High Voltage VLF Series Guide

Safety, Operation, and Procedure Instructions for the VLF Series of

AC Hipots

Danger- Lethal Voltages:

Equipment to be used by trained personnel only

This Operator Manual contains instructions for the operation of a High Voltage po er source. The operator of this equipment

must use good judgement and follo all safety precautions noted in this guide to ensure the protection of himself and others in

close proximity to the test area

. Failure to follow the instructions could result in injury

or death. roper grounding of the test set must be done prior to

connecting this unit to a power source.

sa

Mine

VLF

-

12011CM

SERIES

lease Refer to

Documentation

Before Operation

VLF Operator Manual

HIGH VOLTAGE, INC.

31 Route 7A • P.O.Box 408

Copake, N.Y. 12516

Phone 518/329-3275 • Fax 518/329-3271

http://www.hvinc.com

E-mail: factory@hvinc.com

Last saved 7/26/2006

T:\PRODUCT\DOCUMENTS\Manuals\VLF\M Nvlf12011CM_2k3.doc

Table of Contents

About the Operator Manual 1

S E C T I O N 1

General Information 2

Features and Specifications 2-4

Controls and Indicators 5-8

List of Components 8

S E C T I O N 2

Setting up the Equipment 9,10

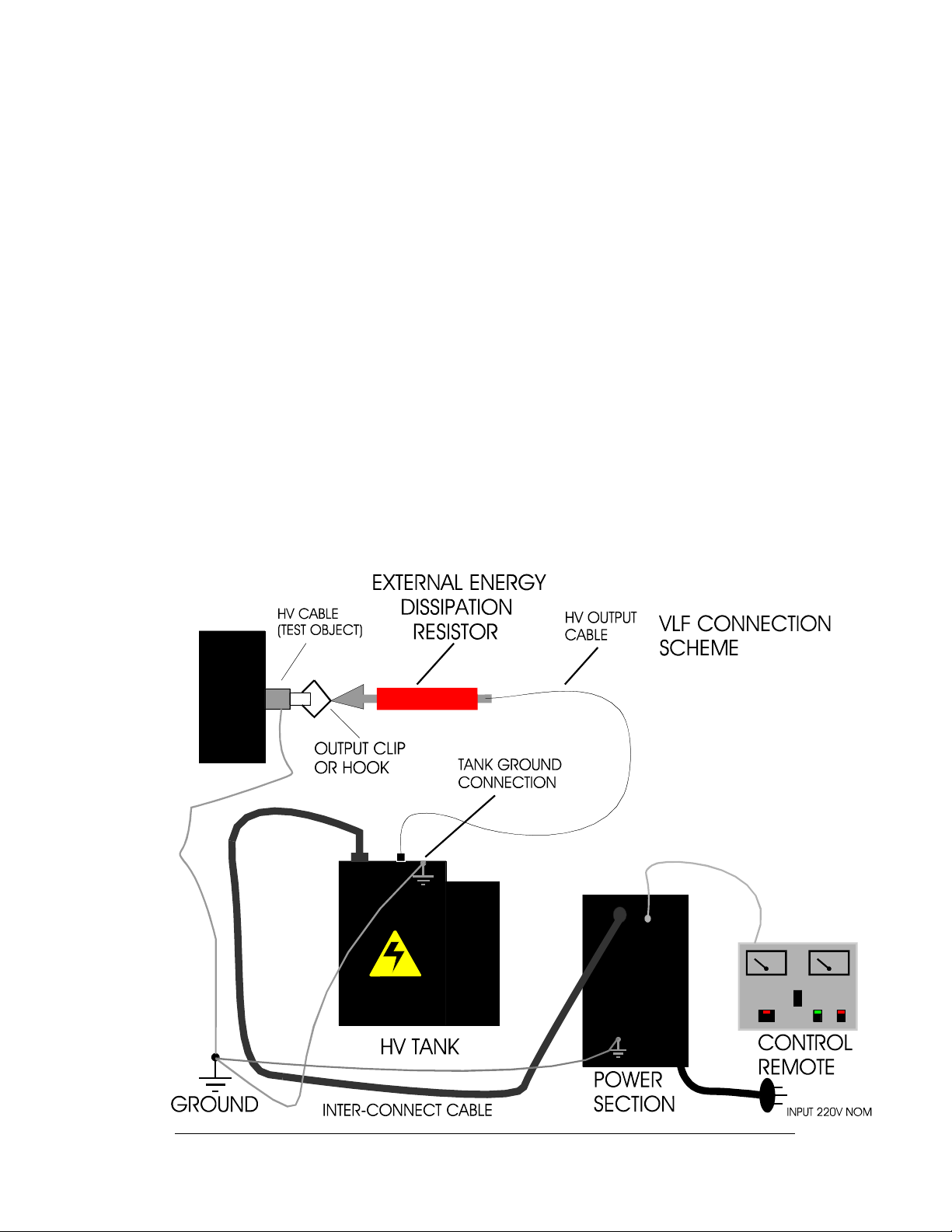

Typical VLF Connection Scheme 11

Operating the Equipment 11-17

Blank Page for Notes 18

S E C T I O N 3

Performing Special Operations 19

Voltmeter Re-calibration 19,20

Current Meter Re-calibration 20

Returned Material 21

Warranty 22,23

O P E R T O R M N U L

- 1 -

About the Operator Manual

Important

This Operator Manual describes the features and safe operation

of a High Voltage AC Test Set. The instructions are intended to be

clear and simple, but the operator must be trained and qualified

according to the customer’s established procedures for the use of

this t pe of equipment.

This Operator Manual is organized to provide information on the VLF-12011CM in steps that

familiarize the ne operator ith the entire scope of operation of this test set.

Section 1: Specifications and Controls.

Section 2: Setup and Operation.

Section 3: Performing Special Operations.

The Functions, Features, and Specifications of the VLF Series of AC Hipots are also discussed in the VLF

Brochure available from High Voltage, Inc.

O P E R T O R M N U L

