Made in Czech Republic

2/2

JA3-014M JA3-014M/E

ELKO

EP

,

s

.r

.o.

|

P

alackého

493

|

769

01

Holešov

,

Všetuly

|

Czech

r

epublic

|

e-mail:

[email protected]TECHNICAL

SUPPORT

|

E-mail:

[email protected] |

Mobil:

+420

777

356

466

|

T

el.:

+420

573

514

276,

+420

573

514

211

|

Fax:

+420

573

514

227

|

www.inels

.com

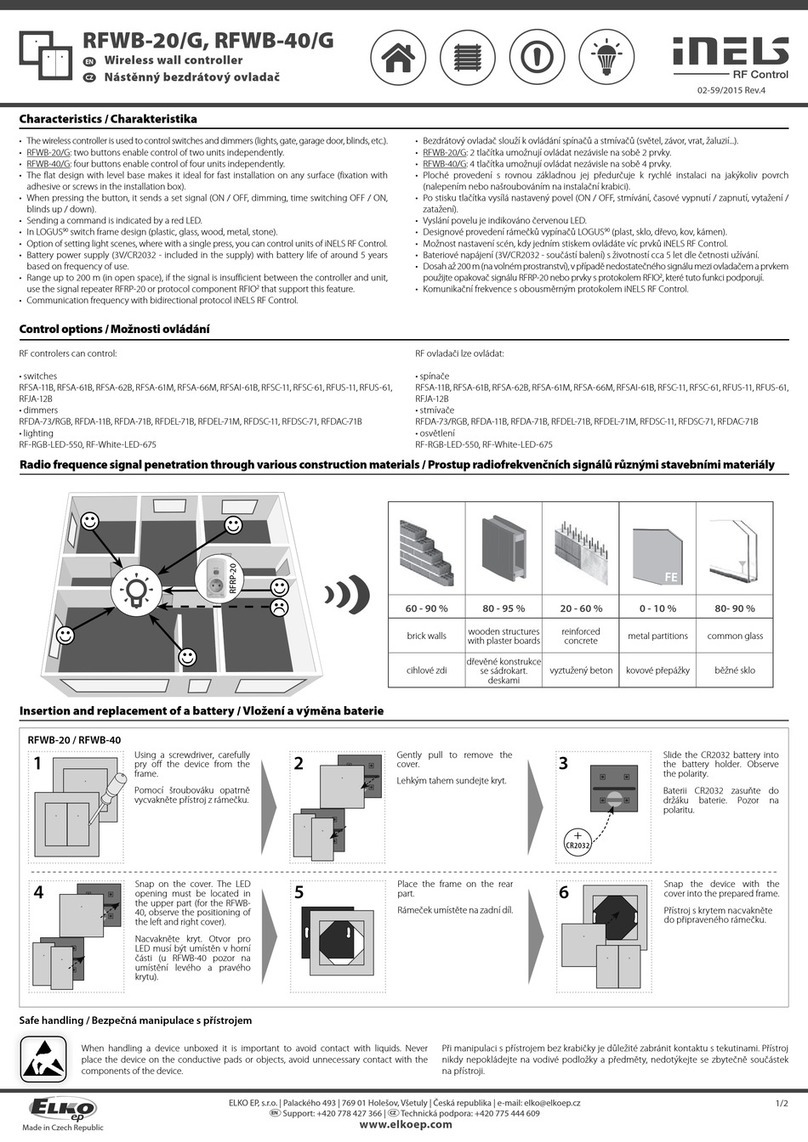

14x yellow LED

14x buttons front panel

Warning

Before the device is installed and operated, read this instruction manual carefully and with full

understanding and Installation Guide System iNELS3. The instruction manual is designated for

mounting the device and for the user of such device. It has to be attached to electro-installation

documentation. The instruction manual can be also found on a web site www.inels.com. Attention,

danger of injury by electrical current! Mounting and connection can be done only by a professional

with an adequate electrical qualification, and all has to be done while observing valid regulations.

Do not touch parts of the device that are energized. Danger of life-threat! While mounting,

servicing, executing any changes, and repairing it is essential to observe safety regulations, norms,

directives and special regulations for working with electrical equipment. Before you start working

with the device, it is essential to have all wires, connected parts, and terminals de-energized. This

instruction manual contains only general directions which need to be applied in a particular

installation. In the course of inspections and maintenance, always check (while de-energized) if

terminals are tightened.

