HikRobot ID2000 Series User manual

ID2000 Series Industrial Code Reader

User Manual

ID2000 Series Industrial Code Reader User Manual

i

Legal Information

© 2023 Hangzhou Hikrobot Co., Ltd. All rights reserved.

About this Manual

The Manual includes instructions for using and managing the Product. Pictures, charts,

images and all other information hereinafter are for description and explanation only. The

information contained in the Manual is subject to change, without notice, due to firmware

updates or other reasons. Please find the latest version of this Manual at the Hikrobot

website (https://www.hikrobotics.com/). Please use this Manual with the guidance and

assistance of professionals trained in supporting the Product.

Trademarks

and other Hikrobot's trademarks and logos are the properties of Hikrobot in

various jurisdictions. Other trademarks and logos mentioned are the properties of their

respective owners.

Disclaimer

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS MANUAL AND THE

PRODUCT DESCRIBED, WITH ITS HARDWARE, SOFTWARE AND FIRMWARE, ARE PROVIDED

"AS IS" AND "WITH ALL FAULTS AND ERRORS". HIKROBOT MAKES NO WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, MERCHANTABILITY,

SATISFACTORY QUALITY, OR FITNESS FOR A PARTICULAR PURPOSE. THE USE OF THE

PRODUCT BY YOU IS AT YOUR OWN RISK. IN NO EVENT WILL HIKROBOT BE LIABLE TO

YOU FOR ANY SPECIAL, CONSEQUENTIAL, INCIDENTAL, OR INDIRECT DAMAGES,

INCLUDING, AMONG OTHERS, DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS

INTERRUPTION, OR LOSS OF DATA, CORRUPTION OF SYSTEMS, OR LOSS OF

DOCUMENTATION, WHETHER BASED ON BREACH OF CONTRACT, TORT (INCLUDING

NEGLIGENCE), PRODUCT LIABILITY, OR OTHERWISE, IN CONNECTION WITH THE USE OF

THE PRODUCT, EVEN IF HIKROBOT HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES OR LOSS.

YOU ACKNOWLEDGE THAT THE NATURE OF INTERNET PROVIDES FOR INHERENT

SECURITY RISKS, AND HIKROBOT SHALL NOT TAKE ANY RESPONSIBILITIES FOR

ABNORMAL OPERATION, PRIVACY LEAKAGE OR OTHER DAMAGES RESULTING FROM

CYBER-ATTACK, HACKER ATTACK, VIRUS INFECTION, OR OTHER INTERNET SECURITY

RISKS; HOWEVER, HIKROBOT WILL PROVIDE TIMELY TECHNICAL SUPPORT IF REQUIRED.

YOU AGREE TO USE THIS PRODUCT IN COMPLIANCE WITH ALL APPLICABLE LAWS, AND

YOU ARE SOLELY RESPONSIBLE FOR ENSURING THAT YOUR USE CONFORMS TO THE

APPLICABLE LAW. ESPECIALLY, YOU ARE RESPONSIBLE, FOR USING THIS PRODUCT IN A

MANNER THAT DOES NOT INFRINGE ON THE RIGHTS OF THIRD PARTIES, INCLUDING

WITHOUT LIMITATION, RIGHTS OF PUBLICITY, INTELLECTUAL PROPERTY RIGHTS, OR

DATA PROTECTION AND OTHER PRIVACY RIGHTS. YOU SHALL NOT USE THIS PRODUCT

FOR ANY PROHIBITED END-USES, INCLUDING THE DEVELOPMENT OR PRODUCTION OF

WEAPONS OF MASS DESTRUCTION, THE DEVELOPMENT OR PRODUCTION OF CHEMICAL

OR BIOLOGICAL WEAPONS, ANY ACTIVITIES IN THE CONTEXT RELATED TO ANY NUCLEAR

ID2000 Series Industrial Code Reader User Manual

ii

EXPLOSIVE OR UNSAFE NUCLEAR FUEL-CYCLE, OR IN SUPPORT OF HUMAN RIGHTS

ABUSES.