2

22

2

General Information

This section familiarizes the operator ith the features and specifications of the

VLF Series of Very Low Frequency AC Hipots manufactured by HIGH VOLTAGE, INC.

Features and Specifications

The VLF-12011CM hipot test set provides true sine ave AC output voltage for the test of high

voltage cables and other capacitive loads.

Standard features of the VLF-12011CM AC Hipot

•

Sine ave output, 0.1, .05, .02 and .01Hz frequencies standard.

•

Continuously adjustable output voltage

•

Continuous duty rating

•

Fixed primary overload

•

“Zero Start” and External Interlock provision

•

Single-range voltmeter

•

Single range current meter ith capacitance measuring scale for determining best test frequency

•

Dual operating mode- Hipot/Burn for either hipotting ith an overload or burning ith current limiting

•

Three piece design, mounted on one Trolley.

•

Transit protected meter prevents damage bet een test sites in vehicle mounted installations

•

20 ft. interconnect cables ith grounds

•

100 ft. shielded X-Ray output cable AND 100 ft. Ground an Cable Reel

SECTION

1

O P E R T O R M N U L

3

33

3

•

Hook type output connector

•

Alligator clip type output connector

•

External Energy Dissipation Resistor

WARNING

DO NOT O ERATE THE VLF HI OT SET IF THE HIGH VOLTAGE TANK IS 5°

°°

° OR

MORE FROM LEVEL.

IF THE UNIT IS O ERATED OUT OF LEVEL, OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DO NOT STORE OR TRANSPORT VLF HIGH VOLTAGE SECTION

ON IT’S SIDE

O P E R T O R M N U L

4

44

4

Operating Environment

Indoor/Outdoor-fair eather

Altitude: 100% of rating;Sea-level, up to 5000ft.(approx.1500M). The output

po er is de-rated 10% above 5000 ft. altitude, 20% above 12,000 ft.( approx.

3600M), and 30% above 15,000 ft.(approx. 4500M)

Storage Temperature: -20°C to 70°C(-4°F to 158°F)

Operating Temperature: -5°C to 45°C(22°F to 113°F) Output po er is de-

rated linearly by 15% from 30 to 45°C ambient.

Maximum Relative Humidity: 80% up to 31°C(88°F), decreasing linearly to

50% at 40°C(104°F)

Mains supply fluctuation: +/-10% of rated voltage

Installation: Category II

Pollution: Degree 2

WARNING

DO NOT O ERATE THE VLF HI OT SET IF THE HIGH VOLTAGE TANK IS 5°

°°

° OR

MORE FROM LEVEL.

