HESHBON HW-105 User manual

HW-105

HESHBON Wheel Balancer

Installation/Operation & Maintenance Manual

Before use, read and understand this manual thoroughly. "Safety Cautions” are established to keep your

safe and prevent damages on properties, so you are wanted to read them carefully. The manual may be

changed without any prior notice for quality improvement.

Registration No.: 105090301A

Copyringht Heshbon Co.,Ltd. MIT Design Group 2009 All rights reserved.

Thanks you for purchasing this automobile

maintenance device of HESHBON.

To use this product safely and efficiently, it is

useful to read this manual carefully.

Better quality and service will be given to you.

Make sure to always keep this manual for future reference.

Refer to this manual for components, installation instructions, usage

and quality assurance.

For safety purpose, this product should be also given to end users.

The copyright on this manual is exclusively owned by

Heshbon Co.,Ltd

Therefore, it is strictly prohibited to illegally

reproduce this manual and use any part of this manual

without permission.

Introduction

Features

Parts' Names

Positions of Name Plate and Labels

Functions of Control Panel

Specification

1

1

3

5

7

8

Installation

Transportation and installation

11

11

Safety Cautions

Danger/Warning/Caution

9

9

Application

Modes according to wheel types

Dynamic Mode

ALU -S Special ALU function

Split function

Self-Calibration

13

13

14

17

20

23

Function Setting

Accessing Menus

MODE1 - AMOUNT OF CUT

MODE2 - CALCULATION UNIT

MODE3 - CALCULATION FOR DIAMETER(D)

MODE4 - RESET POSITION

MODE5 - UNIT (Weight)

MODE6 - UNIT(Distance)

MODE7 - CALIBRATION FOR LENGTH(L)

MODE8 - CALIBRATION FOR WIDTH(W)

25

25

27

28

29

30

31

32

33

34

Maintenance

Maintenance Instructions

Health Check & Expendables list

Troubleshooting guide

35

35

37

39

■This manual is prepared on March 2009.

Specifications in this manual are subject to change for quality improvement

without prior notice.

