HESCH HE 5422 MR User manual

HE 5422 MR

Differential pressure regulator with measuring hose cleaning

Operating manual

Translation of the operating manual

(Original version German)

2Operating manual HE 5422 MR

Version 1.2 • Item number #342232 • 25.03.2019

Imprint

HESCH Industrie-Elektronik GmbH

Boschstraße 8

D-31535 Neustadt

Germany

Phone +49 (0) 5032 9535-0

Fax +49 (0) 5032 9535-99

Internet: www.hesch.de

E-Mail: info@hesch.de

District court Hanover

HRB 111184

Tax-No.: 34/200/22524

VAT No.: DE813919106

Management:

Walter Schröder, Werner Brandis

Publisher:

HESCH Industrie Elektronik GmbH, Documentation Department

Copyrights

© Copyright 2014 HESCH Industrie-Elektronik GmbH. All rights reserved. The content

including pictures and the design of this manual are subject to copyright protection and

other laws for protection of intellectual property. The dissemination or alteration of the

content of this manual is prohibited. Moreover, these contents may not be copied, dis-

seminated, altered or made accessible to third parties for commercial reasons.

Operating manual HE 5422 MR 3

Version 1.2

Table of contents

1 Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Information regarding the usage of these operating instructions. . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Legal provisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Symbols and basic safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Safety during the individual phases of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Display and control elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Differential pressure column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5 Electrical commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Connection diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Parametrization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1 Parametrization using device keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Offset for zeroing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Parametrization using the Service-PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Parameter protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.5 Reset of factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1 Normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Testing function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Differential pressure measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.4 Measuring hose cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

9 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

10 Maintenance and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

10.1 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 1 Foreword

4Operating manual HE 5422 MR

Version 1.2

1 Foreword

1.1 Information regarding the usage of these operating instruc-

tions

Structure

Target group

These operating instructions are intended for qualified electricians that will install, wire, commission

and parametrize the HE 5422 MR Differential Pressure Regulator.

Chapter 1 Foreword

Information on chapter structure, document history, intended use and device

safety.

Chapter 2 Safety information

Important safety information regarding the Differential Pressure Regulator.

Chapter 3 Device description

Description of the Differential Pressure Regulator, control elements and techni-

cal specifications.

Chapter 4 Installation

Dimensions of the device and scope of delivery.

Chapter 5 Electrical commissioning

Connection of supply voltage and signals.

Chapter 6 Parametrization

Parametrization on the device or with a service PC.

Chapter 7 Operation

Information regarding operation, differential pressure measurements, measur-

ing hose cleaning and error messages.

Chapter 8 Error messages

Information regarding error messages that are shown on the display and indi-

cated by the flashing LEDs.

Chapter 9 Declaration of conformity

Chapter 10 Maintenance and service

Information regarding control operations and disposal

Chapter 1 Foreword

Operating manual HE 5422 MR 5

Version 1.2

Document history

Date / Version Description

10/2013 / 1.0 First creation

04/2014 / 1.1 Chapter 3.1, 3.4, 5.2, 5.3: Changed value for wide-range power supply

(100 – 240 VAV). Chapter 2.2: Changed value for surface temperature. Chap-

ter 6.1: Supplemented factory setting of Δp-Measuring-range (mbar). Chapter

9: Added declaration of conformity. Chapter 8: Added error message (E 4).

03/2019 / 1.2 Chapter 3.4 Technical data:

Operating temperature in EX zone added.

Chapter 1 Foreword

6Operating manual HE 5422 MR

Version 1.2

1.2 Legal provisions

Manufacturer

HESCH Industrie-Elektronik GmbH, Boschstraße 8, D-31535 Neustadt, Germany

Intended use

The HE 5422 MR Differential Pressure Regulator serves the purpose of measuring the dif-

ferential pressure using filter elements as part of the industrial fabric filter technologies and

to operate a valve control unit. The differential pressure is monitored by two alarm thresh-

olds.

The control unit can be operated within the usage and ambient conditions stated in this

manual without causing any safety risks.

