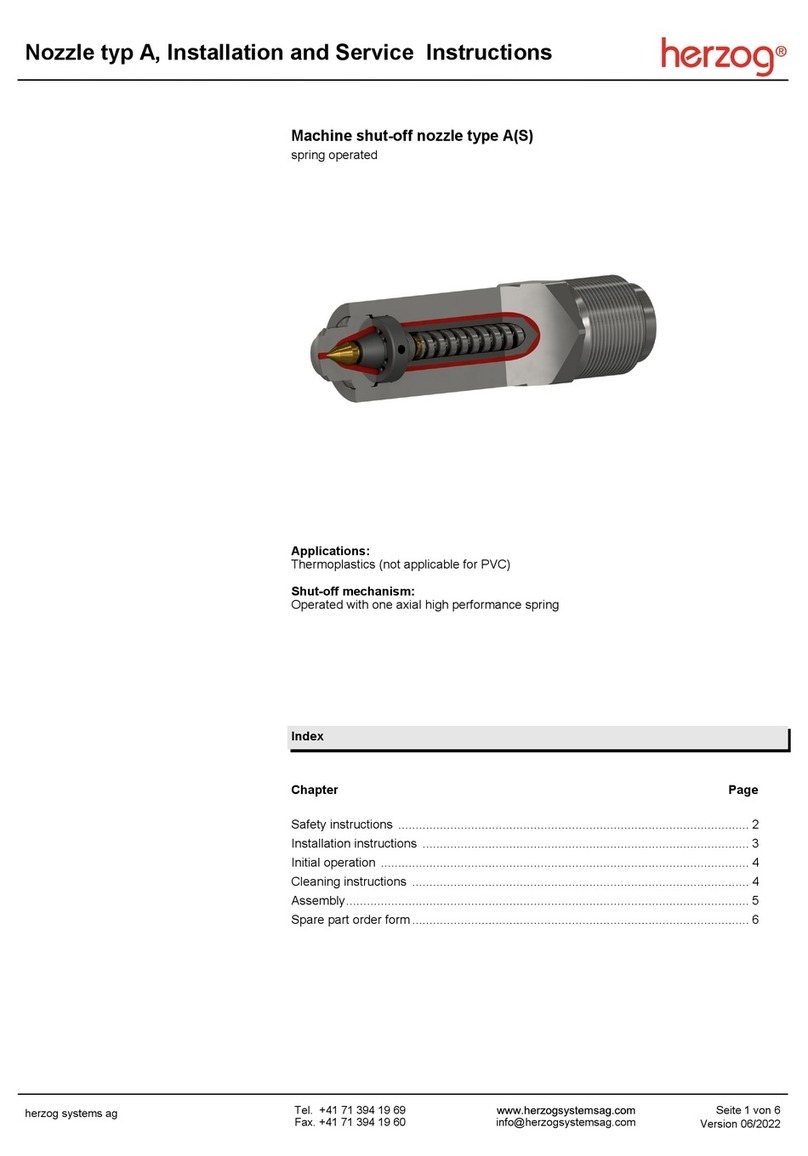

BHP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 (0)71 394 19 69

Fax. +41 (0)71 394 19 60

www.herzog-ag.com

