HG E1000 User manual

User Manual HG E1000 HIGH TIP

Side 1

USER MANUAL

HG E1000 HIGH TIP

SUPER SKUB

User Manual HG E1000 HIGH TIP

Side 2

Table of Contents

User Manual ................................................................................................................................................................ 1

Introduction................................................................................................................................................................. 3

1.Safety instruction............................................................................................................................................... 4

1.1 Read the manual ........................................................................................................................................ 4

1.2 Education.................................................................................................................................................... 5

1.3 The most common causes of accidents are............................................................................................... 5

1.4 Preparation................................................................................................................................................. 5

1.5 Noise and vibration level ............................................................................................................................ 6

1.6 Operation.................................................................................................................................................... 7

1.7 Maintenance............................................................................................................................................... 8

1.8 Transport & Towing .................................................................................................................................... 9

1.9 Disposal & Dismantling............................................................................................................................. 10

2. Charging and Storage .................................................................................................................................... 11

2.1 Charging ................................................................................................................................................... 11

2.2 Storage ..................................................................................................................................................... 12

3. Functions ........................................................................................................................................................ 14

3.1 Instrument panel....................................................................................................................................... 14

3.2 The machine's functional units................................................................................................................. 15

4. Precautions before starting............................................................................................................................. 18

4.1 Tire pressure and tension......................................................................................................................... 18

5. Driving............................................................................................................................................................. 20

5.1 Operation of HIGH TIP ............................................................................................................................. 21

6. Maintenance................................................................................................................................................... 22

6.1 Towing and side tipping of the container during maintenance, service, engine failure, hydraulic failure or

power failure. ...................................................................................................................................................... 23

6.2 Maintenance Points.................................................................................................................................. 24

7. FAQ................................................................................................................................................................. 28

8. Hydraulic diagram and Electrical diagram...................................................................................................... 29

9. Technical specifications.................................................................................................................................. 30

10. Warranty ....................................................................................................................................................... 31

11. EU declaration of conformity ........................................................................................................................ 32

User Manual HG E1000 HIGH TIP

Side 3

Introduction

The HG E1000 High Tip is an electrical, high-

quality dumper with an added benefit –the

ability to unload directly over the rim and into

containers and trailers. It is user-friendly and

provides the same outstanding performance as

the combustion engine alternatives. The high-tip

function is particularly popular for work sites in

tight spaces, such as cities, among rental

companies, landscapers, contractors, and

demolition companies. The HG dumper has total

safety measures that ensure the highest safety

standards for users while being able to load up

to 1000 kg.

Find out more at:

www.hg-machines.com

• Very low noise level

• Minimal maintenance - built to last

• Particle free working environment • Lithium

battery technology

•12 hour run time, more than a full day work

• Fast charging - 20 to 80% battery charge in 90

min.

Manufacturer:

HG Poland Sp. Z. O. O.

+48 91 885 23 04

Prosta 34

72-100 Łozienica

Poland

CVR-nr.: PL7010040430

HG Machines ApS

+45 75 89 12 44

hello@hg-machines.com

www.hg-machines.com

Vejlevej 15

8722 Hedensted

Denmark

User Manual HG E1000 HIGH TIP

Side 4

1. Safety instructions

1.1 Read the manual

Read the manual carefully and make sure that

other potential users of the machine read it as

well. If the user is unaware of certain details

about the machine, this could lead to hazards.

If one of the warning labels is loose, worn or

damaged so that the symbol is illegible, the label

must be replaced.

WARNING!

Next to a text in the manual highlights a risk of

injury if users do not follow the instructions

WARNING!

Hot parts

Do not touch the electric motor during operation

or when the motor has just stopped. Hot parts

can cause severe burns.

WARNING!

Electric shock

We recommend the use of qualified service

staff/workshop for servicing or troubleshooting,

as there is a risk of electric shock. Electric shock

can cause fire damage, death and/or long-term

injuries.

Manuals, parts lists and instructional videos can

be found at www.hg-machines.com.

