HHO Plus DC2000 User manual

DC2000 –Installation Manual

HHO Hydrogen on Demand Dual Fuel Generator Systems

HHO Plus, Alternative Energies, Ltd

Technical Department

Travessa das Serras 33, Vieira de Leiria, Portugal

T: 00 351 244 697 116 E: info@hhoplusgas.com

DC2000 –Installation Manual 2

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

CONTENTS

Safety Precautions 4

Important Information 4

Safety Equipment 4

Enjoy your new system 4

Installation of the hydraulic components 5

General configuration 5

Positioning the Dry-Cell 5

Positioning the Water Tank 8

Positioning the Bubbler 9

Positioning the water and HHO hoses 10

HHO injection point 11

Installation of the electrical components 13

General configuration 13

Battery 13

Identifying the ignition source 13

Dry-Cell electric connections 14

Water and electrolyte setup 16

Principles of the water electrolysis 16

Electrolyte concentration 16

Water levels in the tank 18

Amperage variation in the system 18

Electronic fuel injection 20

Basic Information 20

DC2000 –Installation Manual 3

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Components of the electronic injection 21

MAP/MAF sensor 21

Lambda sensors 22

Resetting the ECU 23

Installing the lambda sensor extender –Pre-Cat Sensor 24

Isolating the lambda sensor body –Pre-Cat and Pos-Cat Sensors 26

Test run and checking your work 27

Maintenance 27

Check-list for HHO system debugging 28

Important information 28

Check-List 28

Parts positioning 30

HHO connection from the water tank to the bubbler 31

HHO connection from the bubbler to the air intake manifold 32

Water connections between the water tank and the dry-cell 33

Electric connection from the battery to the relay (Position 30) 34

Electric connection from the ignition source to the relay (Position 85) 35

Electric connection from the relay (Position 86) to the Ground 36

Electric connection from the relay (Position 87) to the dry cell 37

Electric connection from the dry cell to the ground 38

DC2000 –Installation Manual 4

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Safety Precautions

Important Information

Read and follow these safety precautions to avoid hazards. If you do not understand these instructions or do

not like to work on vehicles, please have a qualified mechanic do the installation for you. Incorrectly installing

or using the HHO System may result in serious damage to you and/or your vehicle.

It should take approximately 3 hours to install this unit, so ensure that you have enough time to complete the

installation. Be sure to work outside, no smoking at any time during the installation; make sure the engine is

off and very importantly, not hot.

Your HHO System does not store hydrogen, subsequently there is no fire hazard when installed properly.

However water electrolysis generates Hydrogen, an explosive gas, which means that you should never light a

match or smoke near or in front of the generators output - the water tank could blow up!

Be careful with the generator working when the car is not moving. A small amount of hydrogen can

accumulate in the air intake of the motor and could explode if you smoke or use an open flame near it.

Safety Equipment

Be sure to wear goggles and rubber gloves and only use professional tools; use common sense and general

safety procedures used for any work carried out on automotive installations and maintenance.

Enjoy your new system

Be safe and enjoy your new Hydrogen on Demand Dual Fuel Generator System, read and understand these

instructions before and during the installation and you will benefit from your new system for years to come.

DC2000 –Installation Manual 5

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Installation of the hydraulic components

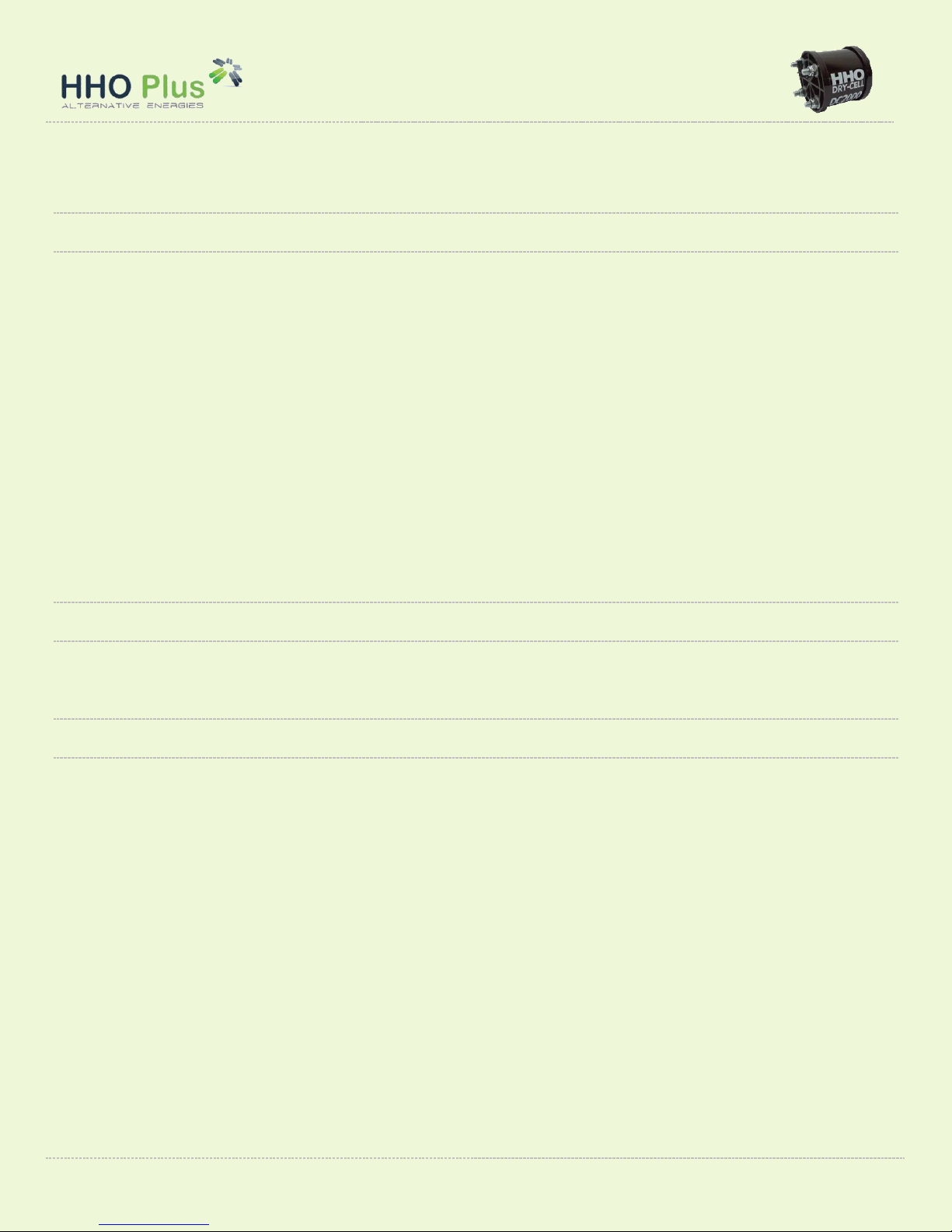

General configuration

Please refer to the illustration below for typical configuration of the mechanical and hydraulic parts of the

HHO system. In the end pages of this manual you will be able to check each one of the individual connections

to be made regarding the installation of the components. We will now only focus on the main aspects of the

installation.

Positioning the Dry-Cell

You will need to find a good place in your engine compartment to mount your new HHO system. Please

remember that the water tank should preferably be placed at least 20 cm above the generator Dry-Cells in

order to guarantee a sufficient water head for the water/hydrogen to flow. But in some cases with not too

much space available to make the installation we just need to make sure that the bottom of the water tank is

a little bit higher than the top of the dry-cell.

