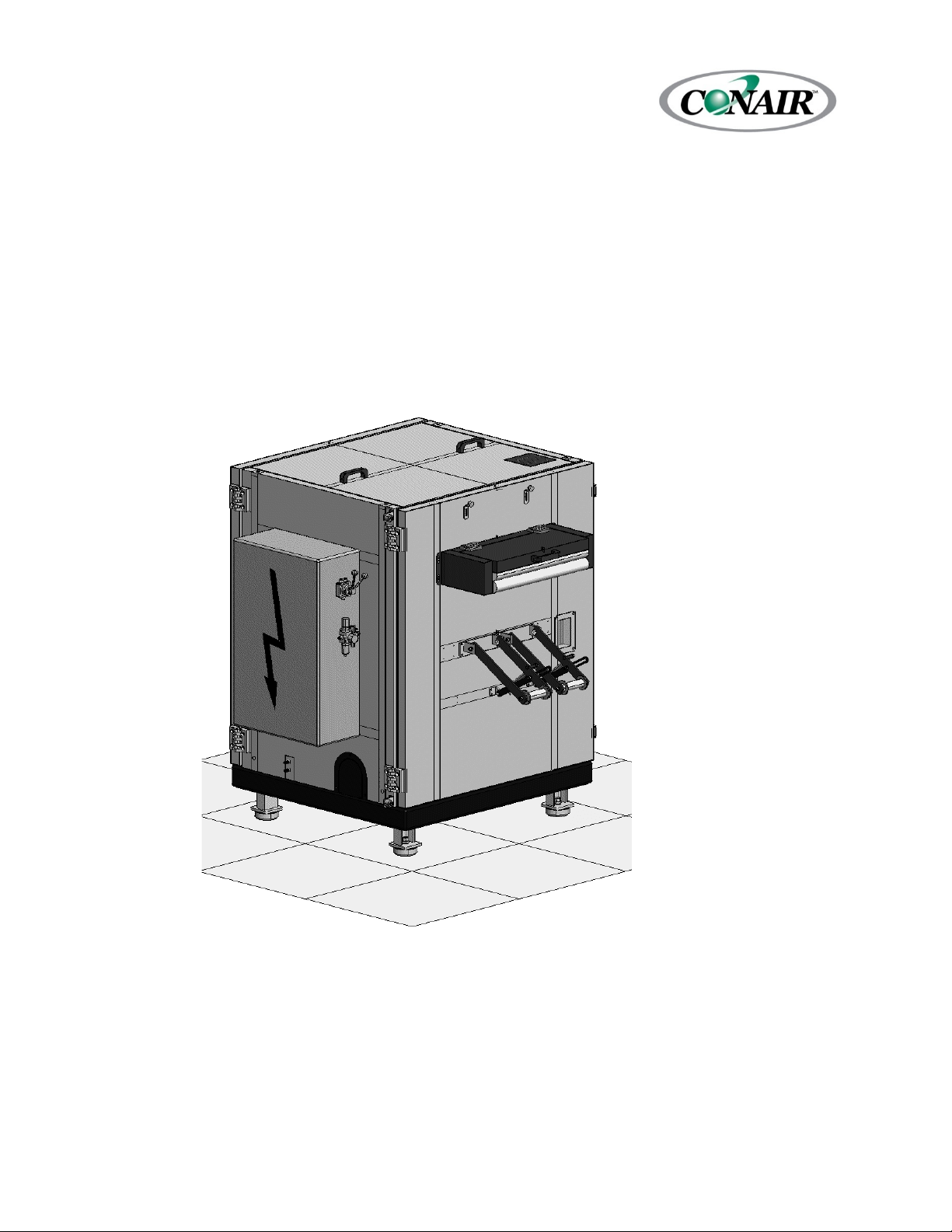

Visually inspect conditions of the system inside and outside the package. Any deformation will show that the system

could have been damaged during hauling. This could affect its normal operation.

In particular, check:

metal and painted surfaces;

tightening of the screws, bolts and fittings.

In case of damaged goods

Before installing the machine, check its conditions. Damages caused by hauling must be immediately communicated to

Conair.

Any damage to the carrier – however this may happen - could harm people or things, in addition to affecting proper

operation of the machine. The customer, or parties concerned, are therefore called to carry out an accurate inspection

before the installation and startup.