TABLE OF CONTENTS

IntroductionInstallation Safety

ApplicationFunction MaintenanceWarranty

1

Features

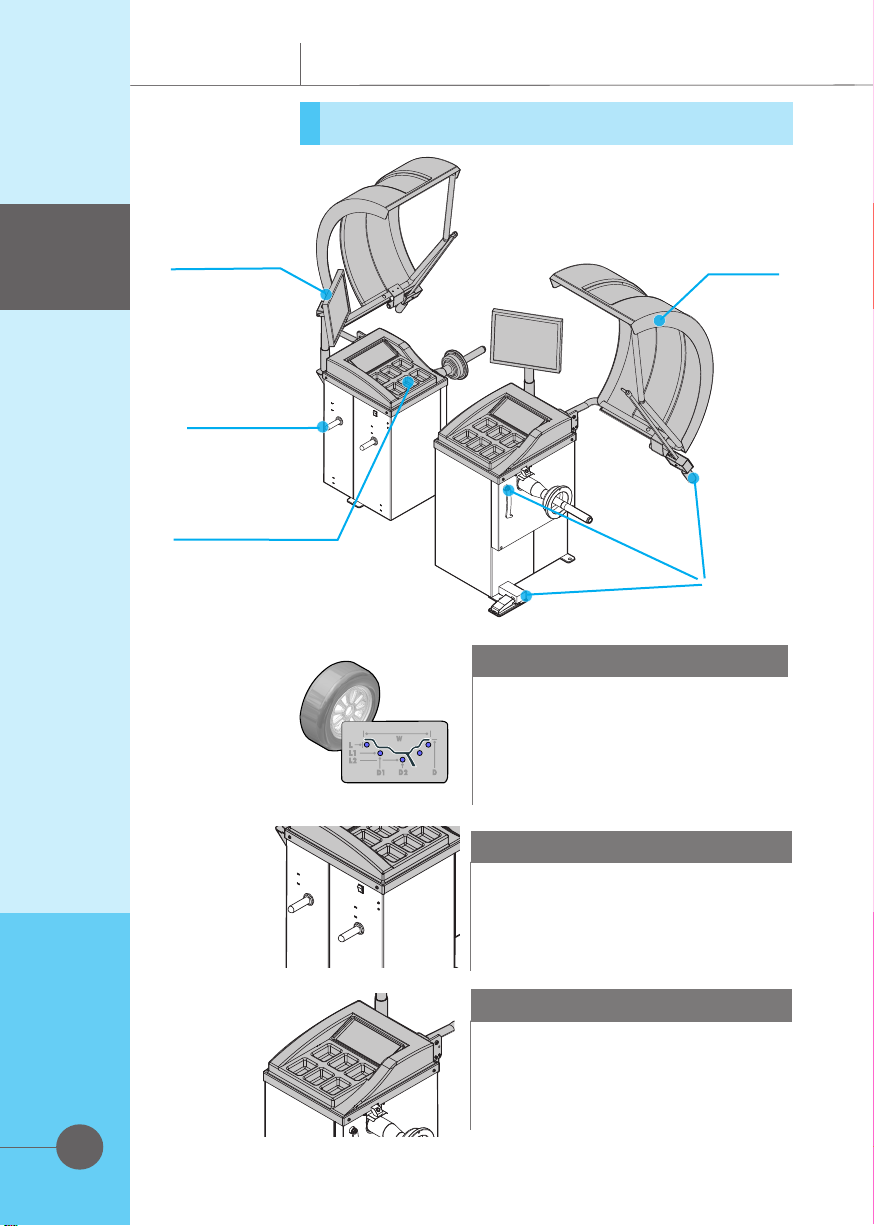

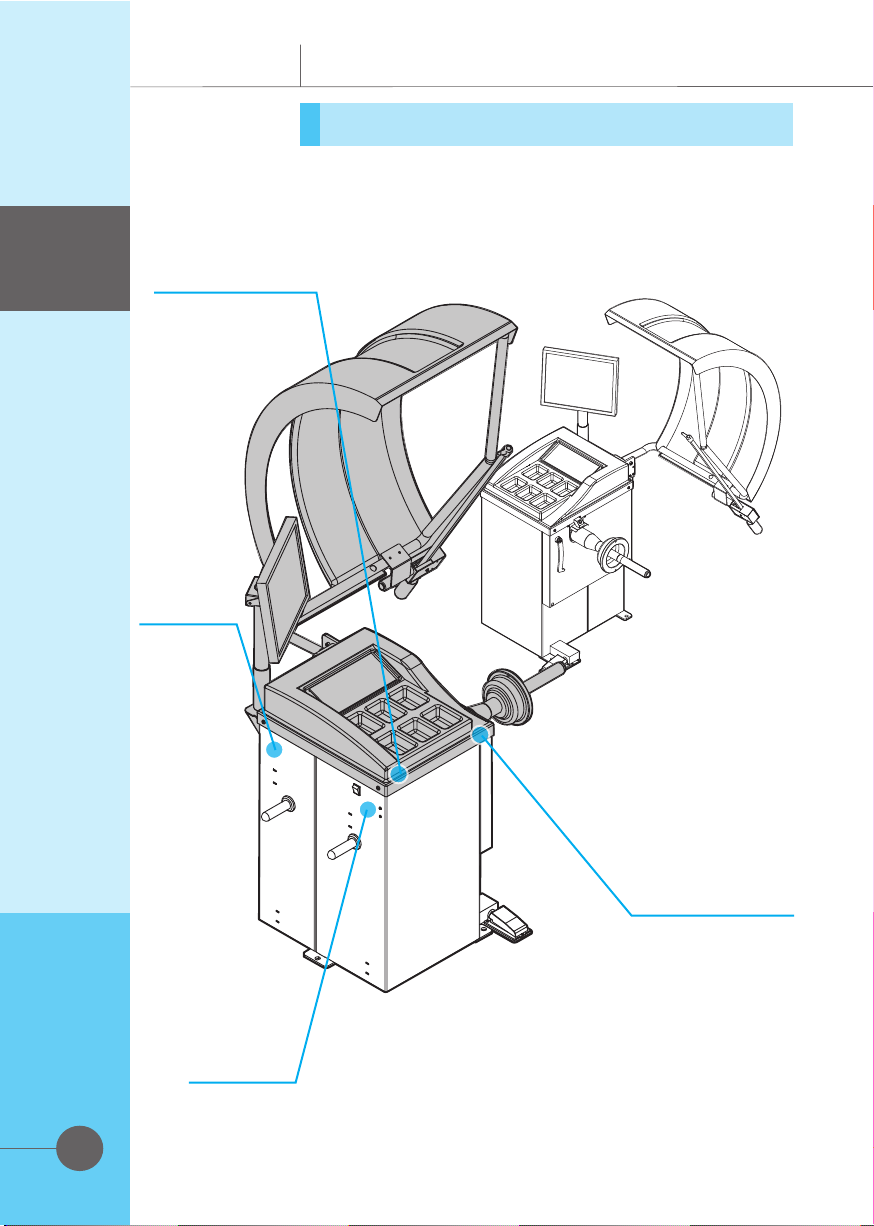

■ Cone Hanger

▶Cones used for holding tires can be easily

and conveniently hung on this hanger.

Besides them, other various tools can be

placed on them.

■ Work Table

▶6 weight pockets(weights) are available to

adjust the balance of wheel and arranged by

sizes.

Wheel guard

Length, diameter

and width auto-

matically entered

Work table

Cone Hanger

Monitor

Introduction Heshbon Wheel Balance features the followings.

■ Various modes to balance wheels

▶Various modes are supported so that tire

wheel can be facilitated conveniently and

easily. Especially, aluminum wheel function

is additionally supported to be applicable to

aluminum wheel recently used by plentiful

drivers.

Introduction

2

■ Weight separation for aluminum wheel

▶Unbalanced position on an aluminum

wheel’s outer plane is divided into two parts,

enabling lead weights to be applied behind two

wheel spokes.

■ Distance, diameter and width

automatically entered

▶Wheel's specifications, length,

diameter and width can be conveniently and

automatically measured using brake pedal,

automatic gauge arm width gauge.

(option)

■ Wheel guard as a

safeguard for operators

▶Wheel guard is prepared to ensure the

safety and convenience of operators during

working.

■Self-calibration function

▶Self-calibration is to be executed for precise

repairs in order to assure right measurements

by zero-setting.

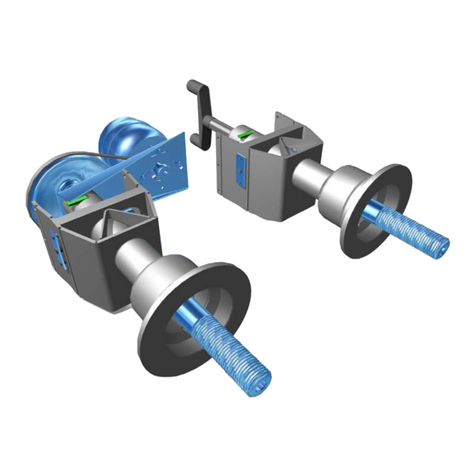

① Width gauge

②Automatic gauge arm

③ brake pedal

①

②

③

Introduction Heshbon Wheel Balance features the followings.

Introduction

■ Laser pointer(Option)

▶Laser pointer indicates the exact weight

correction point with the laser beam so that

can apply the weight easily after measuring.

