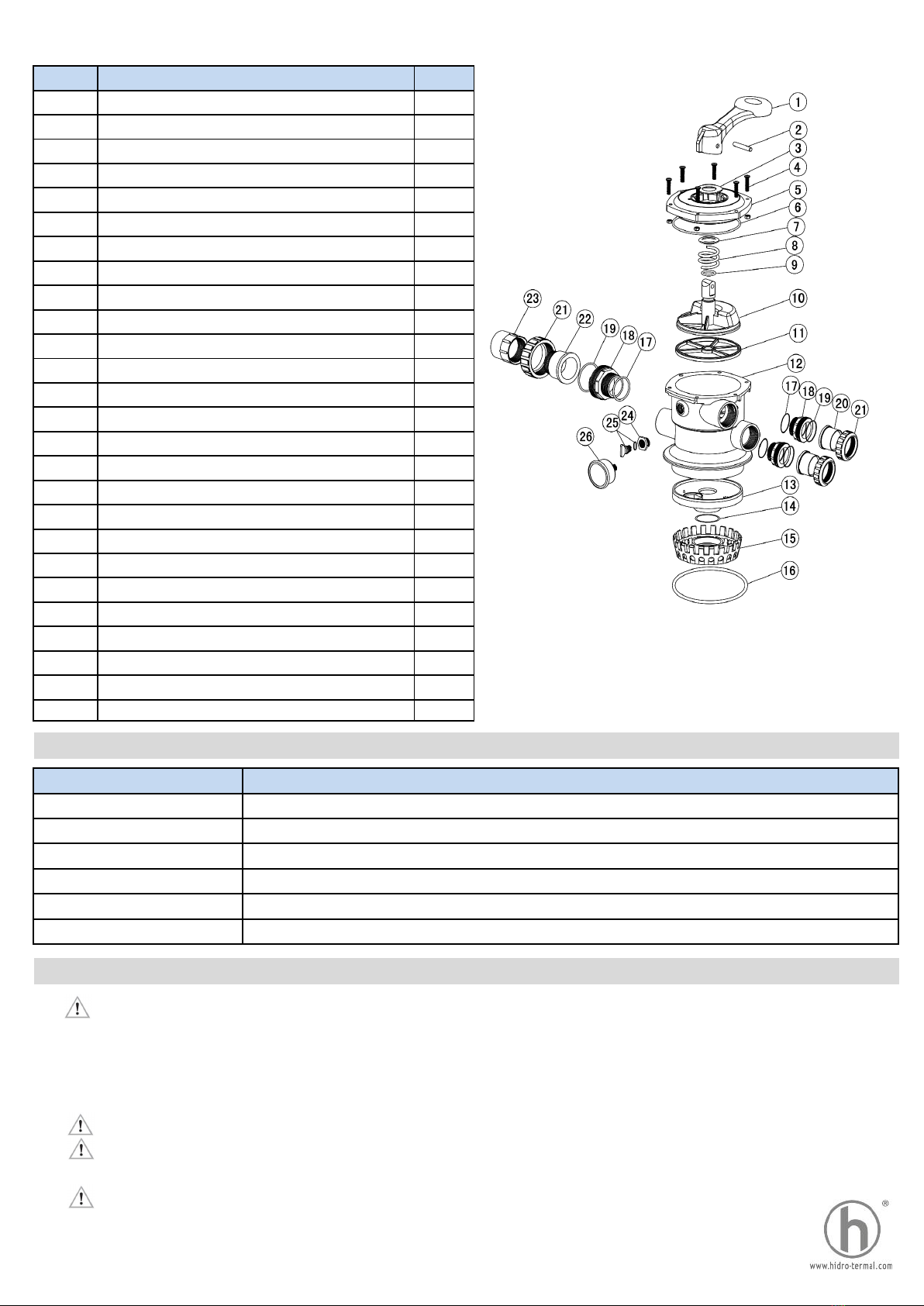

Item Product Description Qty

1 Handle (Big) 1

2 Pin for Handle 1

3 Washer for Handle 1

4 M6*30 Screw with Nut for Standard Lid 6

5 1.5" Top Mount Valve Standard Lid (Black) 1

6 O-ring for 1.5" Valve Lid 1

7 Washer for Spring 1

8 Spring for 1.5" Top Mount Valve 1

9 O-ring for 1.5" Valve Rotor 2

10 1.5" Valve Rotor 1

11 Spider Gasket 1

12 1.5" Top Mount Valve Bottom Body Clamp (black) 1

13 1.5" Diffuser 1

14 O-ring for Diffuser 1

15 1.5" Top Mount Valve Over Drain Diffuser 1

16 O-ring 1

17 O-ring for 1.5" Connector 3

18 1.5" Connector (Black) 3

19 O-ring for 1.5" Union 3

20 1.5" Union (A/E) 2

21 1.5" Union Nut (black) 3

22 1.5" Union with sight glass (short) 1

23 1.5" Union with sight glass holder 1

24 Connector for pressure gauge/stopper 1

25 Drain Plug with O-ring 1

26 Pressure Gauge with O-ring (40psi) 1

5. Valve Positions Function

Valve Position Function

FILTER Normal Filtration and Vacuum

BACK WASH Clean Filter by reversing the flow

RINSE Use after backwash to flush dirt from valve

WASTE By-passes filter, use to vacuum the waster for lowering water level

RECIRCULATE By-passes filter for circulating water to pool

CLOSED Shut off all flow to filter or pool

6.Warning

1. THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE

DEATH, OR PROPERTY DAMAGE.

2. TURN PUMP OFF BEFORE CHANGING VALVE POSITION.

3. TO PREVENT DAMAGE TO THE PUMP AND FOR PROPER OPERATION OF THE