Hills Rotary 400 User guide

Rotary Folding Hoists

Installer’s Manual

To suit models:

Rotary 400TM

Rotary 450TM

Rotary 500TM

Contents

Page

Item 1: Replacing the Upper Cross Cover 4

Item 2: Repairing the Upper Cross Assembly 4

Item 3: Replacing the Locking Collar 5

Item 4: Repairing the Lower Cross Assembly 6

Item 5: Repairing the Latch Assembly 8

Item 6: Repairing the Handle Assembly 9

Item 7: Replacing an Arm Assembly 10

Item 8: Repairing a Tensioner Assembly 11

Item 9: Restringing a Line Segment 11

Item 10: Restringing the Hoist 12

Item 11: Replacing the Ground Socket Locking Collar 12

Item 12: Replacing the Windbrake and Winding Mechanism 13

Line Length Chart 14

4

Item 1: Replacing the Upper Cross Cover

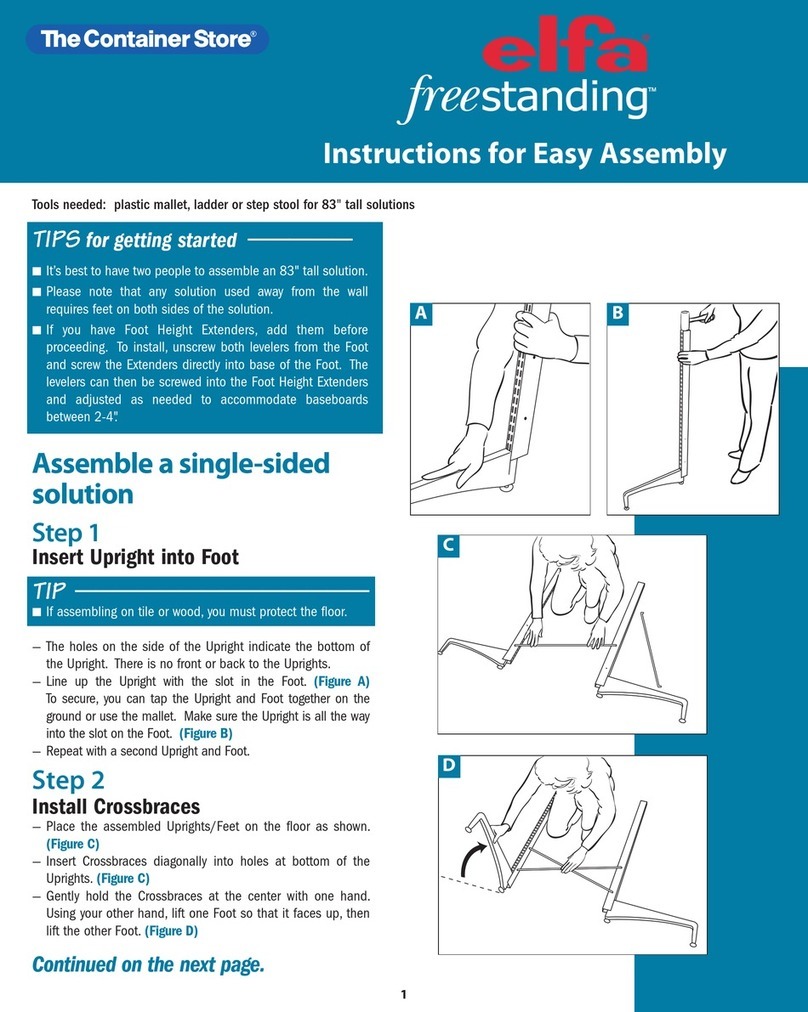

1. Fold up the hoist and secure with the Line Tie-Off Strap (Fig. 1).

2. Remove hoist from the Ground Socket and lay it on the ground.

3. Using a screwdriver, gently lever up one on the bottom flaps to disengage

the central snap (Fig. 2).

4. To replace, snap on the new cover (Fig. 3).

Fig. 1 Fig. 2 Fig. 3

Item 2: Repairing the Upper Cross Assembly

You will require the Upper Cross disassembly tool set (red) for this operation.

