HESCH HE 5733 User manual

#373511 | Version 1.0

Shaker filter controller

HE 5733

Operating instructions

(Translation of Original German version)

2

HE 5733 Operating Instructions

#373511 | Version 1.0

Imprint

AXXERON HESCH electronics GmbH

Boschstraße 8

31535 NEUSTADT, GERMANY

Phone: +49 5032 9535-0

Web: www.hesch-automation.com

Email: [email protected]

District Court Hanover

HRB 111184

VAT.-Id. No. DE813919106

General Management

Werner Brandis

Published by:

AXXERON HESCH electronics GmbH, documentation department

Copyrights

© Copyright 2023 AXXERON HESCH electronics GmbH. All rights

reserved. The content including pictures and the design of these operating

instructions are subject to copyright protection and other laws for the

protection of intellectual property. The operating instructions may only be

distributed as a complete document and only with reference to the source.

The modification of the contents of these operating instructions is

prohibited. In addition, this content may not be copied, distributed,

modified or made available to third parties for commercial purposes.

HE 5733 Operating Instructions

#373511 | Version 1.0

3

Document history

Date / Version

Description / Author

16/11/2023 / 1.0

First version / Bg

4

HE 5733 Operating Instructions

#373511 | Version 1.0

TABLE OF CONTENTS

1LEGAL PROVISIONS................................................................................................................................... 6

2SAFETY INFORMATION ............................................................................................................................. 7

2.1 SYMBOLS AND BASIC SAFETY INSTRUCTIONS...................................................................................................... 7

2.2 SIGNAL WORDS............................................................................................................................................ 7

2.3 SAFETY IN THE INDIVIDUAL OPERATING PHASES................................................................................................... 8

2.4 DEVICE IDENTIFICATION AND NAME PLATES...................................................................................................... 10

2.4.1 Device identification...................................................................................................................... 10

2.4.2 Name plates .................................................................................................................................. 10

2.4.3 Special Regulations........................................................................................................................ 11

3TECHNICAL DATA.................................................................................................................................... 12

4MOUNTING ............................................................................................................................................ 15

4.1 DIMENSIONS ............................................................................................................................................. 15

4.2 TORQUES.................................................................................................................................................. 16

4.2.1 Cable glands .................................................................................................................................. 16

4.2.2 Cable glands .................................................................................................................................. 17

4.2.3 Screw closures ............................................................................................................................... 17

4.3 OPENING THE DEVICE .................................................................................................................................. 18

4.4 MOUNTING THE DEVICE............................................................................................................................... 19

5DEVICE OVERVIEW.................................................................................................................................. 20

5.1.1 HE 5733 shaker filter controller..................................................................................................... 20

5.1.2 Differential pressure module ......................................................................................................... 20

6ELECTRICAL COMMISSIONING ................................................................................................................ 21

6.1 WIRING DIAGRAM ...................................................................................................................................... 22

6.2 SUPPLY VOLTAGE /OPERATION..................................................................................................................... 22

6.3 INPUTS..................................................................................................................................................... 23

6.3.1 Digital inputs ................................................................................................................................. 23

6.4 OUTPUTS.................................................................................................................................................. 24

6.4.1 Digital outputs............................................................................................................................... 24

6.4.2 Relay outputs................................................................................................................................. 24

6.4.3 Analogue outputs .......................................................................................................................... 24

6.5 ASSEMBLY OF MEASURING HOSE ONTO PRESSURE CONNECTION........................................................................... 25

7DISPLAY AND OPERATING ELEMENTS ..................................................................................................... 26

7.1 KEYS AND LED........................................................................................................................................... 26

7.2 DIFFERENTIAL PRESSURE COLUMN.................................................................................................................. 30

8OPERATION ............................................................................................................................................ 31

8.1 SWITCHING THE DEVICE ON .......................................................................................................................... 31

8.2 MALFUNCTION .......................................................................................................................................... 31

8.3 CLEANING WITH DIFFERENTIAL PRESSURE MONITORING...................................................................................... 32

8.4 AUTOMATIC CLEANING................................................................................................................................ 32

8.5 TIME-CONTROLLED CLEANING....................................................................................................................... 33

8.6 COVER SWITCH .......................................................................................................................................... 33

8.7 TEST &SERVICE......................................................................................................................................... 34

8.8 SWITCHING THE DEVICE OFF ......................................................................................................................... 35

9PARAMETRISATION ................................................................................................................................ 36

