HiDew RSO User manual

w w w . h i d e w . i t

i n f o @ h i d e w . i t

RSO

RSV

RSE

U S E R M A N U A L

Dehumidifiers for radiant systems

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

2 - 52

The reproduction, even partial, of this document without the written permission of HiDew S.r.l. is prohibited

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

3 - 52

RSO - RSV - RSE

Dehumidifiers for radiant systems

BEFORE USING THIS UNIT, READ CAREFULLY THIS USER MANUAL

Dear Customer,

Thank you for having chosen one of our products.

We are glad to provide this User Manual to you, in order to allow an optimum usage of the unit, for a better

comfort and a higher safety.

We strongly recommend a careful reading of the directions mentioned in the following pages and to let the

present manual available to all the operators who will work for the management and the maintenance of the

unit itself.

We remain at your disposal for any further information and explication you may need, whether in the first-

starting phase and in every following moment.

For necessary ordinary or extraordinary maintenance operations, we remain at your disposal with our

Technical support Service, to assist you and supply the spare parts.

For a quicker assistance, please contact us at the following references:

HiDew S.r.l.

Operational Headquarter

Via dell’Artigianato, 5 - 35026 - Conselve (PD) –Italy

Tel +39 049 9502511

Registered Office

Viale Spagna, 31/33 - 35020 - Tribano (PD) - Italy

Tel +39 049 9588511 - Fax +39 049 9588522

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

4 - 52

SUMMARY

1INTRODUCTION..................................................................................................................................................5

1.1 RESPONSABILITIES ........................................................................................................................................................................................ 6

1.2 SERVICE RULES.............................................................................................................................................................................................. 6

1.3 INTERVENTION AND MAINTENANCE ............................................................................................................................................................ 7

1.4 USES.............................................................................................................................................................................................................. 7

1.5 RESIDUAL RISK AREAS................................................................................................................................................................................... 7

1.6 GENERALS SAFETY RULES.............................................................................................................................................................................. 8

2PRODUCT DESCRIPTION......................................................................................................................................9

2.1 SERIES ........................................................................................................................................................................................................... 9

2.2 STRUCTURE................................................................................................................................................................................................... 9

2.3 OPERATING LIMITATIONS........................................................................................................................................................................... 10

2.4 OPTIONS ..................................................................................................................................................................................................... 10

3REFRIGERANT AND HYDRAULIC CONNECTIONS .................................................................................................11

3.1 PROJECT CRITERIA ...................................................................................................................................................................................... 12

4ELECTRICAL CONNECTIONS ...............................................................................................................................12

4.1 ELECTRICAL EQUIPMENTS........................................................................................................................................................................... 12

5USER TERMINAL...............................................................................................................................................13

5.1 DISPLAY AND KEYS...................................................................................................................................................................................... 13

5.2 USER PARAMETERS..................................................................................................................................................................................... 14

5.3 OTHER FUNCTIONS ..................................................................................................................................................................................... 15

6TECHNICAL DATA .............................................................................................................................................16

6.1 TECHNICAL DATA TABLES ........................................................................................................................................................................... 16

6.1 AIRFLOW AND STATIC PRESSURE................................................................................................................................................................ 18

6.1 HYDRAULIC CIRCUIT WATER PRESSURE DROPS .......................................................................................................................................... 20

7AFTER-SALES ....................................................................................................................................................21

7.1 FAULTS........................................................................................................................................................................................................ 21

7.2 MAINTENANCE TABLE................................................................................................................................................................................. 22

7.3 ORDINARY MAINTENANCE ......................................................................................................................................................................... 23

7.4 EXTRAORDINARY MAINTENANCE ............................................................................................................................................................... 24

8DISMANTLING OF THE UNIT..............................................................................................................................25

8.1 ENVIRONMENTAL PROTECTION ................................................................................................................................................................. 25

9INSTALLATION..................................................................................................................................................26

9.1 INTRODUCTION........................................................................................................................................................................................... 26

9.2 PLACEMENT ................................................................................................................................................................................................ 27

9.3 CANALIZATION............................................................................................................................................................................................ 30

9.4 HYDRAULIC CONNECTION........................................................................................................................................................................... 30

9.5 ELECTRICAL CONNECTIONS......................................................................................................................................................................... 31

9.6 FIRST STARTING .......................................................................................................................................................................................... 33

9.7 FINISHING ................................................................................................................................................................................................... 34

10 DIMENSIONAL DRAWINGS................................................................................................................................35

10.1 RSO –RSE 020............................................................................................................................................................................................. 35

10.2 RSV –RSVE 020........................................................................................................................................................................................... 38

10.3 RSO –RSE 035............................................................................................................................................................................................. 40

10.4 RSV –RSVE 035........................................................................................................................................................................................... 43

10.5 RSE 050 ....................................................................................................................................................................................................... 45

10.6 RSE 100 ....................................................................................................................................................................................................... 47

10.7 FORMWORK RSV –RSVE 020...................................................................................................................................................................... 49

10.8 FORMWORK RSV –RSVE 035...................................................................................................................................................................... 49

10.9 CARTER RSV –RSVE 020.............................................................................................................................................................................. 50

10.10 CARTER RSV –RSVE 035.............................................................................................................................................................................. 50

11 NOTES..............................................................................................................................................................51

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

5 - 52

1INTRODUCTION

The present User Manual indicates the uses of the unit and gives instructions for transport, installation, assembling and regulation

of the machine. It gives directions about maintenance, spare parts request, residual risks presence and staff education.