IF THE UNIT IS O ERATED OUT OF LEVEL, OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DO NOT STORE OR TRANSPORT VLF HIGH VOLTAGE SECTION

ON IT’S SIDE

O P E R T O R M N U L

5

55

5

Safety Symbol Identification

Warning! lease refer to documentation before

operation

rotective Earth Terminal

Warning: Hazardous Voltage

O P E R T O R M N U L

6

66

6

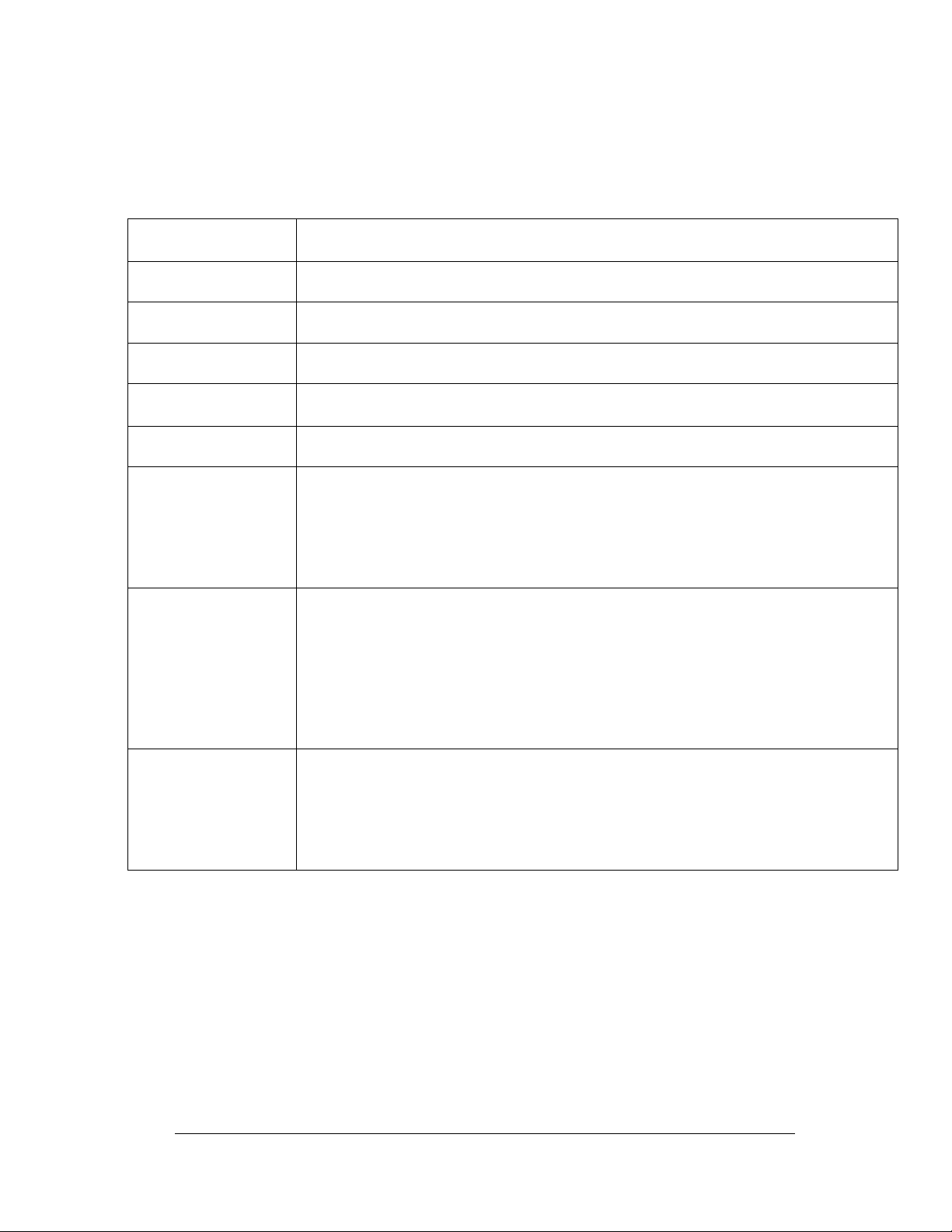

MODEL VLF AC HI OT S ECIFICATIONS

VLF-12011CM( 120 kV,1.1 µF)

Input 230V +/-10%, 50/60 Hz, single phase, 30 A .

