5

Table of Contents

1Description.....................................................................................8

1.1 General............................................................................................8

1.2 Functions.........................................................................................8

1.3 High Voltage Test Configurations....................................................9

1.4 Technical Data ..............................................................................10

1.5 Scope of Delivery ..........................................................................11

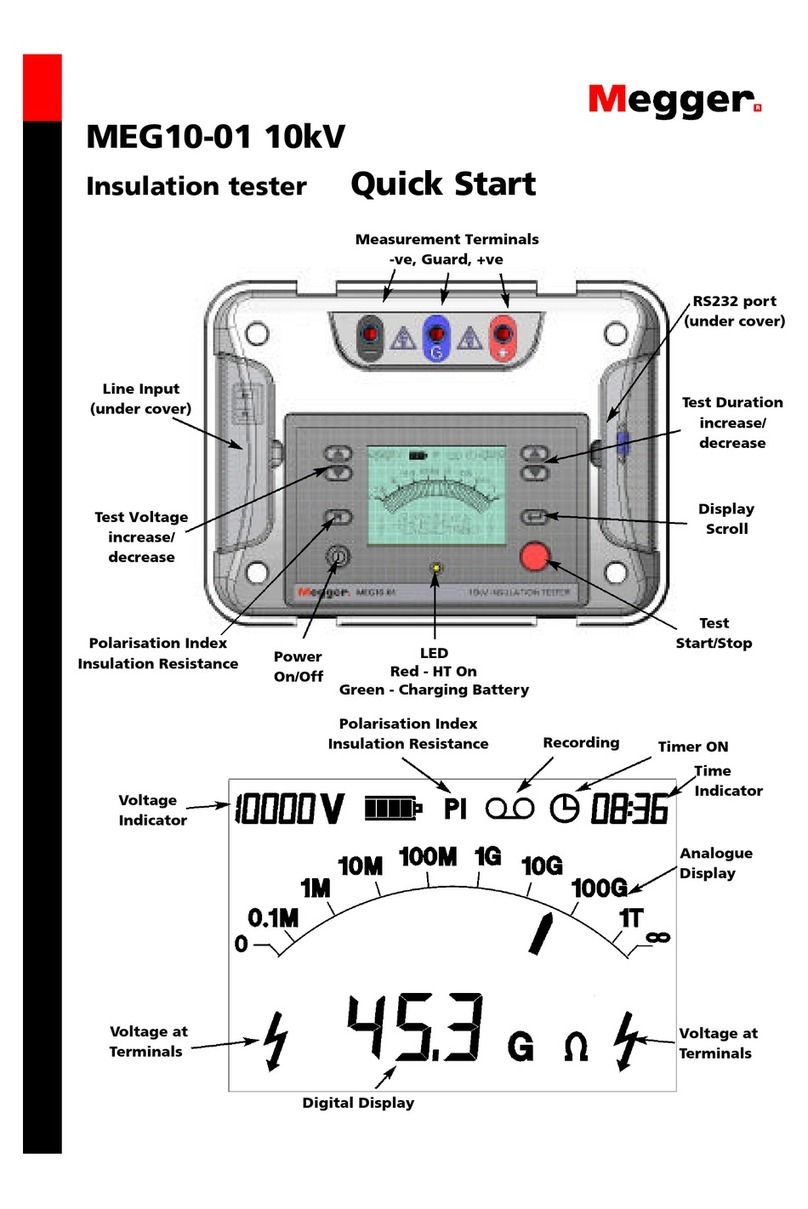

2Operating Panel and Connection Panel ....................................12

3Test System Installations ...........................................................14

3.1 HPG XX-AC...................................................................................14

3.1.1 HPG 35-AC ...................................................................................15

3.1.2 HPG 58-AC ...................................................................................15

3.1.3 HPG 78-AC ...................................................................................15

3.2 HPG XX-H .....................................................................................16

3.2.1 HPG 50-H......................................................................................16

3.2.2 HPG 80-H......................................................................................16

3.2.3 HPG 110-H....................................................................................17

3.3 HPG XX-D .....................................................................................17

3.3.1 HPG 50-D......................................................................................18

3.3.2 HPG 80-D......................................................................................18

4Safety............................................................................................19

4.1 Key Switch.....................................................................................19

4.2 Safety Terms According to VDE 0104...........................................20

4.2.1 READY FOR MAINS CONNECTION ............................................20

4.2.2 READY FOR OPERATION ...........................................................20

4.2.3 READY FOR SWITCHING ON......................................................20

4.2.4 In Operation...................................................................................20

4.2.5 Portable Test Equipment...............................................................21

4.2.6 Forbidden Area..............................................................................21

4.2.7 Emergency Switching Off ..............................................................21

5Placing the Device.......................................................................22

6Connecting the Device................................................................23

6.1 Earthing .........................................................................................24

6.2 Connecting the Control Unit to the HV Transformer......................25

6.3 Connecting the System Earth to the Cable Under Test.................25

6.4 Connecting the HV Output to the Cable Under Test .....................25

6.4.1 Isolation of Open Cable Ends........................................................25