HES HS7003B User manual

===== CONTENTS =====

CHAPTER 1 SAFETY SUMMARY

1-1 INTRODUCTION………………………………………………………………………………………………………………………………………… 3

1-2 SAFETY DURING INSTALLATION…………………………………………………………………………………………………… 3

1-3 SAFETY DURING OPERATION…………………………………………………………………………………………………………… 3

1-4 PRECAUTIONS DURING OPERATION……………………………………………………………………………………………… 4

1-5 SAFETY DURING MAINTENANCE……………………………………………………………………………………………………… 4

1-6 SAFETY WHEN USING ADHESIVE AND SOLVENT…………………………………………………………………… 5

CHAPTER 2 MACHINE FAMILIARIZATION

2-1 INTRODUCTION………………………………………………………………………………………………………………………………………… 6

2-2 SPECIFICATION……………………………………………………………………………………………………………………………………… 7

2-3 FUNCTIONS………………………………………………………………………………………………………………………………………………… 7

CHAPTER 3 UNPACKING AND INSTALLATION

3-1 INTRODUCTION………………………………………………………………………………………………………………………………………… 9

3-2 UNPACKING AND INSTALLATION…………………………………………………………………………………………………… 9

3-3 MACHINE INSPECTION………………………………………………………………………………………………………………………… 9

3-4 INSTALLATION OF ROLLER COATER…………………………………………………………………………………………… 9

3-5 INSTALLATION OF POWER……………………………………………………………………………………………………………… 10

CHAPTER 4 OPERATION INSTRUCTION

4-1 INTRODUCTION……………………………………………………………………………………………………………………………………… 11

4-2 SAFE PRECAUTIONS…………………………………………………………………………………………………………………………… 11

4-3 INSTRUCTION OF CONTROL PANEL…………………………………………………………………………………………… 11

4-4 PREPARATIONS BEFORE OPERATION………………………………………………………………………………………… 13

4-5 NORMAL OPERATION PROCEDURE………………………………………………………………………………………………… 14

4-5-1 PROCEDURE OF TURNING ON MACHINE……………………………………………………………………………… 14

4-5-2 PROCEDURE OF TURNING OFF MACHINE…………………………………………………………………………… 14

4-6 ADJUSTMENT…………………………………………………………………………………………………………………………………………… 15

CHAPTER 5 TROUBLESHOOTING

5-1 TROUBLESHOOTING WHEN OPERATION……………………………………………………………………………………… 16

CHAPTER 6 MAINTENANCE

6-1 HOW TO MAINTAIN THE MACHINE……………………………………………………………………………………………… 19

6-2 HOW TO CLEAN THE ROLLER AND CHANGE HMA………………………………………………………………… 19

CHAPTER 7 DIAGRAMS

CHAPTER 1 SAFETY SUMMARY

1-1 INTRODUCTION

This chapter is to provide related safe precautions while doing

installation, operation and maintenance of Roller Coater (HS7003B-BA)

to prevent personal and equipment’s risk. These safe precautions can

be classified as following:

1.1 Safety during installation

1.2 Safety during equipment operation

1.3 Safety during maintenance

1.4 Safety during use of hot melt adhesive and solvent

1-2 SAFETY DURING INSTALLATION

1) A correct and effective grounding wire must be installed when

installing this roller coater. Without it, any isolation

component would still be conductive, resulting in shock hazard.

2) Check whether the power cords and their isolation protection match

requirement according to the load of the roller coater and its

accessories.

3) Ensure that wire of main power is installed correctly the breaker

from outside.

4) Ensure that the roller coater is working under the proper voltage.

Using wrong voltage may burn this roller coater.

1-3 SAFETY DURING OPERATION

1) Avoid operating the roller coater near the volatile or explosive

materials and gases.

2) DO not operate the equipment without the covers, panels and safety

guards properly installed.

3) Do not operate the machine when the ambient temperature is below

0 or above 50 .

℃ ℃

1-4 PRECAUTION DURING OPERATION

1) Do not use the equipment as a ladder or stepping tools.

