Hide-A-Hose HPHS5000W User manual

14490 167th Ave SE

Monroe, WA 98272

(360) 863-0775

HS5000

INSTALLATION GUIDE

Contents

Plan the Installation .................................................1

Rough-In ............................................................2

Determine Valve Height .............................................2

New Construction ...................................................3

Pipe Run Dos & Don’ts ...............................................4

Low Voltage Wire ....................................................6

Test The System .....................................................6

Typical Pipe Runs ....................................................7

Trim .................................................................8

Retro-t an Existing Home .........................................10

Addendum (100716)................................................11

* IMPORTANT*

This Manual assumes that the installer has working knowledge and

experience installing traditional Central Vacuum Systems.

It is critical that only parts supplied by Hide-a-Hose Inc. be used in

the installation.

Parts include screws, seals, washers, hoses, sweep 90’s, 45’s, etc.

Failure to use these parts will void any warranty oered by the manufacturer.

Installers are responsible for adhering to all local building codes.

HS5000

INSTALLATION GUIDE

Plan the Installation

Planning is the key to the successful installation of a central vacuum

system. A balance between the best locations for the inlet valves and the

practicality of installing in those locations must be obtained. With a little

ingenuity most locations can be reached.

* IMPORTANT*

The maximum wall thickness the valve can work with is 1.5 inches (3.8 cm).

Hose Lengths

Let the customer know that you will custom size the hose to t each oor.

Hose kits come in 30, 40, 50, or 60 foot (9.1, 12.2, 15.2, 18.3 meter) lengths.

Power Unit Selection

It is important to keep in mind that air ow is reduced with longer hoses.

To compensate for the loss of air ow, a larger power unit is required.

Valve locations

A 50’ (15.2 m)hose will usually cover between 1800-2300 sq ft (549-701 sq

m). Placement of the inlets should, if possible, be located in a hallway or in

other areas that do not have high visibility.

Plan pipe runs

Carefully read the section in this guide on “pipe runs”. There are also

diagrams showing four typical pipe runs.

HS5000 INSTALLATION GUIDE - 1 -

HS5000 INSTALLATION GUIDE- 2 -

Rough-In

Determine Valve Height

Light

Switch

Align

Electrical

Outlet

Align

Up Orientation

In an up orientation (hose

exiting the valve towards the

ceiling), most people nd it

more convenient with the valve

mounted at the height of the

light switch outlet.

Down Orientation

In a down orientation (tubing

is being run in the crawl space),

align the bottom of the valve

with the height of the electrical

plug outlets (about 11 inches

or 27.9 cm). Mounting the valve

higher in a down orientation

creates a more dicult angle for

the hose to retract.

New Construction

Insert the

pipe tting.

Attach the frame to the stud.

Be sure the frame is level.

The pipe tting is designed to slide

in the frame to adjust for variations

in wall board thickness.

The maximum wall thickness

the valve can work with is

1.5 inches (3.8 cm).

Install the pipe into the tting.

Glue the pipe into the tting, making

sure it seats all the way to the ridge of

the pipe tting.

Install the mud cover.

HS5000 INSTALLATION GUIDE - 3 -

Pipe Run Dos & Don’ts

Refer to the diagrams on pages 6-8.

Unlike a traditional install, do not join pipe runs until you have enough

pipe length to hold the hose. For example, if using a 40’ (12.2 m) hose,

install at least 44’ (13.4 m) of pipe before connecting to another pipe run.

In order to ensure enough pipe to store the hose, the pipe runs will

sometimes need to begin running away from the power unit, then make a

loop and head back to the power unit.

Any burr or excess glue glob can snag and damage the hose sock as it

travels through the tubing. To prevent this, be sure to always glue the pipe

and not the ttings. Make sure to remove all burrs from the pipe ends that

were cut. Carefully inspect the pipe to make sure the inside is smooth and

that the pipe is round and undamaged.

Only Hide-a-Hose special sweep 90’s, 45’s,

and 22.5’s can be in the section of

pipe that stores the hose.

A 90 to a 22.5 is often

needed to get around

an obstacle.

Try to space out 90’s as much as possible.

The more 90’s used, the more force is needed to pull the hose out of the

wall. Try not to use more than four 90’s for each valve.

HS5000 INSTALLATION GUIDE- 4 -

Try to avoid back to back

90’s, if at all possible.

It is important to

design the pipe

runs so the hose is

stored on one plane.

Hose stored on

two dierent planes.

End of hose

HS5000 INSTALLATION GUIDE - 5 -

Hose

Pipe

Hose

End Cap

Reducer

Coupler

Pipe

Low Voltage Wire

Run low voltage wire to each inlet, just as you would with a standard

central vacuum install.