THE PERFORMANCE DATA IN THIS PUBLICATION IS BASED ON HIKROBOT'S INTERNAL

RESEARCH/EVALUATION. ACTUAL DATA MAY VARY DEPENDING ON SPECIFIC

CONFIGURATIONS AND OPERATING CONDITIONS AND HIKROBOT SHALL NOT BEAR THE

CONSEQUENCES ARISING THEREFROM.

IN THE EVENT OF ANY CONFLICTS BETWEEN THIS MANUAL AND THE APPLICABLE LAW,

THE LATTER PREVAILS.

Regulatory Information

Note

These clauses apply only to the products bearing the corresponding mark or information.

FCC Information

Please take attention that changes or modification not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

FCC Conditions

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions:

●This device may not cause harmful interference.

●This device must accept any interference received, including interference that may cause

undesired operation.

EU Conformity Statement

This product and - if applicable - the supplied accessories too are

marked with "CE" and comply therefore with the applicable

harmonized European standards listed under the Directive

2014/30/EU(EMCD),Directive 2001/95/EC(GPSD) and Directive

2011/65/EU(RoHS).

ID2000 Series Industrial Code Reader User Manual

iii

2012/19/EU (WEEE directive): Products marked with this symbol

cannot be disposed of as unsorted municipal waste in the European

Union. For proper recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or dispose of it at

designated collection points. For more information see:

http://www.recyclethis.info

2006/66/EC (battery directive): This product contains a battery that

cannot be disposed of as unsorted municipal waste in the European

Union. See the product documentation for specific battery

information. The battery is marked with this symbol, which may

include lettering to indicate cadmium (Cd), lead (Pb), or mercury

(Hg). For proper recycling, return the battery to your supplier or to a

designated collection point. For more information see:

http://www.recyclethis.info

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol

Description

Danger

Indicates a hazardous situation which, if not avoided, will or

could result in death or serious injury.

Caution

Indicates a potentially hazardous situation which, if not avoided,

could result in equipment damage, data loss, performance

degradation, or unexpected results.

Note

Provides additional information to emphasize or supplement

important points of the main text.

Available Model

This manual is applicable to the ID2000 Series Industrial Code Reader.

Safety Instruction

These instructions are intended to ensure that the user can use the device correctly to avoid

danger or property loss.

●Read and follow these safety instructions before installing, operating and maintaining the

device.

●To ensure personal and device safety, when installing, operating, and maintaining the

device, follow the signs on the device and in the manual, and all safety instructions

described in the manual.

●The note, warning and danger items in the manual do not represent all the safety

instructions that should be observed, but only serve as a supplement to all the safety

instructions.

ID2000 Series Industrial Code Reader User Manual

iv

●The device should be used in an environment that meets the design specifications,

otherwise it may cause malfunctions, and malfunctions or component damage caused by

non-compliance with relevant regulations are not within the scope of the device's quality

assurance.

●Our company will not bear any legal responsibility for personal safety accidents and

property losses caused by abnormal operation of the device.

Caution:

●In the use of the device, you must be in strict compliance with the electrical safety

regulations of the nation and region.

●Use the power adapter provided by the official manufacturer, and the power supply should

meet LPS or PS2 requirements according to IEC 60950-1 or IEC 62368-1 standard. For the

specific requirements of the power adapter, please refer to the device’s specifications.

●To reduce the risk of fire or electric shock, do not expose the device to rain or moisture.

●Make sure that the device is firmly fixed when installing it in the use environment.

●The plug or socket of the device is for disconnecting the power supply, and do not cover

it.

●Make sure that the device is disconnected from power supply during wiring, disassembly

and other operations, and do not operate with electricity. Otherwise there will be a danger

of electric shock.

●Avoid aiming the lens at strong light (such as lighting, sunlight, or laser beams, etc.),

otherwise the image sensor will be damaged.

●Do not touch the image sensor directly. If cleaning is necessary, please slightly dampen a

soft clean cloth with alcohol and gently wipe off the dust. When the device is not in use,

please attach a dust cover to protect the image sensor.