The User Manual should be read and used in the following way:

- each operator and person concerned with the use and maintenance of the unit should read it carefully and follow the instructions

given;

- the employer has to verify that the operator has the required attitudes to conduct the unit and that he has carefully read th e

manual; the employer is also supposed to inform the operator about the risks of accidents, mainly risks deriving from the noise,

the individual protection devices and the rules preview according to the law, both at an international level and at the destination

Country level;

- the manual should always be available for the user, the transport Company, the operators for the placement, the maintenance, the

reparation and the dismantling of the unit;

- the manual should be protected from humidity and hot zones and considered as an integrant part of the unit for all its lifetime; it

has to be delivered to the next owner of the unit;

- please make sure that every update is included in the manual;

- do not damage, remove, strip or re-write the manual, neither part of it; in case it is lost or damaged, please contact the

manufacturer for the request of a new user manual and communicate the matriculation number of the unit (you find it on the

data label).

Please, take care of the following symbols. Their function is to underline the following information:

It makes reference to dangerous situations that can occur when using the machine, in order to

grant people safety.

It makes reference to dangerous situations that can occur when using the machine, in order to

avoid damages to the unit itself and to things around it.

It makes reference to suggestions or additional integration for a correct use of the unit.

The manufacturer has the right to update products and relative manuals, without being obliged to update previous versions, with

exception of particular cases.

This manual refers to the current technologies adopted at the moment of the selling of the unit and cannot be considered

inadequate according to following updating due to technology evolutions.

To ask for eventual manual updating or for integration, please forward your request to the previously indicated references.

Please contact the manufacturer for further information or suggestions.

In case of re-selling of the unit, please inform the manufacturer about the new owner references, in order to facilitate the

communication between the both of us.

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

6 - 52

1.1 RESPONSABILITIES

The unit is granted according to the contract clauses subscribed in the sales negotiation.

The manufacturer is not responsible for accidents that can occur because of:

- the non-following of the instructions given in this manual about the correct use, maintenance and

first-starting of the machine;

- changes made in the unit or in the safety devices without a written authorization from the

manufacturer;

- non-authorized attempts of repair;

- negligence in constant maintenance or use of non-original spare parts.

Anyhow, if the user accuses the manufacturer for any fault of the unit, he has to demonstrate that the damage occurred has been a

direct consequence of the supposed fault.

1.2 SERVICE RULES

The service rules described in this manual have to be considered as integral part of the unit supplied.

Moreover, these rules are reserved to the operator, who has previously been instructed about the unit in object and they provide

necessary information about safety and correct use of the machine.

Please, consider that incorrect and incomplete education about the units can cause accidents.

Read carefully the following suggestions:

The first-starting of the unit should be done only by a qualified and manufacturer-authorized

operator;

- when installing the unit or when an intervention is required, it is fundamental to follow the rules described in this manual and to

pay attention to the directions given by the control of the machine;

- accidents can be avoided by following these technical instructions, with reference to the machine-directive CE/42/2006 and its

following revisions; in every case, keep attention to the national safety rules;

- do not remove or damage protections, labels and writings, especially those imposed by the law; in case they are no more readable,

please substitute them.

The machine-directive CE/42/2006 gives the following definitions:

DANGEROUS ZONE: every zone internal or in the nearby of a unit where the presence of men is a risk their safety or wealth;

EXPOSED PERSON: every person who stands within or nearby a danger zone;

OPERATOR: the person charged for the installation, the starting, the regulation, the maintenance, the cleaning, the

reparation and the transport of the unit.

All the operators should follow the accidents prevention measures, both international and of the

destination Country, in order to avoid accidents.

Please remember that the European Community has issued several directives concerning workers’ safety and wealth, such as

CEE/391/89, CEE/686/89, CEE/654/89, CEE/655/89, CEE/656/89, CEE/188/89, CEE/58/92 and CEE/57/92, that employers are

supposed to follow and to make them followed.

The units have been realized in conformity with technical laws, dispositions and rules in force.

Used materials, equipment parts, production processes, quality warranty and control satisfy the required maximum safety

standards.

The lifetime of the unit and its correct functioning can be granted by using it for the supposed usages, by moving them carefully and

by following accurately maintenance and revisions.

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

7 - 52

1.3 INTERVENTION AND MAINTENANCE

The service rules described in this manual have to be considered as integral part of the unit supplied.

Moreover, these rules are reserved to the operator, who has previously been instructed about the unit in object and they provide

necessary information about safety and correct use of the machine.

Please, consider that incorrect and incomplete education about the units can cause accidents.

Read carefully the following suggestions:

The first-starting of the unit should be done only by a qualified and manufacturer-authorized

operator;

- when installing the unit or when an intervention is required, it is fundamental to follow the rules described in this manual and to

pay attention to the directions given by the control of the machine;

- accidents can be avoided by following these technical instructions, with reference to the machine-directive CE/42/2006 and its

following revisions; in every case, keep attention to the national safety rules;

- do not remove or damage protections, labels and writings, especially those imposed by the law; in case they are no more readable,

please substitute them.

