HID Aero X1100 User manual

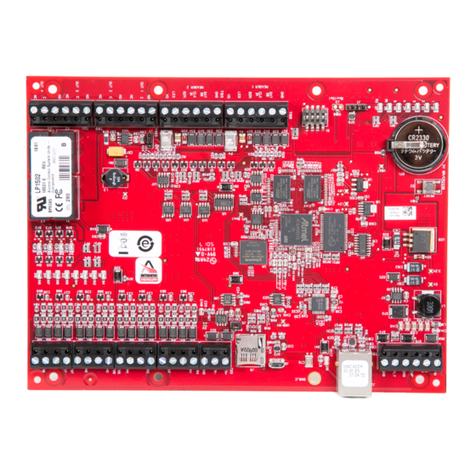

HID Aero™ X1100

Intelligent Controller

Up to 4 Readers, 7 Inputs, 4 Outputs PLT-04233, Rev. A.3

© 2019 - 2020 HID Global Corporation/ASSA ABLOY AB. All rights reserved. HID, the HID Brick logo, the Chain Design, HID Aero, and HID Signo are trademarks or registered

trademarks of HID Global, ASSA ABLOY AB, or its aliate(s) in the US and other countries and may not be used without permission. All other trademarks, service marks, and

product or service names are trademarks or registered trademarks of their respective owners.

hidglobal.com An ASSA ABLOY Group brand

INSTALLATION GUIDE

Supplied parts

HID Aero X1100 Intelligent Controller (1)

Installation guide (1)

Mounting screws (4) 0.138" × 1" (3.5 mm × 25 mm)

Casing screws (4) 0.118" × 0.75” (3 mm × 20 mm)

Recommended parts

(not supplied)

Certified DC power supply

Drill with various bits for mounting hardware

For DIN rail mounting: Brackets (2) - Phoenix Contact,

USA 10 Series Rail Adapter, part number 1201578.

Screws (4) - Self tapping, countersunk,

3.0 mm × 10 mm (or 3.0 mm × 8 mm)

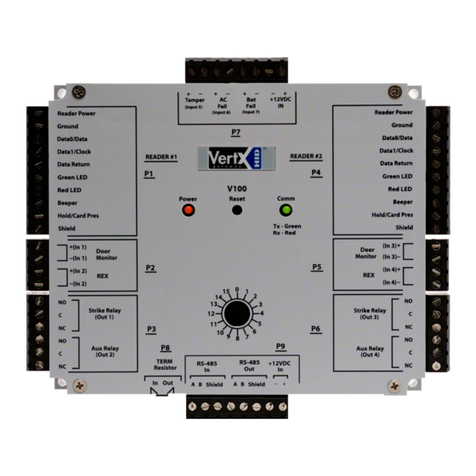

X1100 Overview

The X1100 performs intelligent access control operations, input monitoring and output control for up to:

64 readers, 64 doors, 615 inputs, 388 outputs.

CABLE REQUIREMENTS (NOT SUPPLIED)

Host–Ethernet CAT-5, 328 ft (100 m)

Readers–OSDP

4 conductor twisted pair over-all shield,

Belden 3107A or equivalent. 2000 ft

(610 m) maximum. Utilize one pair for

data and one pair for power

Readers–

Wiegand / C&D

4-conductor, 18 AWG, shielded, 500 ft

(150 m) maximum

IO Modules*

One twisted pair, shielded. 120Ω

impedance, 24 AWG, 4,000 ft

(1,219 m) maximum

Alarm Inputs One twisted pair, 30Ωmaximum,

typically 22 AWG, 1000 ft (304.8 m)

Power and Relays 2-conductor shielded

18 to 16 AWG, 500 ft (150 m)

*VertX wire specifications are compatible with X1100. Utilize existing

VertX V100, V200 and V300 RS-485 wiring when attaching to X1100.

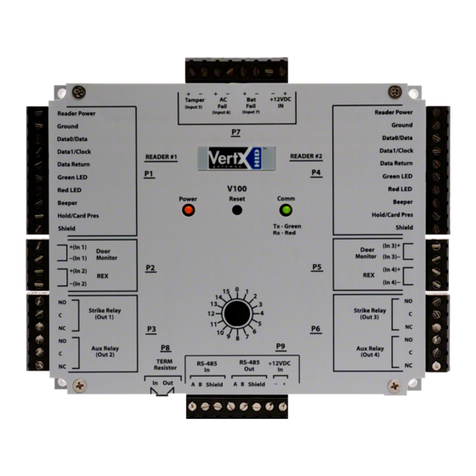

RELAYS 1-4

See step 5.