●If the device does not work properly, please contact your dealer or the nearest service

center. Never attempt to disassemble the device yourself (we shall not assume any

responsibility for problems caused by unauthorized repair or maintenance).

●Please dispose of the device in strict accordance with the relevant national or regional

regulations and standards to avoid environmental pollution and property damage.

●Check whether the device’s package is in good condition, whether there is damage,

intrusion, moisture, deformation, etc. before unpacking.

●Check the surface of the device and accessories for damage, rust, bumps, etc. when

unpacking.

●Check whether the quantity and information of the device and accessories are complete

after unpacking.

●Store and transport the device according to the storage and transport conditions of the

device, and the storage temperature and humidity should meet the requirements.

●It is strictly prohibited to transport the device in combination with items that may affect

or damage the device.

●Please read the manual and safety instructions carefully before installing the device.

●The device should not be placed with exposed flame sources, such as lighted candles.

●Avoid installing the device in a vibration or shock environment, and keep it away from

electromagnetic interference sites (ignoring this may damage the device).

ID2000 Series Industrial Code Reader User Manual

v

●Do not directly touch the heat dissipation parts of the device to avoid burns.

●Do not install the indoor device in an environment where it may be exposed to water or

other liquids.

●Do not use the device in high temperature, low temperature or high humidity environment.

For specific temperature and humidity requirements, please refer to the device’s

specifications.

●Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries

according to the instructions.

Personnel Requirement

Quality requirements for installation and maintenance personnel: Qualification certificate or

working experience in weak current system installation and maintenance, and relevant

working experience and qualifications. Besides, the personnel must possess the following

knowledge and operation skills:

●The basic knowledge and operation skills of low voltage wiring and low voltage electronic

circuit connection.

●The ability to comprehend the contents of this manual.

Electromagnetic Interference Prevention

●When installing the device, if you cannot ensure that the device itself and all equipment

connected to the device are well grounded, you should isolate the device with an

insulating bracket.

●To avoid the accumulation of static electricity, ensure that other equipment (such as

machines, internal components, etc.) and metal brackets on site are properly grounded.

●The power cable, data cable, signal cable, etc. of the device must be wired separately.

Make sure to ground them if the wiring groove is used to separate the wiring and the

wiring groove is metal.

●During the installation and use of the device, high voltage leakage must be avoided.

●Use a figure-eight bundle method if the device cable is too long.

●Do not route the device together with other equipment (especially servo motors, high-

power devices, etc.), and control the distance between cables to more than 10 cm. Make

sure to shield the cables if unavoidable.

●The control cable of the device and the power cable of the industrial light source must be

wired separately to avoid bundled wiring.

●When connecting the device and metal accessories, they must be connected firmly to

maintain good conductivity.

●Use a shielded network cable to connect to the device. If you use a self-made network

cable, make sure that the shielding shell at the aviation head is well connected to the

aluminum foil or metal braid of the shielding cable.

●During the wiring process, evaluate the wiring space reasonably, and do not pull the cables

hard, so as not to damage the electrical performance of the cables.

●The unused cables of the device must be insulated.

●Use the power adapter to supply power to the device separately. If centralized power

supply is necessary, make sure to use a DC filter to filter the power supply of the device

separately before use.

ID2000 Series Industrial Code Reader User Manual

vi

●If the device is powered on and off frequently, it is necessary to strengthen the voltage

isolation, and consider adding a DC/DC isolation power supply module between the

device and the adapter.

Contact Information

Hangzhou Hikrobot Co., Ltd.