Bubbler

Air Intake

Manifold

DC2000 –Installation Manual 6

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Install your new HHO Dry-Cell as far away from the heat of your engine as possible. Normally the best place

to install the dry-cell is in the space between the front grill and the radiator as it is closest to the air entering

the engine compartment and often the largest space available.

DC2000 –Installation Manual 7

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Make sure to install the Dry-Cell in a place that can easily be accessed

and cleaned or inspected from time to time. It should be mounted and

secured in such a manner as to ensure it does not move or bounce

around while the vehicle is in motion, even over rough terrain.

Securing it with a permanent metal bracket (see photos above –metal

bracket not included in the kit) should be sufficient to secure it to the

engine chassis and to operate perfectly.

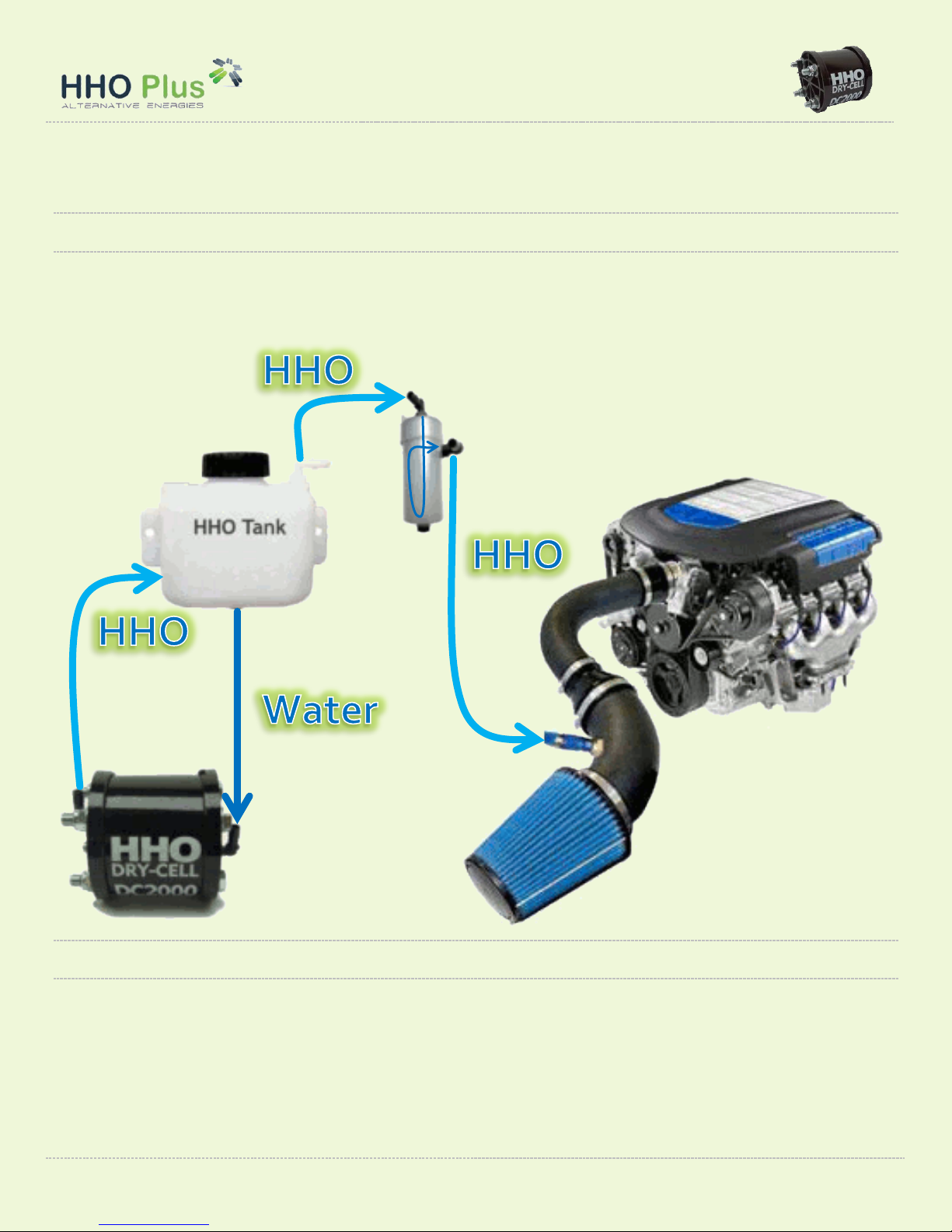

The dry-cell can be mounted in horizontal

or vertical position.

The vertical position does not require any special remarks. The water

intake is connected in the bottom and HHO output will be in the top

of the cell. You just need to make sure that the HHO output hose is always above the top of the cell. If not the

HHO gas will have difficulties moving outside the cell and the production will be reduced.

The horizontal position requires more care in the installation. The cell has to be positioned upright and

leveled to the ground with the tube fittings facing directly to the sky. If you look carefully the cell has 2

openings, one higher than the other. The lower opening is for the water intake and the upper opening for

HHO gas output. We must make sure that the cell is not placed with an angle/rotation that reduces the

distance between the two openings. Please take a look at the pictures below.

If the Dry-Cell is placed as shown in the image on the right you will not use 100% capacity of the generator to

produce HHO gas. Also the HHO gas will have problems getting out of the cell being released gulps. You can

verify this problem if fluctuation of the amperage is very high.

Important Information:

When making the installation

never make any type of

changes in the dry-cell.

Never open it, loosen/tighten

the nuts or cut the screws.

You will damage the dry-

cell and it will not work

properly after. Changes

made in the cell are not

covered by the warranty.