Output Sinusoidal 0-120 kVac peak, 0.1, .05, .02 and .01 Hz frequency

Duty Continuous

Test Capacitance .55µF @ .1 Hz, 1.1µF @ .05 Hz, 2.2 µF @ .02 Hz , 5.5µF@.01 Hz

Kilovoltmeter 3.5 in. , 0-120 PEAK KILOVOLTS

Remote Control Size

Po er Section Size

High Voltage Tank size

17 x 11d x 9.5 high

20 x 14d x 27 high

26 x 26d x 22high

Control Case Wt.

Po er Section Wt.

HV Tank Wt.

20 lbs. (9kg)

160 lbs. (73kg)

390 lbs. (177kg)

765 lbs. (347kg) on Platform Truck ith 100ft. Cable Reel Assembly

Interconnect cable

length

Output cable length

20 ft.(STANDARD)

Shielded X-Ray 100 ft.(STANDARD)

Table 1 VLF-12011CM Specifications

.

O P E R T O R M N U L

7

77

7

OUT UT

FREQUENCY

.05Hz .02Hz

.01Hz.1Hz

BURN

HI OT

OUT UT

MODE

FAULT/RESET

OS

NEG

SCO E

OUT UT

EXT

INTLK

METER

MODE

uF mA

CA

ZERO

CA ACITANCE

SCALE X10

X1

USH TO READ

CA ACITANCE

MEASUREMENT

HOT COM

MAIN

OWER

HIGH

VOLTAGE

RAISE

LOWER

OFF ON

TIMER

START

AC TEST SET VLF SERIES

LEASE REFER TO

DOCUMENTATION

BEFORE O ERATION

Figure 1 VLF Series front panel controls.

M A I N O W E R

The MAIN OWER neon lamp ill light hen the main po er circuit breaker is on in the po er

section and voltage is available to the input terminals.

E X T . I N T L K ( E X T E R N A L I N T E R L O C K )

The Ext. Intlk. connector is provided to allo for a normally open safety interlock s itch to

control the energizing of the high voltage output.

F A U L T / R E S E T

The FAULT/RESET pushbutton illuminates hen the primary current in the po er section has

exceeded the maximum limit. Its delayed trip allo s for the short term overload of the variable

transformer hile still providing proper protection. Depressing the pushbutton resets the circuit.

H I G H V O L T A G E O N / O F F

The HIGH VOLTAGE ON (OFF) pushbuttons activate (de-activate) the high voltage po er

circuits. The LED indicators provide long life positive indication of the circuit status. The RED

(ON) LED lights hen high voltage is energized, the GREEN (OFF) LED lights hen the high

voltage is de-energized.

O P E R T O R M N U L

8

88

8

H I G H V O L T A G E - R A I S E / L O W E R

The RAISE/LOWER control adjusts the output voltage by raising or lo ering the motorized

output control variable transformer. The OUT UT ERCENT meter above the RAISE/LOWER

control indicates the relative position of the variable transformer ith respect to the output

voltage. An automatic return to zero function at time of high voltage off ensures energizing of

high voltage at zero. The control must be at ZERO (0) to energize the high voltage circuits. The

output control must always be returned to zero at the completion of testing, prior to de-

energizing the output , allow the unit to cycle for 60 seconds to assure full discharge of

the capacitance in the load.

V O L T M E T E R

The KILOVOLT METER allo s for accurate output voltage readings. 1-% precision resistors

minimize the need for re-calibration due to aging shift. See Voltmeter Re-calibration in Section

3 for details on calibration.

C U R R E N T / C A A C I T A N C E M E T E R

The CURRENT/CA ACITANCE METER allo s for output current readings. The CURRENT

meter portion of this circuit is for observing the charge and discharge currents in the cable load.

1-% precision resistors minimize the need for re-calibration due to aging shift. The

CAPACITANCE scale on this meter is for measuring the load cable capacitance prior to test to

determine the best operating frequency for that particular cable run.

S C O E O U U T

The SCO E OUT UT allo s for accurate output voltage monitoring. This connector can be fed

into an oscilloscope for the looking at the actual output ave shape. The peak voltage

representing 50 kVac is 5 volts peak.