E-mail: tech_support@hikrobotics.com

Website: https://en.hikrobotics.com/

ID2000 Series Industrial Code Reader User Manual

vii

Contents

Chapter 1 Appearance .................................................................................................... 1

Chapter 2 Connector and Cable....................................................................................... 5

2.1 Type I Device with USB Interface.....................................................................................5

2.2 Type I Device with Fast Ethernet Interface and Type II Device...................................6

2.3 Type III Device.....................................................................................................................9

2.4 Type IV Device with Fast Ethernet Interface ............................................................... 11

2.5 Type IV Device with USB Interface ............................................................................... 13

Chapter 3 Electrical Feature and I/O Wiring ................................................................... 15

3.1 Electrical Feature and Wiring of Type I, III and IV Devices ....................................... 15

3.1.1 Input Signal........................................................................................................... 15

3.1.2 Output Signal........................................................................................................ 16

3.1.3 Bi-Directional Signal ........................................................................................... 17

3.1.4 Input Signal Wiring .............................................................................................. 19

3.1.5 Output Signal Wiring ........................................................................................... 21

3.2 Electrical Feature and Wiring of Type II Device.......................................................... 22

3.2.1 Input Signal........................................................................................................... 22

3.2.2 Output Signal........................................................................................................ 23

3.2.3 Input Signal Wiring .............................................................................................. 24

3.2.4 Output Signal Wiring ........................................................................................... 25

3.3 RS-232 Serial Port .......................................................................................................... 27

Chapter 4 Installation ................................................................................................... 28

4.1 Installation Preparation.................................................................................................. 28

4.2 Install Device.................................................................................................................... 28

Chapter 5 Device Connection ........................................................................................ 30

5.1 Install Client Software .................................................................................................... 30

5.2 Set PC Environment ........................................................................................................ 31

5.2.1 Turn off Firewall for Network Device ................................................................ 31

5.2.2 Set PC Network for Network Device ................................................................. 31

5.2.3 Check USB Drive for USB Device....................................................................... 32

ID2000 Series Industrial Code Reader User Manual

viii

5.3 Set Device Network......................................................................................................... 33

5.4 Connect Device to Client Software ............................................................................... 33

Chapter 6 Client Software Layout.................................................................................. 34

Chapter 7 Device Mode Settings ................................................................................... 36

Chapter 8 Device Settings............................................................................................. 38

8.1 Image Quality Settings ................................................................................................... 38

8.1.1 Set Image .............................................................................................................. 38

8.1.2 Set Polling............................................................................................................. 40

8.1.3 Set Light Source................................................................................................... 43

8.1.4 Set Lens Focus ..................................................................................................... 44

8.1.5 Set Self-Adaptive Adjustment ........................................................................... 48

8.1.6 Set Mirror X ........................................................................................................... 49

8.1.7 Set Test Pattern.................................................................................................... 50

8.2 Code Algorithm Settings ................................................................................................ 50

8.2.1 Add Code ............................................................................................................... 50

8.2.2 Set Code Reading ROI ......................................................................................... 51

8.2.3 Set 1D Algorithm Parameter .............................................................................. 55

8.2.4 Set 2D Algorithm Parameter .............................................................................. 55

8.2.5 Set 2D Code Quality Evaluation ......................................................................... 58

8.2.6 Set Code Score..................................................................................................... 59

8.3 Line Mode Settings ......................................................................................................... 60

8.4 Signal Input Settings ...................................................................................................... 61

8.4.1 Set Trigger Mode.................................................................................................. 61

8.4.2 Enable Internal Trigger Mode............................................................................. 62

8.4.3 Enable External Trigger Mode............................................................................ 62

8.4.4 Stop Trigger .......................................................................................................... 67

8.5 Signal Output Settings ................................................................................................... 71

8.5.1 Select Output Signal............................................................................................ 71

8.5.2 Enable Line Inverter............................................................................................. 71

8.5.3 Set Event Source.................................................................................................. 72

8.5.4 Set Buzzer ............................................................................................................. 75

8.6 Code Reading Result Settings....................................................................................... 75

ID2000 Series Industrial Code Reader User Manual

ix

8.6.1 Set Code Reading Result Output Mode............................................................ 75

8.6.2 Set Filter Rule ....................................................................................................... 76

8.6.3 Set Result Format ................................................................................................ 81

8.7 Communication Settings................................................................................................ 86

8.7.1 Smart SDK............................................................................................................. 86