1. Open the hoist whilst in the Ground Socket.

2. Place disassembly tool into one of the recessed grooves of the Cross Assembly (Fig. 4)

3. Push the tool upwards towards the stay until it locates.

4. Use an 8mm Allen key to turn the central cam through 90 degrees. This action spreads

the locating snap features away from their locking ledge (Fig. 5)

5. Repeat this with the remaining three tools around the cross.

6. Fold up the hoist and attach the line tie-off strap, remove from the Ground Socket.

7. Remove the Upper Cross Cover as described in Item 1.

8. Remove the screw from the top of the hoist (Fig. 6)

9. Using a screwdriver, gently lever the Upper Cross halves apart to separate (Fig. 7)

10. Once the Upper Cross is separated the Arm Stays can be accessed if they need

to be serviced.

11. To remove the Upper Cross Bottom undo the two screws holding it to Secondary

Standard (Fig. 8)

5

12. To re-assemble the Upper Cross Assembly re-attach the Upper Cross Bottom to the

Secondary Standard using the two screws.

13. Place all of the Arm Stays into the pivot recesses in the Upper Cross Bottom.

14. Unlock and remove the disassembly tools from the four recesses around the cross.

15. Locate and push the Upper Cross Top into the Upper Cross Bottom until the locating

snaps have re-engaged (Fig. 9). Note: check all Arm Stay Pivots are engaged correctly.

16. Replace the screw into the top of the assembly.

17. Snap the Upper Cross Cover back on.

Fig. 4 Fig. 5 Fig. 6

Fig. 7 Fig. 8 Fig. 9

Item 3: Replacing the Locking Collar

To service the Locking Collar you must first remove the Upper

Cross Assembly as described in Item 2.

1. Remove the screw from the Locking Collar and slide it

off the top of the Secondary Standard. (Fig. 10)

2. To re-assemble, slide on a new Locking Collar

and re-secure.

3. Re-assemble the Upper Cross Assembly. Fig. 10

90º

6

Item 4: Repairing the Lower Cross Assembly

You will require the Lower Cross disassembly tool set (blue) for this operation.

1. Fold up the hoist and secure with the line-tie off strap (See Fig. 1).

2. Place the disassembly tool into one of the recessed grooves of the Lower

Cross assembly.

Note: Steps 2 to 5 are similar to steps 2 to 5 in item 2, Repairing the Upper

Cross Assembly

3. Push the tool upwards towards the Arm Joiner until it locates.

4. Use an 8mm Allen key to turn the central cam through 90 degrees. This action spreads

the locating snap features away from their locking ledge (See Fig. 5)

5. Repeat this with the remaining three tools around the cross.

6. Remove the hoist from the Ground Socket and lay it down with the

Main Standard supported.