O U T U T F R E Q U E N C Y

The OUT UT FREQUENCY s itch adjusts bet een calibrated frequencies for testing loads

larger than normal .By allo ing slo er frequencies the output aveshape is maintained. Output

frequency choices are .1 Hz for .55 µF, .05 Hz for 1.1 µF, .02 Hz for 2.2 µF, and .01 for 5.5µF

load capacitance.

O U T U T M O D E

The OUT UT MODE is for choosing the operating mode of the overloads. When this control is

in the HI OT mode, the overload ill trip in case of an arc. When in the BURN mode, the

overload is still active. But, if an arc occurs, a reactor is s itched into the primary line to limit

primary current to the maximum rating for the unit allo ing the faulted cable to be burned to a

lo impedance fault. After a short is burned into the cable, conventional fault locating techniques

can be employed.

O P E R T O R M N U L

9

99

9

S T A R T T I M E R

The START TIMER s itch starts the d ell timer on the front panel to time test duration. The

timer can only be started hen high voltage is energized. The timer is reset only after the high

voltage is off and the START TIMER pushbutton is depressed.

Operation of the Timer In the VLF Hipot

The D ell Timer included in our VLF Series of AC Hipots ill function as an end of test alarm only. The timer ill start

upon initiation of the high voltage. The timing function ill count up to the preset value. Upon reaching the d ell time,

an alarm ill sound indicating the need to return the Output Control to zero. Turn off the high voltage, as noted later

in the Operating Manual, by allo ing the output discharge solenoids and polarity solenoids to cycle at least ten more

seconds (one full cycle).

To set the timer.

1) Press 'Mode'. When 'Timing Range' appears. Press '1' pushbutton. When desired range appears move to next

step.

2) Press 'Mode'. When 'UP/Do n Count' appears, press '1' to choose 'UP or 'DOWN'.

3) Press 'Mode". When 'Output Mode' appears, press '1' until Mode 'A' appears.

This setup should be retained in the timers memory. To change the time in the future see step 1.

M E T E R M O D E

The METER MODE s itch configures the current metering circuit for capacitance measuring or

for output current measurement.

C A A C I T A N C E ( U S H T O R E A D X 1 )

U S H B U T T O N

The USH TO READ X1 pushbutton changes the scale of the CAPACITANCE metering. The

modified Wheatstone Bridge incorporated in this circuit indicates x10 readings ithout

depressing the USH TO READ X1 pushbutton. When in the x10 scale and the reading is

below 6

µ

F, the PUSH TO READ X1 should be depressed to get an accurate load

capacitance measurement.

C A Z E R O

This potentiometer is for zeroing the capacitance range at full scale prior to measuring the cable

capacitance.

O P E R T O R M N U L

10

1010

10

C A A C I T A N C E M E A S U R E M E N T O S T S

These posts are for connecting the cable to the capacitance measuring circuit. The HOT post is

for the cable center conductor, the COM post is for the cable's grounded shield. Be sure the

cable is de-energized before connecting this lo voltage circuit or damage ill result. The

resulting capacitance measurement on the cable ill identify the best operating frequency for

that particular cable run. A frequency table is provided in the section O ERATING THE

EQUI MENT.

List of included components ith the VLF Hipot

Ext. Intlk. jumper plug

100 ft. long output X-Ray cable (Standard)

100 FT. Ground Lead

10 ft. interconnect cable ith grounds po er section to HV tank. (Standard)

20 ft. interconnect cable po er section to control box(Standard)

6 ft. BNC to BNC coax cable -scope to panel interconnect

20 ft. red and black test leads for capacitance measurement

External energy (current limit) dissipation resistor

WARNING

DO NOT O ERATE THE VLF HI OT SET IF THE HIGH VOLTAGE TANK IS 5°

°°

° OR

MORE FROM LEVEL.

IF THE UNIT IS O ERATED OUT OF LEVEL, OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DO NOT STORE OR TRANSPORT VLF HIGH VOLTAGE SECTION

ON IT’S SIDE

O P E R T O R M N U L

11

1111

11

SETTING UP THE EQUIPMENT

The setup of this equipment has been minimized by consideration of the operator during design.

The VLF-12011CM three-piece construction on a roll around platform truck relieves the usual

installation and mobility obstacles for AC testing in the field or in a sub-station.

Select a level location

for the high voltage unit that ill allo easy hook-up to the test

cable. The cooling and filter assembly of the VLF series ill not operate properly if the high

voltage tank is placed on uneven ground. A maximum angle for correct operation is 5°. Blocking

the tank to a level condition is acceptable.