Introduction

3

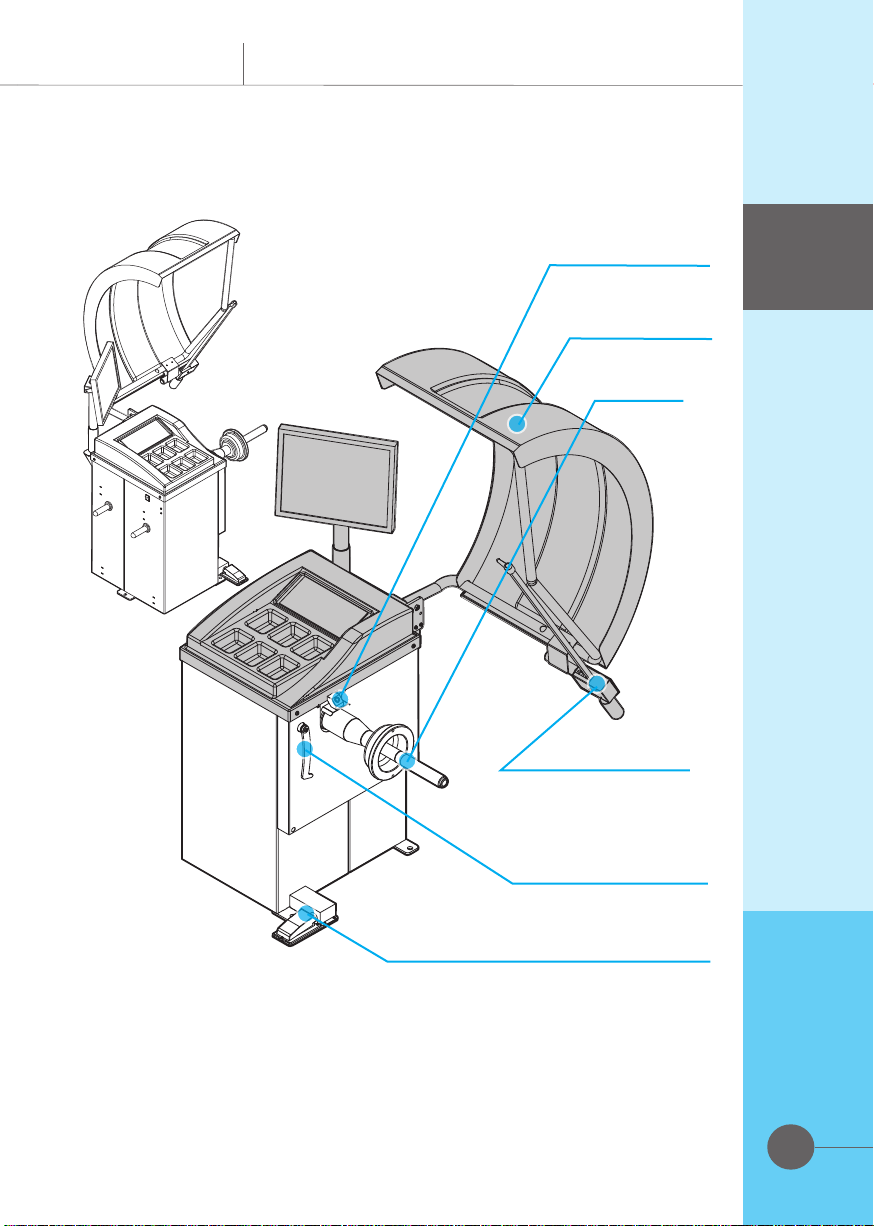

Parts' names

■Monitor

■Work Table

■Control Panel

■Adaptor and

Accessories

Support

■Main S/W

Introduction

Introduction

4

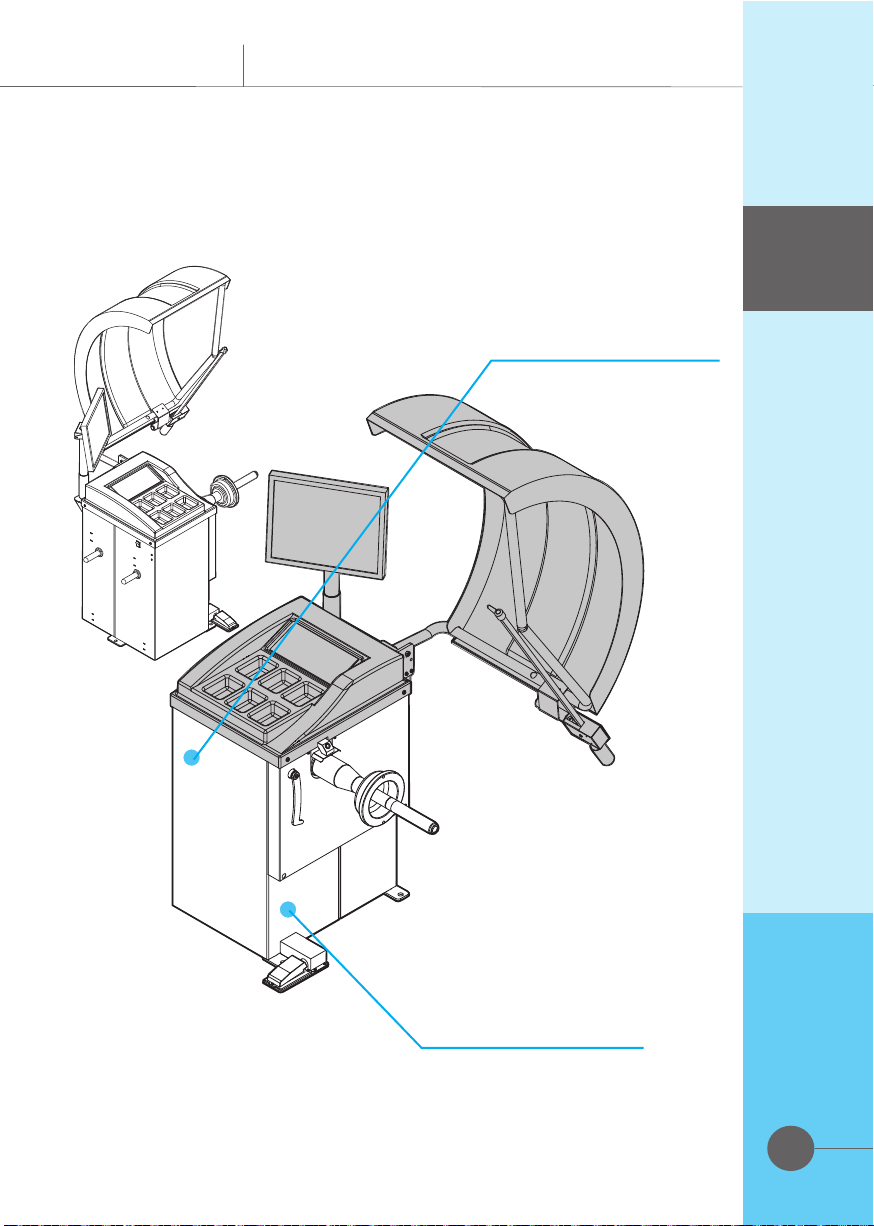

■Wheel Guard

(option)

■Laser Pointer

(option)

■Shaft

■Automatic Gauge Arm

■Automatic Width

Gauge(option)

■Electrical Input Switch

(break pedal-option)

Introduction

5

Positions of name plate and labels

Introduction

Introduction

■Product

Identification

plate