The machine-directive CE/42/2006 gives the following definitions:

DANGEROUS ZONE: every zone internal or in the nearby of a unit where the presence of men is a risk their safety or wealth;

EXPOSED PERSON: every person who stands within or nearby a danger zone;

OPERATOR: the person charged for the installation, the starting, the regulation, the maintenance, the cleaning, the

reparation and the transport of the unit.

All the operators should follow the accidents prevention measures, both international and of the

destination Country, in order to avoid accidents.

Please remember that the European Community has issued several directives concerning workers’ safety and wealth, such as

CEE/391/89, CEE/686/89, CEE/654/89, CEE/655/89, CEE/656/89, CEE/188/89, CEE/58/92 and CEE/57/92, that employers are

supposed to follow and to make them followed.

The units have been realized in conformity with technical laws, dispositions and rules in force.

Used materials, equipment parts, production processes, quality warranty and control satisfy the required maximum safety

standards.

The lifetime of the unit and its correct functioning can be granted by using it for the supposed usages, by moving them carefully and

by following accurately maintenance and revisions.

1.4 USES

RS units are dehumidifiers to be installed combined to radiant systems, which allow to dehumidify, or to cool and dehumidify air.

Its use is recommended within the functioning limitations indicated in this manual.

Place the unit where there are not explosion or fire dangers, neither in vibrating areas or in presence

of electro-magnetical fields. Furthermore, do not operate in ways which differ from those indicated

and do not underestimate safety operations.

1.5 RESIDUAL RISK AREAS

Due to the peculiar functionality of the unit, in some areas of it, there are residual risks which was

not possible to elude during the project neither to reduce. Each operator should be aware of the

residual risks in this unit, in order to avoid accidents.

Residual risk areas:

-Short circuit or fire caused by short circuit risk;

-Explosion danger because of the presence of under pressure circuits or pollution due to the refrigerant gas in the circuit;

-Burn danger because of high temperature pipes;

-Shearing risk

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

8 - 52

1.6 GENERALS SAFETY RULES

1.6.1 Safety clothes

Operators should wear safety equipment

such as gauntlet, helmet, safety glasses,

safety footwear and cap for protection

from the noise.

1.6.2 Fire extinguisher and first aid

Place a first aid box and a fire extinguisher near the unit.

Check regularly that fire extinguishers are charge and that you have understood how to use them.

In case of fire use it according to the regulations in force and contact the fire-men.

Check regularly that the first aid box is fully equipped.

Verify to have nearby the useful emergency phone numbers.

The owner of the place where the unit is installed is responsible for the fire extinguisher and the first

aid box.

1.6.3 Suggestions for advices and maintenance

Put an “under maintenance” label on all sides of the unit.

Check carefully the unit by following the list of operations suggested in the present manual.

1.6.4 Safety labels

General risk

High voltage

Burn danger

Equipment in movement danger

Shearing risk

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

9 - 52

2PRODUCT DESCRIPTION

RSV are vertical dehumidifiers for in-wall installation, RSO –RSE are horizontal

dehumidifiers ductable for ceiling installation. They are suitable for residential and

commercial applications with a high latent load, where it is required functioning 24

h/day.

They are recommended in those buildings where cooling is realized through radiant

systems, such as floor, walls or ceilings.

RS _ A (isothermal) dehumidifiers, if correctly supplied with water at 15°C can

dehumidify the air without changing the temperature. This is possible thanks to the

presence of two heat exchangers which pre-cool the inlet air and post-cool it after the

dehumidifying process.

RS _ I (hybrid) if correctly supplied with water at 15°C can dehumidify the inlet air without changing the temperature; they have also

an ambience thermo-hygrostat and a water plates condenser, which allow the unit to supply cold air if required.

The use of exclusive high-quality refrigerant, hydraulic and electrical components make RS dehumidifiers the state of art in terms of

efficiency, reliability and sound emitted level.

2.1 SERIES

RSO 020 A

RSO 020 I

RSE 020 A

RSE 020 I

RSO 035 A

RSO 035 I

RSE 035 A

RSE 035 I

RSE 050 A

RSE 050 I

RSE 100 A

RSE 100 I

RSV 020 A

RSV 020 I

RSVE 020 A

RSVE 020 I

RSV 035 A

RSV 035 I

RSVE 035 A

RSVE 035 I

2.2 STRUCTURE

The unit is realized with pre-painted white steel panels; structural internal elements are realized in electro-galvanized steel, for a

further corrosion protection. Bolts and screws are made of non-oxidable material, INOX or carbon steel with superficial treatment of

passivation. Panels are covered with synthetic open-cells polyurethane material, in order to ensure the maximum phono-absorbent.

The unit is completely closed and the access is possible only from the front panel for vertical models and from the side for the

horizontal ones. The access to the compressor area is easier thanks to the removable panel, which allows operations without

obstacles.

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

10 - 52

2.3 OPERATING LIMITATIONS

2.4 OPTIONS

2.4.1 Formwork (only for vertical units)

It is a galvanized steel formwork for installation in the wall. It aims to contain the unit and it has all the holes necessary for hydraulic

and electrical connections. It has also the splines in order to allow an optimal fixing on the wall.

2.4.2 White lacquered wooden panel (only for vertical units)

It is a white lacquered wooden panel with holes for suction and supply air. It is suitable for the formwork.