9.1 PARAMETER TABLE ..................................................................................................................................... 36

9.2 OVERVIEW OF PARAMETERS AND THEIR LEDS.................................................................................................. 37

9.3 PARAMETRISATION WITH DEVICE KEYS ............................................................................................................ 38

HE 5733 Operating Instructions

#373511 | Version 1.0

5

9.4 PARAMETRISATION VIA EASYTOOL CONTROLS 4.0............................................................................................ 40

9.5 OFFSET FOR ZEROING .................................................................................................................................. 41

9.6 RESET OF DEFAULT SETTINGS ........................................................................................................................ 42

10 DIFFERENTIAL PRESSURE MEASUREMENT .......................................................................................... 43

11 ERROR MESSAGES............................................................................................................................... 44

12 MAINTENANCE AND SERVICE.............................................................................................................. 46

6

HE 5733 Operating Instructions

#373511 | Version 1.0

1 Legal Provisions

Manufacturer

AXXERON HESCH electronics GmbH, Boschstraße 8, 31535 NEUSTADT, GERMANY

Intended use

The shaker filter controller is a compact controller consisting of an I/O unit and an

operating unit. The shaker filter is used for separating dust from raw gases.

The controller can be operated within the operating and environmental conditions

approved in these operating instructions without impairing its safety.

The manufacturer is not liable for improper use and any resulting personal injury or

material damage. The risk is borne solely by the user. Failure to comply with the

above criteria for intended use will result in the expiry of the warranty and liability for

the device.

Personnel qualification

All work on the device may only be carried out by qualified electricians with sufficient

knowledge in the field of electrical engineering.

Device Safety

The device has been constructed and tested in accordance with VDE 0411 / EN 61010-1 and

has left the factory in perfect safety condition. To maintain this condition and to ensure safe

operation, the user must follow all instructions and warnings in these operating instructions.

Declaration of conformity

The valid declaration of conformity is available in the download centre of our website

https://www.hesch-automation.com/en/support/download-center/.

Click on the tab Declarations of Conformity to select your device.

HE 5733 Operating Instructions

#373511 | Version 1.0

7

2 Safety Information

2.1 Symbols and Basic Safety Instructions

This chapter contains important safety regulations and notes. For protection against personal

injury and material damage, it is necessary to read this chapter carefully before working with

the device.

Symbols used

The following symbols are used in these operating instructions. All safety instructions have a

uniform structure.

Personal injury warning!

The severity of the danger is indicated by the respective signal word.

Explosive area warning!

High voltage warning!

Warning of material damage caused by electrostatic charge!

Material damage warning!

Note!

Indicates possible malfunctions and optimal operating conditions.

2.2 Signal words

DANGER!

Indicates an imminently hazardous high risk situation, which, if not avoided, will result in death

or serious injury.

WARNING!

Indicates a potentially hazardous medium risk situation, which, if not avoided, could result in

death or serious injury.

CAUTION!

Indicates a hazardous low risk situation, which, if not avoided, could result in minor or

moderate injury.

8

HE 5733 Operating Instructions

#373511 | Version 1.0

2.3 Safety in the individual operating phases

When installing the device and during operation, the following safety instructions must be

observed:

Danger of Electrocution!

Before working on the device, switch off all power supplies used. The

electrical cables must be laid according to the respective national

regulations (in Germany VDE 0100). The measuring cables must be laid

separately from the power lines. Connect the protective earth connector

(in the respective equipment carrier) to the protective earth conductor.

Danger of Electrocution!

Any interruption of the protective earth in the equipment carrier can result

in the device becoming a hazard. Intentional interruptions are not

permitted. If it can be assumed that safe operation is no longer possible,

put the device out of operation and secure it against unintentional

operation.

Danger of Electrocution!

Do not open the device while under voltage! When opening the devices or

removing covers and parts, live parts may be exposed. Connection points

can also be live!

Attention!

Never operate the device despite visible damage!

Attention!

During installation, commissioning, maintenance and troubleshooting,

observe the accident prevention regulations applicable to your system,

e.g. DGUV Regulation 3 "Electrical installations and equipment".

Attention!

Clean dirty contacts with oil-free compressed air or with ethyl alcohol and

a lint-free cloth.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to DIN EN 61340-51/-3 to avoid

electrostatic discharge!

Power Connection!

The electrical cables must be laid according to the respective national

regulations (in Germany VDE 0100). The measuring cables must laid

separately from the power lines.