2) Avoid some sharp tools or some impurities damaging the surface

of roller while cleaning.

3) Please start the motor after making sure HMA of tank is melted

completely.

4) Use only the metal base when attempting to lift or move applicator.

Do not use covers, doors, panels, braces or grips of equipment.

5) If accident occurs, like finger or some stuff are rolled by roller,

please immediately press the emergency stop switch to stop

machine.

6) Do not wear gloves while operation to avoid hand being rolled

by roller.

1-5 SAFETY DURING MIANTENANCE

The main precautions to be adopted when carrying out maintenance are:

1) Disconnect the electrical power supply before maintenance the

equipment.

2) Do not wear rings, watches, bracelets, etc. when carrying out

the maintenance.

3) Do not in any way to disassemble or adjust any component of

equipment unless another person who can provide immediate

assistance is nearby.

4) Only qualified person can do maintenance on the equipment.

5) Do not touch bare connection or component without disconnecting

the electrical power supply while power is on. Dangerous voltage

exists at several points in the equipment.

6) Disconnect the power supply before removing any protection case

or changing any electrical components.

7) If possible, please stand on a rubber insulating mat when carrying

out maintenance. Do not work on wet floor or in very damp

surrounding.

8) Always wear the protective glasses, clothing and heat-resistant

gloves to avoid being burned by hot surface of components or

molten glue.

9) Do not use any tool that is with flaming or a sharp tip to clean

melting tank to avoid damaging the Teflon coating on surface of

tank.

10) Please stop operating roller coater immediately when the hot

melt glue is leaking out. And inform the qualified people to

maintain.

1-6 SAFETY WHEN USING HOT MELT ADHESIVE AND SOLVENT

A. HOT MELT ADHESIVE

1) The surface of hot melt adhesive would be solidified immediately

at normal temperature. However, molten adhesive inside is still

high temperature.

2) Always wear protective glasses, clothing and heat-resistant

gloves when load hot melt adhesive into tank or operate machine

close by.

B. SOLVENT

1) Do not use an open flame or uncontrolled heating devices to heat

solvents.

2) Do not use solvent that has high volatility to avoid burning and

exploding at high temperature. And this kind of solvent may result

poison air at high temperature.

3) Make sure the working area is ventilation enough before use

solvents.

4) Do not work under using cleaning solvent for a long time to avoid

breathing too much poison air that caused by high temperature.

NOTICE: If skin is touched by molten hot melt adhesive,

1) Do not try to remove the molten adhesive on the skin.

2) Immerse the affected area into cold water until the adhesive is

cooled down.

3) Do not try to remove the cooing adhesive from the skin.

4) Wrap the wound with clean and wet clothing. If the condition of

injury is very serious, please keep the patient’s body

temperature in normal temperature, and send the patient to the

hospital immediately.

CHAPTER 2 MACHINE FAMILIARIZATION

FIGURE 2.1 APPEARANCE OF HS7003B-BA

2-1 INTRODUCTION

This chapter is to introduce the general characteristics, structure

of this roller coater and how to operate this roller coater. The

figures (2.1 &2.2) of machine’s appearance, hydraulic system and

electronic system are also included in this chapter.

FIGURE 2.2 HYDRAULIC & ELECTRONIC SYSTEMS

2-2 SPECIFICATIONS

ITEM HS7003B-BA

POWER

REQUIREMENT

ψ220VAC/50HZ

POWER 2.4KW

WEIGHT 60KG

DIMENSION 495*430*480

ROLLER WIDTH

300MM

TANK CAPACITY

3.3L

MAX.

VISCOSITY 20,000CPS

MELTING RATE

3.35KG/h

2-3 FUNCTIONS

1) HEATING SYSTEM

Heaters in the bottom of tank and inside the roller provide heating

for HMA. Mechanic temperature controller would automatically control

temperature accordingly. Please start the motor after HMA being

melted completely for protection. It will take about 30 minutes to

melt HMA completely.

