3

1. IDENTIFYING THE MACHINE..................................................................................................... 5

2. INTRODUCTION...................................................................................................................... 5

3. PROPER AND INTENDED USE.................................................................................................... 5

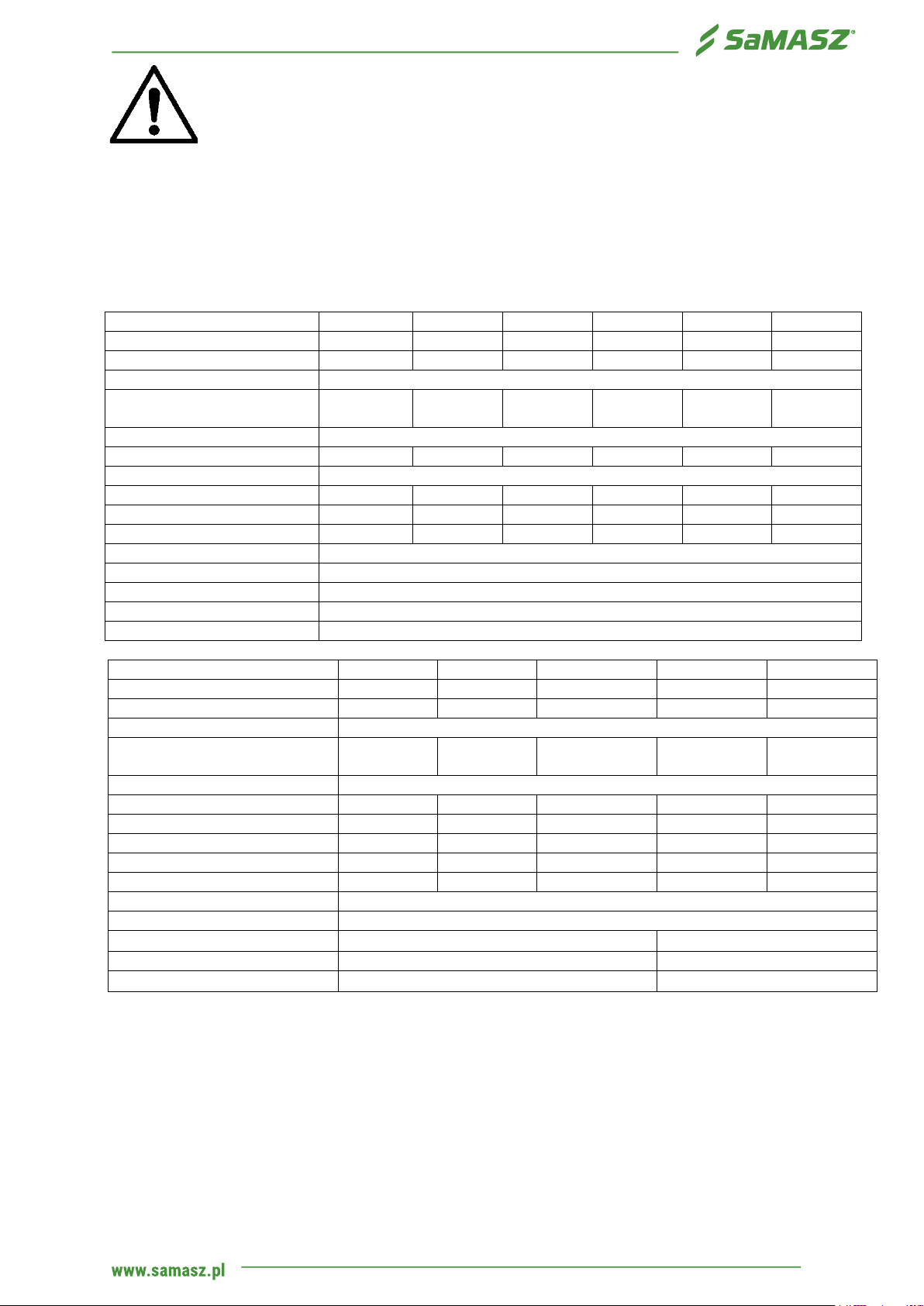

3.1. Technical data ..................................................................................................................................7

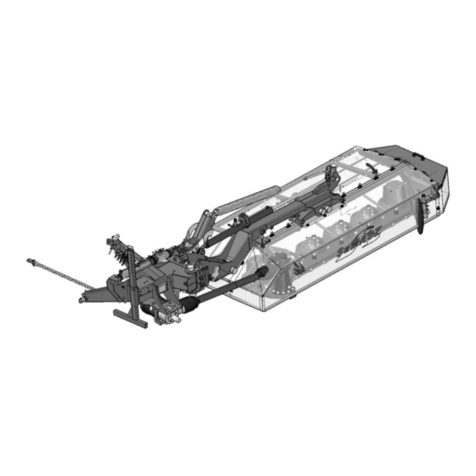

3.2. Design and working principle .............................................................................................................8

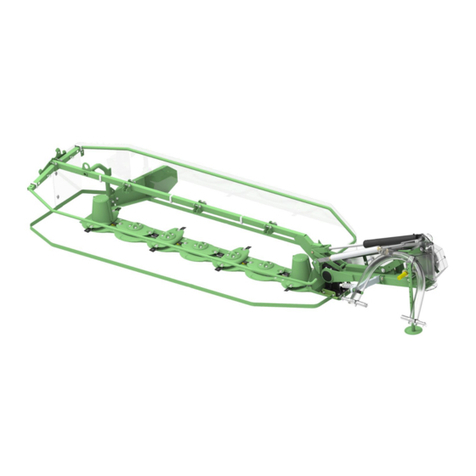

3.2.1. Rear disk mower...........................................................................................................................8

3.3. Rear disk mower with tine condioner..................................................................................................8

3.3.1. Rear disk mower with roller condioner...........................................................................................9

3.4. Equipment and spare parts................................................................................................................9

4. SAFETY PRECATIONS ............................................................................................................11

4.1. General safety rules and regulations ................................................................................................11

4.2. Qualifications of operator................................................................................................................13

4.3. Conditions of mounting mower on tractor ........................................................................................13

4.4. Transport........................................................................................................................................13

4.4.1. Putting the mower onto another vehicle for transport...................................................................14

4.5. Working parts .................................................................................................................................15

4.6. PTO shaft .......................................................................................................................................15

4.7. Hydraulic assembly.........................................................................................................................15

4.8. Residual risk ...................................................................................................................................16

4.8.1. Danger of machine entanglement................................................................................................16

4.8.2. Danger of cutting injury...............................................................................................................16

4.8.3. Danger of injury from liquid ejection out of hydraulic system........................................................16

4.8.4. Forbidden actions.......................................................................................................................16

4.8.5. Residual risk assessment ...........................................................................................................17

4.9. Safety labels and their meaning .......................................................................................................17

5. OPERATION..........................................................................................................................20

5.1. Attaching the mower to the tractor...................................................................................................21

5.2. Mounting PTO shaft ........................................................................................................................22

5.3. Preparing the mower for transport ...................................................................................................23

5.4. Preparing the mower for transport on public roads ...........................................................................24

5.5. Moving from transport to working position.......................................................................................25

5.5.1. Operating positions of the mower ...............................................................................................26

5.6. Preparing the mower for work..........................................................................................................26

5.7. Operation (mowing).........................................................................................................................27

5.7.1. Essential information concerning mowing ...................................................................................27

5.7.2. Design and and operation of safety breakaway device .................................................................29

5.7.3. Mower clogging and jams...........................................................................................................29

5.7.4. Taking turns over swaths............................................................................................................29

5.8. Dismounting mower from tractor .....................................................................................................30

6. MOUNTING AND ADJUSTMENTS..............................................................................................30

6.1. Mounting and timing of the knives ...................................................................................................30

6.2. Checking the knives and knife holders..............................................................................................31

6.3. Replacing the knives and knife holders.............................................................................................31

6.4. Adjusting the swath width ...............................................................................................................33

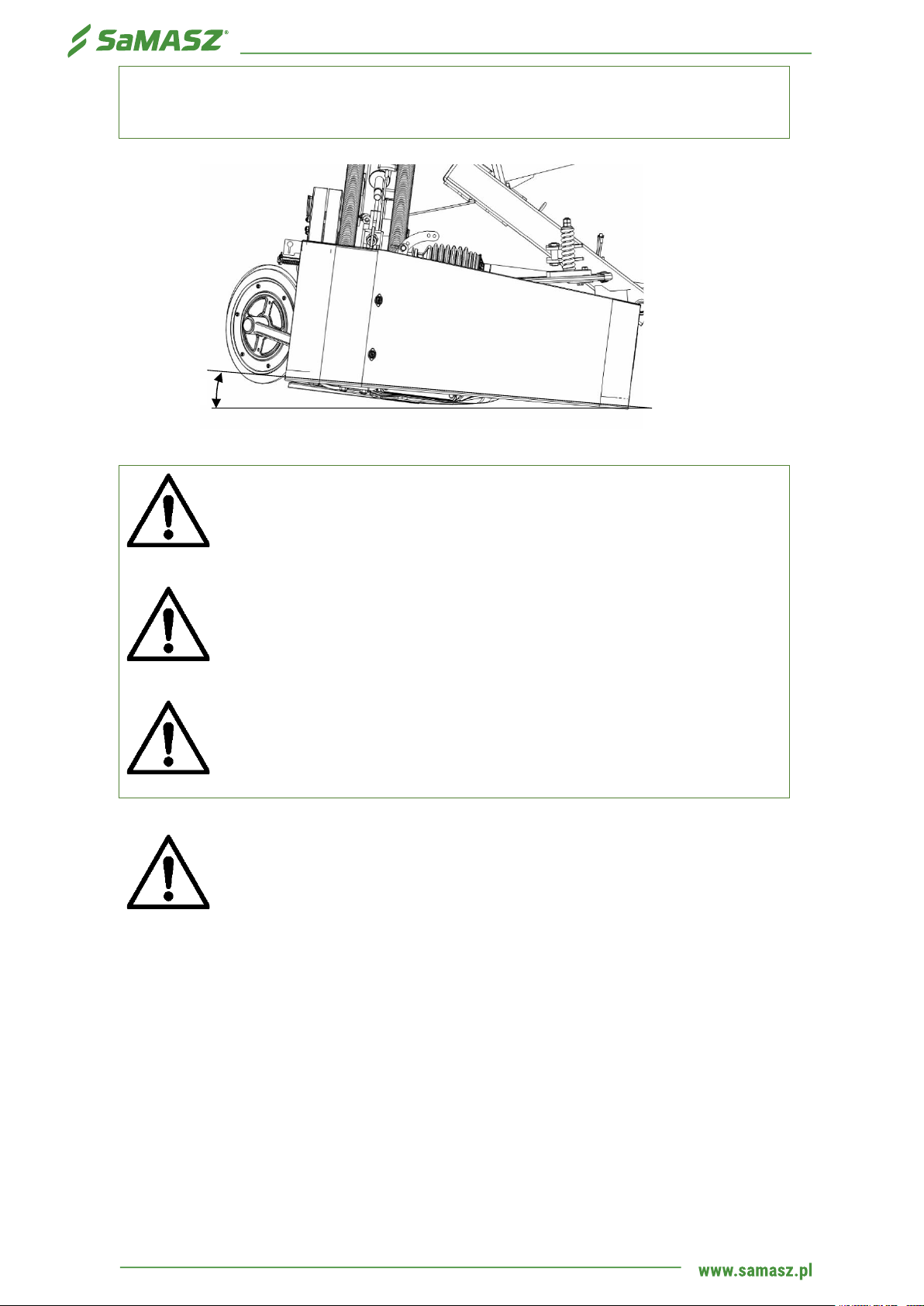

6.5. Adjusting the cutting height.............................................................................................................35

6.6. 3-point linkage support chain...........................................................................................................35

6.7. Adjusting pressure of the cutter bar using support springs................................................................36

6.8. Adjusting the space between tine conditioner’s mask and its shaft ...................................................36

6.9. Replacing the conditioner’s tines .....................................................................................................37

6.10. Adjusting force of the prssure of roller conditioner...........................................................................38

6.11. Maintenance and service.................................................................................................................39

6.11.1. Checking the tension of the V-belts......................................................................................39

6.11.2. Inspection of tension of toothed belt for gears of rollers and conditioner...............................39

6.11.3. Daily maintenance...............................................................................................................40

6.11.4. After-season maintenance and storing of machine ...............................................................41