Hi-Force SJS10-M Quick guide

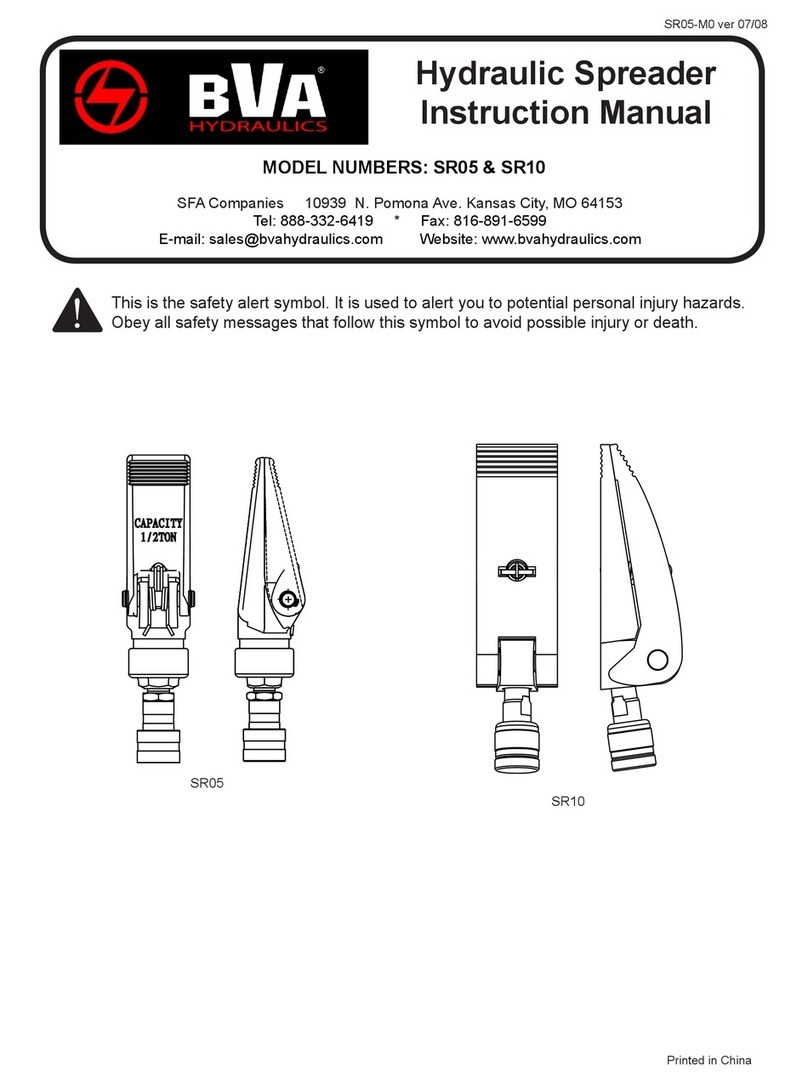

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 1of 9

The Hi-Force SJS10-M hydraulic spreader is a self contained unit, the spreaders are

despatched from the factory pre-filled with oil, and are ready for use.

INSPECTION UPON RECEIPT OF GOODS

On initial receipt of goods visually check for transit damage. If found contact the carrier

immediately.

SAFETY

Read these instructions and safety warnings fully. Failure to do so could result in Death,

Personal injury or equipment damage.

.

Wear suitable personal protection equipment when operating hydraulic equipment.

Keep all body parts away from tool and work piece / load.

Do not work on an assembly held open only by hydraulic means. Always use the safety

block provided to keep a joint open.

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 2of 9

OPERATION

The inbuilt pump is used to advance the tool and the tool is retracted with the aid of a

spring assisted return function.

Hi-Force SJS10M wedges can be used in any orientation.

In instances where the tool is used for separating a pipe flange, for example to

replace the gasket, it is often advantageous to use two spreading wedges

opposite each other. Please consult your distributor for details.

Be aware that as the tool expands, the wedge protrudes out of the end of the

tool as shown in the diagram. The maximum protrusion of this wedge is 49mm.