DC2000 –Installation Manual 8

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

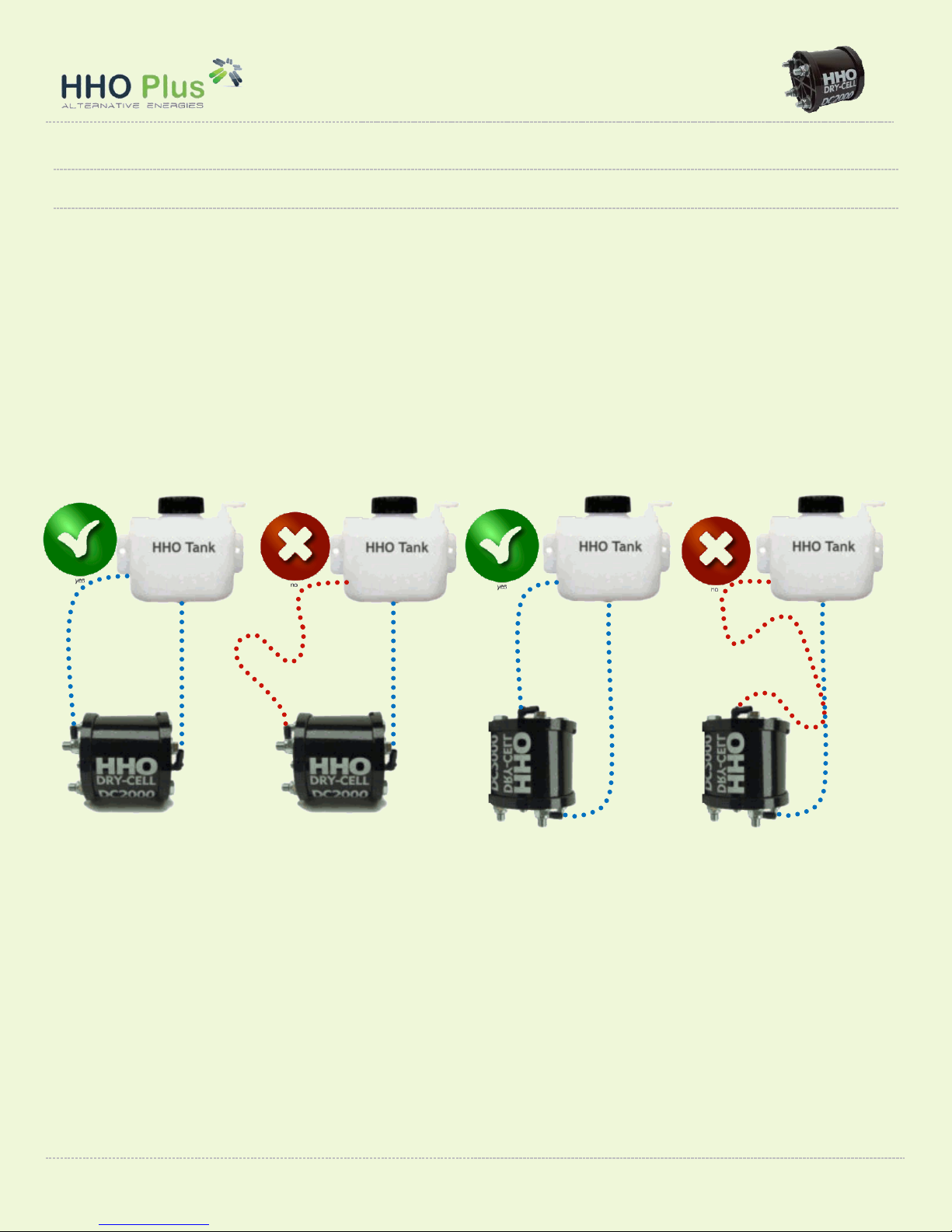

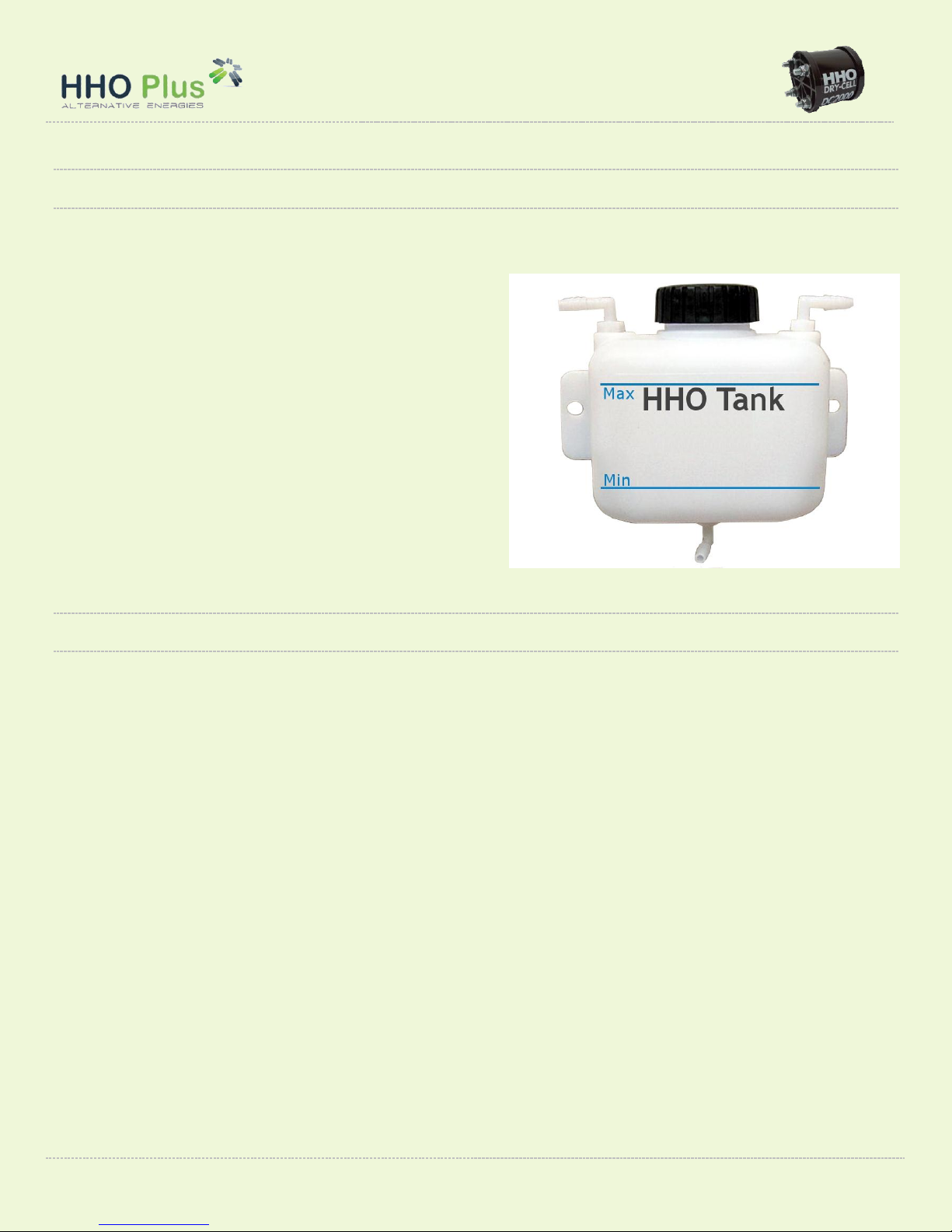

Positioning the Water Tank

Make sure that water tank is installed with the same care as described before for the generator. The water

tank needs preferably to be placed 20 cm above the HHO dry-cell to accomplish the gravity head needed for

the water/hydrogen to flow into the generator. But in some cases with not too much space available to make

the installation we just need to make sure that the bottom of the water tank is a little bit higher than the top

of the dry-cell. Please take a look at the pictures below:

DC2000 –Installation Manual 9

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

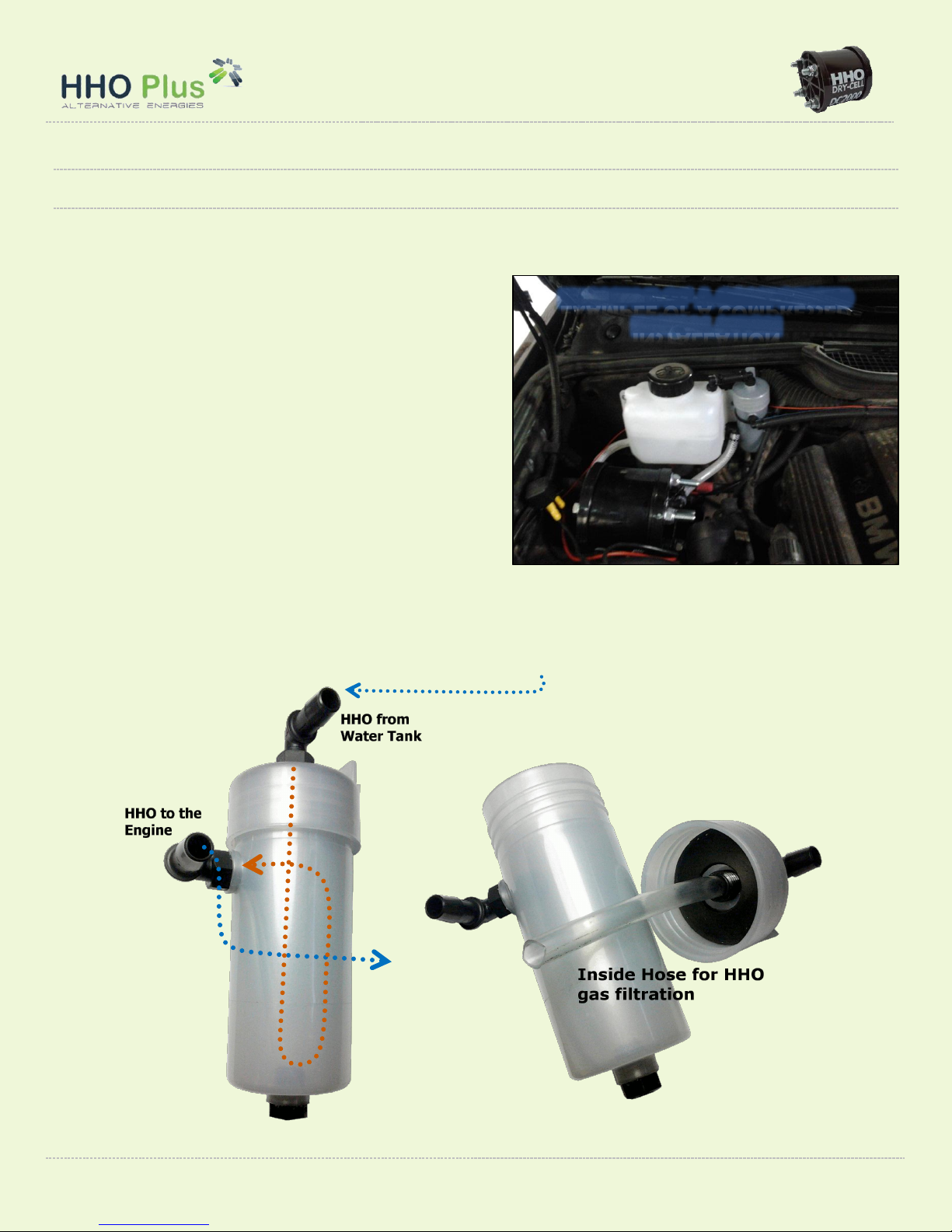

Positioning the Bubbler

The bubbler will serve two purposes: cleaning the HHO gas and act as a safety barrier. When HHO gas is

produced from the dry cell, some small water vapor is produced as well because the water will get a little bit

hot with the passage of current. This water vapor can

carry tiny particles of electrolyte which can cause

damaging corrosion. As the HHO bubbles rise up the

column of water inside the bubbler they are "scrubbed"

of any electrolyte particles that were attached to the

water vapor. The result is much cleaner HHO gas.

In the event of a flashback, the bubbler also acts as a

safety barrier. If a flame reaches the bubbler and ignites

the HHO that has accumulated at the top, the water

column will prevent the HHO from going on to the dry

cell because the flame cannot skip from bubble to

bubble.

Make sure that bubbler is installed above the water tank to accomplish the gravity head needed for a correct

“filtering” of the HHO gas. Please take a look at the pictures below:

EXAMPLE OF A COMPRESSED

INSTALLATION

DC2000 –Installation Manual 10

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Positioning the water and HHO hoses

The hose connections on vertical position of the dry-cell do not require any special remarks. The water

intake is connected in the bottom and HHO output will be in the top of the cell. You just need to make sure

that the HHO output hose is always above the top of the cell. If not the HHO gas will have difficulties moving

outside the cell and the production will be reduced.

The hose connections on horizontal position of the dry-cell require only that the positioning of the HHO

output hose be made also always on an uprising position without ups and downs. If this happens, the HHO

gas will have problems moving into the water tank and will also be released gulps reducing the efficiency of

the system. You may verify this problem if fluctuation of the amperage on your system is very high. Please

refer to the illustration below for typical installation of the hoses coming and going from the water tank:

DC2000 –Installation Manual 11

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

HHO injection point

The system is operated by vacuum suction from your car's air intake which takes the HHO directly to the

combustion chamber mixing it with the air/fuel. The injection point must be done right after the air filter box

and, in modern cars, after the MAF/MAP sensor (air flow sensor) and before the Turbo. Never make the

injection point after the Turbo or Intercooler because the pressure will not allow the best results with the

HHO system.

You will need to remove the air duct, to ensure that you do not leave any residue from the drilling you are

about to do. Drill an 8 mm hole close to the intake manifold. Clean out any drill shavings, insert the high

pressure fitting using goop glue or teflon tape and tighten. Connect the high pressure hose.

DC2000 –Installation Manual 12

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

MAF SENSOR

MAF SENSOR

AIR FILTER BOX

NON RETURN VALVE

DC2000 –Installation Manual 13

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

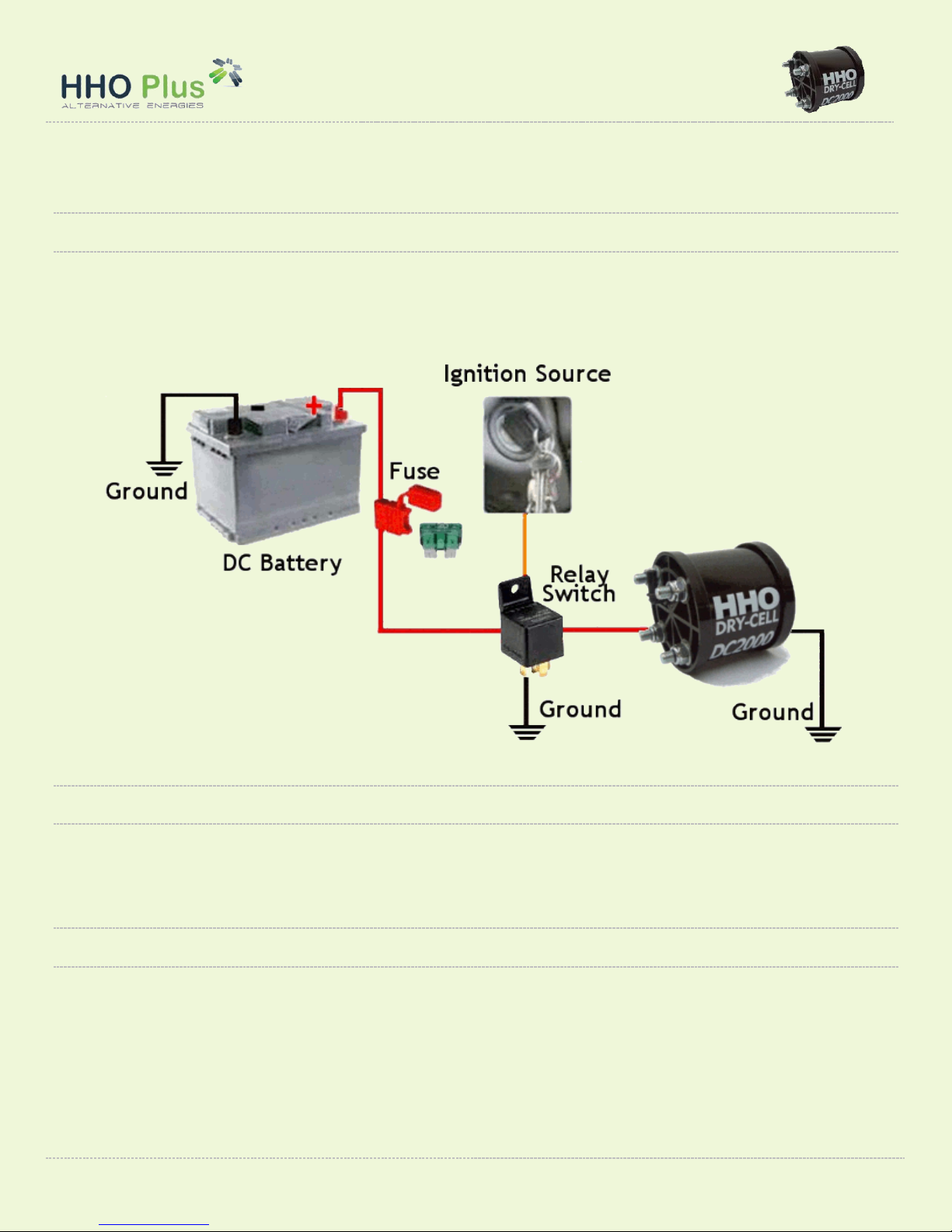

Installation of the electrical components

General configuration

Please refer to the illustration below for typical wiring configuration for powering the system: In the end

pages of this manual you will be able to check each one of the individual connections to be made regarding

the installation of the electrical circuits. We will now only focus on the main aspects of the installation now.