The tank of this roller coater uses power-heating system. Heaters

and RTD are in the bottom of tank and inside the roller. Temperature

of heating system is detected by RTD, and then transfer signal to

the PID, at last controller will decide whether heat or not

accordingly.

When the power is turned on, the temperature control system will

firstly check the electro-circuit, checking the SSR and RTD are

normal or not. Subsequently run the PID of heating area. On first

time to start the motor everyday, please make sure HMA in tank is

melted completely. It will take about 30 minutes to melt HMA

completely.

2) PID TEMPERATURE CONTROLLER

This PID controller includes many functions, like digits display,

alert, adjustment, etc. Especially for temperature adjustment,

because that temperature is measured by RTD then transfer signal to

PID. PID controller will decide whether heater or not accordingly.

3) DRIVING SYSTEM

The motor could be started after temperature is reaching setting

value. Motor will drive the gears of rollers through chain after

starting. The lower roller is dipped in tank, and the HMA could be

rolled up by rolling. Put the material on roller, and then HMA could

evenly be coated on the surface of material.

SPECIFICATION OF MOTOR:

VOLTAGE 220VAC

POWER 200W

FREQUENCY

50HZ

CHAPTER 3 UNPACKING AND INSTALLATION

3-1 INTRODUCTION

This chapter is to introduce how to take out this roller coater from

case and how to install this roller coater and related accessories

properly.

3-2 UNPACKING AND INSTALLATION

This roller coater has been assembled before delivery. Please pay

attention on the process of taking this roller coater out from case,

please put hands under bottom of machine then take it out. It is

forbidden that take this machine out by holding other components of

this machine.

3-3 MACHINE INSPECTIONS

After tacking out the roller coater, the following items are

suggested to check.

1) Check the surface and control panel of this roller coater are

damaged, scratched, eroded or rugged.

2) Open the protective cover, checking whether the electrical wires

in control box are loosened or not.

3) Check all the connected components if they are assembled together

or not.

3-4 INSTALLATION OF ROLLER COATER

Place the roller coater on the flat and proper position that near

production line, and make sure the control panel is easy to operate.

There must be enough space for operators to work.

1) Place the machine on a flat surface, and fix the machine by four

screws fixed on the double edge of machine.

2) Do not install the machine where the ambient temperature is below

0 or above 50 .

℃ ℃

3) If this roller coater is installed outside factory or the

well-ventilated area, please try to avoid the HMA being touched

by ventilation air, due to the coating will be influenced.

4) This roller coater is not a fully hermetic and water-proof

equipment, please do not spray water near machine. It will cause

machine get short, damaged and eroded by these water.

3-5 INSTALLATION OF POWER SUPPLY

The power rate of this roller coater is 220VAC and single phase,

please note the following items while installation.

1) Do not attempt to amend the roller coater to work at other voltage.

Otherwise the roller coater will get damaged.

2) Make sure the external power supply is disconnected before

checking electrical components.

NOTE: After finishing the above steps, please do not turn on the power

immediately. Kindly read the next chapter then turn on the power.

CHAPTER 4 OPERATION INSTRUCTION

4-1 INTRODUCTION

This chapter is to introduce the control panel, precautions before

operation and operation steps of this roller coater and how to change

HMA.

4-2 SAFE PRECAUTIONS

1) Always wear the protective glasses, clothing and heat-resistant

gloves to avoid being burned by hot surface of components or

molten glue.

2) Do not touch the rollers while roller coater is running to avoid

being burnt by components or surface of high temperature.

4-3 INSTRUCTION OF CONTROL PANEL

This control panel includes PID temperature controller, main power

switch, switch for start and stop motor, switch for emergency stop,

fuses, etc. The more details would be introduced by following

sections. Please do read this instruction to avoid roller coater

getting damaged by operation.

FIGURE 4.1 CONTROL PANEL

1

5

3

4

2

6

7

8

1) PID TEMPERATURE CONTROLLER

SV: Setting Temperature

PV: Present Temperature

Press △╱▽ buttons to adjust setting temperature.