WARNING!

Danger of crushing

Avoid contact with moving machine parts. This

applies to both fingers and clothing, as this can

lead to mutilation.

WARNING!

Danger

When servicing and parking the machine, the

motor must be switched off, the ignition key

removed and the main switch turned off.

At HG, we always recommend qualified

staff/workshops for servicing and

troubleshooting.

At HG, we always recommend authorized

personnel/workshop for servicing and

troubleshooting.

User Manual HG E1000 HIGH TIP

Side 5

1.2 Education

Read the instructions carefully. You should be

familiar with all controls, switches, etc. and how

to use the equipment correctly.

To use the motor barrow, the operator must be

over 18 years of age and have normal mental

condition and mobility. Relevant legislation may

mandate a different age limit for operators of the

motor barrow in specific situations.

Remember that the operator is responsible for

any accidents or hazardous situations that may

occur involving other people or their property.

The operator should be given adequate

instructions for using the motor barrow. These

instructions should focus on:

1. The need to be careful and focused

when working with self-propelled

machines.

2. The fact that the operator must have

a good overview of what is

happening in front of/behind the

vehicle - especially where other

people may be present.

1.3 The most common

causes of accidents are

1. Lack of overview

2. The operator's knowledge of the vehicle

is insufficient.

3. Overly steep terrain conditions.

4. Insufficiently stable terrain.

5. The vehicle being used in conditions with

insufficient space.

1.4 Preparation

•Be sure not to wear loose clothing when

driving.

•Ensure that he machine is adequately

charged. HG does not recommend driving

with less than 15% battery capacity.

•Ensure that the machine holds sufficient

hydraulic oil for the tipping function.

•Top up hydraulic oil if required, before

activating the main switch and ignition key to

ON position. Never remove the hydraulic

tank cap or top up the hydraulic oil while the

motor is running or hot.

•In case of spilling hydraulic oil, do not

attempt to turn on the machine until the

hydraulic oil spilled on the machine has been

removed. Hydraulic oil can create very

User Manual HG E1000 HIGH TIP

Side 6

slippery surfaces and can thus increase the

risk of accidents while driving.

•If you get hydraulic oil on your skin, you

should wash your skin thoroughly with soap.

If irritation persists, consult a physician.

•Ingestion of hydraulic oil is potentially fatal.

1.5 Noise and vibration level

Noise level

According to ISO 6396, the max. energy

equivalent sound pressure level is 71 dB (A) at

the operator location, measured during tipping

with an empty skip and at maximum motor

speed.

According to ISO 6396, the highest energy

equivalent sound pressure level is 70 dB (A) at

the operator location, measured during

simulated operating conditions between driving

and tipping.

The uncertainty of the above measurements is ±

2 dB.

HG recommends the use of hearing protection,

even if the noise is below the statutory limit.

Vibration level

According to ISO 1032, the maximum weighted

arm/hand vibration level at the operator location,

measured at empty skip tipping and maximum

motor speed, is: ahv = 5.0 m/s2.

According to ISO 1032, the maximum weighted

arm/hand vibration level at the operator's seat

under simulated driving and tipping operating

conditions is measured as: ahv = 3.0 m/s2.

The uncertainty of the above measurements is

± 25%

User Manual HG E1000 HIGH TIP

Side 7

1.6 Operation

WARNING!

Failure to observe the following operating

instructions may result in injury:

•When driving indoors, make sure you

observe the rules and instructions in force on

site.

•Do not use the machine in places with

flammable dust or explosive gases.

•As far as possible, only use the motor

barrow in daylight or in good artificial

lighting.

Do not drive on

slopes exceeding 5%

(4,5 degrees).

Do not drive across

slopes exceeding: 10°

(10 degrees) on hard

surfaces such as

concrete and asphalt.

5° (4,5 degrees) on

compacted ground

such as gravel and

grass.

•In case of overturning, let go of the

machine and keep your distance. Never

try to hold onto the machine.