■Operator's

Manual Ref-

erence Mark

■Warning Sign

■Warning Sign(Cover)

6

■Warning Sign(Feet)

■Heshbon Logo

Introduction

Introduction

■Warning Sign

7

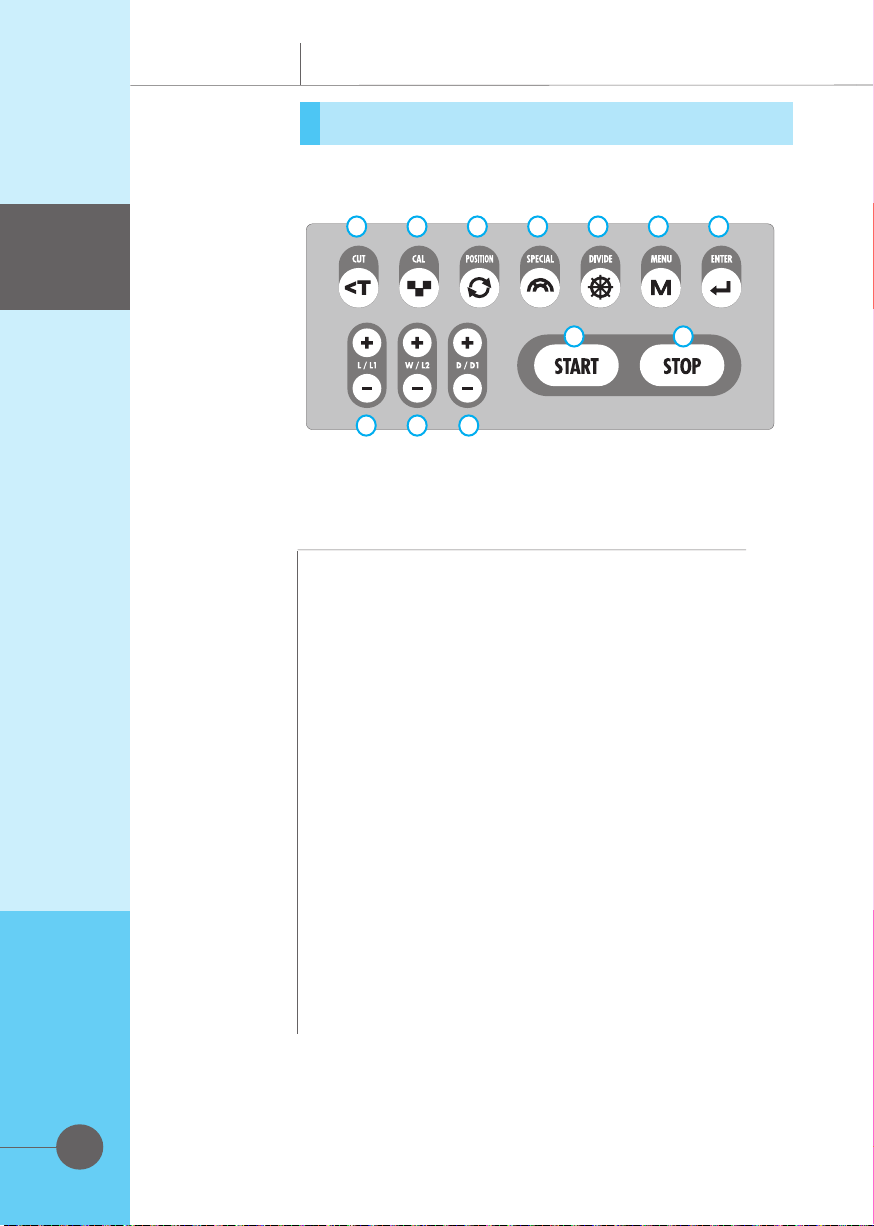

Functions of Control Panel

■ Functions

①Cut -

Button used to check the left weight amount

②Cal -

Press if to run Self-Calibration

③Position -

Automatically stop on an unbalanced position of

the wheel measured(optional)

④Special -

Measure a special aluminum wheel

⑤Divide -

Split function.