INPUTS 1-4

See step 7.

INPUTS 1-4

See step 7.

READERS 1-2

See step 4.

POWER, TAMPER, AC FAIL, BATT FAIL

See step 8.

DIP SWITCH

See step 6.

Status LEDs

See page 6

IO MODULE PORTS

See step 3.

RELAYS 1-4

See step 5.

READERS 1-2

See step 4.

4.53"

(115 mm)

5.51"

(140 mm)

HID Aero™ X1100 Installation Guide

PLT-04233, Rev. A.32

Powering

Trusted Identities

ATTENTION

Observe precautions for handling

ELECTROSTATIC SENSITIVE DEVICES

Always mount the controllers and interface panels

in a secure area.

Mount using the supplied screws 0.138" × 1"

(3.5 mm × 25 mm).

Alternatively mount on a DIN rail using compatible

DIN rail mounting brackets and screws.

See Recommended parts.

Note: The side terminal connectors must be

removed to fit the mounting brackets.

To other

devices

on the

bus

To other

devices

on the

bus

Battery jumper J4

Termination jumper J9

Termination jumper J5

IO MODULE PORT 1 or IO MODULE PORT 2

1. Setting the jumpers

1. If attached, unscrew the four corner casing screws.

2. Remove the X1100 casing to access the battery

jumper and the end of line termination jumpers.

3. Set the battery jumper J4 to ON.

4. Set IO Module Port 1 and 2 end of line termination

jumpers J5 and J9 to IN, only if the X1100 will be the

end of communication bus.

5. Replace the casing and secure with the supplied

four corner casing screws.

Note: The static RAM and the real time clock are

backed up by a lithium battery when input power is

removed. This battery should be replaced annually.

2. Mounting the X1100

3. Communication wiring

Connect the X1100 to additional IO modules using

2-wire RS-485 IO Module ports 1 and 2. Use 1-twisted

pair, shielded cable, 120Ωimpedance, 24 AWG, 4,000 ft.

(1,219 m) maximum.

Each port can support up to 32 (Aero) or 16 (VertX)

IO modules.

Note: Install RS-485 termination jumpers on the

interface boards at each end of the communication

bus only (see step 1 above). Failure to do so

will compromise the proper operation of the

communication channel.

Network connection

The X1100 controller communicates to the host via the

on-board Ethernet 10-BaseT/100Base-TX port.

Ethernet 10-BaseT/

100-TX port

3PLT-04233, Rev. A.3

HID Aero™ X1100 Installation Guide

Powering

Trusted Identities

4. Connecting readers

OSDP (RS-485) signaling requires two 2-conductor

cables. One cable for power (18 AWG) and one

cable for communication (24 AWG, shielded,

twisted pair).

Wiegand or Clock/Data (TTL) signaling requires a

4-conductor cable (18 AWG, shielded) with additional

optional conductors for LED and beeper control.

CAUTION

Readers that require dierent voltage or have high

current requirements should be powered separately.

Refer to the reader manufacture specifications for

cabling requirements.

Note: For OSDP cable lengths greater than 200 ft

(61 m) or EMF interference, install 120Ω+/- 2Ωresistor

across RS-485 termination ends.

Note: Data 0 and Data 1 wires for Wiegand may be

reused for OSDP. However, standard Wiegand cable

may not meet RS-485 twisted pair recommendations.

The reuse of cable works best on shorter cable lengths

at lower data rates.

HID Signo reader

(Wiegand or Clock/Data installation)

Typical reader

(Wiegand or Clock/Data installation)

HID Signo™ reader

(OSDP installation)

Typical reader

(OSDP installation)

READER 1 or

READER 2

READER 1 or

READER 2

READER 1 or

READER 2

READER 1 or

READER 2

HID Aero™ X1100 Installation Guide

PLT-04233, Rev. A.34

Powering

Trusted Identities

- +

To DC power source

Diode

+

-Fuse

DC Strike

RELAY 1 to

RELAY 4

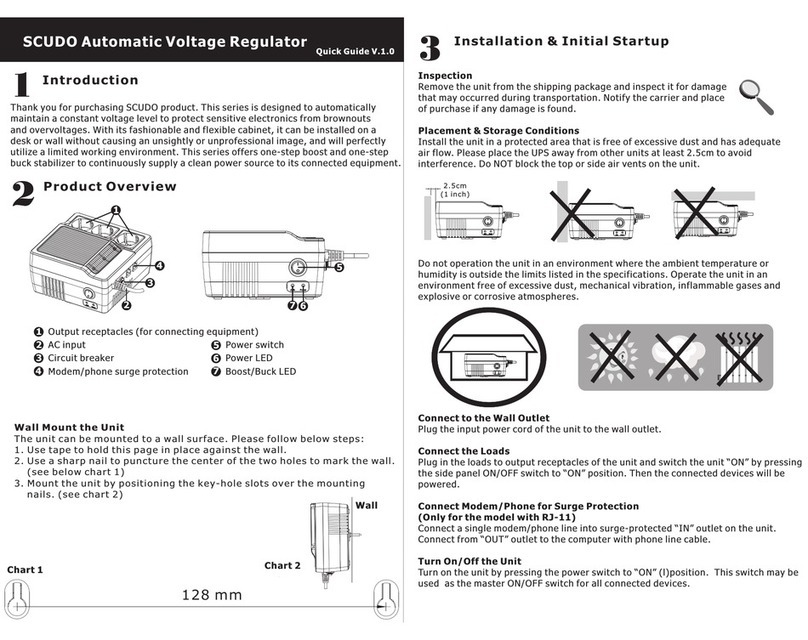

5. Relay circuit wiring

Four relays are provided for controlling door lock

mechanisms or alarm signaling.

When controlling the delivery of power to the door

strike, the NO (Normally Open) and C(Common) poles

are typically used.

When momentarily removing power to unlock the door,

as with a mag lock, the NC (Normally Closed) and C

(Common) poles are typically used.

Check with local building codes for proper egress door

installation.

CAUTION

Door lock mechanisms can generate feedback to the

relay circuit. This can cause damage and premature

failure of the relay, eecting the operation of the

X1100. Use a diode to protect the relay. Use a wire of

sucient gauge to avoid voltage loss.

Diode selection:

Diode current rating: 1x strike current.

Diode breakdown voltage: 4x strike voltage.

For 12 V DC or 24 V DC strike, diode 1N4002

(100V/1A) typical.

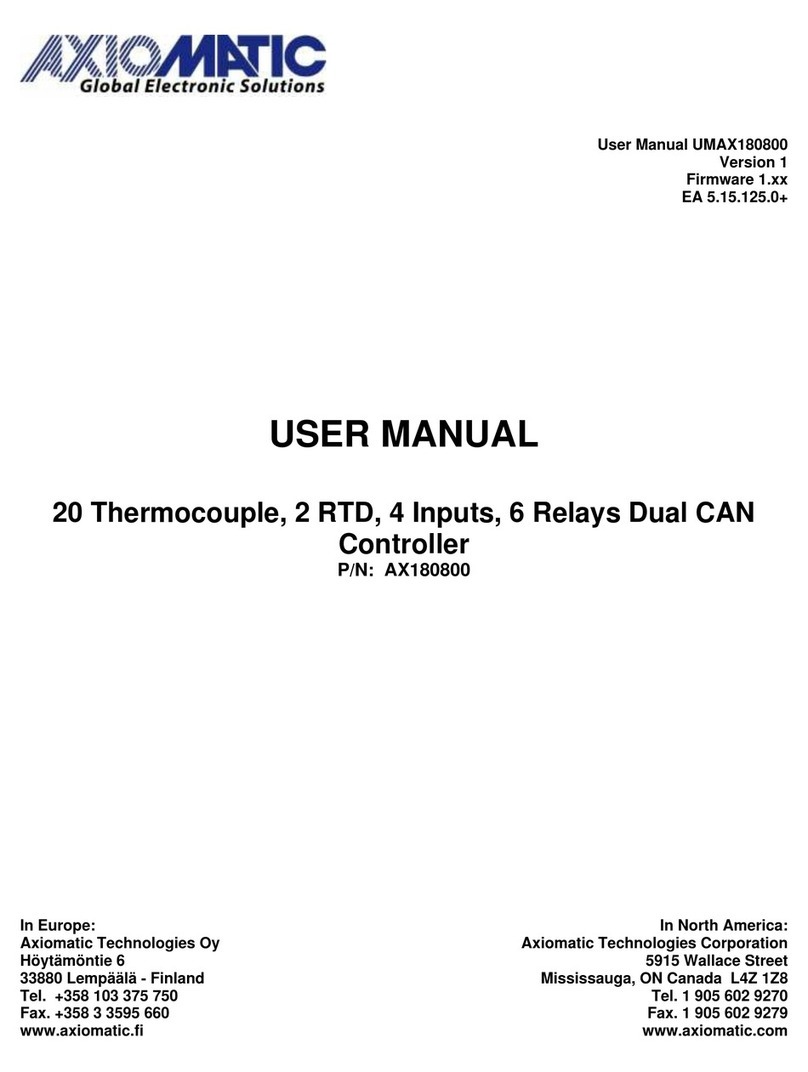

6. DIP switch configuration

The four DIP switches are used to configure the

operating mode of the X1100 processor. DIP switches

are read on power-up except where noted.

Press RESET switch to reboot the X1100.

1 2 3 4 DEFINITIONS

OFF OFF OFF OFF Normal operating mode.

ON X OFF OFF After initialization, enable default User Name (admin) and Password (password). The

switch is read on the fly, no need to re-boot. For additional information, See page 5.

OFF ON OFF OFF Use factory default communication parameters.

ON ON OFF OFF Bulk Erase prompt mode at power up. See page 5.

Note: All other switch settings are unassigned and are reserved for future use. X = don’t care.

Note: In the factory default modes, the downloaded configuration/database is not saved to flash memory.