2.4.3 Painted steel sheet panel with plastic grills (only for vertical units)

It is a white galvanized panel, with plastic grills for suction and supply air. It is suitable for the formwork.

2.4.4 Supply plenum (only for vertical units)

A supply plenum allows the canalization of the supply air with flexible spiral pipe. (More information contacting our offices).

2.4.5 Mechanical humidistat

It is an external device to be installed on the wall and it manages the activation of the unit.

Humidity operating range: 30 –99% RH, precision +/- 3 %.

2.4.6 RS485 serial port

The bus RS485 connection is available to control the unit at distance or by a home automation plant.

(More information contacting our offices).

2.4.7 Supply flange (only for horizontal units)

It is a supply flange to make easier the connection of the unit with ducts for air distribution.

5

10

15

20

25

30

35

35 40 45 50 55 60 65 70 75 80 85 90 95 100

Internal air Temperature [°C]

Internal air humidity [%]

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

11 - 52

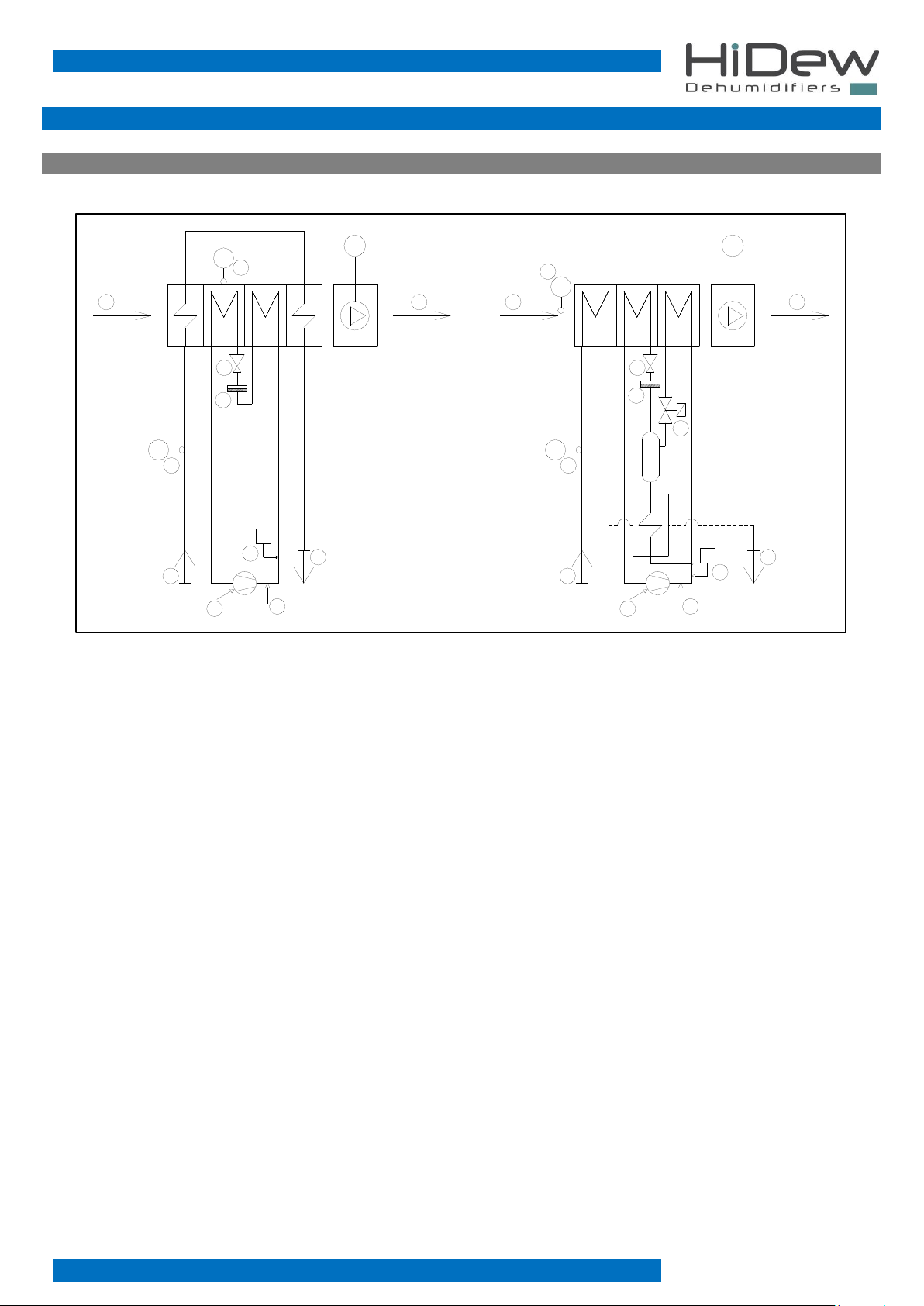

3REFRIGERANT AND HYDRAULIC CONNECTIONS

RS _ A (isothermal) RS _ I (hybrid)

1 Compressor

2 Filter drier

3 Evaporator

4 Condenser

5 High pressure safety switch

6 Service connections

7 Throttling valve

8 Defrosting temperature probe

9 Water plates condenser

10 Solenoid valve for ambient temperature control

11 Liquid receiver

21 Inlet water temperature probe

22 Pre-cooling coil

23 Post-cooling coil

24 Water inlet (from radiant system)

25 Water outlet (to radiant system)

30 Fan

31 Temperature probe

32 Air inlet

33 Air outlet

M

P

T

T

2

7

21

5

66

24

25

8

3023

22

4

3

1

M

T

T21

24

25

31

30

4

3

22

P

66

1

9

5

2

7

11

10

32 33 32 33

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

12 - 52

3.1 PROJECT CRITERIA

All copper pipes are realized under our specifications in order to control all the construction process and to increase our products

quality standards. Each pipe is tested through the FEM code on the more stressed point with a 90° fold and under the maximum

allowed pressure according to the safety coefficient.