⑥Menu -

Press if to run Self-Calibration

⑦Enter -

Enter/exit button

⑧L -

Rim distance setting buttons

⑨W -

Rim width setting buttons

⑩D -

Rim diameter setting buttons

⑪Start -

Button used to start measuring

⑫Stop -

Emergency stop button

■ Name

Introduction

Introduction

1 2 3 4 5 7

810

9

6

11 12

①Cut ②Cal ③Position ④Special ⑤Divide ⑥Menu

⑦Enter ⑧L ⑨W ⑩D ⑪Start ⑫Stop

8

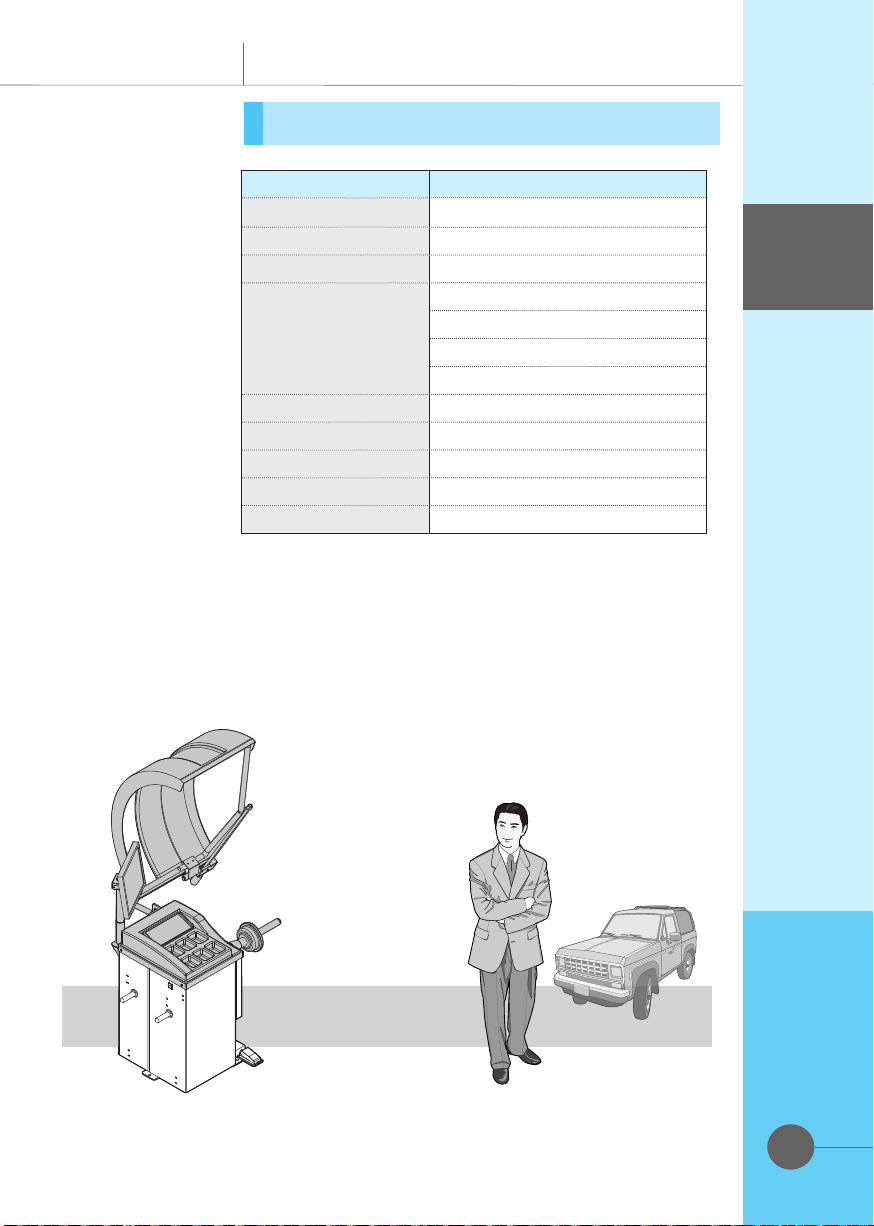

Specification

Model HW-105

Measuring method Both sides(In/Out) at the same time

Measuring unit 1g (both sides)

Measuring time 7 ~ 12sec

Measuring range

Distance 0~18cm

Rim Width 1.5"~20"

Rim diameter 10" ~24"

Weight 65kg

Balancing speed Approx 200rpm

Display LCD Monitor

Rated voltage AC220V(60Hz/50Hz)

Weight 90kg

Nut type One-touch type

Enjoy repairing

Your source of excellent equipment

Introduction

Introduction

Illustrations throughout

this manual

About illustrations

used in this manual

It will help you under-

stand this manual and

please read it carefully.

The rules are limited to

this manual.

9

Danger/Warning/Caution

A user may be injured or even dead unless

the directions are kept.

Not keeping the directions may result in

serious injuries or damages on properties.

Not keeping the directions may result in

injuries or damages on properties.

Terms and descriptions to improve your

understanding

Tips for your efficient use

See the related pages

Do not attempt to

operate this product

unless you are skilled

to do it.

(Operating incorrect

buttons may cause

problems in this

product)

Work only on an

even place for

safety purpose.

Do not install this

product on a place

exposed to rain or

water.

(this product is

indoor use only)

Do not apply

excessive force

to unplug power

cord.

▶ It may case an

electric shock or

a fire.

Do not expose this

product directly to

rain and moisture.

▶It may cause an

injuries or even

death

Do not work with

this product close

to heating source.

▶It may cause an

injuries or even

death.

Do not touch

power cord with

wet hands.