HE 5733 Operating Instructions

#373511 | Version 1.0

9

Explosion Prevention!

The device with closed lid is suitable for use in dust explosion hazardous

areas of zone 22 (applies to all device variants).

Before opening the device, make absolutely sure that there is no

explosive atmosphere.

Before you close the device again, ensure that the device is absolutely

dust-free on the inside.

Troubleshooting!

At the beginning of troubleshooting, all possible sources of faults on

additional devices or supply lines (measuring lines, wiring, downstream

devices) should be taken into consideration. If you have not found the

fault after checking these points, we recommend sending the device to

AXXERON HESCH electronics GmbH.

Decommissioning!

Switch off the power supply on all poles if the device is to be

decommissioned. Secure the device against being unintentionally

switched on!

If the device is connected to other devices and/or equipment, consider

the impacts and take appropriate precautions before switching it off.

10

HE 5733 Operating Instructions

#373511 | Version 1.0

2.4 Device identification and name plates

2.4.1 Device identification

II3D

Device category:

Use in zone 22 for dust during normal operation

Ex

Denotes electrical equipment.

Standards of the EN 60079-0ff. series have been applied.

tc

Type of ignition

protection:

Protection by housing

IIIC

Explosion group:

conductive dusts

T135°C

Temperature class:

maximum permissible surface temperature

Dc

Device protection level:

Use in zone 22 for dust

IP65

Protection type:

Dust-tight and protected against water jets

2.4.2 Name plates

HE 5733 with measuring range 0…50 mbar

HE 5733 with measuring range 0…100 mbar

HE 5733 Operating Instructions

#373511 | Version 1.0

11

2.4.3 Special Regulations

Warning of material damage caused by electrostatic charge!

Clean the device regularly, to prevent increased dust generation on the device.

For cleaning the housing, use moist cleaning supplies only to prevent

electrostatic charging!

Note!

The ATEX approval remains valid only, if the installation is carried out

professionally in compliance with the protection class indicated in the device

identification.

Note!

Close cable glands that are not needed with a locking bolt and housing bores

with blanking plugs.

12

HE 5733 Operating Instructions

#373511 | Version 1.0

3 Technical Data

Supply

Voltage:

400 V AC

Mains frequency:

50 Hz

Max. power consumption:

8.5 kW

Measuring range:

0…50 mbar

Output:

4…20 mbar/ 0…10 V

Fan:

6…10 A

Shaker:

0.9…1.5 A

Inputs and outputs

Output to operating unit:

RJ-45 modular connector

Supply voltage:

24 V DC

Communication:

RS485

1 × 24 V DC digital input

(Cover switch / Enable):

Sensor type:

potential-loaded NPN switching output

Sensor supply:

24 V DC max. 50 mA

Signal:

digital

Input current:

approx. 2 mA

Scanning time:

2 ms

Connection:

3-wire

Potential:

no galvanic isolation

4 × 24 V DC digital inputs (ext.

Start, ext. Stop, fan contactor /

MPS, shaker contactor / MPS):

Sensor type:

potential-free contact

Signal:

digital

Input current:

approx. 1 mA

Scanning time:

2 ms

Connection:

2-wire

Potential:

no galvanic isolation

2 × 24 V DC digital outputs

(fan contactor, shaker contactor):

Type of output:

potential-loaded semiconductor switch with flyback diode

Switching voltage:

24 V DC

Switching current:

200 mA, short-circuit proof

Potential:

no galvanic isolation

HE 5733 Operating Instructions

#373511 | Version 1.0

13

Inputs and outputs

Relais outputs

(RUN/ERRROR, dp-ALERT):

2 × potential-free relay contact without protective circuit

Contact type:

1 × changeover each

Contact rating:

250 V AC / 5A, 24 V DC / 5 A

Protection:

none

dp-module

Measuring range of differential

pressure sensor:

0…50 mbar

Current output:

Excise range:

4…20 mA

Output load:

load ≤ 600 Ω

Linearity:

< 1 %

Precision:

< 1 %

Temperature drift:

≤ 0.1 % / 10 K

Galvanic isolation:

none

Voltage output:

Excise range:

0…10 V

Output load:

load ≥ 1 Ω

Linearity:

< 1 %

Precision:

< 1 %

Temperature drift:

≤ 0.1 % / 10 K

Galvanic isolation:

none

Rotating field detection

Connection:

External conductor L1, L2, L3 (400 V AC / 50 Hz,

-10% / +20%

Potential:

galvanically isolated via optocoupler

Interface for software update

USB/TTL interface adapter:

#58513007

14

HE 5733 Operating Instructions

#373511 | Version 1.0

Housing

Protection type:

IP 65

Material:

Polycarbonate

Flammability class:

V0 (UL 94)

Colour:

Light grey

Dimensions:

271 × 170 × 120 mm (W × H × D)

Display:

4-digit 7-segment display

Display height: 13.2 mm

Environmental conditions

Storage

-40…+70 °C

Transport

-40…+70 °C

Operation

-20…+50° C

-20…+40° C in EX zone 22

Relative humidity

Relative air humidity 95%, no dew permitted, KUF

according to DIN 40040

Air and creepage distances

Pollution degree

2

Overvoltage category

II

Power Connection

Pneumatic connection:

plug connections for pneumatic hose with 6 mm outer

diameter

Electrical connection:

Supply:

cross section rigid/flex: max. 2.5 mm²;

flex .: max. 1.5 mm² with wire end ferrule

Rest:

cross section rigid/flex: max. 1.5 mm²;

flex .: max. 0.75 mm² with wire end ferrule

Cable inlet:

3 x cable terminal screw connection M25

(supply, fan, shaker)

1 x cable terminal screw connection M20

(dp-alert, enable)

1 x cable terminal screw connection M16

(cover switch)

HE 5733 Operating Instructions

#373511 | Version 1.0

15

4 Mounting

Note!

If you want to mount the device onto a wall, Figure 1 can be used as

drilling template.

The ambient temperature at the installation point must not exceed the

permissible temperature for nominal use specified in the technical data. The special

regulations for use in EX ATEX zones must be observed (see chapter 2.3 Safety in the

individual operating phases).

Note!

The device may be installed in EX zone 22. You must necessarily

observe the safety instructions for explosion protection, the indication on

the name plate as well as the special regulations in chapter 2.4 Device

identification and name plates.

4.1 Dimensions

The dimensions including the cable glands are 271 × 170 × 120 mm.

Dimensions HE 5733

16

HE 5733 Operating Instructions

#373511 | Version 1.0

Scope of Delivery

HE 5733 Shaker filter controller

Operating instructions (#373511)

Note!

Check the delivery for completeness and obvious defects after receipt.

Please contact your service representative at AXXERON HESCH

electronics GmbH immediately in the event of a complaint.

4.2 Torques

Note!

When installing the device, you must strictly observe the torques listed in

the following tables.

4.2.1 Cable glands

Type

Clamping range for cables

Screw-in

thread /

Counter nut

Dust

cover

Gasket 1+2+3

Gasket 1 +2

Gasket 1

Nm*

Colour

Min.

Max.

Min.

Max.

Min.

Max.

Ø

Nm*

Ø 1,2

Nm*

Ø

Nm*

Ø1,2

Nm*

Ø

Nm*

Ø2

Nm*

M16 ×

1.5

5.5

1.0

7.0

1.0

7.0

1.0

10.0

1.4

3.3

white

M20 ×

1.5

5.5

1.5

7.0

1.0

7.0

1.5

9.0

1.4

9.5

1.0

13.0

1.7

2.7

white

M25 ×

1.5

8.0

1.5

10.0

2.0

10.0

2.3

13.0

2.6

13.5

1.3

17.5

2.3

3.0

white

M32 ×

1.5

14.0

3.0

17.0

4.0

17.5

1.5

21.0

1.3

5.0

white

*Test torques at 20°C

1 Metal mandrels were used for the tests of the clamping ranges and test torques. The clamping range may vary if you use cables with

different manufacturing tolerances and material properties. In the intermediate range, please use the combination of gasket 1+2+3.

2 The cap nut must be re-tightened when maintenance work is due on the cable glands. This must be taken into account when

choosing the gasket rubbers.

HE 5733 Operating Instructions

#373511 | Version 1.0

17

Gaskets to be used

4.2.2 Cable glands

Type

Clamping range

Gasket 1

Min.

Max.

Ø

Nm

Ø

Nm

M25 × 1.5 double

2×

4.5

2.0

7.0

2.0

M32 × 1.5

quadruple

4×

5.5

1.5

7.0

1.0

4.2.3 Screw closures

Type

Ø1

L1

L2

L3

Screw-in thread /

Counter nut

Weight

approx.