Battery

The system is powered by the 12V battery and controlled by the relay switch. The system will only work if

there is a signal from the ignition source. The positive circuit (red wire) should be connected to the Relay

Switch position 30.

Identifying the ignition source

This is an important connection to be made in order to have the generator working only when the engine is

also working. Identify a point in your vehicle's electrical system which has 12 Volts (positive) present only

when the engine is running. The most secure connection is to excitement signal of the alternator. If you do

not know how to do this connection please ask you mechanic to do it for you. Connect this electric source to

the Relay Switch position 85. This circuit will control the HHO production.

DC2000 –Installation Manual 14

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

This electric connection can also be made to a circuit controlled by the ignition key (position 2), but there is a

risk of hydrogen being produced when the engine is not running if you leave the key permanently in that

position. Try never to make this kind of connection because it increases the risk of some explosion to happen.

Dry-Cell electric connections

Inside each one of the Dry Cells we have 19 plates, 4 of those with a configuration that allows the insertion of

yellow female spade connectors. Not all of the plates are connected because electrolysis would, in this

case, be very intense and damage the surface of the plates. We have to leave between the positive (+) and

the negative (-) some plates without connections –Neutral plates - in order to break the voltage and increase

the electrolysis efficiency with less heat production. Please refer to the picture below for typical wiring

connection of the dry-cells using 12v:

The positive circuit (red wire) should be connected to the Relay Switch position 87. Some relays present the

position 87a. Leave this connection with no connections. Connect the negative circuit (black wire) of the

Generator to a good ground source.

In the next page you can check some photos showing the right way to make the electric connections in the

dry-cell:

DC2000 –Installation Manual 15

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

DC2000 –Installation Manual 16

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Water and electrolyte setup

Principles of the water electrolysis

Electrolysis of water is the decomposition of water molecule (H2O) into oxygen (O2) and hydrogen (H2) gases

due to an electric current passing in the water.

An electrical power source is connected to two electrodes, or two plates (typically made from some inert

metal such as stainless steel) which are placed in the water. In a properly designed cell, hydrogen will appear

at the cathode (the negatively charged electrode, where electrons enter the water), and oxygen will appear at

the anode (the positively charged electrode). The amount of hydrogen generated is twice the number of

moles of oxygen, and both are proportional to the total electrical charge.

Electrolysis of pure water requires excess energy in the form of potential to overcome various activation

barriers. Without the excess energy the electrolysis of pure water occurs very slowly or not at all. This is in

part due to the limited self- ionization of water. The efficacy of electrolysis is increased through the addition

of an electrolyte (such as a salt, an acid or a base).

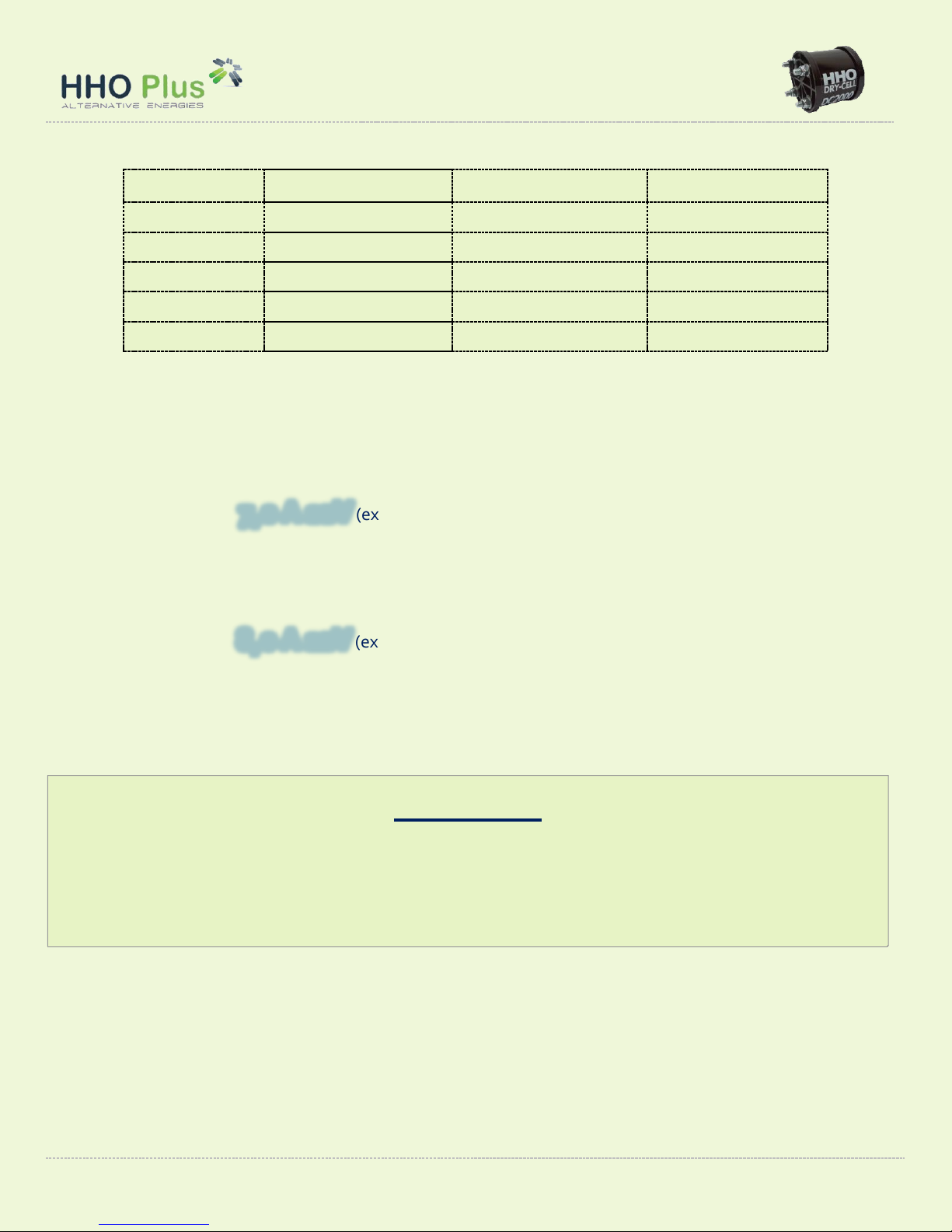

Electrolyte concentration

The electrolyte should be added to the water the first time that

you use the system, and also when refilling, but in lower

quantities. Amperage should be measured to ensure the right

operative conditions according to the table below.

The electrolyte concentration to use in the HHO system depends

on the type of electrolyte and the purity of the product. The best

electrolytes are KOH (Potassium hydroxide) and NaOH (caustic

soda).

The more electrolyte you add to the water, the more amperage you will have in the system and also more

HHO gas will be produced. But, It is false to assume that a higher HHO gas production will mean a higher

fuel savings. There is an optimum point for all internal combustions engines. In diesel cars the system should

provide around 0,25 liter/min of HHO gas per each 1000 cm3of engine displacement. You will be meeting this

standard running your generator with:

Water is getting a brown color

after only a few hours

working?