General instrucionsTechnical parameters

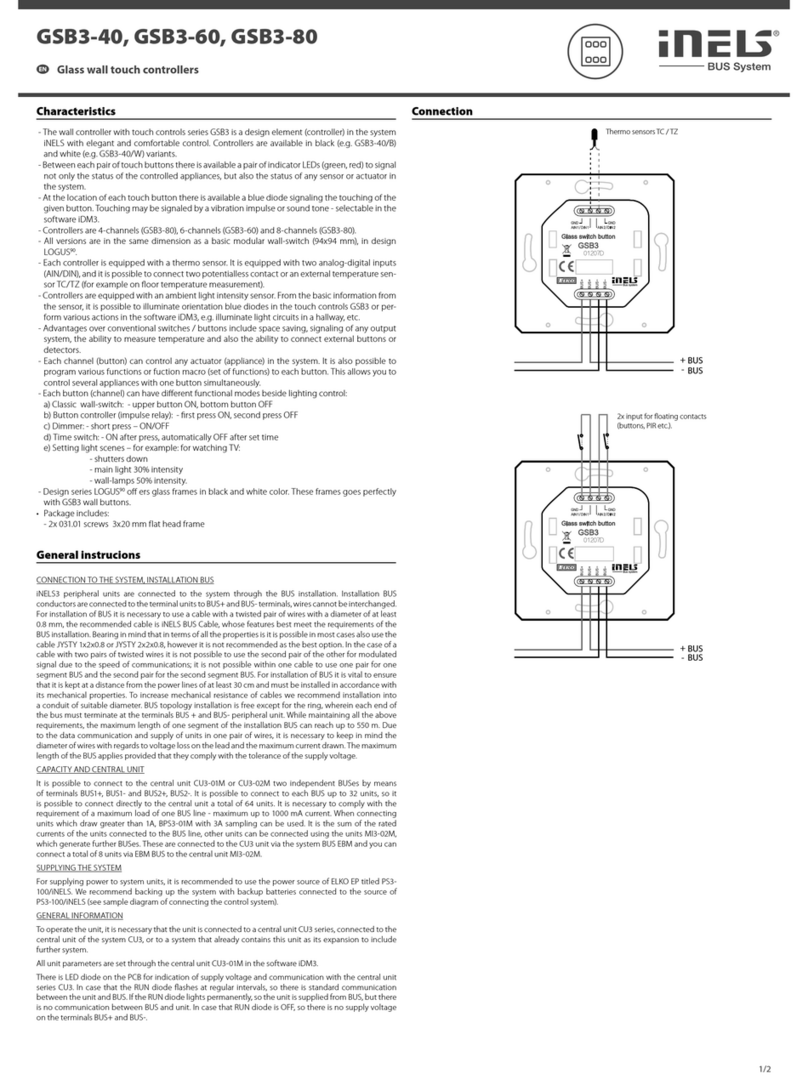

CONNECTION TO THE SYSTEM, INSTALLATION BUS

iNELS3 peripheral units are connected to the system through the BUS installation. Installation BUS

conductors are connected to the terminal units to BUS+ and BUS- terminals, wires cannot be in-

terchanged. For installation of BUS it is necessary to use a cable with a twisted pair of wires with a

diameter of at least 0.8 mm, the recommended cable is iNELS BUS Cable, whose features best meet

the requirements of the BUS installation. Bearing in mind that in terms of all the properties is it is

possible in most cases also use the cable JYSTY 1x2x0.8 or JYSTY 2x2x0.8, however it is not recom-

mended as the best option. In the case of a cable with two pairs of twisted wires it is not possible

to use the second pair of the other for modulated signal due to the speed of communications; it

is not possible within one cable to use one pair for one segment BUS and the second pair for the

second segment BUS. For installation of BUS it is vital to ensure that it is kept at a distance from the

power lines of at least 30 cm and must be installed in accordance with its mechanical properties.

To increase mechanical resistance of cables we recommend installation into a conduit of suitable

diameter. BUS topology installation is free except for the ring, wherein each end of the bus must

terminate at the terminals BUS + and BUS- peripheral unit. While maintaining all the above require-

ments, the maximum length of one segment of the installation BUS can reach up to 300 m. Due to

the data communication and supply of units in one pair of wires, it is necessary to keep in mind the

diameter of wires with regards to voltage loss on the lead and the maximum current drawn. The

maximum length of the BUS applies provided that they comply with the tolerance of the supply

voltage.

CAPACITY AND CENTRAL UNIT

It is possible to connect to the central unit CU3-01M/02M or miniCU CU3-07/08/09/10M independ-

ent BUSes by means of terminals BUS1+, BUS1- or BUS2+, BUS2-. It is possible to connect to each BUS

up to 32 units, so it is possible to connect directly to the central unit a total of 64 units. It is necessary

to comply with the requirement of a maximum load of one BUS line - maximum up to 1000 mA

current. When connecting units which draw greater than 1A, BPS3-01M with 3A sampling can be

used. It is the sum of the rated currents of the units connected to the BUS line, other units can be

connected using the units MI3-02M (for CU3-01M/02M) , which generate further BUSes. These are

connected to the CU3-01M/02M unit via the system BUS EBM and you can connect a total of 8 units

via EBM BUS to the central unit MI3-02M.

SUPPLYING THE SYSTEM

For supplying power to system units, it is recommended to use the power source of ELKO EP titled

PSM3-30/iNELS, PSM3-60/iNELS, PSM3-100/iNELS or PS3-30/iNELS . We recommend backing up the

system with backup batteries.