8.7.2 TCP Client.............................................................................................................. 86

8.7.3 Serial ...................................................................................................................... 87

8.7.4 FTP ......................................................................................................................... 87

8.7.5 TCP Server............................................................................................................. 88

8.7.6 Profinet .................................................................................................................. 88

8.7.7 MELSEC or SLMP ................................................................................................. 89

8.7.8 Ethernet/IP............................................................................................................ 91

8.7.9 ModBus.................................................................................................................. 92

8.7.10 UDP ...................................................................................................................... 93

8.7.11 Fins....................................................................................................................... 94

8.7.12 USB ...................................................................................................................... 95

8.8 Set Multicast .................................................................................................................... 97

8.9 Main-Sub Networking..................................................................................................... 98

8.10 Contrast Control Settings .......................................................................................... 100

8.11 Statistics Information................................................................................................. 102

8.12 Event Report................................................................................................................. 103

8.13 User Set Customization ............................................................................................. 104

Chapter 9 Device Operation ........................................................................................ 105

9.1 Live View......................................................................................................................... 105

9.2 Enable Acquisition......................................................................................................... 105

9.3 Add Cross Line............................................................................................................... 106

9.4 Start Recording.............................................................................................................. 106

9.5 Split Window .................................................................................................................. 107

9.6 View Reports .................................................................................................................. 107

9.7 View Log.......................................................................................................................... 108

9.8 Set Time.......................................................................................................................... 108

9.9 Enable Device Auto Work ............................................................................................. 109

ID2000 Series Industrial Code Reader User Manual

x

Chapter 10 Device Maintenance.................................................................................. 110

10.1 Update Firmware......................................................................................................... 110

10.2 Reboot Device.............................................................................................................. 110

Chapter 11 FAQ (Frequently Asked Question) ............................................................. 112

11.1 Why the image is very dark? ..................................................................................... 112

11.2 Why the image's frame rate is very low in the live view? ..................................... 112

11.3 Why there is no device listed after I run the IDMVS client software? ................ 112

11.4 Why there is no image in the live view?................................................................... 113

ID2000 Series Industrial Code Reader User Manual

1

Chapter 1 Appearance

Note

Appearance here is for reference only. Refer to the device's specification for detailed

dimension information.

●Type I device is a vari focal device that supports adjusting focus manually via its focus

knob. This type device has two kinds of data interfaces, including fast Ethernet and USB.

●Type II and type IV devices are fixed focal device whose focus cannot be adjusted, and

type IV device has two kinds of data interfaces, including fast Ethernet and USB.

●Type III device is a vari focal device that adopts vari focal lens to adjust focus.

Figure 1-1 Appearance (Type I)

ID2000 Series Industrial Code Reader User Manual

2

Figure 1-2 Appearance (Type II)

Figure 1-3 Appearance (Type III)

ID2000 Series Industrial Code Reader User Manual

3

Figure 1-4 Appearance (Type IV)

Table 1-1 Component Description

No.

Name

Description

1

Focus Knob

It is used to adjust focal length manually.

Note

Only type I device has the focus knob.

2

Screw Hole

It is used to fix the device to the installation position.

●For type I, II and III devices, you should use M2 screw.

●For type IV device, you should use M3 screw.

3

Trigger Button

When the device is in trigger mode, press the button and the

device triggers once.

4

SR Cable

SR cable connector provides power, I/O, Ethernet, and serial port.

ID2000 Series Industrial Code Reader User Manual

4

No.

Name

Description

5

LNK Indicator

It is a network status indicator. The indicator is flashing green

when the network transmission is normal. Otherwise, it is unlit.

Note

Type IV device does not have a LNK indicator.

6

Status Indicator

For type I, II and III devices, it is a STS indicator. And for type IV

device, it is an OK/NG indicator.

●Regarding STS indicator, it is green when the device operates

normally, and it is red when the device is powered on or operation

error occurs.

