2. Turn the impeller by hand to make sure it is free. If it does

not turn or if pump is tripping circuit breaker, or not operating

properly after cleaning, return to Little Giant or its authorized

service center. Do not attempt repairs yourself. If it does turn,

replace volute and re-install into parts washer.

3. Be certain power cord is protected from solvent and has no

nicks or cuts.

Do not remove housing screws.Will void warranty.

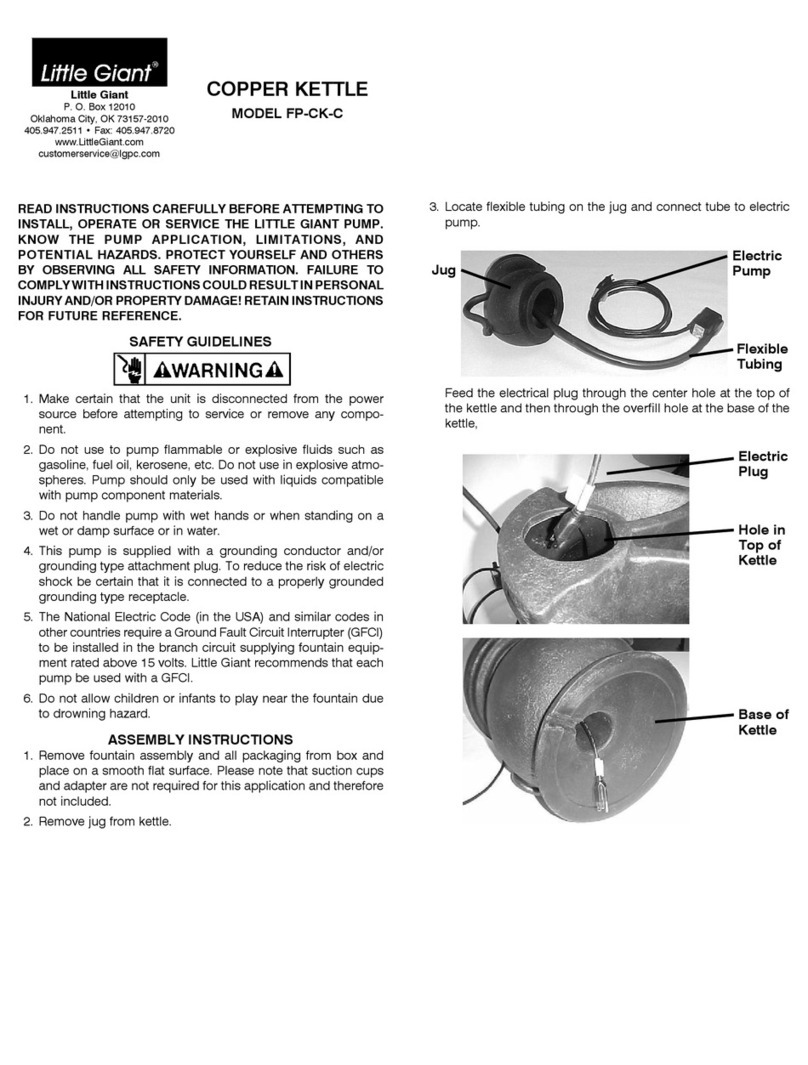

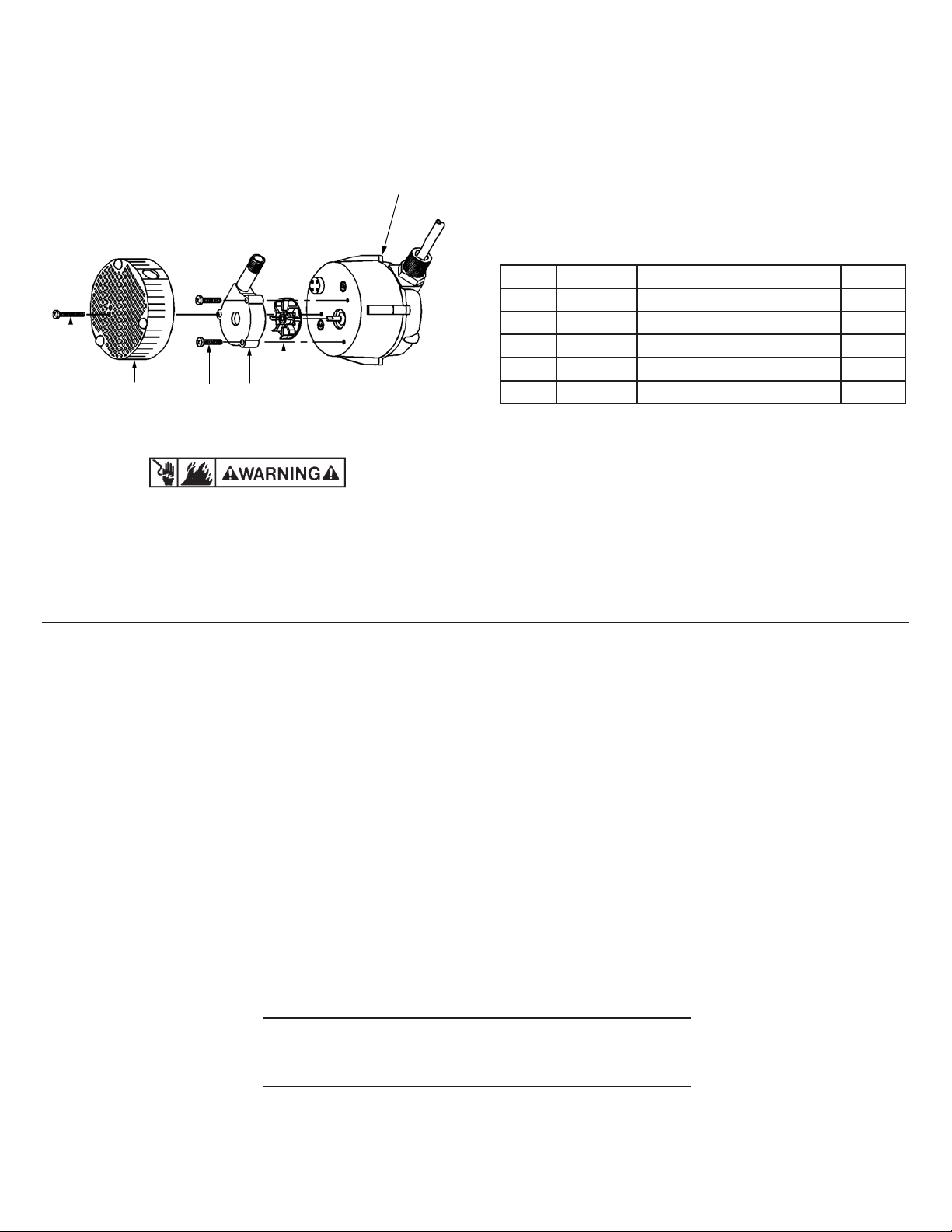

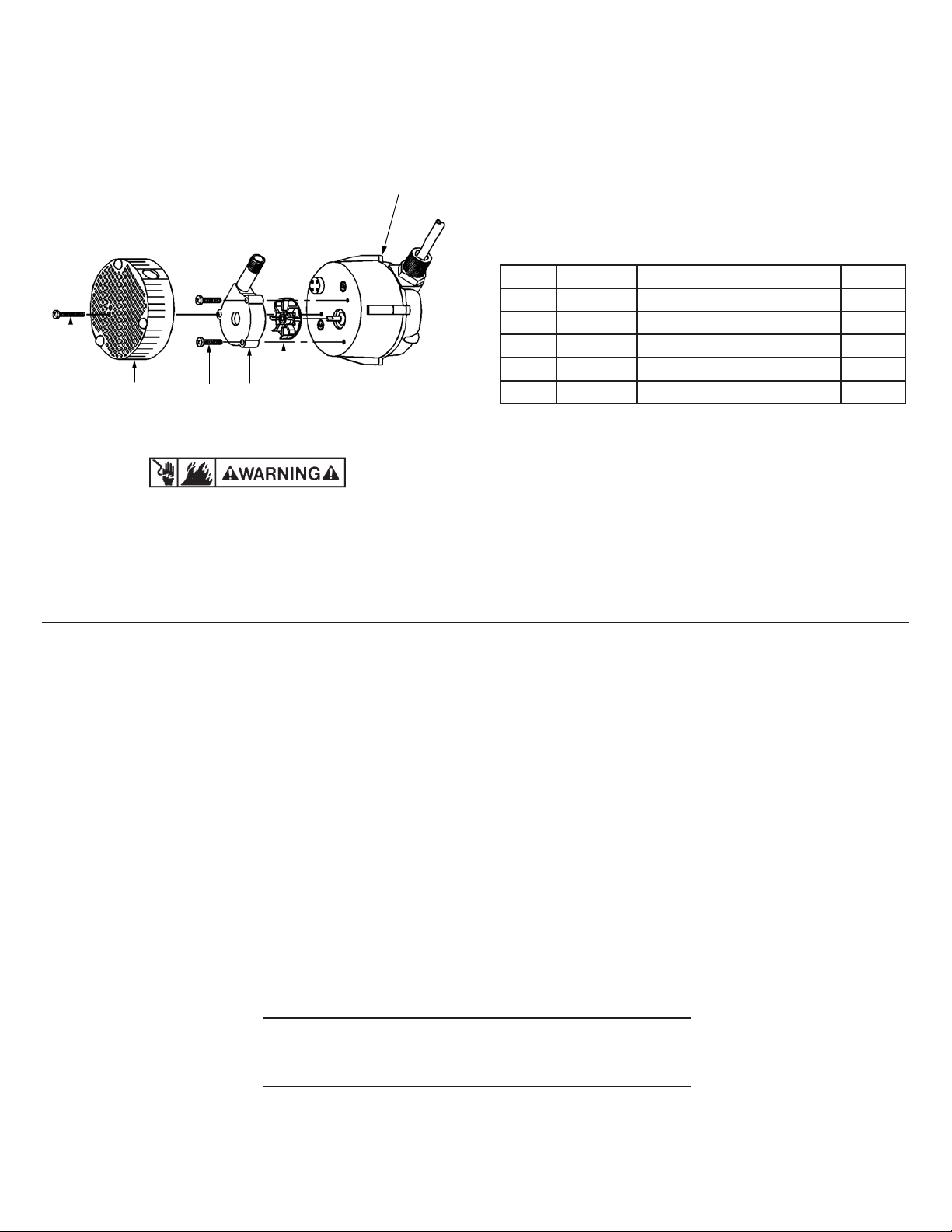

51 234

Figure 2

TROUBLESHOOTING

CAUTION: Do not open the sealed portion of the unit or remove

the housing screws.

1. Should the unit fail to operate, check the following:

a. Power supply and connections

Form 993855 - 12/2007

© 2007 Franklin Electric Co., Inc.

Little Giant® is a registered trademark of Franklin Electric Co., Inc.

b. Is the pump below liquid level?

c. Is air trapped in the pump head?

d. Is there sediment build-up over pump inlet?

2. An air lock or bubble will prevent the unit from pumping.

Trapped air can usually be removed by turning the pump

off and restarting. Ensure that the discharge line is sloping

upward to prevent formation of air pockets.

3. If these operations do not restore the unit to full service, call

your dealer or service technician.

REPLACEMENT PARTS

ITEM PART NO. DESCRIPTION QTY.

1 101903 Screen 1

2 902411 Screw, 8-18 X 1” 2

3 101351 Volute 1

4 101433 Impeller assembly 1

5 902408 Screw, #8 self-tapping 1