Factory default communication parameters

Network: static IP address: 192.168.0.251

Subnet Mask: 255.255.0.0

Default Gateway: 192.168.0.1

DNS Server: 192.168.0.1

Primary Host port: IP server, Data Security: TLS if

Available, port 3001, communication address: 0

Alternate Host Port: Disabled

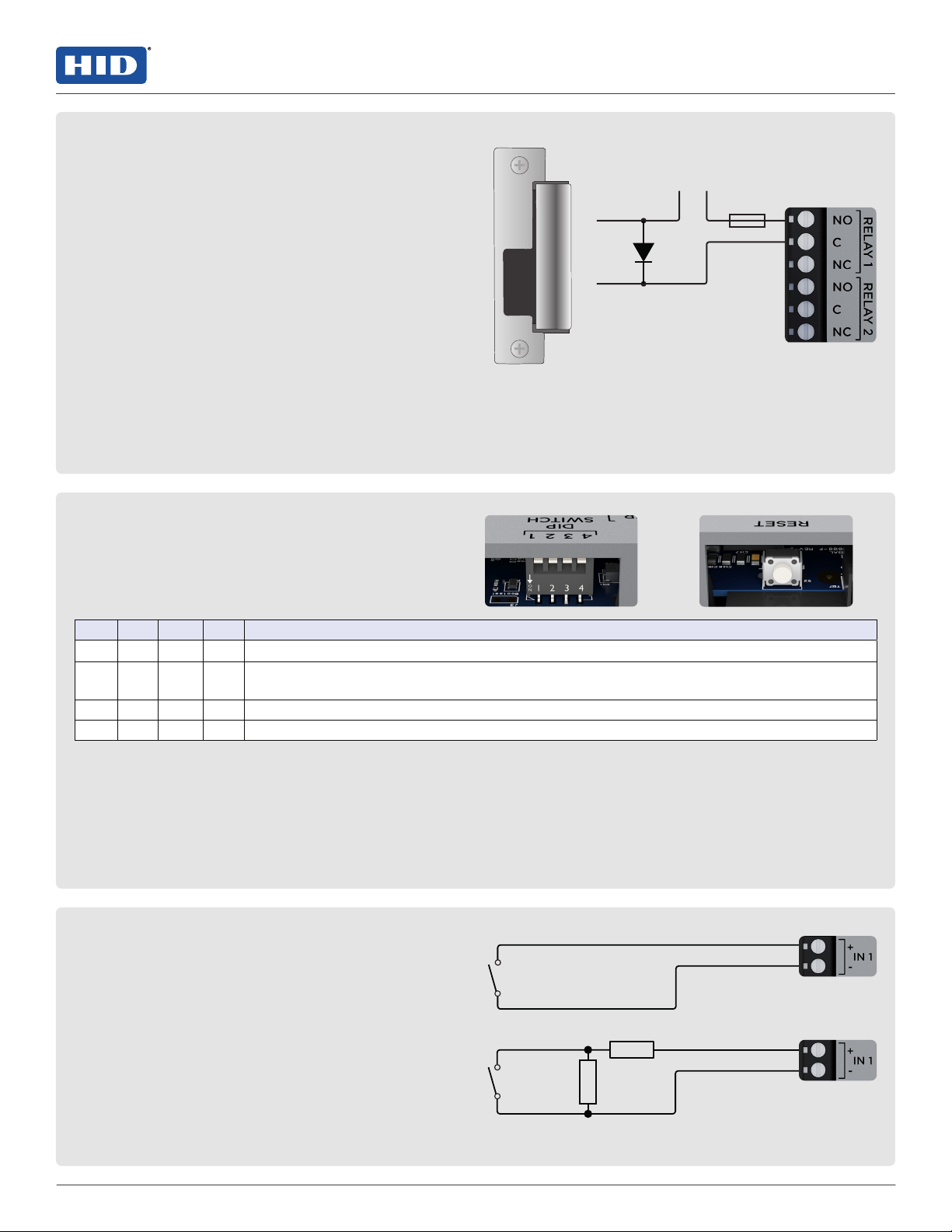

Unsupervised circuit IN 1 to IN 4

Supervised circuit IN 1 to IN 4

7. Input circuit wiring

Inputs are typically used for the following:

To monitor door position.

Request to exit.

Alarm contacts.

Input IN 1 to IN 4 circuits can be configured as

unsupervised or supervised and can use normally open

or normally closed contacts.

For a supervised circuit, add two 1KΩ, 1% resistors as

close to the sensor as possible.

Custom end of line (EOL) resistances may be configured

via the host software.

Note: The input circuit wiring configurations shown are

supported but may not be typical.

1K,1%

1K,1%

5PLT-04233, Rev. A.3

HID Aero™ X1100 Installation Guide

Powering

Trusted Identities

Bulk erase configuration memory

The bulk erase function can be used for the following:

Erase all configuration and cardholder database (sanitize board, less third party applications).

Recover from database corruption causing X1100 board to continuously reboot.

Note: If clearing the memory does not correct the initialization problem, contact technical support.

Bulk erase steps

1. Set DIP switches 1 and 2 to ON, and 3 and 4 to OFF.

2. Apply power to the X1100 board.

3. LED ONLINE is on for about 15 seconds while the X1100 boots up.

4. Change DIP switches 1 or 2 to OFF within 10 seconds, after LEDs ONLINE and HOST COMM and LEDs IO INTERNAL

and IO PORT 1 start flashing alternately at a rate of 0.5 seconds.

Note: If these switches are not changed, the X1100 board will power up using the OEM default communication

parameters.

5. LED HOST COMM will flash, indicating that the configuration memory is being erased.

Note: Full memory erase takes up to 60 seconds.

6. When complete, only LEDs ONLINE and IO PORT 1 will flash for about 3 seconds.

7. The X1100 board will complete its initialization two seconds after LEDs ONLINE & IO PORT 1 stop flashing.

CAUTION: Do not remove power during the bulk erase process.

IT security

Ensure that the X1100 is installed securely. Create user

accounts to the web configuration page using secure

passwords.

Ensure that all DIP switches are in the OFF position for the

normal operating mode.

After powering up the X1100 and connecting Ethernet,

connect to the X1100 configuration manager by opening a

browser and connecting to 192.168.0.251.

The X1100 is shipped with a default login account, which

is enabled when DIP 1 is moved from OFF to ON (See step

6. DIP switch configuration). The default login User Name

(admin) and Password (password) will be available for

five minutes once the DIP switch is toggled. It is therefore

important that at least one user account is defined, and

the DIP switches are set to OFF before the X1100 is

commissioned.

Configuring the X1100 with an IP address that is accessible

from the public Internet is not recommended.

The following options are available to improve network

security:

Disable SNMP.

Disable Zeroconf discovery.

Disable the web configuration module.

Enable data encryption over the host

communication port.

8. Input power, cabinet tamper, and UPS fault input wiring

The X1100 requires 12-24 V DC power. Connect power

with minimum of 18 AWG wire.

Connect the power ground to earth ground in only

ONE LOCATION within the system. Multiple earth

ground connections may cause ground loop problems

and is not advised.

Observe POLARITY on 12-24 V DC input.

Connect the AC FAIL and BATT FAIL inputs to the

corresponding contacts provided on the power supply.