•Be aware that the driving characteristics

of the motor barrow change significantly

between an empty and a full skip, as the

center of gravity of the motor barrow is

higher when the skip is full.

Do not use the motor

barrow with insufficient

ceiling height.

NEVER drive on slopes

with an empty or full

container when HIGH TIP

is activated.

Only drive on horizontal

and stable ground when

the HIGH TIP has been

driven out.

Do not drive and unload

close to excavations and

unstable edges.

•Unloading of frozen loads or highly adhesive

materials such as clay must not be

performed by tipping, as the machine may

tip over.

•Driving on soft, loose and uneven surfaces is

prohibited, as the operator may be exposed

to inappropriate loads on the body when

operating the machine.

User Manual HG E1000 HIGH TIP

Side 8

•When leaving the motor barrow, remove the

ignition key and turn off the main switch.

•Always turn off the ignition and main switch

before carrying out any service or repair

works.

•Always turn off the ignition and main switch

before charging the machine.

•Do not touch the motor or other electrical

parts when the machine is on and/or

running.

•The machine may only be used for

transporting materials.

When reversing, the

operator must pay

special attention to

uneven surfaces and

objects that the

operator may fall

over or drive into.

The operator must be

aware of persons in the

area so that they are

not crushed under the

truck bed when it is

being lowered.

•The area around the machine must be

kept tidy to avoid accidents caused by

falling.

1.7 Maintenance

Each time the machine is used, visual inspection

and inspection must be performed to ensure:

•That there are no leaks in the hydraulic

system by hoses, tank etc.

•That there are no worn or damaged cables.

•That bolts, nuts, etc. are properly tightened.

•That the radiator grille and radiator fins on

the motor are free of dirt.

•That no hydraulic oil has been spilled on or

around the machine.

•That the motor barrow is stationary when the

propulsion lever is not activated.

•That the safety plate activates forward

movement when activated.

•That the tires have the correct pressure and

are lubricated.

•That the battery pack is not defective or has

loose plug connections.

User Manual HG E1000 HIGH TIP

Side 9

WARNING! Always fit the safety bracket of the

tipping cylinder before starting the inspection

work.

1.8 Transport & Towing

In order for the machine to be towed without the

motor being started, the release button on the

right side below the control panel must be

activated. The traction wheels are released and

the machine can be moved. See pos. 10

NOTE: The release handle must always be

pushed up during normal operation, as the

brake is otherwise disengaged

When lifting the machine, the three attachment

points on the front and on the instrument panel

must be used. Attachment must be sufficiently

stable and executed in such a way that

detachment cannot take place.

Lifting of the machine may ONLY be done with

an empty container.

NEVER use the control handle, safety plates or

anything else around the instrument panel to

clamp the machine.

The image may differ depending on the model

type.

User Manual HG E1000 HIGH TIP

Side 10

The machine may only be

transported with means of

transport with sufficient

ground clearance, as

there is a risk of serious

injury to the

operator/damage to the

machine and means of

transport

During transportation, the machine must be

attached to the load surface or cargo hold in

accordance with relevant regulations.

1.9 Disposal & Dismantling

When, many years from now, the motor barrow

is worn out and has to be disposed of,

Hedensted Gruppen will perform the dismantling

by agreement, as this should take place in an

environmentally sound manner. During

dismantling, the machine parts are sorted

according to type of material: in other words,

steel separately, rubber seals separately etc.

The various types of material are then disposed

of in accordance with relevant current

legislation.

User Manual HG E1000 HIGH TIP

Side 11

2. Charging and

Storage

2.1 Charging

1) Switch off the

machine at the main

switch, see figure pos.

11.

2) The charging plug is

found behind the door

on the left side of the

machine seen from the

direction of travel see figure pos.13

3) Connect the plug to the mains, see figure pos.

15

4) ) Check that the machine is charging the

battery. On the right side of the machine, seen

from the direction of travel, a pictogram is

mounted which describes the charger's various

indicator lamp states. At the bottom of the

pictogram there is an arrow, below the arrow

and through the ventilation holes on the side of

the machine you can see the indicator lights on

the charger. During charging, the yellow lamp on

the charger will flash. See figure item 16.

