W H E E L B L A N C E R

- 6 -

4. Tire Balance operation

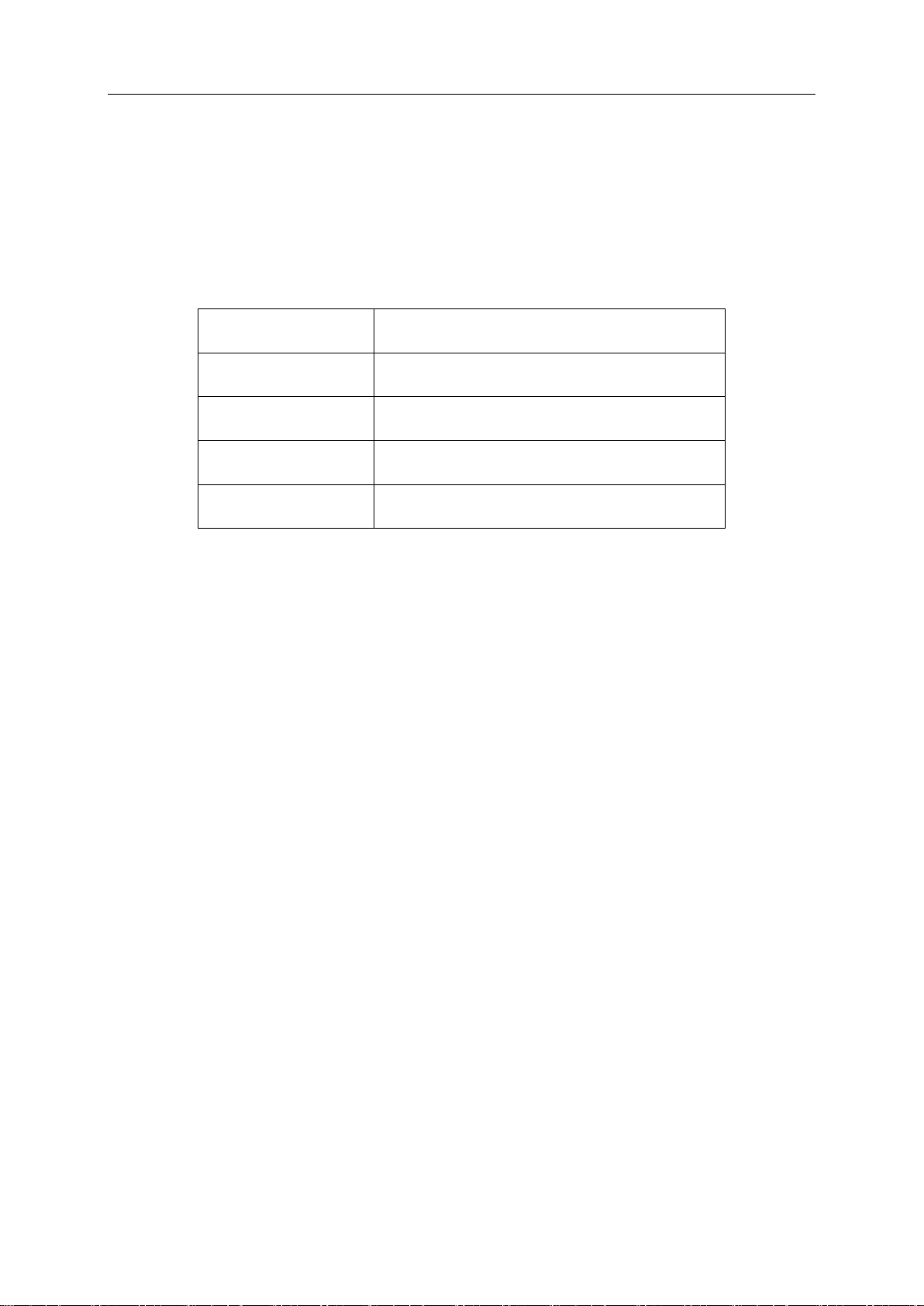

4.1 After the power is turned on and the device code is displayed, the

display window displays "8.0 5.7 14.0", which proves that the

machine is normal.

4.2 Installation of Wheels

(1) preparation before the test: check and remove the dust, soil and

tread of the tire whether there are metal, stone and other foreign

bodies; Check whether the tire pressure is in line with the specified

value; Check whether the positioning surface and mounting hole of

the rim are deformed, check whether there are foreign bodies in the

tire; Remove the original balance block.