▶ It may cause

injuries or even

death.

Do not use dam-

aged power plug

or loosened outlet.

▶ It may cause

injuries or even

death

Safety

Safety

Cautions

10

Be cautious that

fingers may be

hurt by the rotating

shaft.

▶ It may cause

serious injuries.

Do not insert

multiple plugs on

an outlet.

▶ It may cause an

electric shock or

a fire.

Make sure that

electric contacts/

pins should be

maintained clean.

▶ It may cause an

electric shock or

a fire.

Read this manual

carefully before

use.

Do not attempt to

push any incorrect

button while it is

working.

▶ It may cause un-

expected malfunc-

tion.

Do not apply any im-

pact on the balance

body frame[housing]

or expose it to dust.

▶It may cause unex-

pected malfunction.

Do not expose this

product to direct

sunrays.

▶ It may cause

unexpected mal-

function.

Do not modify the

control panel and

structure volun-

tarily.

▶ It may cause

unexpected mal-

function.

Do not apply any

impact on it nor

expose it to dust

or moisture.

Make sure to in-

stall it indoors only

and protect it from

rain or snow.

Read this manual

carefully before use.

▶ Serious accidents

may happen unless

the danger/warning

information is kept.

Do not bend the

power cord or

place any heavy

article on it, prob-

ably cutting it off.

Safety

Cautions

Safety

11

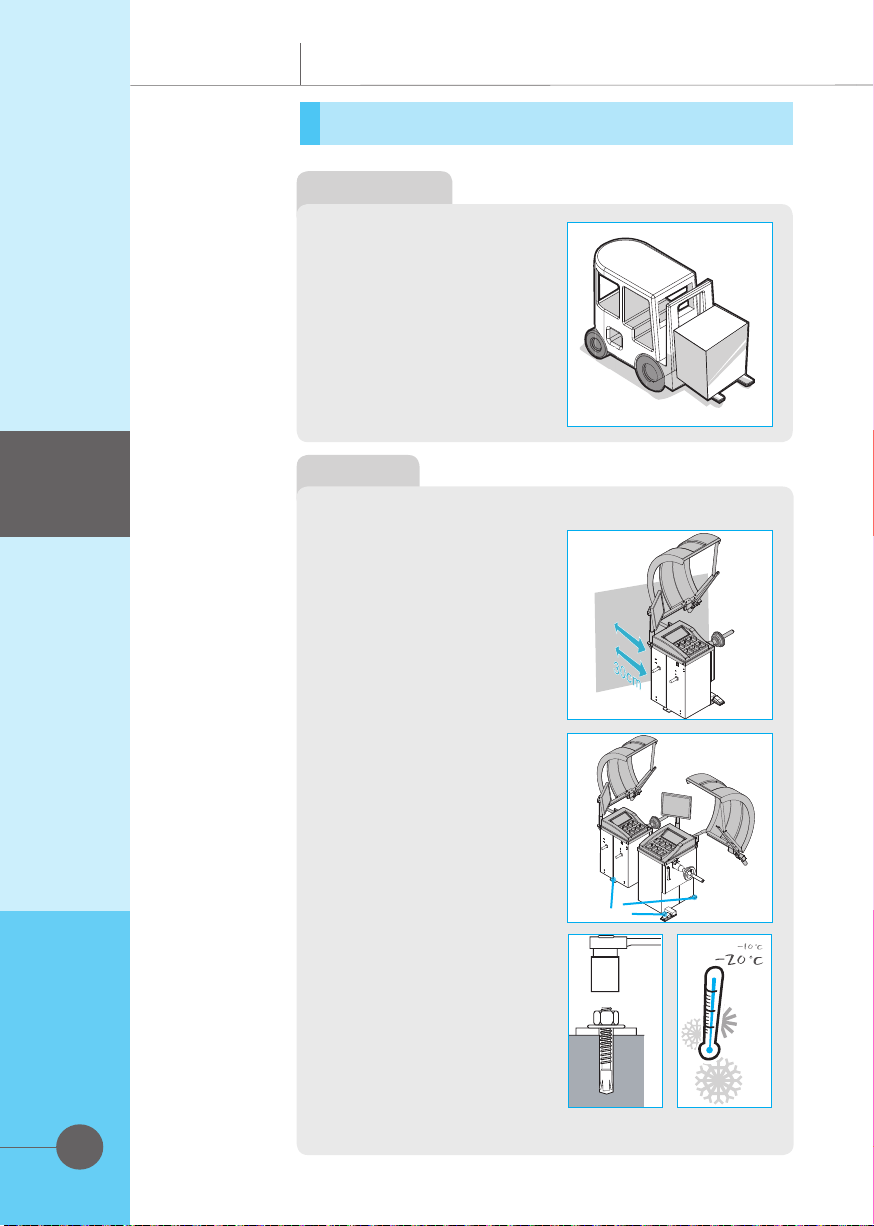

Transportation and installation

Anchor bolt

Installation

Installation

Transportation

▶Upon arrival at an installa-

tion place, move this package

to an installation location using

a forklift or truck.

▶Unpack and check the com-

ponents in the package. If any

missing component is found,

immediately contact your deal-

er or the company.

Installation

▶LOCATION

The wheel balancer must be

located on a solid floor in

concrete or similar material.

An underlying cavity could

cause imprecise imbalance

readings.

▶SAFE DISTANCE:

For the safe and ergonomic

use of the machine it is advis-

able to locate it a minimum of

300 mm from the surrounding

walls.

▶FIXING INSTRUCTIONS:

The machine base has 3 holes

for fixing to the floor with an-

chor bolt. This is essential to

ensure accurate and consist-

ent readings.