Connect the TAMPER input to a tamper switch on the

enclosure.

TAMPER, AC FAIL, and BATT FAIL connections are

identical to inputs IN 1 to IN 4 and can be configured

as unsupervised or supervised. See step 7. Input circuit

wiring.

HID Aero™ X1100 Installation Guide

PLT-04233, Rev. A.36

Powering

Trusted Identities

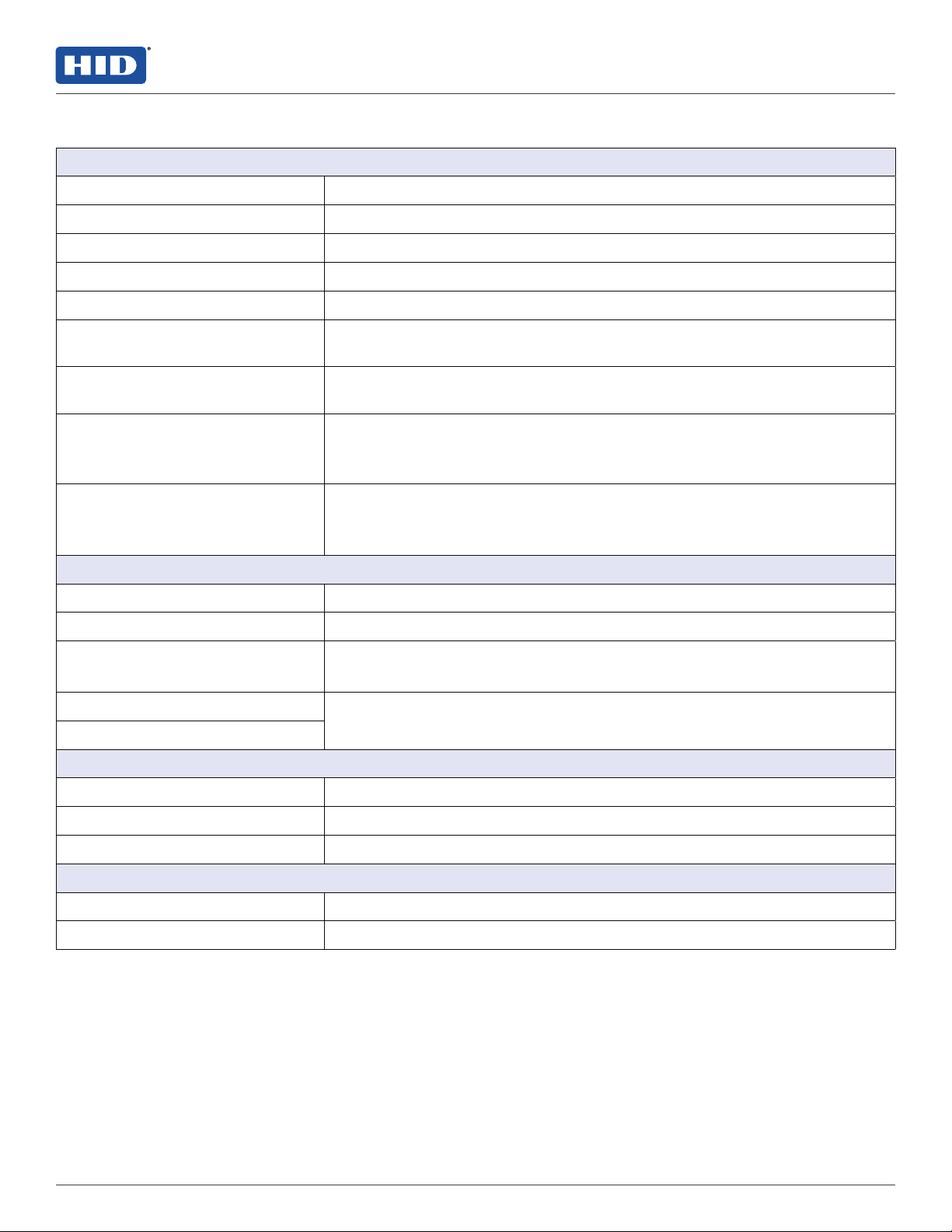

LED POWER ON SELF-TEST NORMAL OPERATION

BATT FAIL On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

AC FAIL On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

TAMPER On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

IN 1 On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

IN 2 On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

IN 3 On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

IN 4 On then OFF OFF = Inactive, ON = Active, Flash = Fault.*

ONLINE ON for approximately 15 seconds

O-Line / On-Line and battery status.