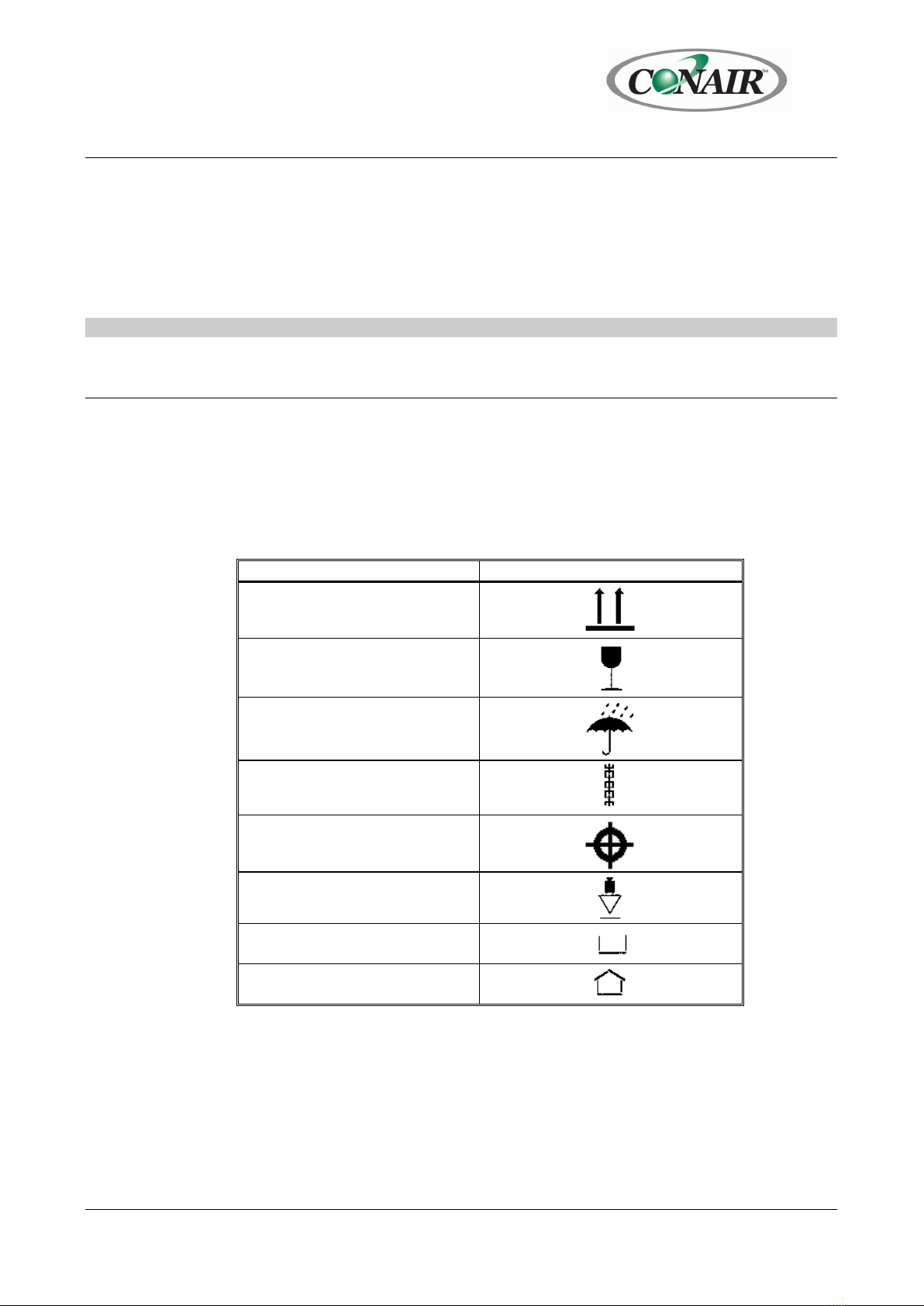

Storage of the machine

All specifications described in this section shall be observed during temporary storage periods of the system and that

may occur in the following situations:

installation of the system not immediately after its supply;

removal of the system and storage pending a relocation.

Physical features of storage areas

In the event of machine storage, appropriate traffic and maneuvering spaces are required in order to allow personnel to

easily and safely sling and lift all parts.