5) When the machine is fully charged, the green

lamp on the charger will light up steadily. Then

remove the plug from the mains and roll the

charging cable around the hangers on the

battery door. Then close the door, see pos. 13.

6) When the machine has been inspected as

described under "safety" and "precautions

before start-up", it is ready for operation.

User Manual HG E1000 HIGH TIP

Side 12

2.2 Storage

In conditions where a machine is to be stored

without operation for a longer period, HG

recommends that the machine's battery pack be

placed in "storage mode" and with a minimum of

40% power on the battery pack.

If the machine does not have at least 40%

power on the battery pack at the time of the

recommendation, it must be charged to this or

above. The current power level can be read on

the battery indicator mounted in the instrument

panel. See figure item 6.

When the machine's battery pack has reached a

current level of at least 40% or more, the entire

container is tipped to the side, this is done by

loosening the two bolts on the left side and

rotating around the hinges on the right side seen

from the direction of travel. See figure pos 17

and 18.

WARNING! The rotation of the container

must be carried out by two people. The

container must be so long that there is no

possibility of tipping back accidentally.

User Manual HG E1000 HIGH TIP

Side 13

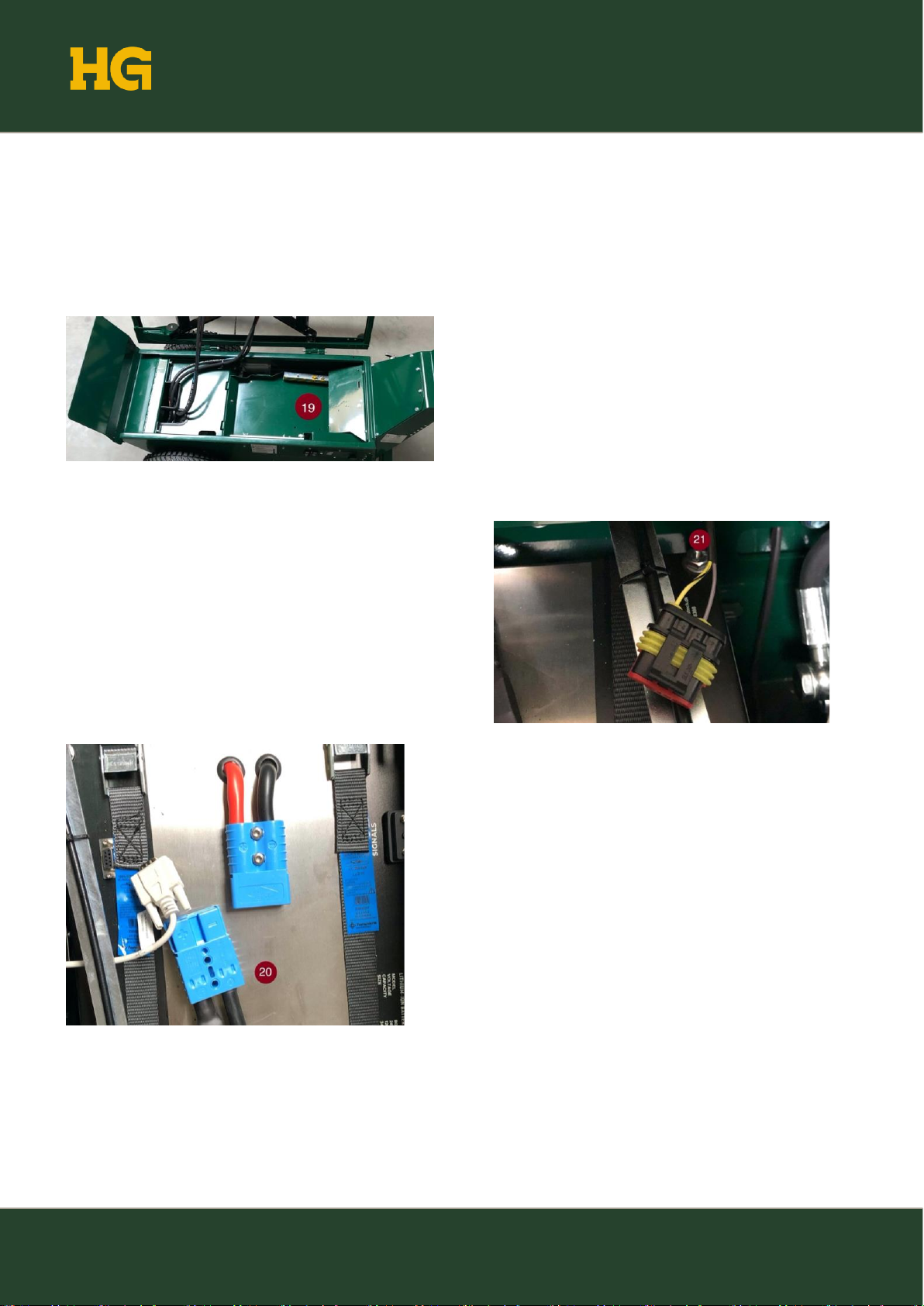

The top plate for the battery compartment is

then removed by lifting into the elongated hole.

The plate is held in place by magnets. See

figure pos. 19

The blue connector on the battery, which

consists of two counterparts, is pulled apart. The

gray COM connector must also be removed.

See figure pos. 20. When the two blue

counterparts and the COM connector are

separated, the top plate for the battery

compartment can be fitted again and the

container can be rotated into place.

The machine is now ready for storage and will

automatically go into "storage mode" as it will

not register any discharge. In "storage mode"

the battery pack will only consume 1-2% of

operation ready level mode. However, the

battery must be inspected every 2.5 months and

recharged to a minimum of 40%. If the machine

in use or the battery pack is to be recharged,