No DISPLAY Specification

1 PV

Displaying Present Temperature of

tank

2 SV Displaying Setting Value

3 AL Indicator for Alarm: ON/OFF

4 OUT Indicator for output: ON/OFF

5 AT Indicator for Auto Tune: ON/OFF

6 SET Select/confirm Key

7

▽

Decrease Key

8

△

Increase Key

9 AT(key) Auto Tune Key

2) MAIN POWER SWITCH

Switch to “ON” position, the light inside switch will be on, meaning

the power is turned on.

3) START SWITCH

Press this switch to start running the motor. Please make sure HMA

inside tank is melted completely before starting motor.

4) STOP SWITCH

Press this switch to stop running the motor.

5) VOLTMETER

This voltmeter is to display the working voltage of heater of roller.

Use high voltage for high viscosity HMA; use low voltage for low

viscosity HMA. The voltage of voltmeter can be adjusted by turning

the resistance that inside side plate.

6) EMERGENCY STOP

Press the RED BUTTON would instantly stop motor.

7) FUSE

The fuse would avoid electronic components being burnt.

8) INVERTER

Turn the knob on control panel of inverter to adjust speed of motor.

4-4 PREPARATIONS BEFORE OPERATION

1) Load clean and dry HMA into melting tank. And close tank lid to

avoid some impurities falling into melting tank.

FIGURE 4.2 MELTING TANK

NOTE: Please disconnect the external power supply before loading HMA

into tank. Otherwise there is still some voltage at wire head.

2) Turn on the external power supply.

3) Turn on the main switch on control panel, and refer to 4-3 to make

setting on PID temperature controller.

4) Prepare some materials, like leather, cloth, etc. for trial

coating.

5) Start motor after temperature reaching setting value, and make

sure HMA inside tank being melted completely.

4-5 NORMAL OPERATION PROCEDURES

4-5-1 PROCEDURE OF TURNING ON MACHINE

1) Turn on the external power supply.

2) Turn on the main power switch on control panel.

3) Check HMA inside tank is at least 30% in tank. (80% full of tank

is suggested.)

FIGURE 4.3 CAPACITY OF MELTING TANK

4) Check the temperature on PID controller whether it is reaching

setting value. (SV=PV)

5) When setting value is reaching, checking HMA inside tank is melted

completely, and then the motor can be started.

4-5-2 PROCEDURE OF TURNING OFF MACHINE

1) Turn off main power switch on control panel.

2) Disconnect the external power supply.

4-6 ADJUSTMENTS

4-6-1 ADJUSTMENT OF COATING THICKNESS

Turn the black knob behind the roller coater to adjust coating

thickness. (Clockwise turning is for more glue amount;

anti-clockwise turning is for less glue amount)

FIGURE 4.3 GLUE AMOUNT ADJUSTER

4-6-2 ADJUSTMENT OF MOTOR SPEED

Turn the knob on control panel of inverter to adjust speed of motor.

(Clockwise turning is for high speed; anti-clockwise turning is for

low speed)