Check that the supply voltage

is the same as that indicated

on the machine identification

plate(220V±10%, 50/60㎐)

▶Connect the electrical power

plug to an outlet that con-

forms with European stand-

ards or the standards of the

country in which the machine

is used.

The plug must have a ground/

earth connection.

12

Transportation and installation

Installation

Installation

▶Check the effectiveness of the

ground/earth connection.

▶The machine must be connected to

the supply through a multi-pole cut-off

switch in conformity with European

standards and with contact opening

gap of at least 3 mm.

▶When connected and switched on,

mounted wheels must rotate in a

clockwise direction as seen from the

right-hand side of the machine. The

correct direction of rotation is indi-

cated with an arrow on the machine

body.

▶If the machine functions abnormally

immediately switch off the main

switch and check the troubleshooting

section of the Instructions

Manual.

Installation

This product is limited to in-

door use only. Therefore, do

not install it at a place ex-

posed to rain, snow or dust.

In case it should be inevitably

installed at an improper place,

it is necessary to manage

this product thoroughly at all

times for performance main-

tenance. To store this prod-

uct for a long time, turn it off

first and cover it with packing

material.

13

Modes according to Wheel Types

From the measurement screen, press button ALU to

select the type required. The 5-LED displays show the

position where to apply the weights. If a spin has al-

ready been performed, the processor automatically re-

calculates, for each change of mode, the amounts os

unbalance according to the new calculation.

Application

Application

Lead attach-

ment location

Wheel's cross

section

Balancing of steel or light alloy rims with

application of clip-on weights on the rim

edges.

■DYNAMIC

The static mode is necessary for

motorcycle wheels or when it is not

possible to place the counterweights on

both sides of the rim.

■STATIC

Balancing of light alloy rims with

application of adhesive weights on the

rim shoulders

■ALU1

Balancing of light alloy rims with hidden

application of the outer adhesive weights.

■ALU2

■ALU3

Combined application: clip-on weight

inside and hidden adhesive weight on

outside.

■ALU4

Combined application: adhesive weight

inside and clip-on weight outside.

14

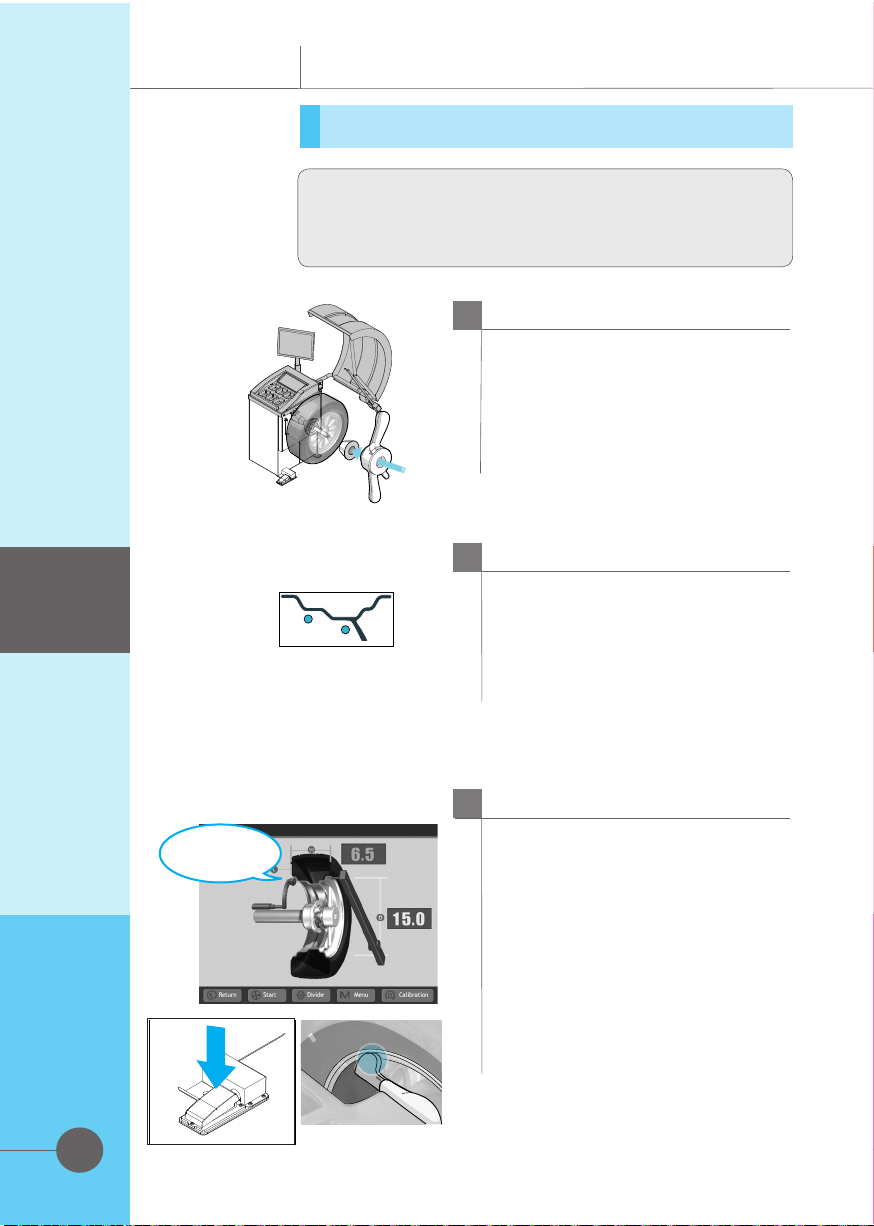

1

Switch on the machine with the main switch.

Power supply

2

Mount the wheel on the machine, centering it

on the relevant cone or adaptor and tighten

it carefully with the quick-nut.

Tire wheel placement

Application

Application

DYNAMIC

▶applicable to general wheels

Measuring

them at the

same time.

(option)

3

3.1 Automatic rim Distance (offset) and Diameter -

Move the automatic gauge arm to the inside edge of

the rim, touch the pointer to the rim edge, touch the

tip of the width arm to the outside rim edge where

weights will be placed as illustrated in left Figure.

Press the pedal. Then the beeper will sound when the

parameter values are calculated and entered auto-

matically. Return the arms to its home rest position

on the balancer. Do not allow the measurement arms

to “dangle”.

3.2 Manual Parameter Entry-In the event of auto-

matic gauge failure, ANY parameter value can be in-

put manually.

3.2.1 Manual Distance Entry - Move the distance

gauge arm to touch the inner edge of the wheel where

weights are to be placed and observe the reading on

the scale of the distance gauge. Press manual Wheel

Parameter button followed by pressing the + or -

button(L) until value is displayed in the left display

window.

3.2.2 Measure Rim Width Manually using rim width

calipers. Measure wheel where corrective clip-on

weight would be applied. Enter the measured width

by pressing the Parameter button followed by the +

or - button(W) until the desired value appears in the

right display.

3.2.3 Manual Rim Diameter Entry-Read the rim di-

ameter marked on the sidewall of the tire <picture A>.

Enter the measured rim diameter by pressing the Pa-

rameter button followed by the + or - button(D) until

the desired value appears in the right display.

NOTE: For a more precise balancing of performance

wheels, an “ALU-S” Mode is available for

precision determination of wheel parameters. This

feature allows exacting placement of corrective

weights as well. See Page for detailed instructions.

NOTE: The parameter arms must be in the Home

rest position when the balancer is powered up.

This establishes the arm starting position.

Enter rim parameters

<Picture A>

Tire rotation

Correct

balancing

position

Weight

attachment

15

DYNAMIC ▶CORRECTION OF THE UNBALANCE

5

Spin the wheel by lowering the wheel

guard or by pressing the Start but-

ton. When the balancing cycle is

completed the wheel will stop auto-

matically and the unbalance values

will appear on the monitor.

Closing Wheel guard

6

Read the unbalance value on the

outer display. Values are displayed in

grams but can be displayed in ounc-

es if required and are automatically

rounded to the nearest commercial

wheel weight.

Unbalance values

7

Raise the wheel guard and turn the

wheel until the displays of the outer

plane unbalance position arrow is il-

luminated red in the screen. A tone

will sound indicating top dead cent-

er. Apply the wheel weight at twelve

o’clock position. Use the foot op-

erated shaft lock to prevent shaft

rotation while placing weights.

Correcting OUTER values.

Before spinning the wheel make

sure proper eye protection is worn

by all personnel in the vicinity of

the balancer.

Application

Application

16

8

Correct the inner plane in the same

manner.

Correcting INNER values

9

Lower the wheel guard to spin the wheel

again and check that the readout is

“00” “00”(OK message will appear

in the screen). If a residual imbalance is

displayed:

A. Check the rim parameters, if entered

value is incorrect, correct as needed.

Imbalance values will be recomputed

after re-spinning wheel.

B. Check if the balancing mode selected

is the most appropriate. If not, choose

the right mode and re-spin.

C. The wheel weight could have been

placed at a wrong position. To check

this, position the wheel at the correction

position for the outer plane.

If the wheel weight previously attached

is in sector ‘L’ or ‘R’ <Picture B>,

move the wheel weight up about 1”

(2.54cm).

If the wheel weight is in sector ‘D’

cut a piece of the wheel weight of an

approximate value corresponding to

the value shown on the right display, or

replace the wheel weight with a lighter

one. If the wheel weight is in sector

‘U’ add a weight of value indicated by

the display or replace the wheel weight

with a heavier one. Repeat the same

operation for the inner plane.

NOTE: If this situation is repeated, your

machine may be out of calibration and a

calibration operation might be required

as instructed on page __ .

D. If an ALU function was selected

ensure that the wheel weights have been

placed in accordance to the program

chosen.

E. Check that the quick nut is tight and

that the wheel is not slipping against the

backing collar.

F. Check that the wheel and adaptors

are clean.

Verification of the results

Application

Application

If vibration is still present after balancing,

check the following possible sources of

vibration:

1. Stones caught in the tire tread.

2. Tire slippage on the wheel.

3. Incorrectly mounted wheel.

4. Imbalanced wheel covers.

5. Excessive radial or lateral runout in the

tire or wheel.

6. Damaged wheel bolt holes.

7. Worn universal joints.

8. Imbalanced brake rotors or drums.

9. Worn or damaged balancer ccessories.

<Picture B>

17

ALU -S Special ALU function

1

Switch on the machine with the

main power.

Follow the procedures below

2

Press the ALU button three times to

activate the Special ALU mode(ALU

2 mode), the display will read “ALU

L - 2” when activated.

Mode change - ALU2

This is a mode similar to ALU mode 2. The difference

is that the distance and width parameters are accurately

defined for a more exacting weight placement,

3

Extend the automatic gauge arm

and touch the position of the left

weight position, then press the

brake pedal.

The high tone will sound when

dimension is entered. Return the

gauge arm to the rest position.

The width arm is not used in this

procedure.

Measuring ALU L-1 values

Application

Application

ALU-S mode display

left weight

position

Table of contents

Popular Wheel Balancer manuals by other brands

Hofmann

Hofmann geodyna 7340 Operation manual

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats 885 Safety Instructions, Set Up Instructions, Operation Instructions, Maintenance Instructions

Hunter

Hunter GSP9712 Operation instructions

Weaver

Weaver W-957-40 Operation manual

Sun Microsystems

Sun Microsystems SWB 300 Operator's manual

ATH-Heinl

ATH-Heinl W62 operating instructions