follow the same procedure as above, where the

blue connector consisting of two halves and the

COM connector, instead of being separated, are

instead assembled.

This is a programming plug. See pos. 21.

User Manual HG E1000 HIGH TIP

Side 14

3. Functions

3.1 Instrument panel

1) Operating push buttons for HIGH TIP

function. If the left button is pressed and

held, the container will lift. If the right button

is pressed and held, the container will lower.

2) Operating push buttons for tipping the

container. Press and hold the left button to

tilt the container. Press and hold the right

button to lower the container.

3) Emergency stop. If the emergency stop is

pressed, the machine and all its functions

will stop immediately. To activate the

machine again after pressing the emergency

stop, the emergency stop must be rotated ¼

clockwise, then the machine can be

activated again.

4) Signal horn. When the horn is pressed, it

emits a loud noise. The horn is used, for

example, to prevent or avert hazardous

situations.

5) Emergency stop/safety plate. Activating the

plate activates forward movement so the

operator does not risk getting trapped.

6) Control handle for driving backwards. The

handle is clamped up against the handlebar.

The more the lever is squeezed, the higher

the speed.

7) Battery indicator. Shows a snapshot of the

power level of the machine battery pack.

8) Control lever for forward travel. The handle

is pulled up towards the handlebar. The

User Manual HG E1000 HIGH TIP

Side 15

higher up the lever is pulled, the higher the

speed.

9) Key start ON/OFF - when OFF the machine

is turned off; when the key is turned to ON,

the machine is turned on.

10) Activation button. Pressing the button

activates the machine. A green light

indicates that the machine is activated and

the timer function has started. If the machine

is not operated for 5 minutes, the machine

will shut down and the button must be

activated again for driving to take place (the

timer is not active when driving the

machine).

3.2 The machine's functional

units

Release. If the release lever is pushed down,

the electric motor is disengaged and the

machine can be pushed. If the lever is pushed

up, the electric motor is engaged and the

machine can be operated via the control levers.

See figure pos. 10.