(2) There are three types of wheel installation, including positive

positioning, reverse positioning and additional flanges for large and

medium tires. A positioning method can be selected arbitrarily

according to the actual situation.

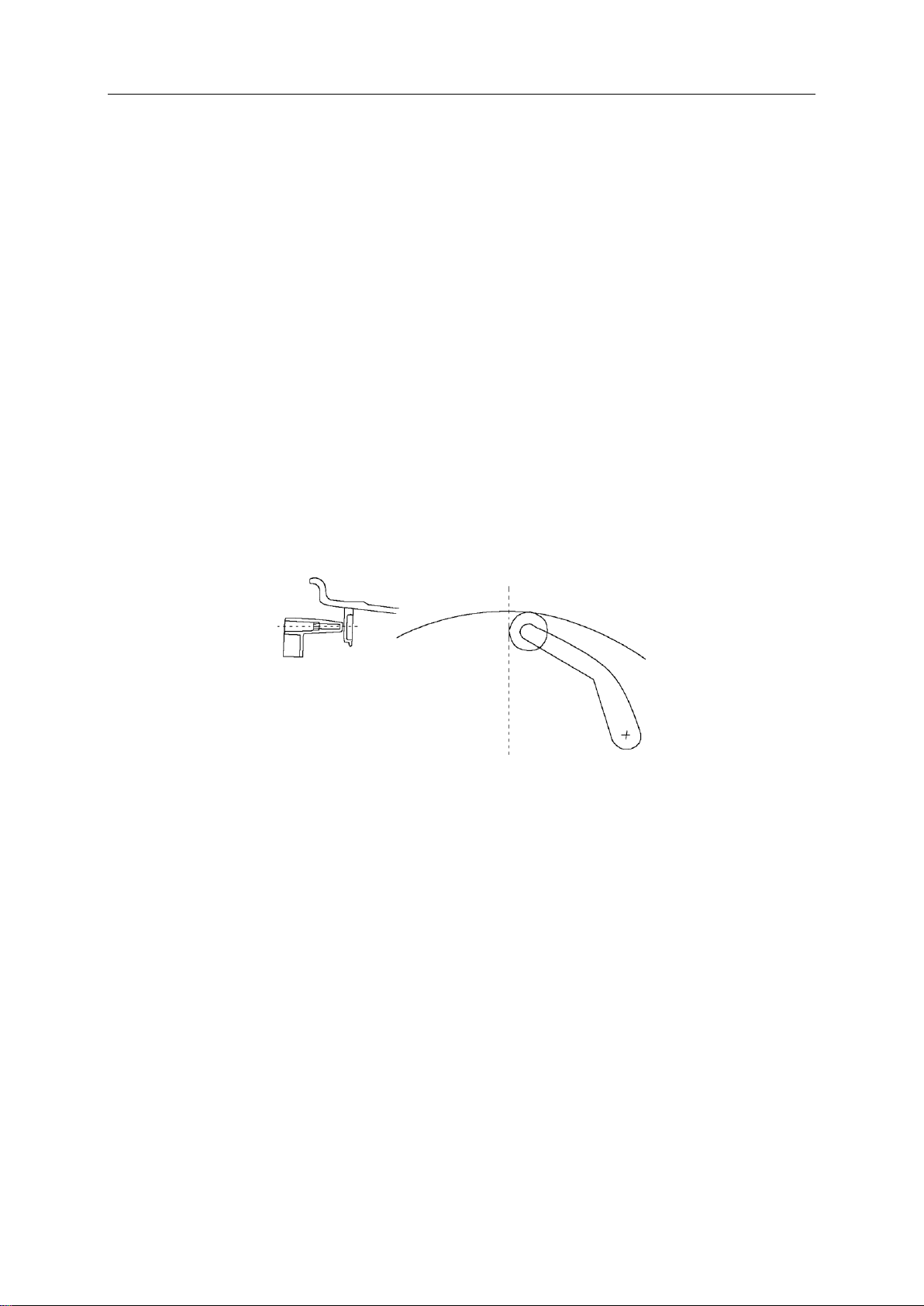

4.2.1 forward positioning

Spindle - Wheels (rim mounting face

inwards)- Fit cone (small head

inwards)- Wheels - Quick nut

forward positioning is a common positioning

method, the operation is simple and fast, mainly suitable for

ordinary steel ring and thin aluminum alloy ring, this

positioning is suitable for the steel ring deformation is

small。