The manufacturer is not liable for improper usage and the resulting personnel injuries or

damage; the risk lies entirely with the operator. Failure to comply with the above mentioned

criteria regarding intended use may void the warranty – the manufacturer cannot be held li-

able for damage to the device in this case.

Personnel qualification

Only qualified electricians with the appropriate knowledge in the field of electrical engineering are

allowed to conduct any work on the Differential Pressure Regulator.

Device safety

The device was built and tested in accordance with VDE 0411 / EN 61010-1 and has left the fac-

tory in an operationally safe condition. In order to maintain this condition and to ensure safe opera-

tion, the user has to follow the instructions and warnings contained in this manual, see chapter 2

"Safety information" on page 7.

Chapter 2 Safety information

Operating manual HE 5422 MR 7

Version 1.2

2 Safety information

2.1 Symbols and basic safety information

This chapter contains important safety provisions and information. In order to protect against per-

sonnel injury and damage, it is necessary to carefully read this chapter before working with the de-

vice.

Used symbols

The following symbols are used in this manual. All safety information notes are structured in a uni-

form manner.

Warning of personnel injury!

The severity of the danger is indicated by the respective signal word, see page 8.

Warning of explosive atmosphere!

Warning of dangerous electrical voltage!

Warning of material damage due to electrostatic charging!

Warning of material damage!

Note!

Indicates possible malfunctions and provides information regarding optimal oper-

ating conditions.

Chapter 2 Safety information

8Operating manual HE 5422 MR

Version 1.2

Signal words

DANGER!

Indicates an immediate danger with high risk that will result in death or serious injury if not avoided.

WARNING!

Indicates a possible danger with medium risk that may result in death or serious injury if not

avoided.

CAUTION!

Indicates a danger with low risk that might result in slight or moderate injury if not avoided.

Structure of warning notes

All warning notes in these operating instructions are structured in a uniform manner. The pictogram

designates the type of danger.

SIGNAL WORD!

An informative text describes the danger and suggests how it can be avoided.

Chapter 2 Safety information

Operating manual HE 5422 MR 9

Version 1.2

2.2 Safety during the individual phases of operation

The following safety notes must be observed when installing the device and during operation.

Danger of electric shock!

Disconnect the power supply before working on the device. Install the electrical

lines in accordance with the respectively applicable local regulations (VDE 0100

in Germany). Lay the measuring lines separately from the power lines. Produce a

connection between the protective ground connection (in the respective device

carrier) and a protective ground.

Danger of electric shock!

Any interruption of the protective ground in the device carrier may cause the de-

vice to become dangerous. Deliberate interruptions are not permissible. If it can

be assumed that safe operation is no longer possible, then the device shall be

put out of commission and be secured against unintended operation or re-activa-

tion.

Danger of electric shock!

Do not open the device under voltage! When opening the devices or removing

covers and parts, live parts may become exposed. Connecting points may also

be live!

Caution!

The device may not be put into operation when there is visible damage on the

device.

Caution!

Observe the accident prevention regulations applicable to the system, such as

BGV A 3 "Electrical Systems and Equipment" during installation, commissioning,

maintenance and troubleshooting.

Caution!

Clean soiled contacts using oil-free compressed air or spirit and a lint-free cloth.

Material damage due to electrostatic charging!

Observe the safety measures according to DIN EN 61340-51/-3 in order to pre-

vent electrostatic discharging!

Chapter 2 Safety information

10 Operating manual HE 5422 MR

Version 1.2

The following provisions must be observed:

Attach the cables to the cable glands correctly.

Provide unneeded housing bores with locking bolts.

It is only permitted to clean the housing with wet cleaning agents in order to avoid static

charging.

It is required to clean the device in order to prevent increased dust formation.

Electrical connection!

Install the electrical lines in accordance with the respectively applicable local reg-

ulations (VDE 0100 in Germany). Lay the measuring lines separately from the

power lines. Produce a connection between the protective ground connection (in

the respective device carrier) and a protective ground.

Explosion protection!

The device is suitable for operation in explosion zone 22 with the lid closed. Prior

to opening the device, it has to be ensured that there are no explosive ambient

conditions, such as dust development.