GENERAL INFORMATION

To operate the unit, it is necessary that the unit is connected to a central unit CU3 series, connected

to the central unit of the system CU3, or to a system that already contains this unit as its expansion

to include further system. All unit parameters are set through the central unit CU3-0XM in the

software iDM3. There is LED diode on the PCB for indication of supply voltage and communication

with the central unit series CU3. In case that the RUN diode fl ashes at regular intervals, so there is

standard communication between the unit and BUS. If the RUN diode lights permanently, so the

unit is supplied from BUS, but there is no communication between BUS and unit. In case that RUN

diode is OFF, so there is no supply voltage on the terminals BUS+ and BUS-.

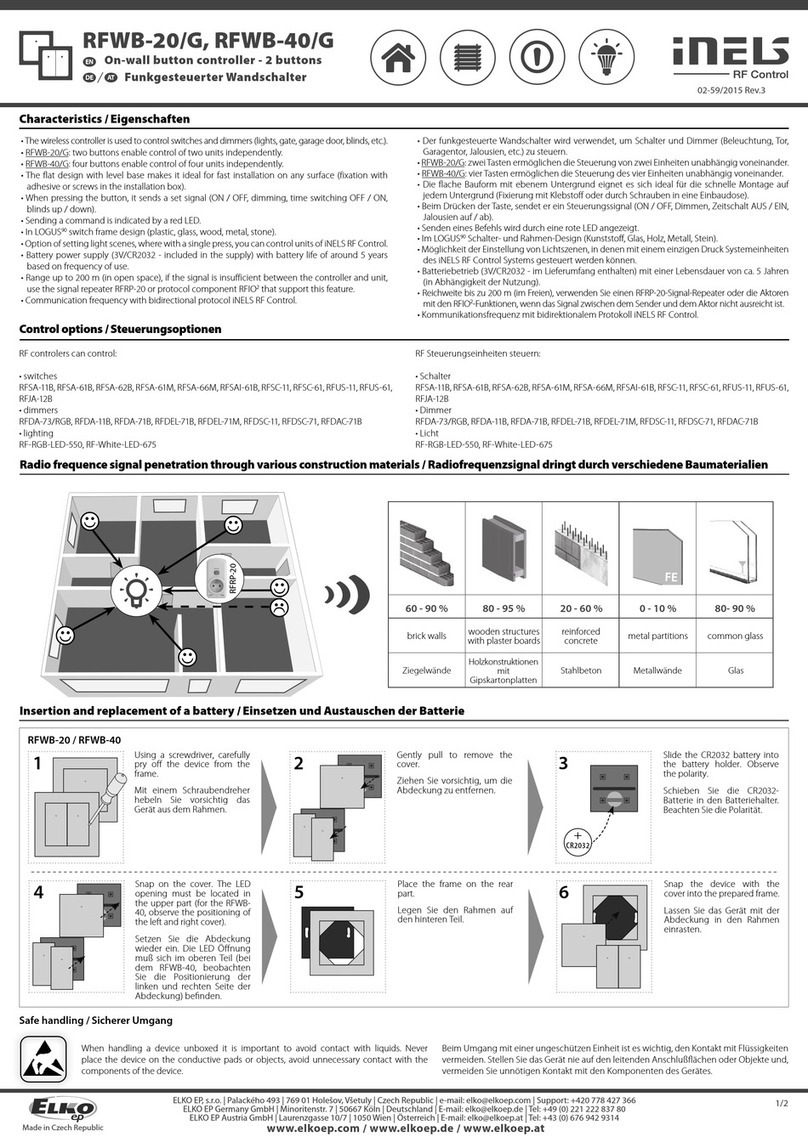

14x switching 0.5 A/AC15

250 VAC, 30 V DC

125 VA/AC15

10 A

10A circuit breaker with tripping characteristic B

reinforced insulation

(Cat. II surges by EN 60664-1)

reinforced insulation

(Cat. II surges by EN 60664-1)

1 kV

12 A

100 mA/10 V DC

300 min-1

15 min-1

1x 107

1x 105

yes (relay switching in zero)

110-230 V AC / 50-60 Hz

-

-

BUS

green LED RUN - status led for relay | only RUN LED

27 V DC, -20/+10 %, 150 mA

max. 2.5 mm2/1.5 mm2with sleeve

-20 to +55 °C

-30 to +70 °C

IP20 device, IP40 mounting in the switchboard

II.

2

any

switchboard on DIN rail EN 60715

6-MODULE

90 x 105 x 65 mm

310 g

Outputs

Output:

Switched voltage:

Switched output:

Peak current:

Pre-assigned protection of the relay

contact:

Output relays separated

from all internal circuits:

Isolation between relay outputs

COM 1,2 COM 3,4 COM 5,6 COM

7,8 COM 9,10 COM 11,12:

Isolates. voltage open

relay contact:

Max. current of one

common terminal:

Minimal switched current:

Switching frequency without load:

Switching frequency with rated load:

Mechanical life:

Electrical life AC1:

Mains voltage detection:

Output indication:

Control:

Communication

Installation BUS:

Status indication unit:

Power supply

Voltage of BUS/tolerance/

nominal current:

Connection

Terminal:

Operating conditions

Operating temperature:

Storing temperature:

Protection degree:

Overvoltage category:

Pollution degree:

Operating position:

Installation:

Design:

Dimensions and weight

Dimensions:

Weight: