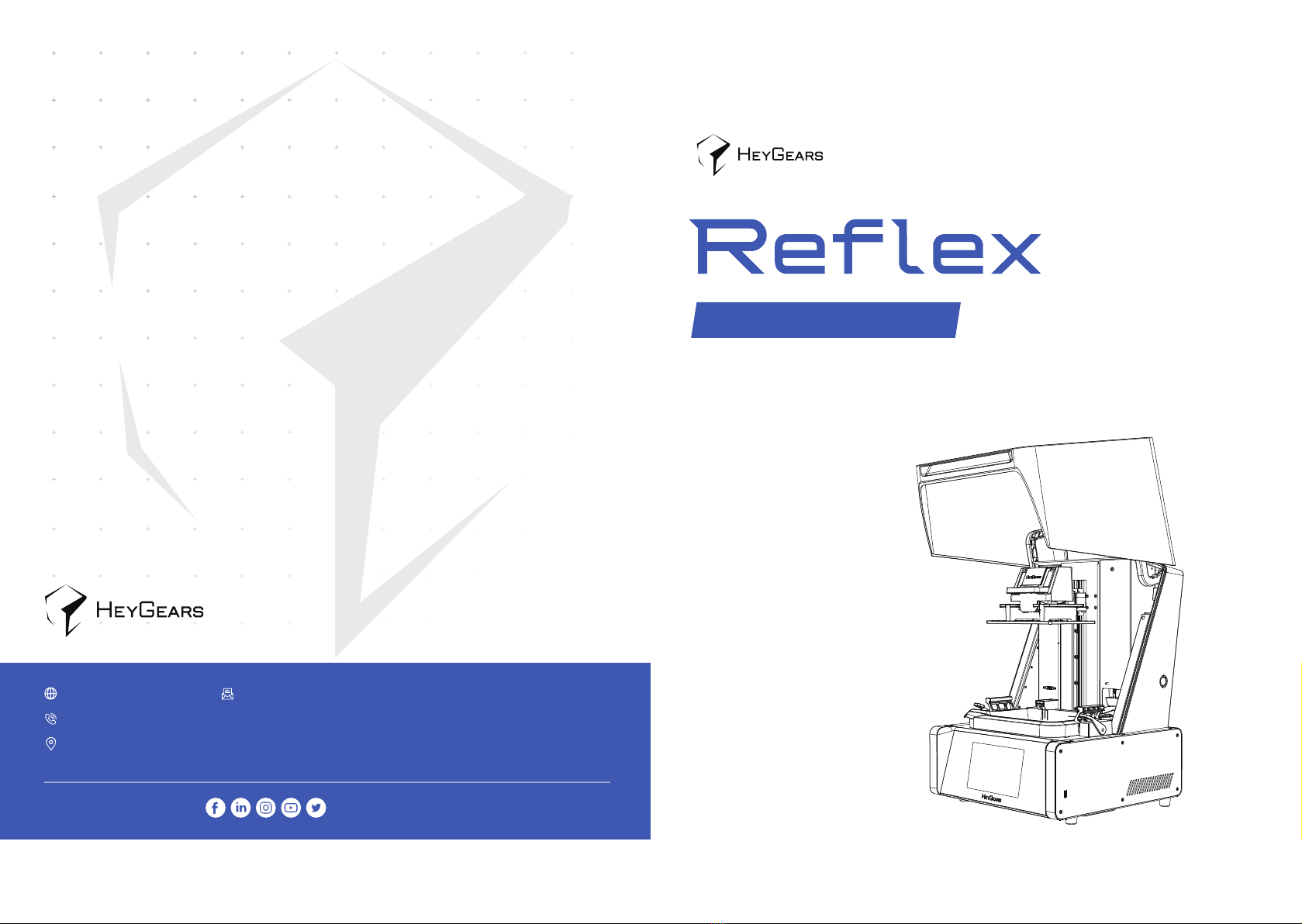

HeyGears Reflex User manual

Quickstart V1.0

Personal Desktop 3D Printer

Follow us @HeyGears

USA-17931 Sky Park Circle, Suite E, Irvine, CA, 92614

CHN-Block B2, 501, 601, Enterprise Accelerator, Kaifa District, Guangzhou City

Tel: +1 (318) 353-4295 (Global)/ +1 (949) 418-9418 (USA) / +44 148-396-8549 (EU)

heygears.com [email protected]

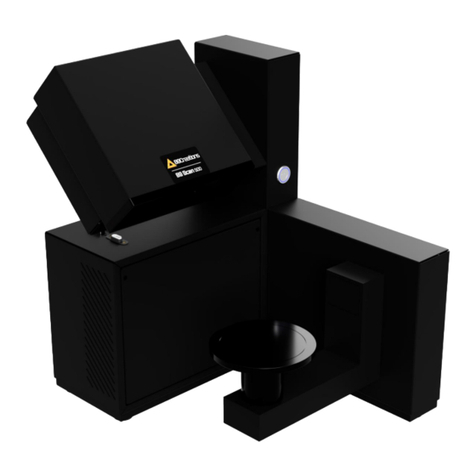

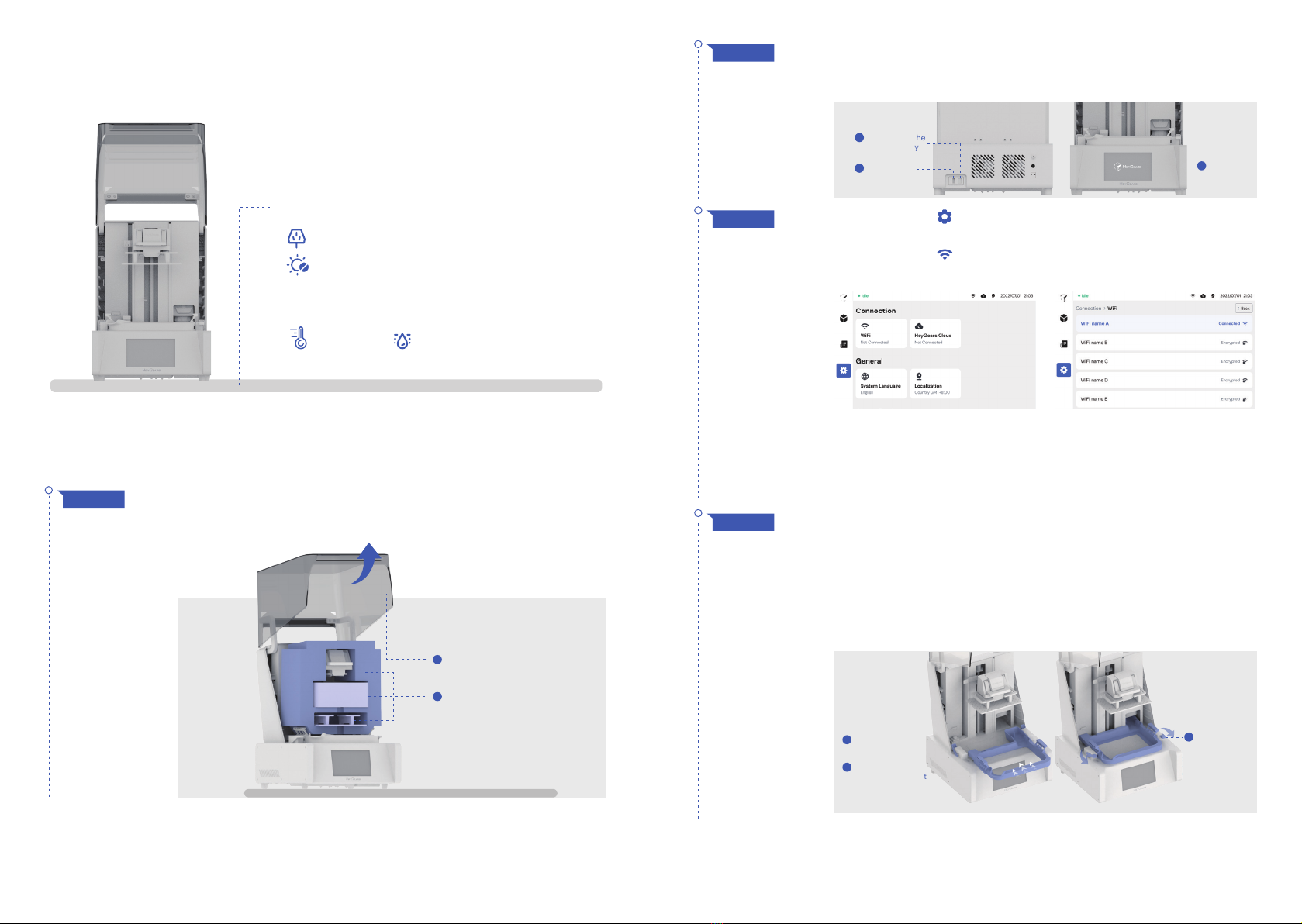

Components

2

Items & Parameters

1

Thank you for choosing HeyGears. For safety, please contact HeyGears support staff for

assistance regarding unpacking and installing the machine. If you fail to comply with the

instructions in this manual, HeyGears will not be liable for the consequential damages unless

required by federal and local ordinances.

Please keep this operation manual properly for future reference. The pictures are for reference

only and the products are subject to the actual product.

This quick start must be read and

understood before operating the machine

Printer

X1

Power Cord

X1

Resin Tank Lid

X1

Build Platform

X1

Release Film

Spare Module

X1

Build Platform

Resin Tank

Detachable Resin

Filling Gate

Touch Screen

Suspension Button

Power Switch

Power Port

Resin Bottle

Insert Location

Air Tube Port

UltraCraft Reflex

400*420*572 mm

UltraCraft Rapid

Production System 100-240 V~ 50/60 Hz

25 kg

350 W

Snipper

X1

Allen Wrench

X3

Rubber Gloves

X2

Parts Removal

Tool

X1

Scraper

X10

Filter Paper

Main Axis

Temperature and

Liquid Level Sensor

Hood

USB Port

Resin Tank

X1

Simple Cleaning Box

X1

Screwdriver

X1 X5

Inflation Module Port

Ethernet Port

Name

Model

Size

Input

Weight

Power

Installation Requirements

3

Operation Steps

4

Connect the power supply as shown, and turn on the power switch,

then the touch screen lights up to indicate that the power is

successfully connected.

STEP 2

Place the printer on a smooth horizontal surface, check the

appearance of the printer to make sure it is in good condition, lift

the hood to the highest position and remove the filler inside.

STEP 1

Position the printer onto a stable table

100-240 V power socket nearby

Protected from exposure to direct sunlight

18~25°C

Temperature & Humidity Control:

<50%

Connect to the

power supply

1

Turn on the

switch

2Screen

lights up

3

Click the button on the left navigation bar to enter the "Settings"

interface.

Click the button in the function list to enter the "Connection"

interface.

Go through the list of available Wi-Fi, click on which you want to

connect to: if the Wi-Fi you choose does not require password

verification, click Confirm and the printer will automatically connect to

it. Otherwise, you need to type in the password at first connection time.

STEP 3

Remove the resin tank inside the printer, and check whether the

outer foam and release film are complete or not. Tear off the

dustproof film of the LCD screen and ensure that there is no dust

and foreign matters on its surface.

After checking, hold its handles on both sides, aligning with the

locking module on both sides, install it into the cabinet with the

overhang part facing inward, then pull the locking handles forward.

You can shake the resin tank slightly to ensure that it is locked.

STEP 4

Tear off the

dustproof film

1

Install the resin

tank in the correct

direction

2

1

2

Tighten the

locking handle

by pulling

forward

3

Take out the filler

buid platform and cleaning box

Open the hood

Replace the release film

5

Follow the Ultraflow guide to complete the device binding and

pre-processing, and send the job to the printer for printing.

In the idle status, gently pull the resin bottle up along the track

and press the suspension button on the side of the printer, then

release the bottle so that it is stuck in suspension. When the resin

no longer drips naturally from the bottle, remove the bottle along

the rail and press the suspension button again to return it to the

original state.

When printing finished, open the hood and unlock the build

platform to take it out.

If you need to recover residual resin from the parts, hang the build

platform on the main axis at an angle as shown until the resin no

longer drips heavily.

After removing the platform, follow the instructions for the

post-processing like washing, removing parts and supports, and

post-curing etc.

STEP 7

STEP 6

STEP 5

STEP 8

STEP 1

Take out the liquid & temperature sensor and install it in the resin

tank as shown below. Make sure that the sensor is magnetically

attracted to the resin tank, and the convex part at the end is

inserted into the specified position, then you can shake it gently to

make sure it is fitted well.

Take out the build platform in the package and keep the locking

wrench raised, then install the build platform along the slide. Inset

it to the bottom, lock down wrench and close the hood.

Fully shaken the bottle and open it, then unscrew the cap as shown.

Insert the resin bottle downward along the slot into the printer, and

lift the top cover of the printer if using a 2L resin bottle.

Insert the resin bottle until you get tactile feedback and the display

shows that the resin bottle is inserted.

Keep the locking wrench raised

1

Twist the cap

counterclockwise

1

Install the build platform along the slide

2

Lock down the wrench

3Close the hood

4

CAUTION: Once the resin bottle is inserted into the printer,

the resin will flow into the resin tank, please make sure the

resin inserted is correct.

Resin tank and Release Film Spare Module are shown in the picture:

Replacement steps

Release Film Spare Module

Insert the resin bottle

downward along the slot

into the printer

2

1 2

Keep the platform unlocked, install the

platform diagonally as shown in the picture to

the end and wait for the resin inside the

model to flow out naturally

Lifting the locking handle and remove the

build platform with parts slightly

Resin Tank

Cautions

6

Remove the resin filling gate in the direction shown.

STEP 2

STEP 3

STEP 4 Use the attached wrench to remove the screws of the release film

at the bottom of the resin tank. Take out the release film after all

the screws are removed.

Remove the resin tank by pulling back the locking handle on both

sides of it.

STEP 5 Install the new release film into the resin tank in the same position

and re-lock the removed screws to the original holes. Reinstall the

resin tank according to the guidelines.

Please close the hood in time after installing or removing

the platform and resin tank to avoid dust entering the

printing area.

Remove the screws

1

Pull back the locking handle

1Lift up the resin tank slightly to remove it

2

Take out the release film

2

Install the new release film

1

Re-lock the screws

2

Apply the film life detection

label to the resin tank

3

Remove the resin filling gate

Pull out the

resin bottle upward

1 2 43

01

Before removing the resin tank or resin bottle, please

press down the suspension button to stuck the resin bottle

and wait for several minutes until the resin stops drippong.

02

It is recommended to store the resin tank and release film

spare module in a dust-proof place and keep the

temperature between 20~25℃.

03

Please avoid contaminating the liquid level sensor power

supply with resin.

04

Please clean the liquid level and temperature sensor

probes when changing the material; Not to invert the

sensor when the probes are covered with resin.

05

Press the suspension button

Release the resin bottle so

that it is stuck

Remove the resin bottle

when the resin no longer

drips from the bottle

Press the suspension

button again to return it to

the original state

Table of contents