Test the System

It is a good idea to test the system by retracting a hose before the walls are

sheetrocked.

Since the doors are needed to seal the system, a hand ball can be placed

over each valve opening that is not being tested to seal the system. In an

up orientation, you will need to tape the hand ball in place.

Using a portable source of vacuum, check the system for sealed vacuum.

Sealed vacuum at the valve should not vary more than three to ve inches

from the sealed vacuum at the power unit.

When using the Rapid Flex hose,

we recommend installation of a

reducer in the pipe run, before the

rst standard tting. This prevents

the possibility of the hose

getting stuck in a tight tting, if

it stretches when retracted. See

diagram below for positioning.

Hose

ends

Reducer

positioned

before rst

standard tting.

HS5000 INSTALLATION GUIDE- 6 -

Typical Pipe Runs

Down orientation on two oors.

It is important

to keep the hose

stored on the

same plane.

Only Hide-a-Hose special

sweep 90’s, 45’s, and 22.5’s

can be in the section of

pipe that stores the hose.

Align valve

with bottom

of electrical

outlet

Try and limit the

number of 90’s.

HS5000 INSTALLATION GUIDE - 7 -

Typical Pipe Runs

Up orientation on two oors.

Up two oors

needs a strong

power unit.

Align valve

with top of

electrical

switch

In order to ensure enough pipe to store

the hose, the pipe runs will sometimes

need to begin running away from the

power unit, then make a loop and head

back toward the power unit.

HS5000 INSTALLATION GUIDE- 8 -

A lubricant has already

been applied to the

o-ring on the pipe tting.

Pointed

tabs

Switch

Align

to

frame

holes

Using wire nuts, connect

the two leads from the

switch that is mounted on

the outside of the valve to

the low voltage wire.

Insert the valve assembly into

the rough-in frame.

Align the four holes in the

valve assembly with the holes

in the frame. Secure with the

four screws included in the

trim kit.

Trim

The pointed tabs are only used

in retrotting existing homes.

(See Retrot section)

HS5000 INSTALLATION GUIDE- 9 -

Retrot an Existing Home

Pointed

tabs

Use the mud cover as a template

to cut the hole.

To allow the frame to fit through

the valve hole in the sheetrock,

cut approximately 3/4” (1.9 cm)

o the forks.

You will need to score and cut

o both of the mounting tabs in

order for the rough-in frame to t

in the hole.

Insert the Rough-in frame

horizontally. Then turn it back

upright behind the wall.

Push the bottom two pointed

tabs into the sheetrock. The top

pointed tab can be bent down

as you pull the top of the frame

into the hole. The tabs will help

hold the frame in place while you

install the valve. You may need to

push a couple of small nish nails,

horizontally into the sheetrock,

through the holes located on the

side of the frame.

Installation of pipe runs and trim

can follow same instructions as for

new construction.

Finish

nail

Finish

nail

HS5000 INSTALLATION GUIDE- 10 -

Addendum

Important Information for Installing

the HS5000 valve in a Down Orientation

This much

pressure can

cause the

valve to break

Pipe is too far

forward and

can’t move

Shim

1/2” wall

board

Pipe

tting

Foam

2 9/16”

hole

Figure 2Figure 1

Avoid Potential Issue

One of the advantages of the HS5000 is that it can adjust for wall

thicknesses from 1/2” to 1 1/2”. As shown in Figure 1, with 1/2”sheetrock,

the pipe tting is pushed all the way to the back of the wall. Problems can

arise when the bottom hole is too far forward. The pipe is too short to ex

enough, thus putting a large amount of pressure on the back of the valve.

We have actually seen valves break under these extreme conditions.

Solution

Drill a larger hole (2 9/16”) to allow the pipe to have some movement (see

Figure 2). Before installing the valve, reach in and make sure the pipe can

ex forward and back inside the wall. Sometimes the foam insulation will

need to be broken up with a long screwdriver.

If you nd that it is going to require a lot of force to push the pipe back, it

is a good idea to put a shim between the pipe and the front wall board, to

take the pressure o of the valve, as shown in Figure 1.

HS5000 INSTALLATION GUIDE - 11 -

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Yamatake-Honeywell

Yamatake-Honeywell 7800 Series Product data

Maker Factory

Maker Factory MAKEVMP400 user manual

Intrepid Control Systems

Intrepid Control Systems RAD-wBMS user manual

Albalá Ingenieros, S.A.