You have too much electrolyte

in the system that is "eating"

the generator plates too fast.

Remove the water immediately

and start all over again.

DC2000 –Installation Manual 17

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Engine Size

HHO (liter/min)

Start Amperage (A)

Final Amperage (A)

1 600 cc

0,40

5,5

6,5

1 800 cc

0,45

6,5

7,5

2 000 cc

0,50

7,0

8,0

2 200 cc

0,55

7,5

9,0

2 400 cc

0,60

8,0

10,0

* The values presented in the table may have a variation of ±15% according to the different driving and

mechanical conditions of each car.

For example, using KOH as electrolyte, with 90% purity, we should start using a concentration of 2% in the

water solution (20 g/liter). You should right after measure the current intensity going into the generator and

increase slowly the concentration until you reach the first standard operation amperage:

(example for a 2 liter engine –see table above)7,0 A 12V

The HHO generator will start producing HHO gas and temperature will increase with time making higher the

electric conductivity of the solution and amperage until we reach the final standard operation:

(example for a 2 liter engine –see table above)8,0 A 12V

Warning: Do not fall in the temptation of not measuring the current or increase the electrolyte concentration

more than is advised in this manual, because in long term, the generator will not work properly and you may

also not save any fuel.

Another thing that should consider is steam. Some of the early cell developers run their units with so much

amperage that the unit was producing more steam than HHO. If your unit runs hot to the touch, you must

suspect that at least part of your output is steam. One way to test for steam is to run your gas outlet over

some ice. If you get significant amounts of fog forming (water droplets), you know that at least part of your

output is steam.

Important

Remember that we are not changing diesel fuel for another type of fuel. We just want to put

enough HHO gas inside the engine to allow the normal diesel fuel to burn better thus

increasing fuel economy. If we put too much hydrogen we may not have any positive results

because we will be forcing the alternator and engine without increase in fuel efficiency.

DC2000 –Installation Manual 18

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Water levels in the tank

Once you have your mixture ready, pour it into the top of the water tank, up to the water level line shown in

the picture bellow. Try to only fill your unit about 70% full. This is imperative to allow the HHO produced to

enter the gap left in the Tank and avoid any risks of some

water getting into the engine.

The standard water tank is a 1,2 liters unit which will

provide you with approximately 800 kilometers of

driving. Be sure to make your maintenance plan with that

in mind and refill the tank when it is required. Try to refill

as often as it is possible for you in order to keep the

generator running cool.

In our store we have a product that can help you to

control better the water levels in the water tank and

reduce the problems with the management of the

system. It is called the water level control switch.

Amperage variation in the system

When operating the system the water molecule will be "brocken" into HHO gas to be used by the engine. The

water level in the tank will slowly go down but the electrolyte will continue in the system with an increase of

the concentration and, therefore, amperage being drawn into the generator. This means that when you start

using the system, with the tank full (Max level), you have 8,0A and after some time when the tank is at the

lower point (Min level) you will have 10,0A

If you put too much electrolyte, there are a combination of heating factors at work and can cause a situation

called Thermal Runaway, where an increase in ambient temperature combined with excess electrolyte mix

leads to overheating in the generator shortening the “life” of system.

When applying a direct current to the HHO generator, a high resistance will be present in the water

(electrolyte mixture). High resistance generates heat causing the water to heat up. As the temperature rises,

the resistance in the water goes down, allowing more current to pass through the fuel cell. By the end of the

day, the current will be higher than the value you started with at the beginning of the day. One way to control

this is using a PWM –Pulse Width Modulator

DC2000 –Installation Manual 19

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

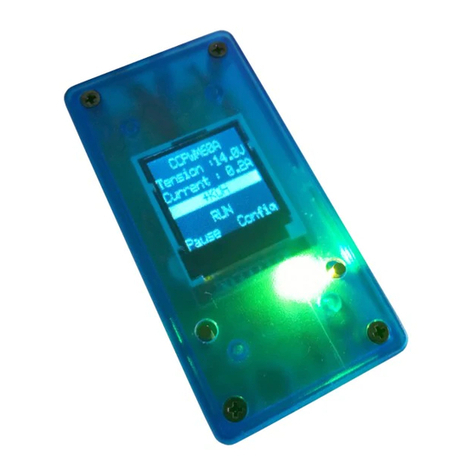

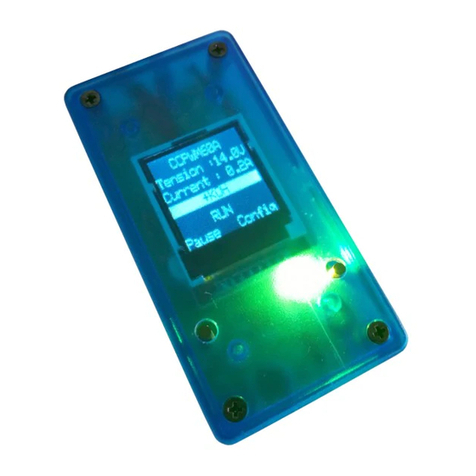

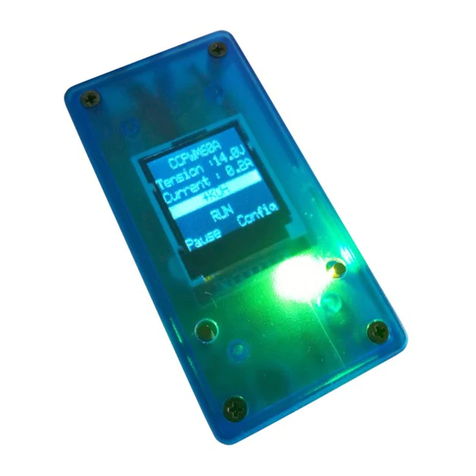

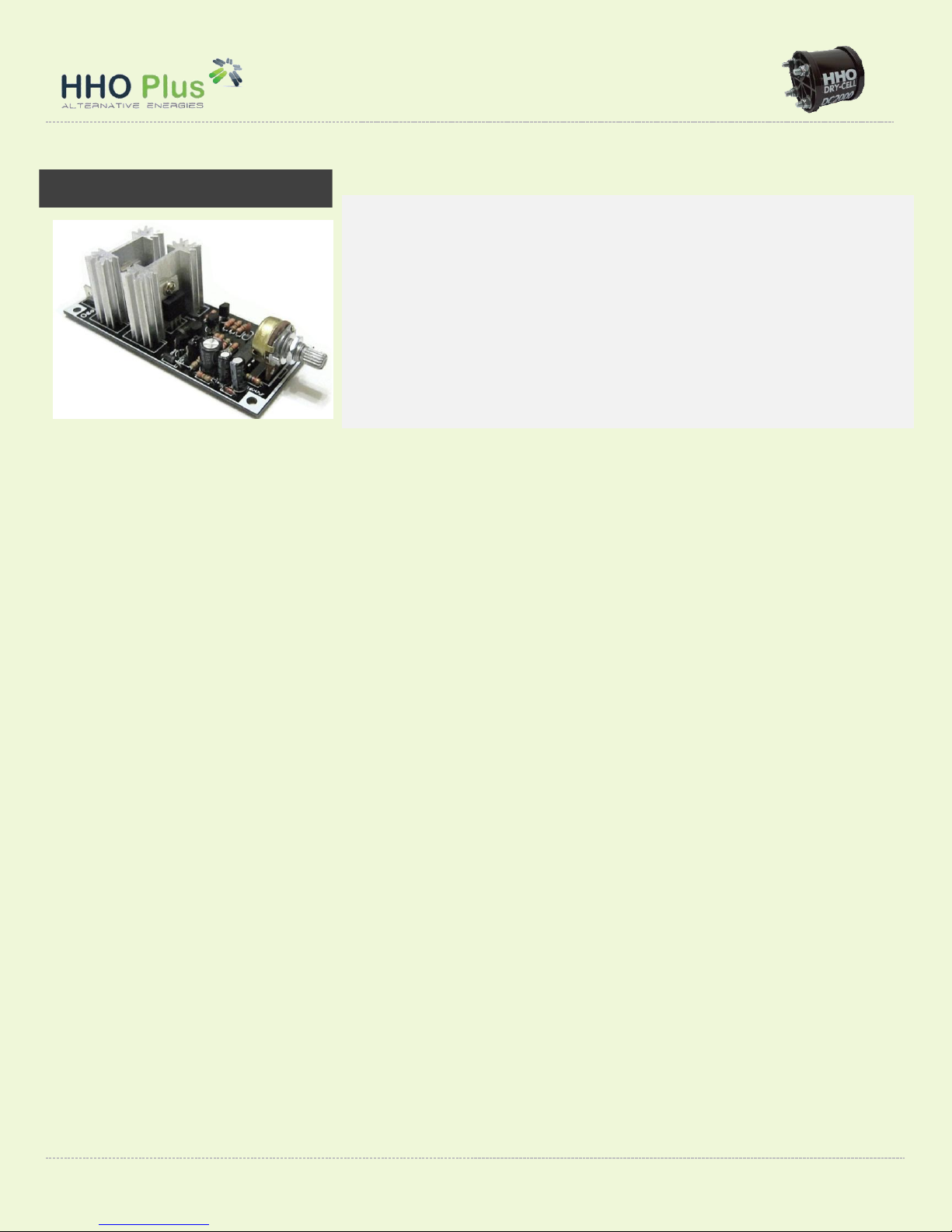

PWM PULSE WIDTH MODULATOR

Pulse Width Modulation, is a method of transmitting information on a series of

pulses, changing the frequency, rather than a continuously varying analog signal. It

will allow you to control the amperage going into the generator in a very easy way.

This ability keeps the cell running at cool operating temperatures and prolongs the

life of the cell while increasing the HHO output

Efficiency: HHO generators will run cooler than standard linear power amps,

requiring substantially less heat sink mass;

Amperage control: the control of the amperage going into the generator will be very

easy to control. The ability to control the amperage keeps the cell running at cool

operating temperatures and prolongs the life of the cell while increasing the HHO

output.

DC2000 –Installation Manual 20

HHO Plus, Alternative Energies, Lta –Travessa das Serras 33, Vieira de Leiria, Portugal –Tel. 00351244697116 –Email: [email protected]

Electronic fuel injection

Basic Information

When adding a HHO gas to the engine of an old car, we will see immediate economies in fuel consumption.

However, this is not the case for some modern electronic fuel injected vehicles equipped with an engine

control unit (ECU), because the fuel burned inside the cylinders has significantly improved, but the sensors

continue expecting the same amount of unburned oxygen to come out of the exhaust of the engine.

This causes a signal to be fed back to the ECU, that after will give orders to inject more fuel increasing the

air/fuel mixture (Richer), which will counter act the fuel gains you may be expecting.

So we need to make some changes according to the cars*

1

. The different possibilities are:

1.1 Petrol Engines –Carburetor (before 1992)

Fuel savings: 30 –45%

Requirements: Right amount of HHO inside the engine. Tune the carburetor.

1.2 Petrol Engines –Electronic Injection (1992-2001)

Fuel savings: 20 –30%

Requirements: Right amount of HHO inside the engine. Reset the ECU. Install the lambda sensor extender.

Isolate the body of the lambda sensors;

Optional: MAF/MAP Sensor Enhancer to increase fuel savings

1.3. Petrol Engines –Electronic Injection (2001-2012)

Option 1

Fuel savings: 20 –30%

Requirements: Right amount of HHO inside the engine. Reset the ECU. Install the lambda sensor extender.

Isolate the body of the lambda sensors;

Optional: MAF/MAP Sensor Enhancer to increase fuel savings

Option 2

Fuel savings: 25 –35%

Requirements: Right amount of HHO inside the engine. Reset the ECU. Install the HEC Chip

2.1. Diesel Engines –Mechanic Pump (before 1998)

Fuel savings: 20 –35%

Requirements: Right amount of HHO inside the engine. Tune the injection rate of the fuel pump.

1

The dates can change according to each country and manufacturers.

Table of contents

Other HHO Plus Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

WeatherTech

WeatherTech No-Drill MudFlap installation instructions

Goobay

Goobay 11425 user manual

Classic Accessories

Classic Accessories QuadGear Extreme ATV EVOLUTION FRONT RACK... quick start guide