Ensure there will be no obstruction beyond the tips of the jaws as the tool is

operated. This will damage the tool and the equipment being worked upon.

Ensure that the wedge step is inserted as far as possible into the components to be

separated. Do not hammer the tool into a gap which is too small.

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 3of 9

Using the key on the end of the operating lever, turn release valve screw clockwise to

close. Do not use excessive force.

Operate the pump to expand the wedge.

Insert a safety block into the gap and then with the key on the end of the operating lever

turn the release valve screw anti-clockwise to open i.e. release hydraulic pressure. So the

gap is held open by the safety block whenever it is required to work within the opened

space. Do not rely on hydraulic means to keep a gap open.

Keep fingers and other body parts clear of closing gaps as the wedge contracts.

When it is necessary to increase the spreading capacity of the tool, one or two stepped

blocks can be added as required (one each side as shown in the diagram). Attach the

stepped blocks with fixing screws as shown.

Note: in certain circumstances when the hydraulic pressure is released and the tool is

under external load, the tool will not retract. A gentle blow on the side of the wedge from a

soft mallet is usually enough to free up the tool. If this occurs repeatedly it may be that the

wedge is un-lubricated or possibly has been damaged in use.

CARE AND MAINTENANCE

Before each use fully expand the tool and grease the exposed protruding wedge surfaces

with molybdenum disulphide grease. This will help to ensure smooth operation and

prolong the life of the tool.

Always use genuine Hi-Force hydraulic oil. The use of other fluids may invalidate your

warranty.

After use, always fully retract the tool.

Protect tools from the elements when not in use. If storing for prolonged periods, grease

exposed metal parts. Never store the tool in an expanded condition.

To protect your warranty, have your cylinder serviced and repaired by an authorised Hi-

Force repairer. Only use genuine Hi-Force spare parts. Spare parts sheets can be

downloaded from our website www.hi-force.com

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 4of 9

TROUBLESHOOTING

Refer to the following table to help identify the most common faults:-

PROBLEM

POSSIBLE CAUSE

Tool will not expand

Pump release valve open

Pump oil level too low

Pump malfunctioning

Pump pressure relief valve set too low

Load too great for tool

Tool already at full stroke

Tool only advances part way

Pump oil capacity insufficient

External obstruction

Tool does not advance smoothly

Air in system

Tool advances but will not hold load

Leaking seals

Pump or valve malfunctioning

Tool leaking

Cylinder damage

Seal damage

Tool slow to retract/does not retract

Broken retract spring

Damaged wedge

Valve malfunction

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 5of 9

NOTE(S):-

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 6of 9

NOTE(S):-

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 7of 9

NOTE(S):-

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 8of 9

UK Head Office:

Hi-Force Limited

Prospect Way

Daventry

Northamptonshire

NN11 8PL

United Kingdom

Tel: + 44 1327 301000

Fax: + 44 1327 706555

Email: daventry@hi-force.com

Hi-Force Regional Offices:

Hi-Force Australia Pty. Ltd

Rockingham

Australia

Tel: +61 8 9591 1288

Email: australia@hi-force.com

Hi-Force Hydraulics (Asia) S.B

Selangor

Malaysia

Tel: +603 5569 4209

Email: malaysia@hi-force.com

Hi-Force Nederland BV

Strijen

Netherlands

Tel: +31 78 6745488

Email: holland@hi-force.com

Hi-Force Hydraulics (Pty) Ltd

Midrand

South Africa

Tel: +27 11 314 0555

Email: south.africa@hi-force.com

Hi-Force Hydraulic Equipment

(Shanghai) Ltd. Co.

Shanghai, China

Tel: +86 21 6697 3010

GLOBAL BRAND. LOCAL

SERVICE.

www.hi-force.com

SJS10-M HYDRAULIC STEPPED JAW SPREADER

OPERATING AND SAFETY INSTRUCTIONS

TDS:-

1374

Prepared by:-

Matthew Hughes

Approved by:-

Mark Dalley

Date:05/12/12

REV NO:-

002

ECO:-

3957

Page 9of 9

Table of contents