1.

Be sure that all the controls are off

,

in their de-energized or fully

counterclock ise position.

2.

Secure ground leads to the high voltage tank brass stud, and the

power section brass stud.

The Ground

leads should be of sufficient ampacit

to carr an expected fault currents from the load cable.

3.

Secure the interconnect cables from the power section to both the

control and the high voltage tank.

4.

Insert the coaxial output cable into the high voltage output

connector on the tank.

Tighten the clamping nut securely. The free hanging

lead from the center of the cable reel assembly connects to the high voltage tank.

Note:

The Output Cable from the cable reel must be uncoiled to the desired length

before the connection to the high voltage tank is made.

5.

Extend the GROUND CABLE on the reel to desired length

. Clamp the

orking end to the test cable shield. Clamp the reel end to a solid Station Ground.

6.

Insert the EXT INTLK plug into the socket on the control panel.

The

plug may also be ired to a normally open contact of a safety s itch for added

protection.

SECTION

2

O P E R T O R M N U L

12

1212

12

7.

Wire the input power terminal block to power as specified in Table

1, VLF-12011 specifications. ower wire should be rated for 30

Amps.

The setup of the VLF AC Test Set does not address the need for proper safety

grounding of the test cable load. The identification and disconnecting of cables from

service and the subsequent verification of the cables being de-energized may vary

for different types of tests or setups. lease consult the local codes where applicable

or reference the guidelines provided by your employer for maximum safety.

WARNING

DO NOT O ERATE THE VLF HI OT SET IF THE HIGH VOLTAGE TANK IS 5°

°°

° OR

MORE FROM LEVEL.

IF THE UNIT IS O ERATED OUT OF LEVEL, OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DO NOT STORE OR TRANSPORT VLF HIGH VOLTAGE SECTION

ON IT’S SIDE

O P E R T O R M N U L

13

1313

13

Operating the Equipment

This section provides step-by-step instruction on various test methods. Many facilities

have their o n in-house test procedures, and this manual is not to supercede these.

The purpose of this section is to explain the capabilities of this test set in real- orld

applications.

When testing cables, either single or three phase, there are certain extra steps that must be

observed to ensure safe operation.

AC Cable Insulation Testing

1.

Ensure that all the steps listed in Setting up the Equipment have been

accomplished. Take special note to ground the po er section and the high voltage

tank to a solid earth ground.

O P E R T O R M N U L

14

1414

14

Caution!!

Before makin any cable connections, ensure that the cable

bein tested has been properly identified, de-ener ized,

and rounded!

2.

Make sure that all insulators, stress cones, and pot heads are clean and free of

moisture. This ill prevent flashover and minimize leakage.

3.

Isolate the far end of the conductors under test for the test voltage; that may mean

separating some of the conductors in a multi-conductor cable from each other and

their shields.

4.

Any conductors or ires in the cable or the vicinity not being tested must be

grounded to avoid a buildup of charge and possible shock hazard.

5.

Voltage must be applied according to specifications from the cable manufacturer or

any other applicable test standards

6.

Prior to connecting anything to the test sample, be sure the test sample is

identified, de-energized and grounded.

7.

First, the cable capacitance must be measured to determine the best operating

frequency. Place the control near the cable being tested.

8.

Connect the input po er terminal block to a grounded 220 v (+/-10%), 50/60 Hz

source. A generator is an acceptable po er source.

9.

Turn on the main circuit breaker. The MAIN POWER light ill illuminate at both the

po er section and the control.

10.

Operate the METER MODE to µ

µµ

µF position. Adjust the CA ZERO for full scale

deflection (ZERO) on the meter.

11.

Connect the HOT post to the center conductor of the test cable. Connect the COM

post to the grounded shield of the test cable. Read the CA ACITANCE scale(x10).

12.

If the reading is belo 6.0µF depress the x1 pushbutton. Then follo ing table

provides operating frequency versus capacitance.