Audiovox

Audiovox 50-0312x SERIES installation instructions

Thule

Thule 1101 instructions

Prorack

Prorack K1215 instructions

Circutor

Circutor Raption 150C Series instruction manual

Conrad

Conrad TK-3008-4 operating instructions

Metra Electronics

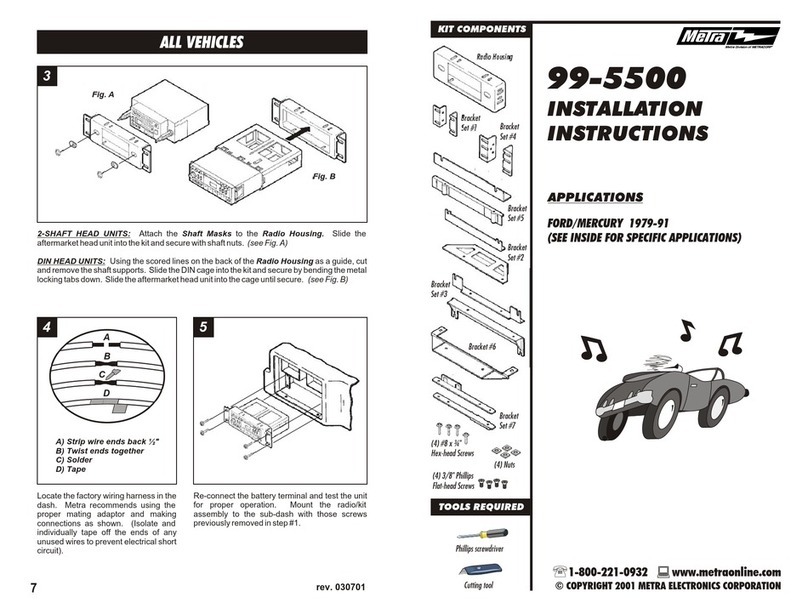

Metra Electronics 99-5500 installation instructions

ECS Electronics

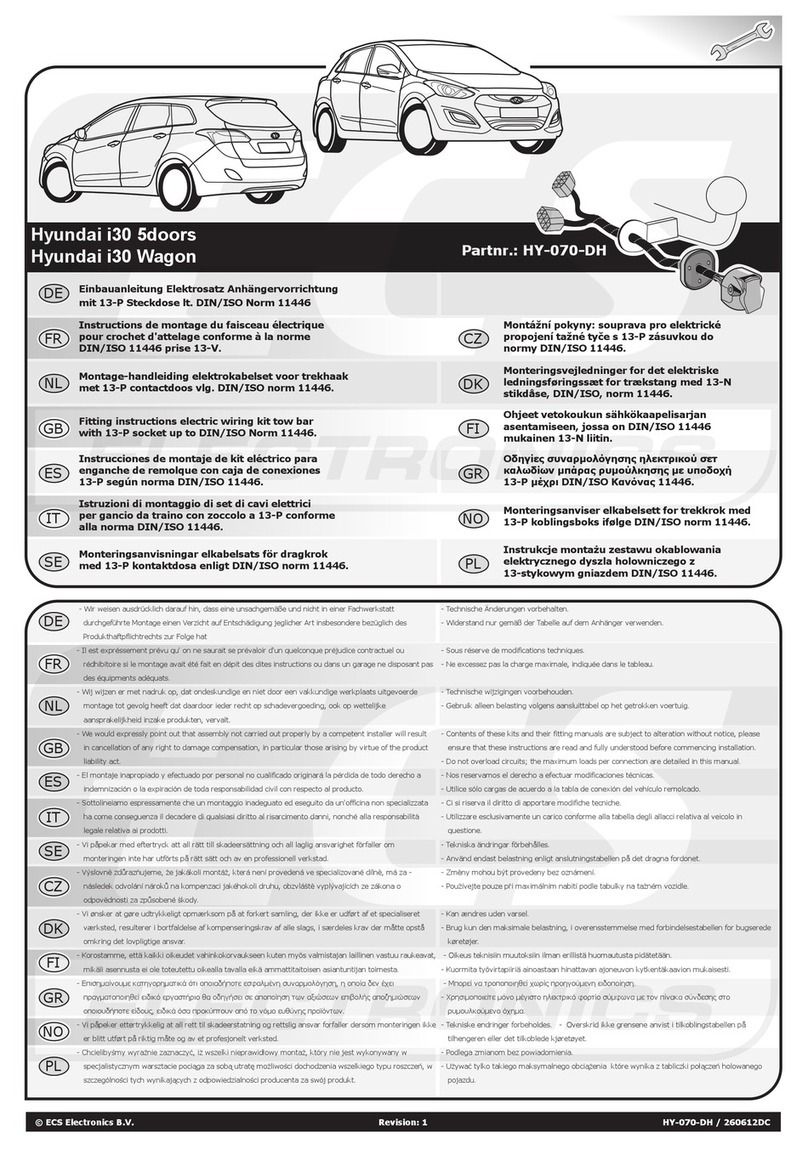

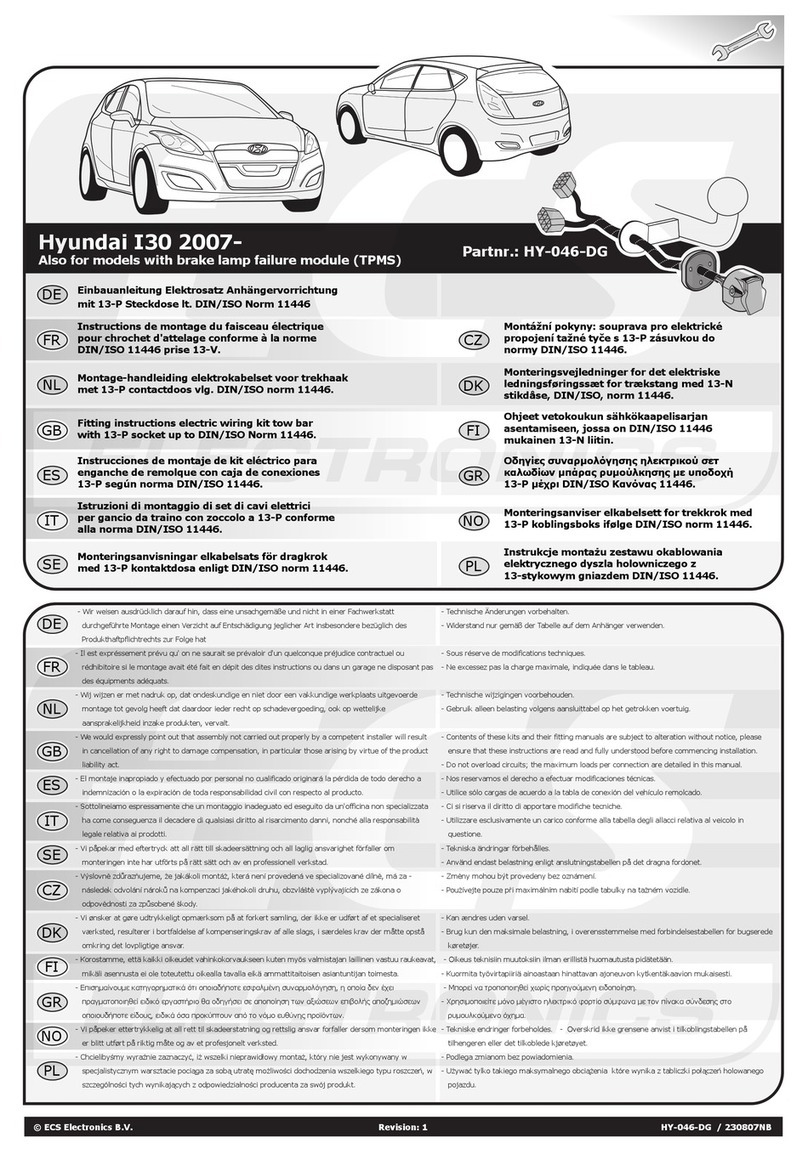

ECS Electronics HY-046-DG Fitting instructions electric wiring

Bully Dog

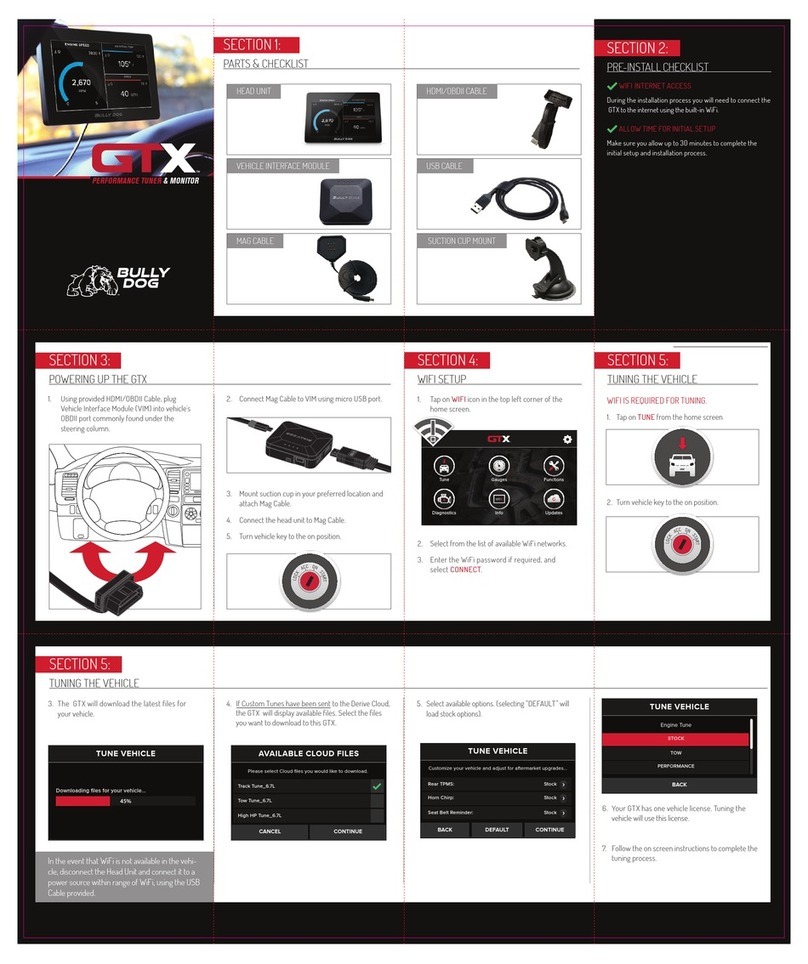

Bully Dog GTX user manual

Opel

Opel OPEL INSIGNIA Infotainment manual