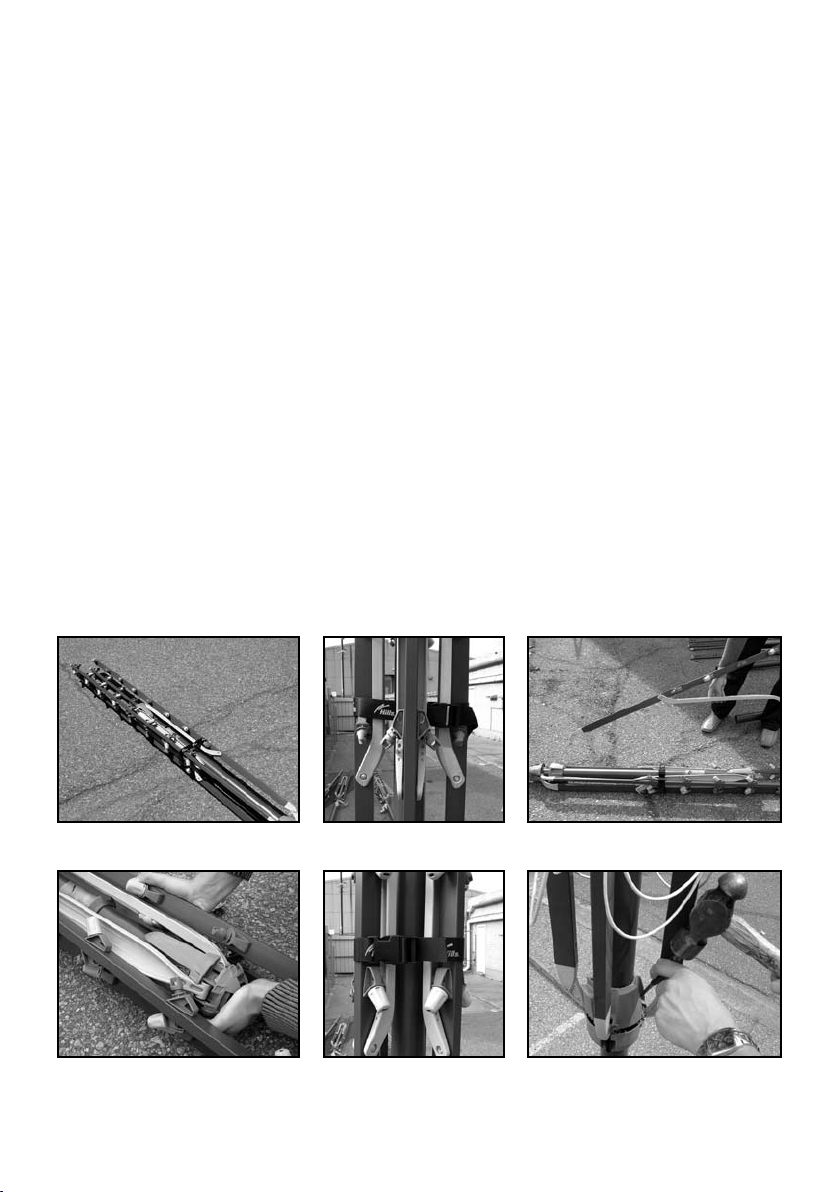

7. Using a screwdriver, gently lever the cross halves apart to separate the cross (Fig. 11).

8. Once the cross is separated the Arm and Latch assemblies can be accessed.

9. To replace the Lower Cross Assembly you will need to remove the Handle assembly (Item

6) and also the Locking Pin and Locking Collar (Item 11) from the main standard.

10. Once these items are out of the way the halves can be slid off the bottom of the hoist.

(Fig. 12 and 13)

11. After the Lower Cross Assembly has been serviced or replaced re-assemble the

components that were removed in points 8, 9 and 10 (Fig. 14).

12. Place the hoist back into the Ground Socket.

13. Align the top of the Lower Cross Assembly and Latch with the screw in the Locking Collar

to ensure correct hoist operation (Fig. 15).

14. Locate and secure the Arm Joiners by locating them into the pivot recesses in the Lower

Cross Top.

15. Unlock and remove the disassembly tools from the four recesses around the cross.

16. Push the two halves of the cross together to line up the 8 snap hooks (Fig 16).

17. Using the Pin Punch provided and a hammer knock the two halves of the cross assembly

together (Fig. 17).

18. Ensure all 8 hooks have engaged and the Arm Joiners are seated correctly before opening

the hoist.

7

Fig. 11 Fig. 12 Fig. 13

Fig. 14 Fig. 15

Fig. 16 Fig. 17

8

Item 5: Repairing the Latch Assembly

1. Disassemble the Lower Cross Assembly as described in Item 4, Steps 1 to 8 (Fig. 18).

2. Lever the Latch assembly off the retaining ledge (Fig. 19).

3. Service the Latch Assembly (Fig. 20).

4. Ensure when Locking Fork is replaced with the Sliding Latch, the lower snap detail

is facing towards the Main Standard (Fig. 21).

5. Slide the assembly into the locating slot until it has re-engaged the snap

detail (Fig. 22 and 23).

6. Re-assemble the Lower Cross Assembly (Fig. 23). Refer to Item 4, Steps 16, 17 and 18.

Fig. 18 Fig. 19 Fig. 20

Fig. 21 Fig. 22 Fig. 23

9

Item 6: Repairing the Handle Assembly

1. To remove the Handle Assembly, the Shroud Plug and Badge need to be removed.

2. The Badge will disengage from the Handle Assembly by gently levering using a small

screwdriver (Fig. 24).

3. Remove the Shroud Plug by punching a hole in the centre, then lever out the retaining

snaps. This prevents damaging the Handle Shroud (Fig. 25).

4. Remove the two screws and pull the Handle Assembly away from the standard

(Fig. 26 and 27).

5. Ensure the Handle Spring does not fall out of the Handle Assembly when removing

the assembly. (Fig. 28).

6. To replace the Handle use a pair of pliers to disengage the snaps at the back of the

Handle Shroud (Fig. 29).