O P E R T O R M N U L

15

1515

15

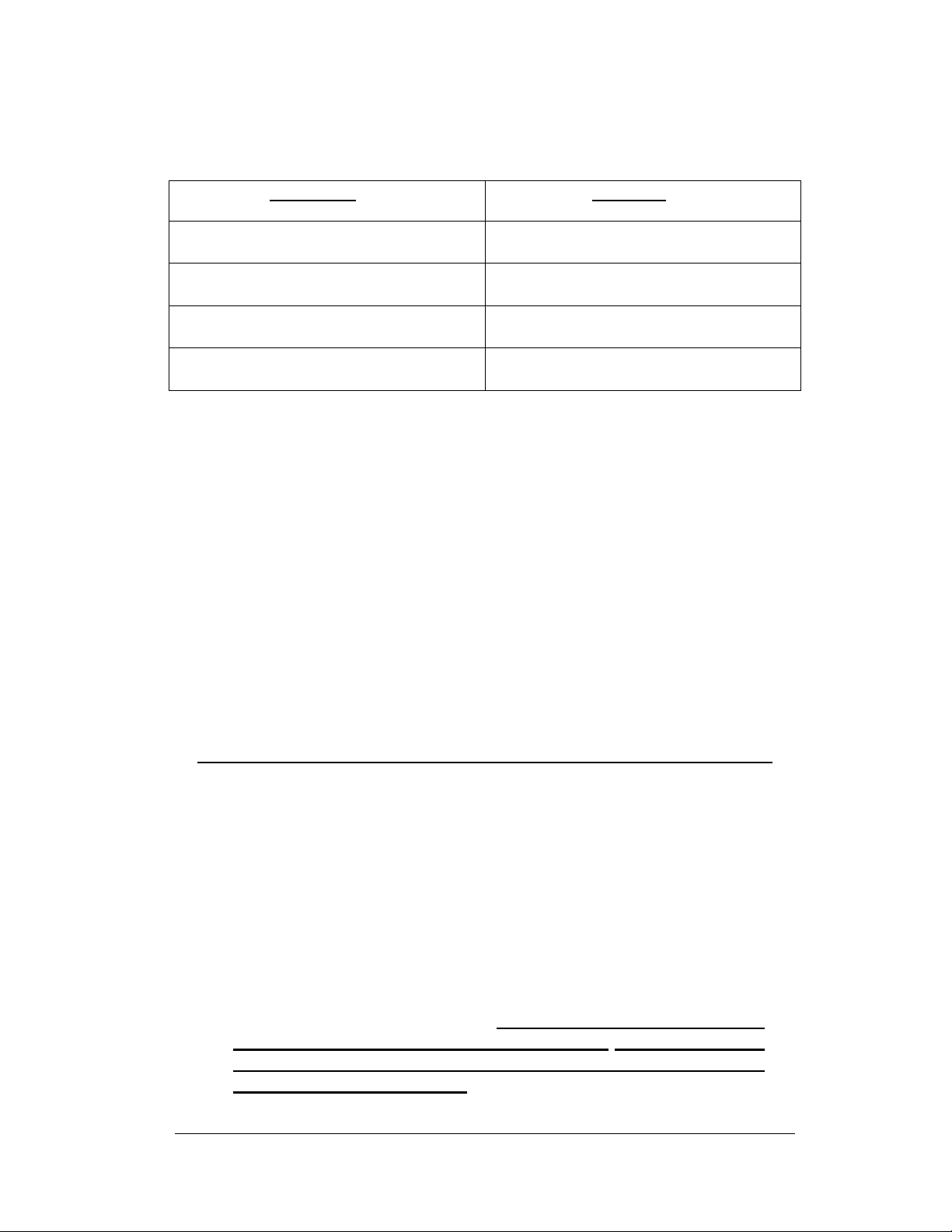

Capacitance Frequency

.55µF or less .1 Hz

1.1µF or less .05Hz

2.2µF or less .02Hz

5.5 µF or less .01Hz

13.

An oscilloscope (optional) can be connected to the SCO E OUT UT on the

control for ave shape monitoring. The oscilloscope should be properly grounded

and the input should be set to 1 volt/ division, the time base should be 5

seconds/division and the trigger should be set to roll display to vie the ave

shape. An oscilloscope ith signal memory display is best used for this application.

A BNC to BNC shielded jumper should be used for connection bet een the

SCO E OUT UT and the oscilloscope. A digital meter can be used to monitor this

connector. The voltage feedback calibration for this connector is 1 volt for 10 kV of

output.

* * * C A U T I O N * * *

O T E N T I A L L Y L E T H A L V O L T A G E S

M A Y B E R E S E N T

14.