Albalá Ingenieros, S.A. AEM3000C01 manual

Innogy

Innogy SHC manual

VIA Technologies

VIA Technologies VX800 Series Programming manual

National Instruments

National Instruments NI R Series user manual

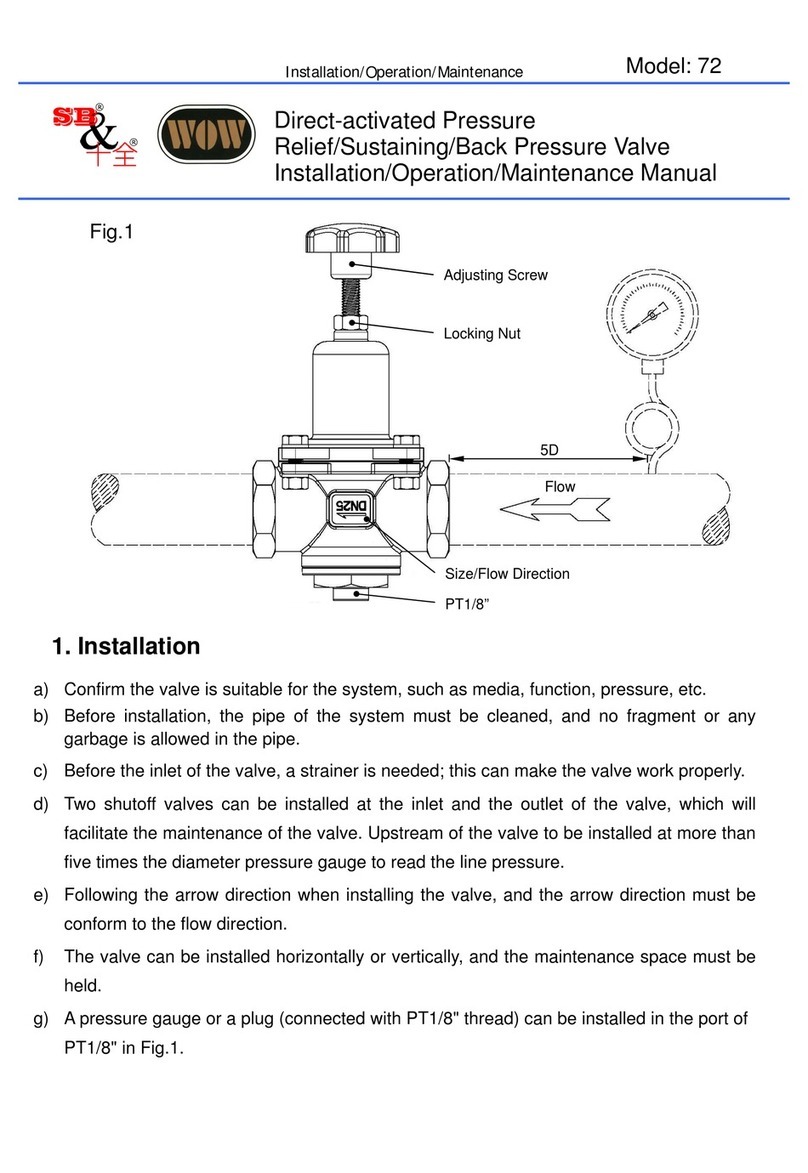

King Technology

King Technology 72 Installation operation & maintenance