On-Line = A long flash ON and a short flash OFF.

O-Line = A short flash ON and a long flash OFF.

Double flash if battery is low.

HOST COMM ON for approximately 1 second Host communication activity (Ethernet).

IO INTERNAL ON for approximately 1 second Internal IO module communication activity.

IO MODULE PORT 1 ON for approximately 1 second External IO module activity (Port 1).

IO MODULE PORT 2 ON for approximately 1 second External IO module activity (Port 2).

READER 1 ON for approximately 1 second

OSDP Mode = Flashes when transmitting data.

Wiegand or C&D Mode = Flashes when data is received,

either input.

READER 2 ON for approximately 1 second

OSDP Mode = Flashes when transmitting data.

Wiegand or C&D Mode = Flashes when data is received,

either input.

RELAY 1 OFF ON = Energized.

RELAY 2 OFF ON = Energized.

RELAY 3 OFF ON = Energized.

RELAY 4 OFF ON = Energized.

ETHERNET OFF

ETHERNET LED on Cover: Flashing = Ethernet activity

ETHERNET JACK:

Green/Left ON = good link

Yellow/Right is ON = 100 Mb/s and OFF = 10 Mb/s

*If this input is defined, every three seconds the LED is pulsed to its opposite state for 0.1 seconds, otherwise,

the LED is OFF.

Status LEDs

7PLT-04233, Rev. A.3

HID Aero™ X1100 Installation Guide

Powering

Trusted Identities

Specifications

AERO X1100

Input Voltage 12 to 24 V DC ±10%

Maximum Input Current 1.9 A (550 mA excluding readers and USB)

Micro USB Port 5 V DC, 500 mA maximum (reserved for future use)

Memory and Clock Backup Battery 3 Volt Lithium, type CR2032

microSD Card Format: microSD or microSDHC; 2GB to 8GB (reserved for future use)

Host Communication Ethernet: 10Base T/100Base-TX

Micro-USB port (2.0)

IO Modules Two independent ports: 2-wire RS-485, 2,400 to 115,200 bps, asynchronous,

half-duplex, 1 start bit, 8 data bits, and 1 stop bit

Inputs

Seven unsupervised/supervised, standard EOL: 1k/1kΩ, 1%, ¼ watt

(Includes TAMPER, AC FAIL, and BATT FAIL inputs)

UL evaluation for access control use only

Output

Four relays, Form-C with dry contacts:

Normally open contact (NO): 5 A @ 30 V DC resistive

Normally closed contact (NC): 3 A @ 30 V DC resistive

READER INTERFACE

Power 12 V DC ±10%, 500 mA maximum each reader

Data Inputs TTL compatible or 2-wire RS-485

OSDP (RS-485) Mode 9,600 to 230,400 bps, asynchronous, half-duplex, 1 start bit, 8 data bits,

and 1 stop bit. Maximum cable length: 2000 ft. (609.6 m)

LED Output

Open collector, 12 V DC open circuit maximum, 40 mA sink maximum

Beeper Output

ENVIRONMENTAL

Operating Temperature 32 to 158°F (0 to +70°C)

Storage Temperature -67 to 185°F (-55 to +85°C)

Humidity 5 to 85% RHNC

MECHANICAL

Dimension 6.46" × 5.51" × 1.02" (164 mm × 140 mm × 26 mm)

Weight 352 g

These specifications are subject to change without notice.

hidglobal.com An ASSA ABLOY Group brand

HID Aero™ X1100 Installation Guide

Powering

Trusted Identities

Powering

Trusted Identities

PLT-04233, Rev. A.3

Brazil

Condomínio Business Center

Av. Ermano Marchetti, 1435

Galpão A2 - CEP 05038-001

Lapa - São Paulo / SP

Brazil

Phone: +55 11 5514-7100

Asia Pacific

19/F 625 King's Road

North Point, Island East

Hong Kong

Phone: 852-3160-9833

Americas & Corporate

611 Center Ridge Drive

Austin, TX 78758

USA

Phone: 866-607-7339

Europe, Middle East & Africa

3 Cae Gwyrdd

Green Meadow Springs

Cardi CF15 7AB

United Kingdom

Phone: +44 (0) 2920 528 500

15

E4662

Complies with

IMDA Standards

DB106440

Singapore

Regulatory

UL Recognized Component (UL294)

All National and local Electrical codes apply.