Connect the output lead of the cable reel to the test sample through the External

Energy Dissipation Resistor. Be sure that there is enough clearance to grounded

objects for the expected test voltage. The minimum clearance in air is 10 kV

ac/inch.

15.

Place the OUT UT MODE in the HI OT position

16.

With the OUT UT control at zero (zero start interlock engaged), depress the HV

ON pushbutton. The HV ON light ill glo . At this time the pump and fan on the

high voltage section ill also energize. If this is the first test at this location,

leave the output control at zero and allow the pump to circulate oil for 15

minutes prior to raisin the output volta e and startin the test. This will

pur e air from the coolin system.

O P E R T O R M N U L

16

1616

16

17.

Increase the output by operating the HIGH VOLTAGE control to the RAISE

position until the desired output voltage is reached. Raising the output too fast ith

large capacitive loads may trip the output overload. Observe the OUT UT

ERCENT meter to rough in the set voltage. Please recognize that the output

cycle is: 100 seconds for a full sine ave @.01 Hz, 50 seconds fro a full sine ave

@ .02 Hz, 20 seconds for a full sine ave @ .05 Hz, and 10 seconds for a full sine

ave @ .1 Hz. . To set the output voltage you may need more than one cycle to

read the output accurately.

18.

18.18.

18.

Maintain the output voltage for the test time specified in your standard procedures.

19.

After the test is complete, depress the HIGH VOLTAGE control in LOWER

position, allo ing the load to return to zero and the unit to cycle for about 60 more

seconds prior to depressing the HV OFF pushbutton. Allo ing the unit to cycle for

some time allo s for the complete discharge of the load and avoiding the normal

self recharge that capacitive loads ill exhibit.

20.

If the test sample fails during the test, the overload circuit ill de-energize the high

voltage. Should an overload occur, the normal sine ave cycle is interrupted and

the load may bleed do n much more slo ly than hen the unit is cycling normally.

Depress the FAULT/RESET pushbutton to resume testing.,

21.

21.21.

21.

rior to removing the output cable from the load, observe that the output

voltmeter is at zero, and then use a GROUND STICK to positively ground the

test sample.

Note: Be sure to disconnect the output cable from the high

voltage tank before coiling the output cable onto the cable reel

assembly.

WARNING

DO NOT O ERATE THE VLF HI OT SET IF THE HIGH VOLTAGE TANK IS 5°

°°

° OR

MORE FROM LEVEL.

IF THE UNIT IS O ERATED OUT OF LEVEL, OVERHEATING AND INTERNAL ARCING MAY OCCUR.

DO NOT STORE OR TRANSPORT VLF HIGH VOLTAGE SECTION

ON IT’S SIDE

O P E R T O R M N U L

17

1717

17

Using the BURN MODE on AC Cables

1. Ensure that all the steps listed in Setting up the Equipment have been

accomplished. Take special note to ground the po er section and the high voltage

tank to a solid earth ground.

Caution!!

Before makin any cable connections, ensure that the cable

bein tested has been properly identified, de-ener ized,

and rounded!

2. Make sure that all insulators, stress cones, and pot heads are clean and free of

moisture. This ill prevent flashover and minimize leakage.

3. Isolate the far end of the conductors under test for the test voltage; that may mean

separating some of the conductors in a multi-conductor cable from each other and

their shields.

4. Any conductors or ires in the cable or the vicinity not being tested must be

grounded to avoid a buildup of charge and possible shock hazard.

5. Voltage must be applied according to specifications from the cable manufacturer or

any other applicable test standards

6. Prior to connecting anything to the test sample, be sure the test sample is

identified, de-energized and grounded.

7. First, the cable capacitance must be measured to determine the best operating

frequency. Place the control near the cable being tested.

8. Connect the input po er terminal block to a grounded 220 v (+/-10%), 50/60 Hz

source. A generator is an acceptable po er source.

9. Turn on the main circuit breaker. The MAIN POWER light ill illuminate at both the

po er section and the control.

10. Operate the METER MODE to µ

µµ

µF position. Adjust the CA ZERO for full scale

deflection (ZERO) on the meter.

11. Connect the HOT post to the center conductor of the test cable. Connect the COM

post to the grounded shield of the test cable. Read the CA ACITANCE scale(x10).

Other manuals for VLF Series

1

This manual suits for next models

1

Table of contents

Other High Voltage Power Supply manuals