FIGURE 4.4 INVERTER

CHAPTER 5 TROUBLESOOTING

5-1 TROUBLESHOOTING WHEN OPERATION

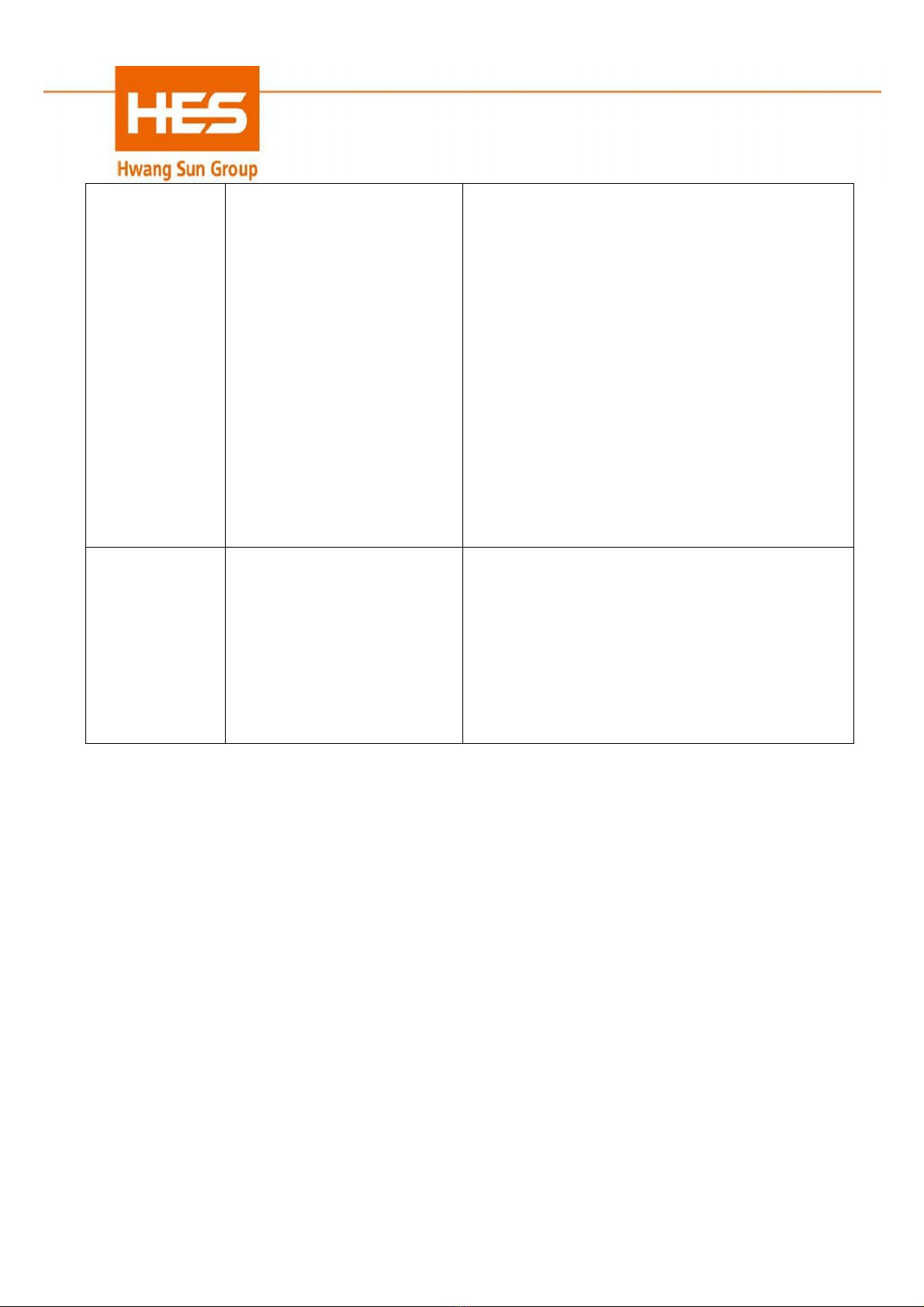

PROBLEM POSSIBLE CAUSE TROUBLESHOOING

There is

some HMA

on surface

of roller

1.

The surface of

roller is not

clean. (It may

some

impurities or

cloth on the

surface)

1. Please stop

motor and clean

the roller immediately when

some impurities are

sticking on the surface of

roller.

Uneven

coating

1.

Some impurities

are possible to

stick between

blade and

roller,

affecting glue

coating.

2.

Probably HMA

inside tank is

not enough.

1. Clean the roller and

change HMA.

2.

Check if HMA inside tank

is enough.

The end of

material

still with

HMA after

coating

1.

Temperature of

roller is not

hot enough.

(Different HMA

has different

melting

temperature)

2.

HMA is not

suitable for

coating.

(Viscosity of

HMA is too

high)

1. Re-adjust temperature of

roller.

2.

Change other suitable HMA.

HMA inside

melting

tank is

easy to be

charred or

yellowish

1.

Temperature of

roller is too

high.

2.

Length of

coating is too

long, causing

much air to be

brought into

melting tank.

3.

HMA is poor i

n

the ability of

anti-

oxidizatio

n.

1.

Properly adjust temperature

of roller.

2. Please stop running motor

without coating.

3.

Change HMA that has better

anti-oxidization.

Materials

rolled

into

melting

tank while

coating

1. Temperature of

roller is not

enough.

2.

Materials are

too thin and

soft to be

coated.

1. Adjust temperature of

roller.

2. Select other kind of

applicator to coat HMA on

these soft or thin materials.

Roller or

melting

tank is

not

heating

1.

Heaters are

damaged or power

is failure.

2.

PID temperature

controller is

damaged.

3.

Fuse of main

power supply is

damaged.

4.

RTD is damaged.

5.

Power cords are

damaged or

short.

6.

The mechanic

temperature

controller to

avoid tank

overheating is

damaged.

1. Replace a new heater.

2.

Replace a new PID temperature

controller.

3. Replace a new fuse (12A)

4. Replace a new RTD.

5. Connect the power cords or

replace new power cord.

6. Replace a new mechanic

temperature controller.

Indicator

to start

motor is

on, but

motor

cannot be

started

1.

Fuse is broken.

2.

Bearing of

roller is

damaged.

3.

Power cords are

damaged.

1. Replace a new fuse.

2. Replace a new bearing.

3. Connect the power cord or

replace new power cord.

Edges of

lower

roller are

leaking

HMA out

1.

Screws of side

plate are loose.

2.

O-ring is

damaged.

1. Tighten those screws.

2. Replace a new O-ring.

CHAPTER 6 MAINTENANCE

6-1 HOW TO MAINTAIN THE MACHINE

1) Please keep surface of machine clean. Do not use volatile

solvent to clean, such as gasoline, toluene, etc.

2) HMA inside melting tank will get charred and aged after a period

of heating, please change HMA regularly for ensuring coating

quality.

3) Please do not run the motor while doing maintenance to avoid

hands being rolled by roller.

4) Once cloth or any impurity fall into melting tank during

operation, please clean it out. Those stuff will affect glue

coating.

5) Always wear the protective glasses, clothing and

heat-resistant gloves to avoid being burned by hot surface of

components or molten glue.

6) Regularly smear some lubricant on chain and gear.

6-2 HOW TO CLEAN THE ROLLER AND CHANGE HMA

6-2-1 THE WAY TO CHANGE HMA

1) This melting tank coated by Teflon, so the surface is

non-adhesive and easy to clean.

2) Heat roller and tank at the same time, and ensure HMA is melted

completely. Then raise the back of machine around 15 degree

to make HMA flow to front of tank, subsequently turn off power

to cool down HMA.

3) When temperature of HMA is down to 50~60℃, take out the HMA

from tank by hands.

4) Please heat the rest of HMA, and then use cloth to clean it.

5) Surface of melting tank coated by Teflon, please do not scratch

it by any sharp tools. It may cause bad separation effect.

6-2-2 THE WAY TO CLEAN THE ROLLER

1) Once cloth or any impurity fall into melting tank during

operation, please clean it out. Those stuff will affect glue

coating.

2) Start the motor with lower speed, and turn the knob behind

machine to increase glue amount.

3) After finishing above steps, impurities will be rolled out by

roller running. And please stop machine and remove impurities

by tools.

6-2-3 MAINTENANCE OF DRIVING SYSTEM

It’s very important to maintain driving system of this machine.

Because this part is close to melting tank, although this part

protected by cover, it is still possible to be stuck by HMA. Driving

system will be affected by HMA being solidified on chain or gear.

Even cause motor or inverter to get damaged. If any HMA on chain,

please clean it right away by tools.

Besides, it is necessary to smear lubricant on chain and gear, and

check if any HMA leakage occurs from tank.

This manual suits for next models

1

Table of contents

Other HES Industrial Equipment manuals