LITTLE GIANT WARRANTY STATEMENT

Your Little Giant product is guaranteed to be in perfect condition when it leaves

our Factory. It is warranted against defective materials and workmanship for

a period of 12 months from date of purchase by the user. Any product that

should fail for either of the above two reasons and is still within the warranty

period, will be repaired or replaced if returned prepaid to our Factory. All

defective products returned under warranty will be fully inspected to determine

“CAUSE OF FAILURE” before any warranty is approved. Little Giant will honor

the warranty within the warranty time period specified on satisfactory written

proof of purchase.

DISCLAIMER: Any oral statements about the product made by the seller,

the manufacturer, the representatives or any other parties, do not constitute

warranties, shall not be relied upon by the user, and are not part of the contract

for sale. Seller’s and manufacturer’s only obligation, and buyer’s only remedy,

shall be the replacement and/or repair by the manufacturer of the product as

described above. Neither seller nor the manufacturer shall be liable for any

injury, loss or damage, direct, incidental or consequential (including, but not

limited to, incidental or consequential damages for lost profits, lost sales, injury

to person or property, or any other incidental or consequential loss), arising

out of the use or the inability to use the product, and the user agrees that no

other remedy shall be available to it. Before using, the user shall determine

the suitability of the product for his intended use, and user assumes all risk of

liability whatsoever in connection therewith. The warranty and remedy described

in this limited warranty is an EXCLUSIVE warranty and remedy and is IN LIEU

OF any other warranty or remedy, expressed or implied, which other warranties

and remedies are hereby expressly EXCLUDED, including but not limited to

any implied warranty of MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Some states do not allow the exclusive or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to

you. This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Warranty will be VOID if any of the following conditions are found:

1. Sealed motor housing opened.

2. Product connected to voltage other than indicated on name plate.

3. Cord cut off to a length less than three feet.

4. Pump allowed to operate dry (fluid supply cut off).

5. Product abused by customer.

6. Pump used to circulate anything other than room temperature PJQU, UL

Classified Metal Parts Cleaning Solvents with a minimum flash point of

100 deg. F. Highly flammable fluids such as gasoline, some chlorinated

solvents, alcohols, acetone, or toluol should not be used. These fluids are

dangerous and may cause explosions or fire.

For parts or repair, please contact . . . . . . . . . . . . . . . . . . . . 1.888.572.9933

For technical assistance, please contact . . . . . . . . . . . . . . . 1.888.956.0000

www.LittleGiantPump.com