M16 × 1.5

21 mm

12 mm

11 mm

4.0 mm

3.3 Nm

2.4 g

M20 × 1.5

25 mm

13 mm

12 mm

4.0 mm

2.7 Nm

4.3 g

M25 × 1.5

30 mm

13 mm

12 mm

4.0 mm

3.0 Nm

6.6 g

M32 × 1.5

37 mm

15 mm

14 mm

5.5 mm

5.0 Nm

12.0 g

Cable diameter 9mm

e.g. for M25 × 1.5

Use gaskets 1+2+3

Gasket 2

Gasket 3

Gasket 1

Cable diameter 12mm

e.g. for M25 × 1.5

Gasket 1

Gasket 2

Gasket 3

Use gaskets 1+2

Remove gasket 3

Cable diameter 16mm

e.g. for M25 × 1.5

Sealing 1

Sealing 2

Sealing 3

Use gasket 1

Remove gaskets 2+3

18

HE 5733 Operating Instructions

#373511 | Version 1.0

4.3 Opening the device

The opening and closing works without screws by means of hinge technology. A flat-tip

screwdriver is needed to open the device. Apply the screwdriver at the respective position on

the housing lid, in order to lift up the hinge (see Figure 3 step 1).

Note!

Make sure to move the screw driver to the right to open the hinge (see

Figure 3 step 2). If the screwdriver is moved to the left, the housing cover

may be damaged.

Open the housing cover to the left up to an angle of 105° (see step 3 in Figure 3).

Optionally, the housing cover can be closed with 4 screws to prevent the device from

unauthorised access (for further information, please contact the service of AXXERON HESCH

electronics GmbH, see chapter 12 Maintenance and Service).

The screwless hinge closure is recommended for quick service access.

Opening the housing cover (figure shows similar device with same housing)

1

2

3

HE 5733 Operating Instructions

#373511 | Version 1.0

19

4.4 Mounting the device

4 screws are required to fasten the device to the wall. (Not included in the scope of delivery!)

Note!

The position of the boreholes are identical for every housing. Figure 4 shows an

exemplary housing.

Back of the housing

Note!

Alternative: wall mounting with wall brackets. For more information, please

contact the service of AXXERON HESCH electronics GmbH (see chapter 12

Maintenance and Service).

20

HE 5733 Operating Instructions

#373511 | Version 1.0

5 Device overview

The HE 5733 is available in different versions. On one hand with a measuring range of 0…50

mbar (#573311002D50)) and on the other with a measuring range of 0…100 mbar

(#573311002D60) (see name plate in chapter 2.4 Device identification and name plates).

5.1.1 HE 5733 shaker filter controller

Front of HE 5733 shaker filter controller

5.1.2 Differential pressure module

The I/O-unit offers a slot for a differential pressure module. The differential pressure module

offers the following functions:

EEPROM

Differential pressure measurement

Analogue output (with current and voltage output)

Position of

name plate

Table of contents

Other HESCH Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens Reyrolle 7SR45 Engineering guide