Afag

Afag RM12 RMZ 16 Assembly and operating instructions

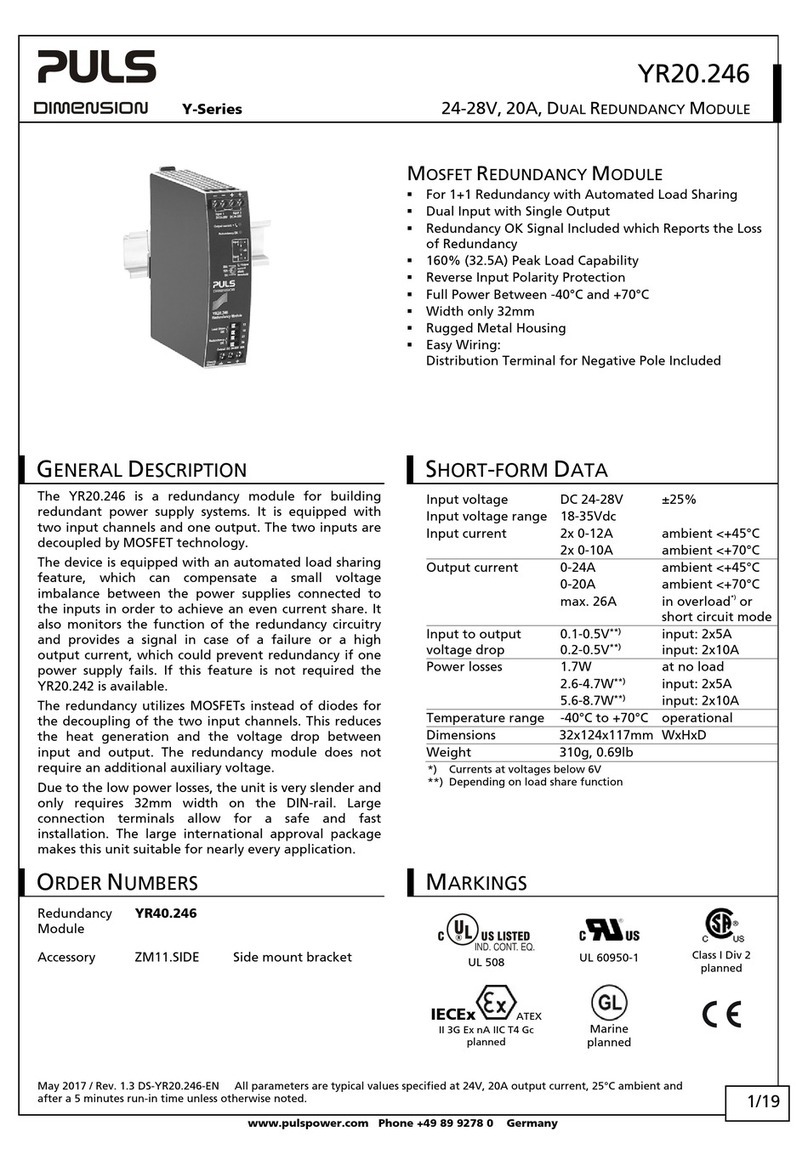

Puls

Puls DIMENSION YR40.246 manual

Siemens

Siemens Flowrite 599 Series Technical instructions

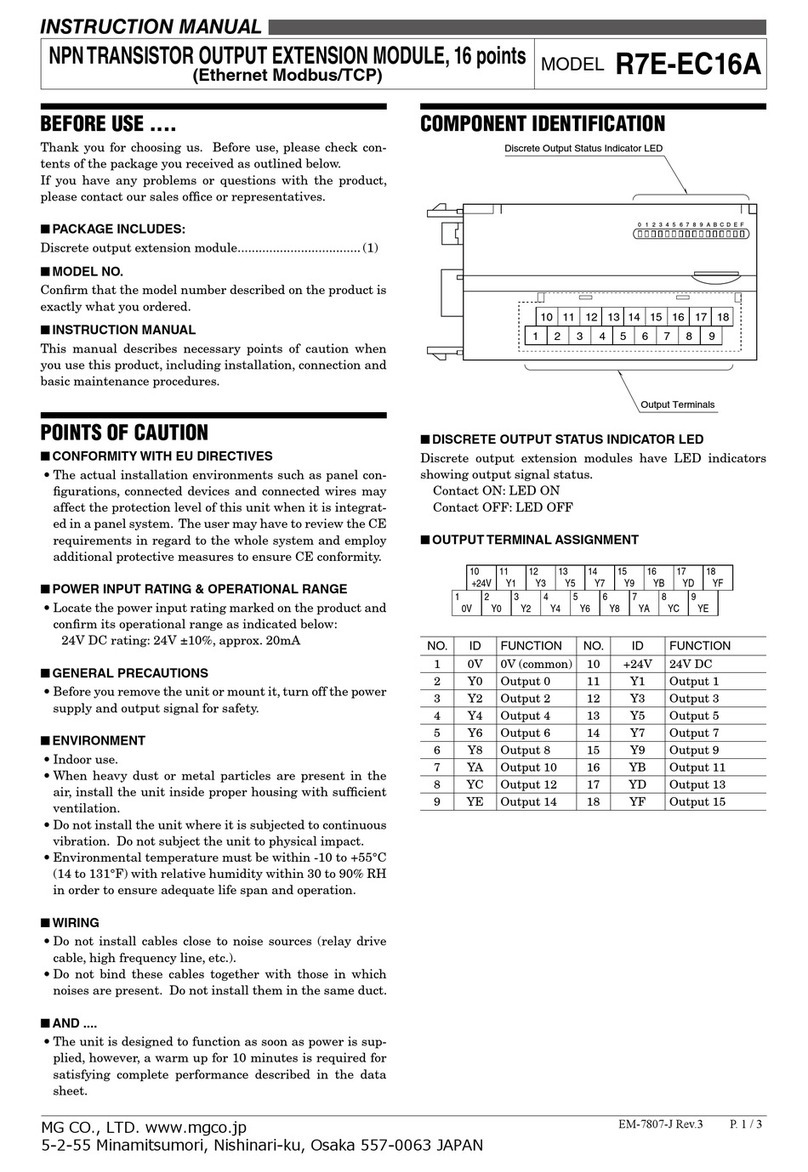

MG

MG R7E-EC16A instruction manual