●Regarding OK/NG indicator, it is red when the device is powered

on or operation error occurs, and it is unlit when the device

operates normally without reading codes. The indicator is green

lasting 0.5 s when the device reads codes successfully, and is

solid green when the device reads codes continuously.

7

PWR Indicator

It is a power indicator. The indicator is red during the device’s

power-on process. After the device is powered on, the indicator is

green.

8

Light Source

It is the LED light source used to provide light when the device

acquires images.

Note

The light source color is different by device models.

9

Sensor

It is used to acquire images.

10

Aiming Light

It helps to indicate the field of view and aim targets.

11

Buzzer

The buzzer beeps three times continuously when the device is

powered on, beeps twice when the device reads setting codes

successfully, and beeps once when the device reads codes

successfully.

Note

Only type IV device has a buzzer.

ID2000 Series Industrial Code Reader User Manual

5

Chapter 2 Connector and Cable

This section introduces the device’s connector on its SR cable and the supplied cable in the

package.

Note

The device’s connector and connector pin definitions may differ by device models.

2.1 Type I Device with USB Interface

Type I device with USB interface has a 17-pin M12 connector. Refer to the figure and table

below for connector pin definitions.

Figure 2-1 17-Pin M12 Connector

Table 2-1 Pin Definitions (Type I Device with USB Interface)

No.

Signal

I/O Signal Source

Description

1

DC_PWR

--

Direct current power supply positive

3

USB_DM

--

USB signal negative

11

GND

--

Direct current power supply

negative

12

USB_DP

--

USB signal positive

You should use the supplied 17-pin cable for USB device to wire the type I device with USB

interface. The cable has a 17-pin M12 connector for connecting with the device, and a USB

interface for connecting with the PC.

Figure 2-2 17-Pin Cable for Type I Device with USB Interface

ID2000 Series Industrial Code Reader User Manual

6

2.2 Type I Device with Fast Ethernet Interface and Type II

Device

Both type I device with fast Ethernet interface and type II device have a 17-pin M12

connector, but their corresponding connector pin definitions are different. Refer to the figure

and table below for details.

Figure 2-3 17-Pin M12 Connector

Table 2-2 Pin Definitions (Type I Device with Fast Ethernet Interface)

No.

Signal

I/O Signal

Source

Description

Supplied Cable

1

DC_PWR

--

Direct current power supply

positive

Red open line

2

GND

Line 0/1/2/3-

Direct current power supply

negative

Brown open line

3

Reserved

4

RS232_TX

--

RS-232 serial port output

DB9 female serial

port

5

RS232_RX

--

RS-232 serial port input

DB9 female serial

port

6

MDI0+

--

Fast Ethernet signal MDI0+

RJ45 Ethernet

connector

7

MDI1-

--

Fast Ethernet signal MDI1-

RJ45 Ethernet

connector

8

GPIO2

Line 2+

It can be configured as input

or output, and is output by

default.

Blue/white open

line

9

GND

Line 0/1/2/3-

Direct current power supply

negative

Blue open line

ID2000 Series Industrial Code Reader User Manual

7

No.

Signal

I/O Signal

Source

Description

Supplied Cable

10

GPIO3

Line 3+

It can be configured as input

or output, and is output by

default.

Brown/white

open line

11

GND

Line 0/1/2/3-

Direct current power supply

negative

Black open line

12

Reserved

13

Reserved

Purple open line

14

MDI0-

--

Fast Ethernet signal MDI0-

RJ45 Ethernet

connector

15

MDI1+

--

Fast Ethernet signal MDI1+

RJ45 Ethernet

connector

16

GPIO0

Line 0+

It can be configured as input

or output, and is input by

default.

Gray open line

17

GPIO1

Line 1+

It can be configured as input

or output, and is input by

default.

White open line

Table 2-3 Pin Definitions (Type II Device)

No.