Compressors

Reciprocating compressors are mounted on the units. Engines are thermally protected through an internal protection

which controls the temperature of winding and disables the power supply in case of maintenance.

Refrigerant components

oFilter drier with molecular sieve

oThrottling valve

oSchrader valve for control / maintenance

Thermal exchange coils

oCopper pipes and aluminum fins

Condensate tray (below coils)

oINOX steel

4ELECTRICAL CONNECTIONS

4.1 ELECTRICAL EQUIPMENTS

The electrical panel is realized and wired according to the Regulations mentioned in the Declaration of Conformity.

The control circuit is protected by a dedicated fuse.

All the remote commands are realized with low tension, supplied by an insulation transformer.

To stop the group do not remove tension through the protection at the base of the unit: this organ

should be used to section the whole unit for maintenance. To turn off, use the user terminal.

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

13 - 52

5USER TERMINAL

The unit leave the factory with status “OFF” (to turn it on, keep pressed for more than 1 second the [STAND-BY] key, and it will turn

to “ON”), ready to function.

The control manages all the functions and the devices of the unit, by operating under the call from the external humidistat.

Remember that the compressor has a delay when starting and re-starting of 5 minutes, in order to avoid mechanical damages to the

internal components.

Every problem / error is displayed, according to the DIAGNOSTICS AND ALARMS chapter.

By default, the ventilation is combined with the compressor starting.

Some of these regulations can be modify according to the PARAMETERS TABLE below.

5.1 DISPLAY AND KEYS

UP ( ▲)

Increases the values / Browses parameters.

Turns off the sound alarm, if present.

DOWN ( ▼)

Decreases the values / Browses parameters.

STAND-BY

Hold down more than 1 second, it changes the OFF status to the ON one and vice-versa.

When the status is changed, a sound signal is emitted.

In stand-by status, unit stops and on the display there is OFF.

SET

Allows to set the parameters.

Restores the sound alarm, if present.

Except from the programming, it has no functions.

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

14 - 52

1. TEMPERATURE / PARAMETERS values

2. COLD CALLING icon

Led OFF = Cold calling OFF

Led ON = Cold calling ON

Led flashing = Cold calling ON, but waiting for the re-starting time

3. HOT CALLING Icon (if active)

Led OFF = Hot calling OFF

Led ON = Hot calling ON

4. DEFROST CALLING icon

Led OFF = Defrost calling OFF

Led ON = Defrost calling ON

5. FANS CALLING icon

Led OFF = Fans calling OFF

Led ON = Fans calling ON

6. DIGITAL INPUT ACTIVATED BY HUMIDISTAT (if active)

Led On = Active digital input

Led flashing = Compressor off because of missed humidistat consent

7. ALARM icon

Led OFF = No alarms present

Led flashing = Alarm present

5.2 USER PARAMETERS

To enter the user parameters setting menu, it is necessary to:

1. Hold down for 3 seconds the keys UP () and DOWN () till you see on the display the first variable. A sound will be

emitted.

2. Select with the keys UP () or DOWN () the variable to modify.

3. It is possible to change the value holding the SET key and the key UP () or DOWN ().

4. At the end of the setting, to exit the menu, hold down the keys UP () or DOWN () or wait 30 seconds without.

The status of the unit (OFF or ON) appears on the display. A sound will be emitted.

5. Confirmation of the modifications will be automatic after the exit from the configuration menu.

PARAM

DESCRIPTION

DEFAULT

Setting temperature set-point (if active)

26,0

Display temperature:

- water probe

Reading

Display temperature:

- coil probe - (version A isothermal)

- ambient probe - (version I hybrid)

Reading

Software release

Reading

For the dehumidifiers with cold integration, the defrost is cyclic, every 120 minutes.

This time is set by default.

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

15 - 52

5.3 OTHER FUNCTIONS

5.3.1 DEFROST MANUAL ACTIVATION

When the activation conditions are satisfied (temperature read by the probe lower than 5°C), it is possible to activate the defrost

manually, by holding down the () key for more than 3 seconds; a sound will be emitted as confirmation.

In this way, the defrost is activated by turning off the compressor and keeping on the fan.

5.3.2 DEFROST END MANUAL FORCING

During the defrost, holding down the key () for 3 seconds, it is possible to force the end of the defrost; a sound signal will be

emitted as confirmation.

This function cannot be activated from the programming menu.

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

16 - 52

6TECHNICAL DATA

6.1 TECHNICAL DATA TABLES

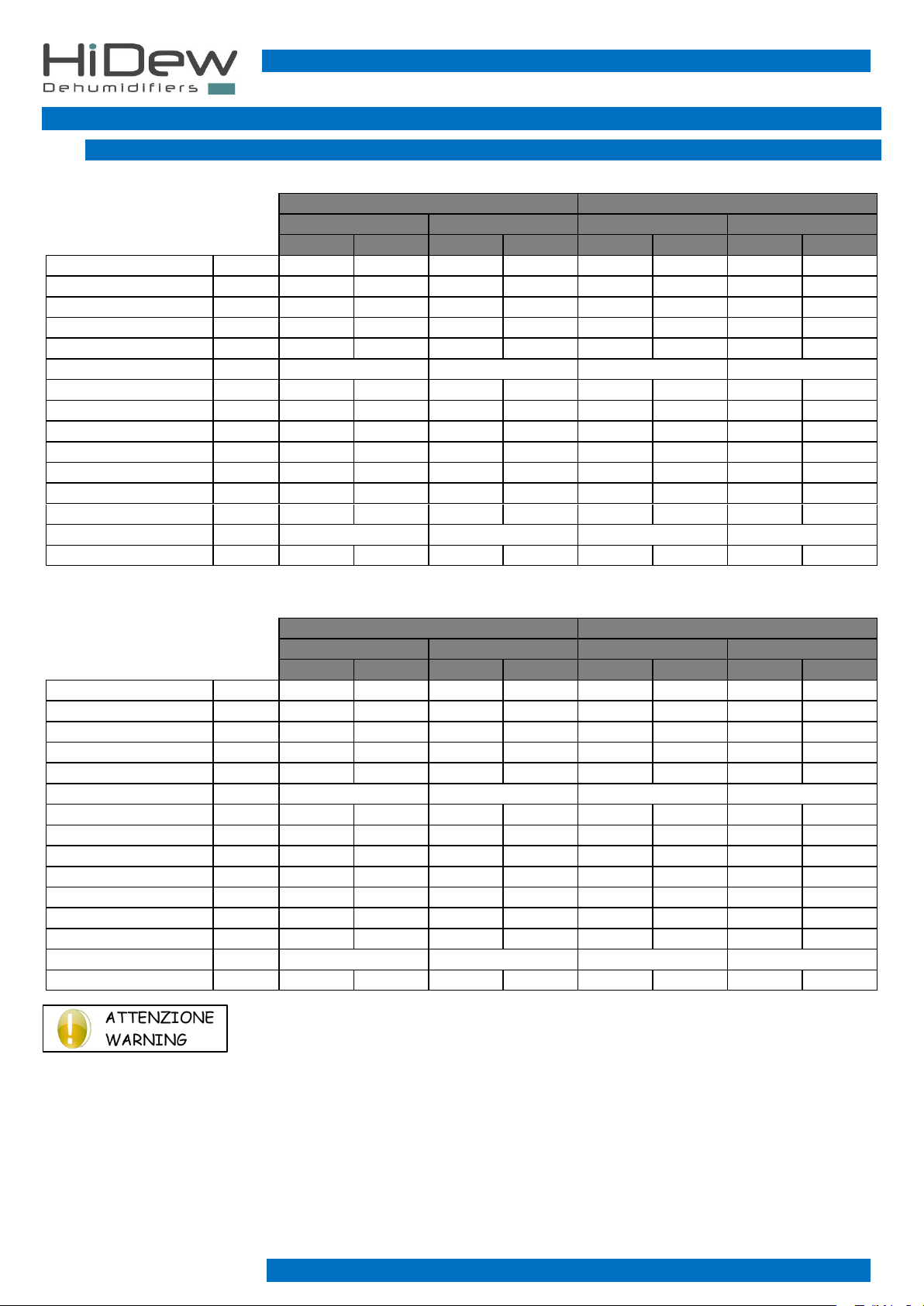

6.1.1 Size 020

Horizontals

Verticals

RSO

RSE

RSV

RSVE

A

I

A

I

A

I

A

I

Dehumidification capacity

l/day

20

20

20

20

20

20

20

20

Refrigerant

-

R134a

R134a

R134a

R134a

R134a

R134a

R134a

R134a

Cooling capacity

W

/

1240

/

1240

/

1240

/

1240

Absorbed power

W

250

250

240

240

250

250

240

240

Absorbed current

A

1,7

1,7

1,8

1,8

1,7

1,7

1,8

1,8

Electrical supply

V/ph/Hz

230 / 1+N / 50

230 / 1+N / 50

230 / 1+N / 50

230 / 1+N / 50

Airflow

m³/h

250

250

250

250

250

250

250

250

Available static pressure

Pa

40

40

180

180

40

40

180

180

Nominal water flow

l/h

150

150

150

150

150

150

150

150

Water pressure drop

kPa

15

15

15

15

15

15

15

15

Storing temp. limit

°C

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

Storing humidity limit

%

90

90

90

90

90

90

90

90

Sound pressure level

dB(A)