The device is marked with:

II Not suitable for mines susceptible to firedamp

3D Dusts, normal safety

T135°C Surface temperature

IP65 Protection class: dust-proof, scoop-proof

Troubleshooting!

When beginning to troubleshoot, all possible sources of error regarding additional

equipment or cables (measuring cables, wiring, slave devices) should be taken

into consideration. If no error source can be found after examining these points,

we recommend to send the device to the supplier.

Decommissioning!

Disconnect the power supply entirely if the device is to be decommissioned. Se-

cure the device against inadvertent operation!

If the device is interconnected with other devices and/or equipment, the effects of

the deactivation should be considered prior to disconnecting the device and the

appropriate precautions should be taken beforehand.

Chapter 3 Device description

Operating manual HE 5422 MR 11

Version 1.2

3 Device description

3.1 Overview

Fig. 3.1: Overview

A. Type designation

B. Display and control elements

C. Cable glands

A

B

C

Chapter 3 Device description

12 Operating manual HE 5422 MR

Version 1.2

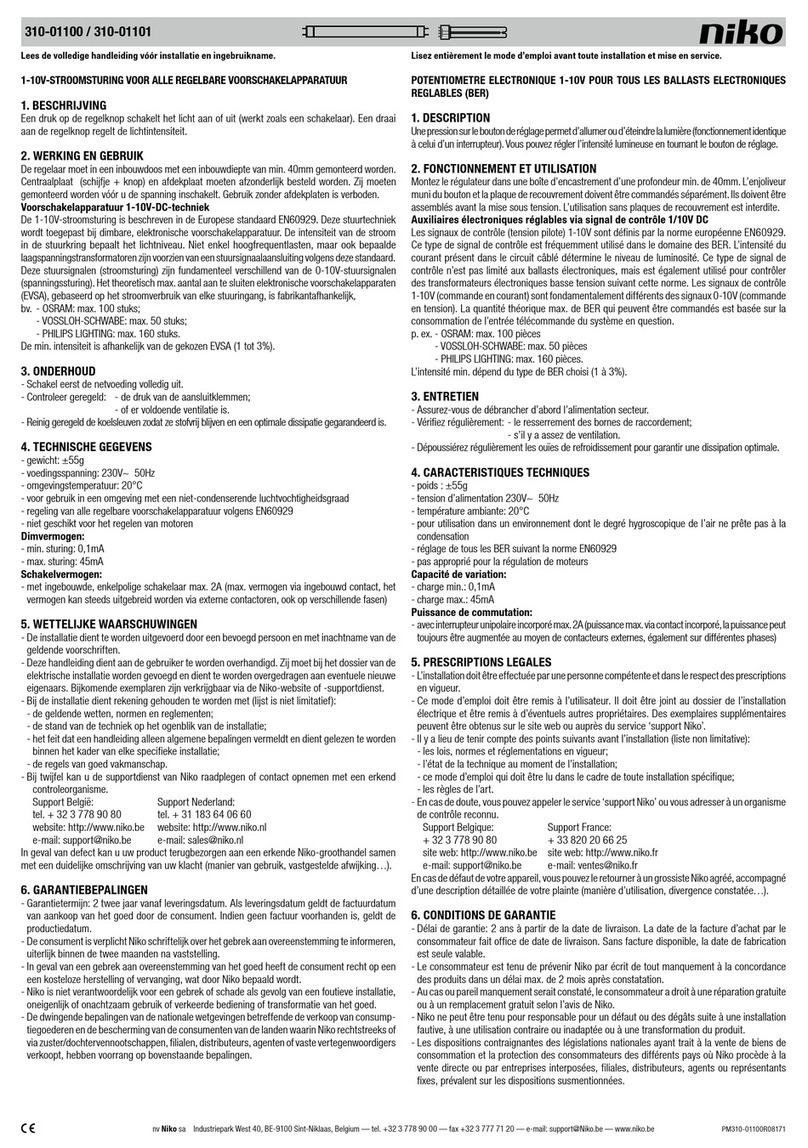

3.2 Display and control elements

Fig. 3.2: Display and control elements

Symbols Meaning

Operation message

Cleaning active

Alarms active

Interruption on one valve

Short-circuit of a valve (over current)

Filter constant of the differential pressure measurement

Post cleaning time

Normal operation: LED lights up when post cleaning is active

Parametrization mode: LED flashes when the parameter can be selected

Blowing time: opening time of the blow air valve

Chapter 3 Device description

Operating manual HE 5422 MR 13

Version 1.2

3.3 Differential pressure column

Fig. 3.3: Differential pressure column

In normal operating mode, the LEDs serve the purpose of displaying the differential pressure.