Main switch seen in switched off position. When

using the machine the main switch is rotated 90º

clockwise. HG recommends using the turned-off

position when the machine is not used for a

longer period, e.g. at the end of the working day.

See figure pos. 11

Filling the hydraulics. Remove the plate using

the two screws and add hydraulic oil to the

plastic tank. See figure pos. 29, 30 and 31.

User Manual HG E1000 HIGH TIP

Side 16

For charging, the charging connection is located

behind the door. The charger can be connected

to 16-30A group 220V . The plug is of the type

is of the type 16A 2P+E Male type F. See figure

pos. 13.

Tip protection for the container's hydraulic

cylinder. The tipping protection is mounted on

the cylinder's stick during service or other

inspection where the container must be tipped

up. See figure pos. 14.

Side tipping of container. To facilitate

accessibility of the machine's internal parts,

the container can be advantageously tipped

to the side by loosening the two bolts on the

left side of the machine. See figure pos. 17.

NOTE: This operation must be performed

by two people, as heavy lifting will occur.

With the help of two people, the container

can be tipped to the side. HIGH TIP does not

need to be raised as shown in figure pos. 24.

Alternatively, the machine's container can

also be tipped without HIGH TIP is raised

figure pos. 27 and 28. The advantage of a

User Manual HG E1000 HIGH TIP

Side 17

raised HIGH TIP or only tipped container is

that the container can thereby be placed

directly on the surface on which the machine

stands. See figure pos. 28.

If the HIGH TIP is not raised, the container,

when it is tipped to the side, must be

supported by a suitable stable object such

as support frame

with approved

carrying capacity of

at least 200kg. See

figure pos. 25.

NOTE: In this case, it must always be

ensured that the container is tipped at least

125* degrees above the horizontal surface

where the container has its normal position,

precisely to avoid the container falling back.

User Manual HG E1000 HIGH TIP

Side 18

4. Precautions before

starting

Visual inspection of the machine. Make sure the

machine and all warning pictograms are intact.

Make sure the control panel buttons and

handles are intact.

Tip the container up and install the tip protection

on the cylinder block.

Remove the top plate for the battery

compartment and visually inspect the battery

pack, make sure that the battery pack is

fastened so that it cannot move while driving,

tighten if necessary the battery stoppers. After

inspection,

the top plate

is fitted, the

tip

protection is

removed

and the

container is

closed.

4.1 Tire pressure and tension

To achieve optimal ergonomic conditions, all

tires must have the correct air pressure.

•Driving wheels: 53 psi/3,7 bar

•Steering wheels: 67 psi/4,6 bar.

Tighten wheels once a week.

Tightening torque:100 Nm

User Manual HG E1000 HIGH TIP

Side 19

Safety plate test

The safety plate must activate forward travel

upon impact, so that the operator is not pinched

in connection with reversing/reversing.

NOTE: Before the test is started, a free space

of at least 15 meters must be ensured all the

way around the machine.

Start the machine and test the plate. In order to

simulate a possible pinching during

reverse/reversing, the safety plate is pressed in

quietly, the machine must start moving forward,

the more the plate is pressed in, the faster it

runs.

The machine must not be used if it does not

move forward when pressed on the plate

The system must be undamaged and able to be

moved without difficulty.

User Manual HG E1000 HIGH TIP

Side 20

5. Driving

Turn the main switch

to the closed position.

The battery pack is

now connected to the

machine's

components.

Turn the ignition key to the ON position, the

battery status indicator should now light up.

Press the activation button (now lights up

green) and the machine is now active.

Check via the battery status that the machine is

sufficiently charged. HG does not recommend

driving with current below 10%, as this can

damage and shorten the life of the batteries.

Both hands are placed on the handlebars so that

the fingers can reach the propulsion handle. The

machine moves forward by pulling up on the

right side of the handle and stops by letting go. If

the left side of the handle is pulled up, the

machine moves backwards.

NOTE: Backing/reversing requires thorough

orientation to the rear before starting the

movement.

Other manuals for E1000

1

Table of contents

Other HG Farm Equipment manuals