38

38

39

39

38

38

39

39

Dimensions

mm

530x600x242

530x600x242

480x220x665

480x220x665

Weight

kg

35

37

35

37

34

36

34

36

6.1.2 Size 035

Horizontals

Verticals

RSO

RSE

RSV

RSVE

A

I

A

I

A

I

A

I

Dehumidification capacity

l/day

28

28

28

28

28

28

28

28

Refrigerant

-

R134a

R134a

R134a

R134a

R134a

R134a

R134a

R134a

Cooling capacity

W

/

1740

/

1740

/

1740

/

1740

Absorbed power

W

800

800

780

780

800

800

780

780

Absorbed current

A

4,8

4,8

4,9

4,9

4,8

4,8

4,9

4,9

Electrical supply

V/ph/Hz

230 / 1+N / 50

230 / 1+N / 50

230 / 1+N / 50

230 / 1+N / 50

Airflow

m³/h

350

350

350

350

350

350

350

350

Available static pressure

Pa

40

40

180

180

40

40

180

180

Nominal water flow

l/h

260

260

260

260

260

260

260

260

Water pressure drop

kPa

18

18

18

18

18

18

18

18

Storing temp. limit

°C

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

-10 / +43

Storing humidity limit

%

90

90

90

90

90

90

90

90

Sound pressure level

dB(A)

39

39

40

40

39

39

40

40

Dimensions

mm

680x600x242

680x600x242

630x220x665

630x220x665

Weight

kg

42

44

42

44

41

43

41

43

Units “I” need to be supplied with cold water in order to function properly, otherwise units cannot

function and they will block.

Units “A” can function without cold water, in this case dehumidification capacity decrease and air is supplied at temperature higher

than the inlet.

1. Dehumidification capacity is declared at nominal conditions 26°C, 65% RH with water at 15°C.

In other conditions dehumidification capacity varies.