In parametrization mode, the selected parameter value is indicated by flashing.

Recovery time: delay to restore the pressure balance after the blowing time

Interval: waiting time until the next measuring line cleaning cycle

TEST button: testing mode ON/OFF

PARA button: parametrization mode ON/OFF

UP button: increase displayed value

DOWN button: reduce displayed value

ENTER button: accept/confirm displayed value

Display:

Normal operation: current differential pressure

Parametrization mode: parameter values

Alarm indications

Symbols Meaning

ΔP measuring range

High alarm

Upper threshold – Cleaning start

Lower threshold – Cleaning stop

Low alarm

Post cleaning threshold

Zeroing

Chapter 3 Device description

14 Operating manual HE 5422 MR

Version 1.2

3.4 Technical data

Technical data

Measuring range: Maximum of 35 mbar (90 or 450 mbar on request)

Maximum differential

pressure:

160 mbar

Basic accuracy: ± 1% of final value

Temperature drift: ± 0.05% / K of final value

Hysteresis: ± 0.5% of final value

Intended use: Differential Pressure Regulator with integrated Measuring Hose Clean-

ing used to control the cleaning of industrial filtration plants

Supply voltage: 100 – 240 VAC ±10%

24 VDC ±10%

Power consumption: Max. 30 W

Display: 7-segment display, 3 digits, 14 mm high, red for differential pressure dis-

play, parameter values and alarm messages

LEDs: 7 LEDs for status indications

16 LEDs for differential pressure indications

Buttons: PARA (ESC), UP, DOWN, ENTER, TEST

Analogue output: 4...20 mA

Galvanically isolated

Max. permissible load: 400 Ω

Digital inputs: Start, post cleaning. Internally supplied by 24 VDC / 1 mA

Relay outputs: 1 change-over contact 250 VAC, 5 A as a combined operating and

fault indicator

1 NO contact 250 VAC, 5 A as a cleaning indicator

2 change-over contacts 250 VAC, 5 A as alarm indicators

Interfaces: USB Device, Type B for reading and writing of parameters (USB / TTL

adapter required)

Creepage distances

and clearances:

Contamination Class 2

Over voltage Category II

EMV: Interference emission: DIN EN 61000-6-4

Interference immunity: DIN EN 61000-6-2

Housing: ABS (acrylonitrile-butadiene-styrene)

IP65 Protection Class

Dimensions: 200 mm × 150 mm × 100 mm (W × H × D)

Cable glands: 1 x M25 with multiple sealing insert for 4 liens with 6 mm diameter

1 x M20 for supply and communication

Electrical connections: Power supply: rigid/flex cross-section 2.5 mm2; flex.: max. 1.5 mm2

with wire end ferrule

Rest: rigid/flex cross-section 1.5 mm2; flex.: max. 0.75 mm2 with

wire end ferrule

Chapter 3 Device description

Operating manual HE 5422 MR 15

Version 1.2

Subject to technical changes.

Pneumatic connections: Pressure measuring line: 2 × push-in bulkhead connector for Ø6 mm

hose

Blowing pressure connection: 1 × push-in bulkhead connector for

Ø8 mm hose

Maximum blowing pressure: 8 bar

Installation: Wall mounting, mounting position: vertical

Ambient conditions

Climatic

Storage -20°C … +70°C

Transport -40°C … +85°C

Operation -20°C … +50°C

in EX zone: -20 °C ... +40 °C

Relative humidity Relative humidity 95%, no condensation allowed, KUF in accordance

with DIN 40400

Technical data

Chapter 4 Installation

16 Operating manual HE 5422 MR

Version 1.2

4Installation

The ambient temperature at the installation position may not exceed the permissible temperature

for rated use listed in the data sheet. The device may be installed in areas subject to the EX ATEX

Zone 22 Explosion Class. The special provisions should be observed, see chapter 2.2 "Safety dur-

ing the individual phases of operation" on page 9.