info@herzog-ag.com 3

M. S. Version 0.3

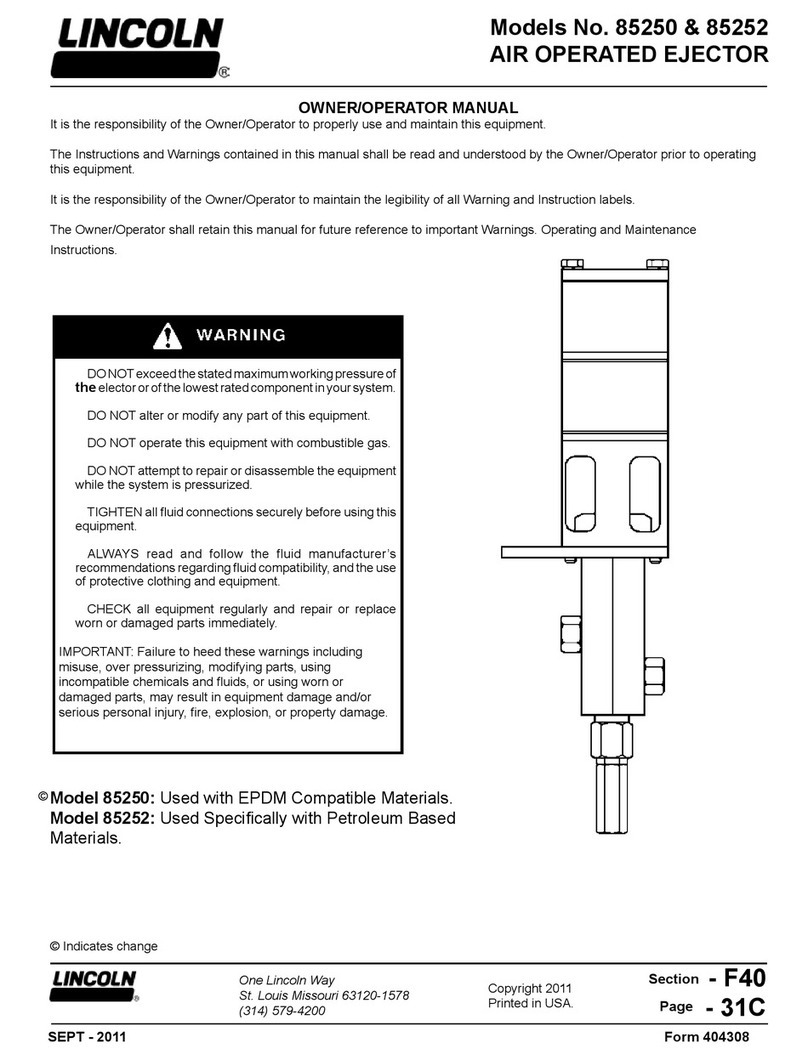

Read safety instructions!

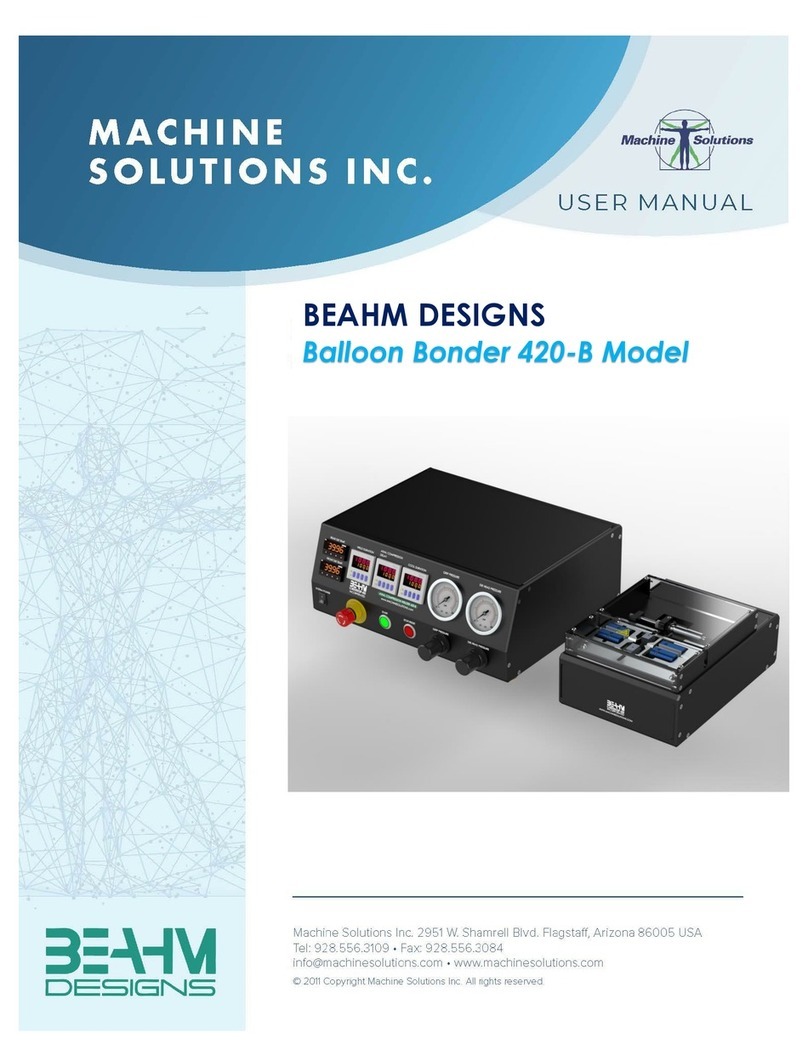

Initial operation:

1. Bring nozzle to operating temperature

2. Only by first initial operation: tighten screws and heater band screws to the maxi-

mum recommended torques

3. Make sure that the Polymer is completely melted

4. Eject the heated material. This follows after extrusion at low speed (time ca. 25 - 30

S) or through injecting out at three to five times the rate of injection

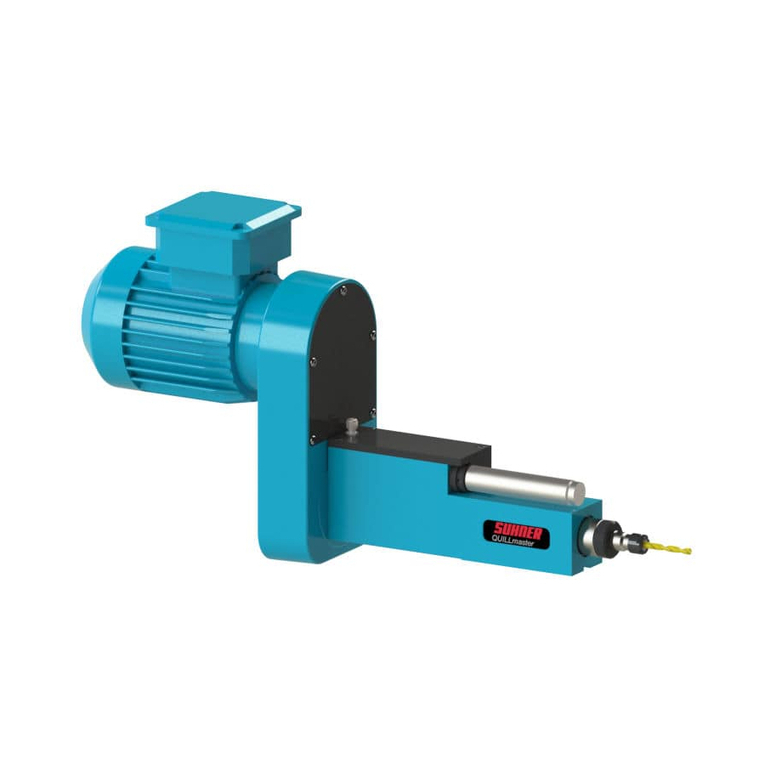

Actuator:

Operational data according to engraving on cylinder

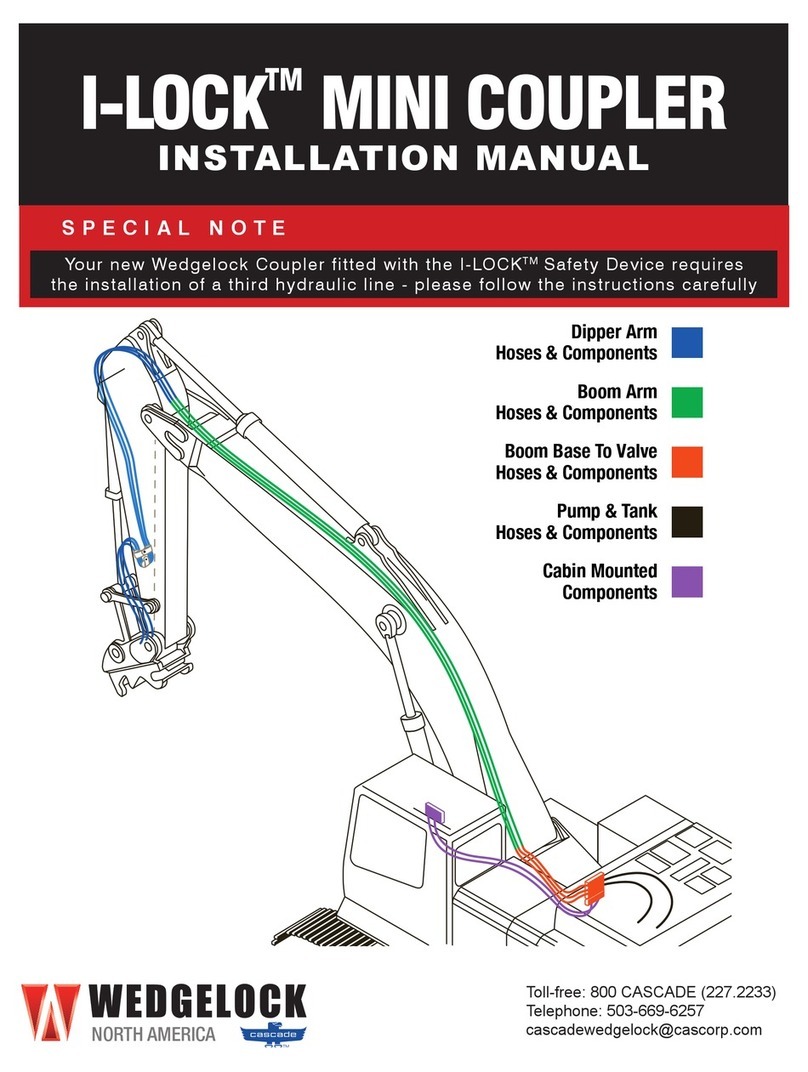

Leakage:

Between bolt and guide there is a melt film which prevents the needle from blocking. The

melt film will be continuously renewed and will eventually leak out of the nozzle.

At machine downtimes: nozzle temperature must be lowered.

Initial operation

Cleaning instructions

While the nozzle is still installed, clean as far as possible in a heated state and finally

disassemble completely and clean individual parts.

Plastics such as; LCP or PPS burn away when the nozzle is heated in an oven for tow

hours at 500°C.

Never heat steel parts above 500°C!

Clean pneumatic or hydraulic actuator separately with max. 150°C!

Avoid kinking the heater bandand sensor cables!

Help tools for cleaning:

•

Sand fluidized bed

•

Glass bead blasting

•

Cleaning oven

•

Gas burner

•

Wire brush

•

Steel wool

Before reassembly check all parts for damage or wear.

Profit from our cleaning service. The nozzle is disassembled, checked and repaired if

necessary after customer approval.