OVERALL DIMENSIONS

LITTLE GIANT WARRANTY STATEMENT

Your Little Giant product is guaranteed to be in perfect condition when it leaves our Factory. It is warranted against defective materials and

workmanship for a period of 12 months (90 day warranty on Models: 1-AA-OM, GKPK-SC, PP-1, PPS-1, PP-12, PPS-12 , PP-230 and Cooler King)

from date of purchase by the user. No warranty on brush wear in Model 35-OM and impeller or cam in Models PP-1, PP-12, and PP-230. Any

product that should fail for either of the above two reasons and is still within the warranty period will be repaired or replaced if returned prepaid to our

Factory. All defective products returned under warranty will be fully inspected to determine "CAUSE OF FAILURE" before any warranty is approved.

Little Giant will honor the warranty within the warranty time period specified on satisfactory written proof of purchase.

DISCLAIMER: Any oral statements about the product made by the seller, the manufacturer, the representatives or any other parties, do not constitute

warranties, shall not be relied upon by the user, and are not part of the contract for sale. Seller’s and manufacturer’s only obligation, and buyer’s only remedy,

shall be the replacement and/or repair by the manufacturer of the product as described above. Neither seller nor the manufacturer shall be liable for any injury,

loss or damage, direct, incidental or consequential (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss), arising out of the use or the inability to use the product, and the user agrees that no other remedy shall

be available to it. Before using, the user shall determine the suitability of the product for his intended use, and user assumes all risk of liability whatsoever in

connection therewith. The warranty and remedy described in this limited warranty is an EXCLUSIVE warranty and remedy and is IN LIEU OF any other

warranty or remedy, expressed or implied, which other warranties and remedies are hereby expressly EXCLUDED, including but not limited to any implied

warranty of MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow the exclusive or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Warranty will be VOID if any of the following conditions are found:

1. Sealed motor housing opened.

2. Product connected to voltage other than indicated on name plate.

3. Cord cut off to a length less than three feet.

4. Pump allowed to operate dry (fluid supply cut off).

5. Pump used to circulate anything other than fresh water, light oils, or other mild liquids at approximately room temperature.

6. Product abuse by customer.

The National Electric Code requires a Ground Fault Circuit Interrupter (GFCI) be installed in the branch circuit supplying fountain

equipment rated above 15 volts. Part number 599335, GCI-1, is in stock and we recommend each pump be used with a GCI.

LIMITED

WARRANTY

LIMITED

WARRANTY KEEP THIS FOLDER

File this for safe keeping. It may be valuable to you for service

under the term of the warranty.

Date of Purchase _______________________________________

Name of Dealer ________________________________________

Little Pump Company

GIANT

Little Giant Pump Company

P.O. Box 12010

Oklahoma City, OK 73157-2010

(405) 947-2511 • Fax: (405) 947-8720

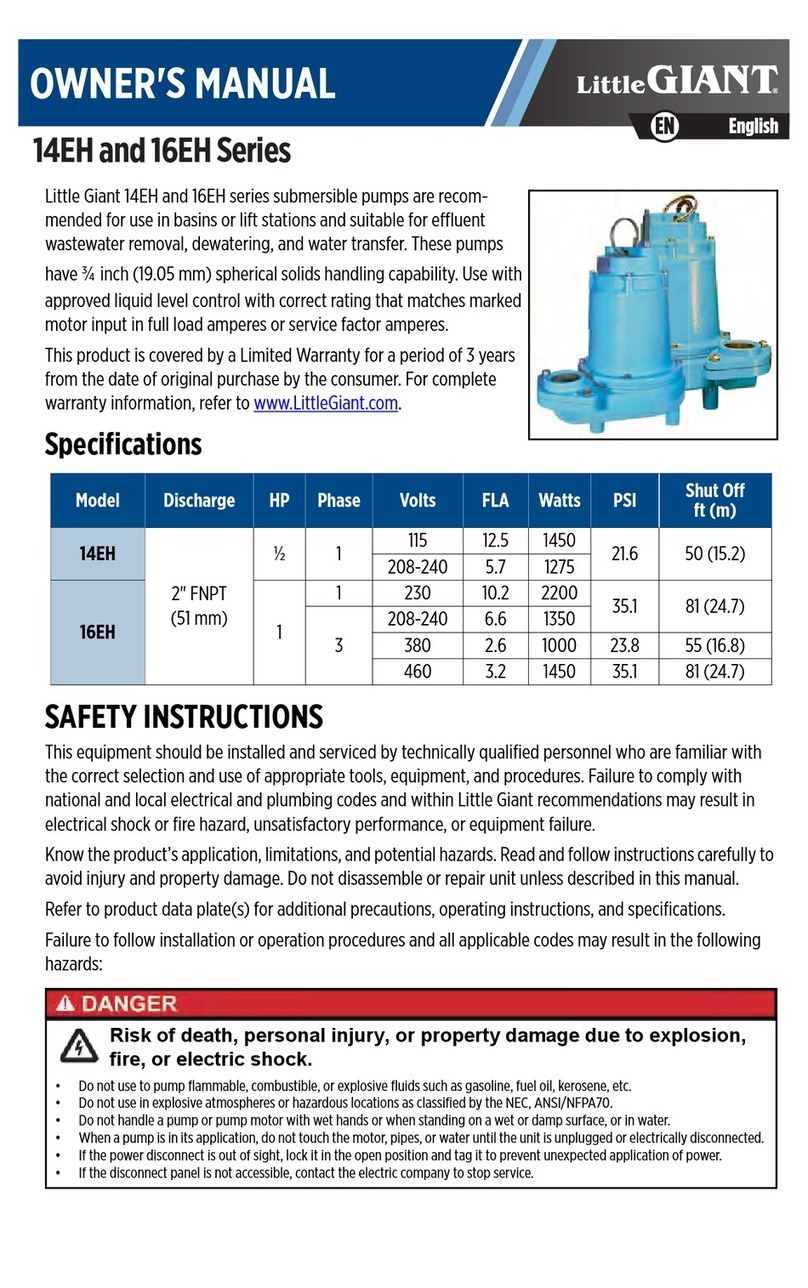

TOTAL HEAD IN FEET

CAPACITY IN U.S. GALLONS PER MINUTE

PUMP PERFORMANCE CURVE*

CMD-100 SERIES

115 VOLTS, AC 60 HZ.

A = CMD-100-3B

B = CMD-100-5B

*Pumping Room Temperature (23° C) water

For Replacement Parts, contact:

Grainger Parts

1657 Shermer Road

North Brook, IL 60062-5362

Phone: 800.323.0620

Fax: 847.498.3402

PumpAgents.com - Click here for Pricing/Ordering

PumpAgents.com - Click here for Pricing/Ordering