2. Sound pressure level is declared in free field at 1 m from the unit ducted.

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

17 - 52

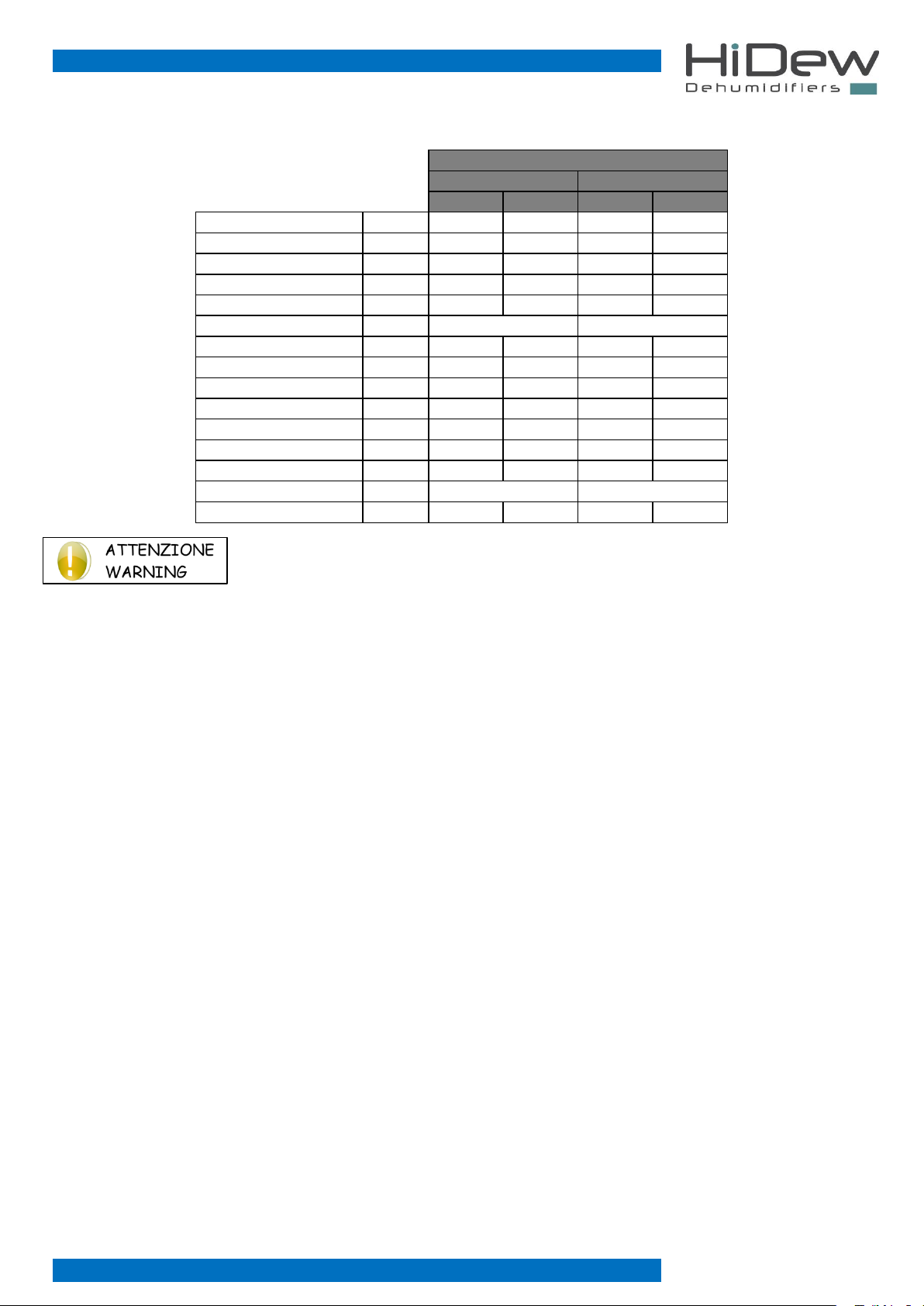

6.1.1 Sizes 050 e 100

Horizontals

RSE 050

RSE 100

A

I

A

I

Dehumidification capacity

l/day

48

48

100

100

Refrigerant

-

R134a

R134a

R410A

R410A

Cooling capacity

W

/

3360

/

6800

Absorbed power

W

800

800

1460

1460

Absorbed current

A

5

5

7

7

Electrical supply

V/ph/Hz

230 / 1+N / 50

230 / 1+N / 50

Airflow

m³/h

600

600

1000

1000

Available static pressure

Pa

150

150

150

150

Nominal water flow

l/h

500

500

950

950

Water pressure drop

kPa

30

29

28

28

Storing temp. limit

°C

-10 / +43

-10 / +43

-10 / +43

-10 / +43

Storing humidity limit

%

90

90

90

90

Sound pressure level

dB(A)

43

43

46

46

Dimensions

mm

760x650x350

1000x600x450

Weight

kg

52

55

80

82

Units “I” need to be supplied with cold water in order to function properly, otherwise units cannot

function and they will block.

Units “A” can function without cold water, in this case dehumidification capacity decrease and air is supplied at temperature higher

than the inlet.

1. Dehumidification capacity is declared at nominal conditions 26°C, 65% RH with water at 15°C.

In other conditions dehumidification capacity varies.

2. Sound pressure level is declared in free field at 1 m from the unit ducted.

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

18 - 52

6.1 AIRFLOW AND STATIC PRESSURE

6.1.1 RSO e RSV 020 –3 velocities

Units install a three velocities fan; medium velocity is set as default.

Refers to “Installation” paragraph for velocity change.

CURVE A = high velocity

CURVE B = medium velocity

CURVE C = low velocity

6.1.2 RSE e RSVE 020 –potentiometer

Units install an electronic fan with inverter and brushless motor

controlled by a potentiometer. A default velocity is set in factory.

Refers to “Installation” paragraph for velocity change.

CURVE A = maximum limit

CURVE B = suggested curve

6.1.3 RSO e RSV 035 –3 velocities

Units install a three velocities fan; medium velocity is set as default.

Refers to “Installation” paragraph for velocity change.

CURVE A = high velocity

CURVE B = medium velocity

CURVE C = low velocity

0

10

20

30

40

50

60

70

0 100 200 300 400

Prevalenza [Pa]

Portata [m³/h]

0

100

200

300

400

500

600

700

0 200 400 600 800

Prevalenza [Pa]

Portata [m³/h]

0

10

20

30

40

50

60

70

80

0 100 200 300 400 500 600

Prevalenza [Pa]

Portata [m³/h]

B

A

C

A

B

C

A

B

USER MANUAL - rev 10

RS Dehumidifiers for radiant systems

19 - 52

6.1.4 RSE e RSVE 035 –potentiometer

Units install an electronic fan with inverter and brushless motor

controlled by a potentiometer. A default velocity is set in factory.

Refers to “Installation” paragraph for velocity change.

CURVE A = maximum limit

CURVE B = suggested curve

6.1.5 RSE 050 –potentiometer

Units install an electronic fan with inverter and brushless motor

controlled by a potentiometer. A default velocity is set in factory.

Refers to “Installation” paragraph for velocity change.

CURVE A = maximum limit

CURVE B = suggested curve

6.1.6 RSE 100 –potentiometer

Units install an electronic fan with inverter and brushless motor

controlled by a potentiometer. A default velocity is set in factory.

Refers to “Installation” paragraph for velocity change.

CURVE A = maximum limit

CURVE B = suggested curve

0

100

200

300

400

500

600

0 200 400 600 800 1000 1200

Prevalenza [Pa]

Portata [m³/h]

0

50

100

150

200

250

300

350

0 200 400 600 800 1000

Prevalenza [Pa]

Portata [m³/h]

0

100

200

300

400

500

600

0 400 800 1200 1600 2000 2400

Prevalenza [Pa]

Portata [m³/h]

B

A

B

A

B

A

rev 10 –USER MANUAL

RS Dehumidifiers for radiant systems

20 - 52

6.1 HYDRAULIC CIRCUIT WATER PRESSURE DROPS

X axis water flow, Y axis water pressure drops

020 A 020 I

035 A 035 I

050 A 050 I

100 A 100 I

0

10

20

30

40

50

60

0 100 200 300 400

kPa

l/h

0

10

20

30

40

50

60

0 100 200 300 400

kPa

l/h

0

20

40

60

80

100

120

140

0 200 400 600 800

kPa

l/h

0

20

40

60

80

100

120

140

0 200 400 600 800

kPa

l/h

0

10

20

30

40

50

60

70

0 200 400 600 800

kPa

l/h

0

10

20

30

40

50

60

70

0 200 400 600 800

kPa

l/h

0

10

20

30

40

50

60

70

0 400 800 1200 1600

kPa

l/h

0

10

20

30

40

50

60

70

0 400 800 1200 1600

kPa

l/h

Other manuals for RSO

1

This manual suits for next models

22

Table of contents

Other HiDew Dehumidifier manuals