Signal

I/O Signal

Source

Description

Supplied Cable

1

DC_PWR

--

Direct current power

supply positive

Red open line

2

OUT_COM

LineOut 0/1

signal ground

Output common port

Brown open line

3

Reserved

4

RS232TX

--

RS-232 serial port output

DB9 female serial

port

5

RS232RX

--

RS-232 serial port input

DB9 female serial

port

6

MDI0+

--

Fast Ethernet signal MDI0+

RJ45 Ethernet

connector

7

MDI1-

--

Fast Ethernet signal MDI1-

RJ45 Ethernet

connector

8

OPTO_OUT0

LineOut 0 signal

Opto-isolated output 0

Blue/white open

ID2000 Series Industrial Code Reader User Manual

8

No.

Signal

I/O Signal

Source

Description

Supplied Cable

line

line

9

IN_COM

LineIn 0/1

signal ground

Input common port

Blue open line

10

OPTO_OUT1

LineOut 1 signal

line

Opto-isolated output 1

Brown/white open

line

11

GND

--

Direct current power

supply negative

Black open line

12

Reserved

13

Reserved

Purple open line

14

MDI0-

--

Fast Ethernet signal MDI0-

RJ45 Ethernet

connector

15

MDI1+

--

Fast Ethernet signal MDI1+

RJ45 Ethernet

connector

16

OPTO_IN0

LineIn 0 signal

line

Opto-isolated input 0

Gray open line

17

OPTO_IN1

LineIn 1 signal

line

Opto-isolated input 1

White open line

For the type I device with fast Ethernet interface and the type II device, you should use the

supplied 17-pin cable below to wire them. The cable has a 9-pin serial port connector that

corresponds to 4th and 5th pins of the device’s 17-pin interface, and a RJ45 connector that

corresponds to 6th, 7th, 14th, and 15th pins of the 17-pin interface.

Figure 2-4 17-Pin Cable for Type I Device with Fast Ethernet Interface and Type II Device

Note

●For type I device with fast Ethernet, the pink line in the open line is Line 0/1’s pull-up and

pull-down resistor, and black/white line in the open line is Line 2/3’s pull-up and pull-down

ID2000 Series Industrial Code Reader User Manual

9

resistor.

●For type II device, the pink line in the open line is LineIn 0/1’s pull-up and pull-down resistor,

and black/white line in the open line is LineOut 0/1’s pull-up and pull-down resistor.

Caution

You cannot use the 12 V power plug of the 9-pin serial port connector and power supply

open line at the same time. Otherwise, damaging to power supply may occur.

2.3 Type III Device

Type III device also has a 17-pin M12 connector. Refer to the figure and table below for

connector pin definitions.

Figure 2-5 17-Pin M12 Connector

Table 2-4 Pin Definitions (Type III Device)

No.