This equipment is intended to be powered from a limited power source output, of a UL294 Certified Power Supply.

Install in accordance with NFPA70 (NEC) Local Codes, and authorities having jurisdiction. Follow all National and

Local Codes.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority

to operate the equipment.

UL 294 Performance Levels

MODEL # ACCESS CONTROL

LINE SECURITY LEVEL

DESTRUCTIVE

ATTACK LEVEL

ENDURANCE

LEVEL

STAND-BY

POWER LEVEL CONDITIONS

X1100 Level I Level I Level IV Level I

US-FCC:

Class A Digital Devices FCC Compliance Statement:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at their own expense.

Taiwan-BSMI Class A Notice

警告使用者:

這是甲類的資訊産品,在居住的環境中使用

時,可能會造成射頻干擾,在這種情況下,

伊用者會被要求採取某些適嘗的酎策。

Your HID product is marked to indicate its compliance class:

Federal Communications Commission (FCC) – USA

Industry Canada Equipment Standard for Digital Equipment (ICES-003) – Canada

CE Mark – Europe

RCM Mark – New Zealand and Australia

Voluntary Control Council for Interference (VCCI) – Japan

Bureau of Standards Metrology and Inspection (BSMI) – Taiwan

Infocomm Development Authority (IDA) – Singapore

Korea Communications Commission (KCC) – Korea

UL Recognized Component (UL294)

Japan

この装置は、クラスA機器です。この装置を住宅環境で使用す

ると電波妨害を引き起こすことがあります。この場合には使用者が適切な

対策を講ずるよう要求されることがあります。VCCI -A

Table of contents

Other HID Controllers manuals

HID

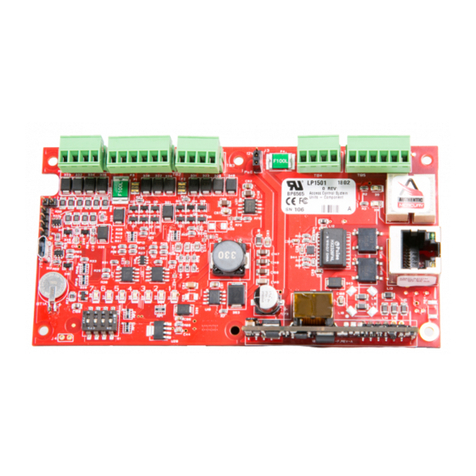

HID Mercury LP1501 User manual

HID

HID Signo 25B User manual

HID

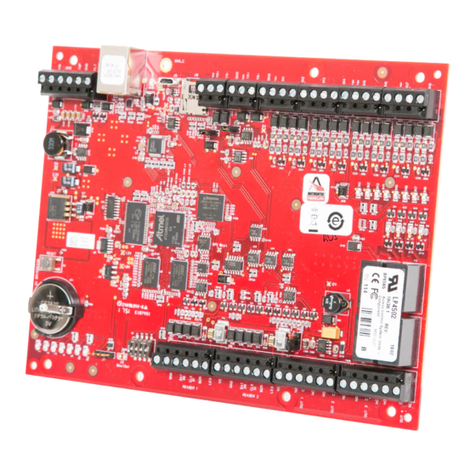

HID Mercury LP4502 User manual

HID

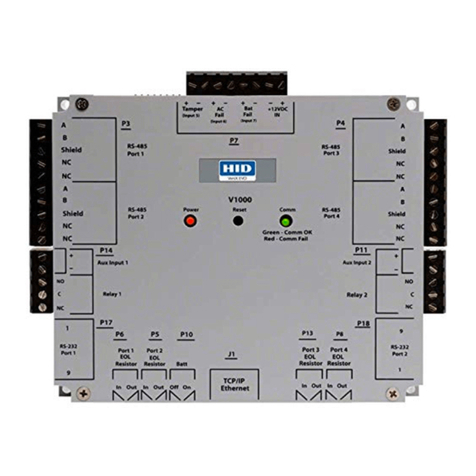

HID VertX EVO V1000 User manual

HID

HID ACW2-XN User manual

HID

HID Mercury LP1502 User manual

HID

HID VertX EVO V2000 User manual

HID

HID iCLASS SE RB25F User manual

HID

HID Vertx CS V100 User manual

HID

HID EDGE EVO EH400-K User manual