Dimensions

Fig. 4.1: Dimensions

Scope of delivery

HE 5422 MR

Operating Manual

Note!

After receiving the delivery, check it for completeness and obvious defects. In

case of a complaint, immediately contact your local HESCH representative.

Chapter 5 Electrical commissioning

Operating manual HE 5422 MR 17

Version 1.2

5 Electrical commissioning

Mind the following points prior to turning on the device:

Firmly connect the cables to the glands. The supply voltage must match the specifications

on the type plate.

The device may only be operated in a closed state.

The temperature limitations specified for use of the device have to be observed before and

during operation.

The protective ground connection in the appropriate device carrier has to be conductively

connected to the protective ground

5.1 Safety notes

Danger of electric shock!

Only perform the electrical installation in a dead-voltage state.

Material damage due to electrostatic charging!

Observe the safety measures according to DIN EN 61340-51/-3 in order to pre-

vent electrostatic discharging!

Note!

Only qualified specialists may work on the electronics.

Chapter 5 Electrical commissioning

18 Operating manual HE 5422 MR

Version 1.2

5.2 Supply voltage

Fig. 5.1: Supply voltage

1. Loosen the screws on the housing cover (lid) and remove the cover.

2. Read the supply voltage value off the type plate (for example 100 – 240 VAC and 24 VDC

mains voltage).

3. Connect PE conductors.

Note!

Both supply voltages may be connected at the same time.

100 – 240 VAC

24 VDC

+24 VDC

GND

PE

L1

N

PE

Chapter 5 Electrical commissioning

Operating manual HE 5422 MR 19

Version 1.2

5.3 Connection diagram

Fig. 5.2: Connection Diagram

5.4 Inputs

The ΔP controller has 2 inputs: Start and Post cleaning. The inputs are internally supplied with +

24 V DC and are active when they are switched to ground (GND) with a potential-free contact.

5.5 Outputs

Relay

The device is equipped with 4 potential-free relay outputs.

The contacts can each be loaded with 250 VAC / 5 A.

Analogue output

The current differential pressure is reported by a galvanically isolated 4…20 mA signal.

Note!

The inputs refer to the same ground (-). It is permissible to use one ground wire

for both inputs.

Chapter 6 Parametrization

20 Operating manual HE 5422 MR

Version 1.2

6 Parametrization

6.1 Parametrization using device keyboard

1. Press the PARA button to change the system parameters.

A flashing LED indicates the current value to be changed.

2. Select the desired parameter using the UP / DOWN buttons.

The respectively current value is indicated on the display.

3. Press the ENTER button to start changing the value of the parameter.

The first digit to be changed starts flashing in the display.

4. Press the UP / DOWN buttons to select or change the value of the digit.

5. Press the ENTER button to accept the current value.

The next digit will subsequently flash in the display.

6. Repeat steps 4 – 5 until the last digit has been changed.

The next parameter is offered.

7. If necessary, change the next parameter.

8. The parametrization mode is exited by pressing the PARA button again.

Main parameter Setting area Factory setting

ΔP-Filter [s]

Filter constant for the current dif-

ferential pressure

OFF, 0.2 – 60.0 s 2

Post cleaning time [min]

The cleaning relay is closed for

the parametrized time for post

cleaning purposes.

OFF, 1 – 999 min 10 min

Blowing time [s]

During the blowing time, the com-

pressed air is blown into the

measuring lines.

1 – 999 s 10 s

Recovery time [s]

Delay used to restore the pres-

sure balance after the blowing

time.

1 – 999 s 50 s

Interval [min]

Waiting time until the next meas-

uring line cleaning cycle.

0 – 999 min 60 min

Table of contents

Other HESCH Controllers manuals