Overland Storage

Overland Storage NEO 200S instructions

Linear Technology

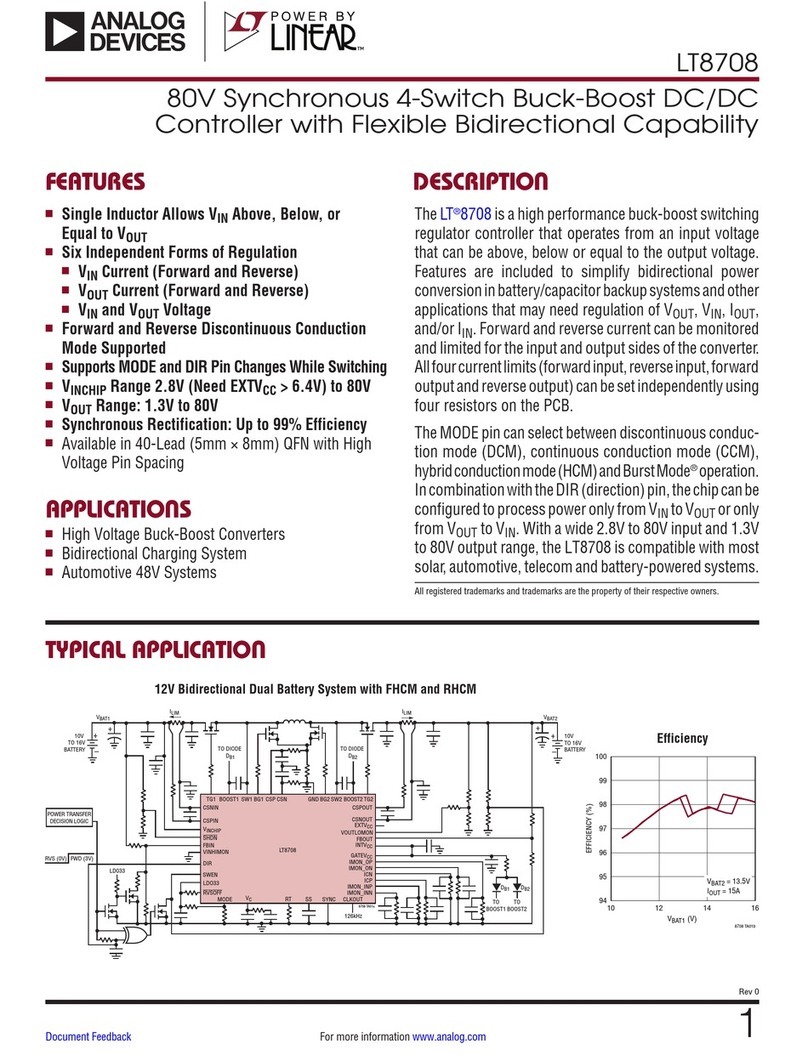

Linear Technology Analog Devices LT8708 datasheet

Linear Technology

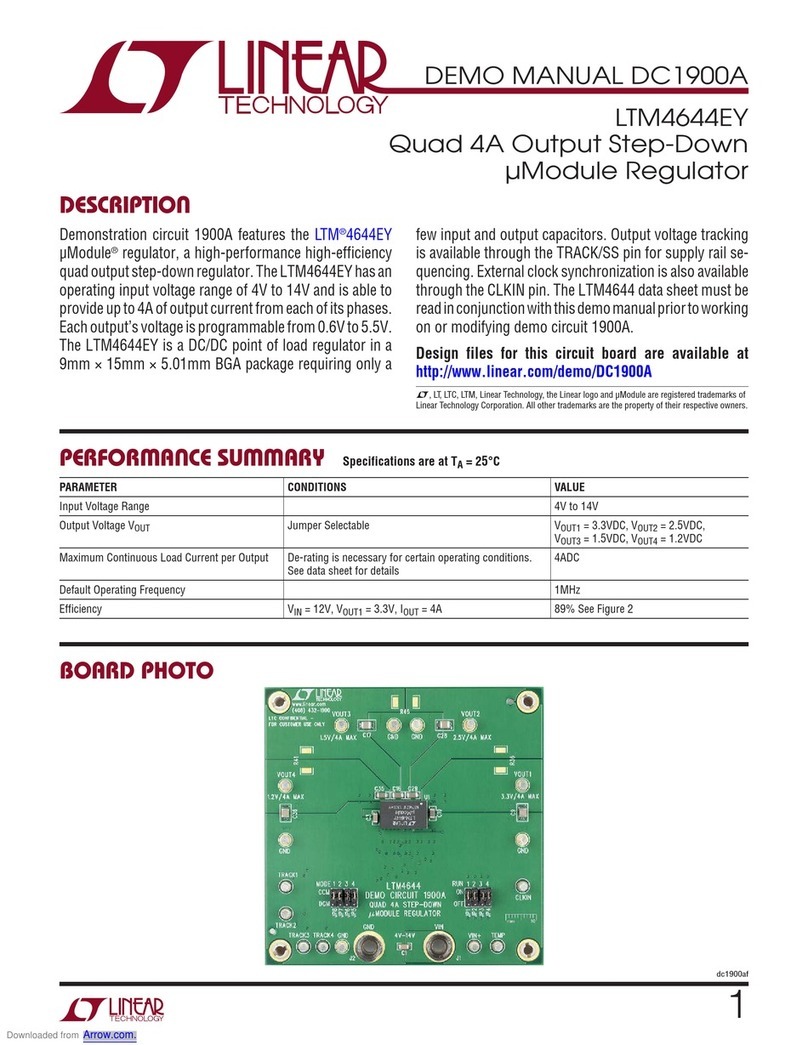

Linear Technology DC1900A Demo Manual

Traxxas

Traxxas Velineon 3350 owner's manual

Full Gauge Controls

Full Gauge Controls TC-900R instructions