Signal

I/O Signal

Source

Description

Supplied Cable

1

DC_PWR

--

Direct current power supply

positive

Red open line

2

Reserved

Brown open line

3

Reserved

4

RS232_TX

--

RS-232 serial port output

DB9 female serial

port

5

RS232_RX

--

RS-232 serial port input

DB9 female serial

port

6

MDI0+

--

Fast Ethernet signal MDI0+

RJ45 Ethernet

connector

7

MDI1-

--

Fast Ethernet signal MDI1-

RJ45 Ethernet

Other manuals for ID2000 Series

3

Table of contents

Other HikRobot Barcode Reader manuals

Popular Barcode Reader manuals by other brands

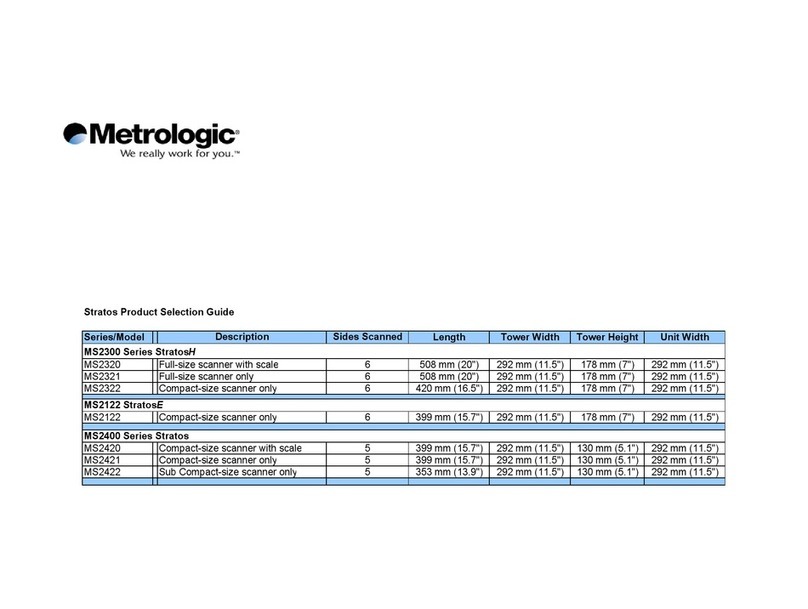

Metrologic

Metrologic MS9530 Series Installation and user guide

Generalscan

Generalscan MiniRing GS R5000BT-51C Configuration guide

RIOTEC

RIOTEC RIOSCAN iCR6307AS quick guide

Datalogic

Datalogic MAGELLAN 8300 Product reference guide

SICK

SICK Lector61 Series operating instructions

Avery Dennison

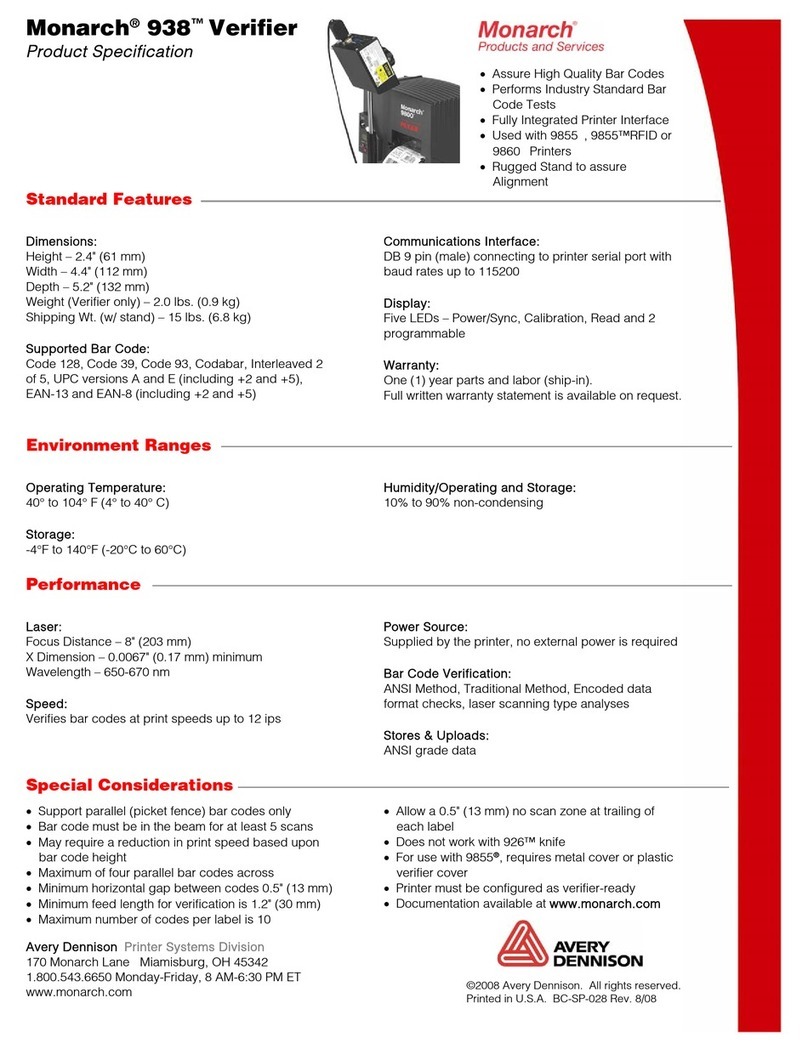

Avery Dennison Monarch 938 specification