7. To reassemble the Handle snap it back into the Handle Bush with the Handle Shroud

and Spacer Ring in between (Fig. 30).

8. Re-attach the assembly to the standard with the two fasteners, replace the Badge and

snap in a New Shroud Plug (Fig. 31 and 32).

Fig. 24 Fig. 25 Fig. 26

Fig. 27 Fig. 28 Fig. 29

Fig. 30 Fig. 31 Fig. 32

10

Item 7: Replacing an Arm Assembly

1. Remove all of the line segments from the hoist to prevent tangling (Fig. 33).

2. Lock into place the 8 disassembly tools in both the Upper and Lower Crosses (as per item

2 and 4). Do not lever the crosses apart.

3. Fold up the hoist and attach the line tie-off, only securing the arm assemblies that are not

being replaced (Fig. 34).

4. Place the hoist on the ground.

5. Disassemble the Upper Cross Assembly as per Item 2.

6. Disassemble the Lower Cross Assembly as per Item 4.

7. Remove the damaged Arm Assembly from the cross assemblies (Fig. 35).

8. Place the Arm Stay Pivot of the new assembly into the Upper Cross, ensuring the others

have not fallen out.

9. Re-assemble the Upper Cross (Fig. 36) as per Item 2, Steps 13 to 17.

10. Re-attach the Line Tie-Off strap to include all 4 arms (Fig. 37).

11. Replace the hoist in the Ground Socket.

12. Place the Arm Joiners into the pivots of the Lower Cross bottom.

13. Re-assemble Lower Cross (Fig. 38) as per Item 4, Steps 14 to 18.

14. Re-attach the lines.

Fig. 33 Fig. 34 Fig. 35

Fig. 36 Fig. 37 Fig. 38

11

Item 8: Repairing a Tensioner Assembly

1. Remove the Line Segments and Cover Caps that are attached to both sides of the

Tensioner Assembly (Fig. 39).

2. Flex the Tensioner assembly upwards. This will allow the snaps to disengage so the

tensioners can be removed (Fig. 40).

3. To replace the tensioners, locate them into the corresponding holes in the arms with the

word “TOP” facing upwards. If the tensioners do not assemble by hand, use a pair of

large multi-grips (Fig. 41). Note: ensure they are assembled in the correct orientation.

4. Once the tensioners are assembled to the arm, the line and caps can be reattached.

Fig. 39 Fig. 40 Fig. 41

Item 9: Restringing a Line Segment

1. Establish the line segment that needs replacing and refer to the Line Length Chart for

correct line length (see Page 14).

2. Attach and tension the lines as per following sequence of diagrams.

Step 1

Remove the line cover by rotating

anti-clockwise.

Step 4

Feed the line up and through the

front slot of the tensioner and

pull tight.

Step 2

After unthreading the line from

the tensioner, pull the line through

tensioner until desired tension is

reached. Do not overtension.

Step 5

Using scissors carefully trim off

excess line, leaving approximately

10mm sticking out.

Step 3

Loop line around the rear groove

of the tensioner and pull tight to

prevent line from slipping.

Step 6

Re-attach line cover by rotating

clockwise. This will obscure

the small piece of excess

line remaining.

10mm

12

Item 10: Restringing the Hoist

1. Cut the line sections for the complete hoist as per the Line Length Chart (see page 14).

2. Initially only restring the 4 outside line segments.

3. Attach the four outside line segments to each of the four outside tensioners, tension

the line. Note: ensure Cover Caps are threaded onto each line before tensioning and

fastening.

4. Look down each arm to ensure the squareness of the hoist.

5. Attach the remaining line segments.

6. Review all lines and check to determine if any segments require re-tensioning.

7. Fold the hoist up and down to ensure hoist is not over tensioned and restricting the

engagement of the Lower Cross and Latch with the Locking Collar.

8. Once complete, trim off excess line leaving about 10mm protruding from each tensioner.

Fit Cover Caps.

Item 11: Replacing the Ground Socket Locking Collar

1. Remove the Locking Pin from the bottom of Main Standard, use the

Pin Punch provided (Fig. 42).

2. Remove damaged part (Fig. 43).

3. Install a new part and replace the Locking Pin (Fig. 44).

Fig. 42 Fig. 43 Fig. 44

13

Item 12: Replacing the Windbrake and Winding Mechanism

1. Remove the hoist from the Ground Socket and lay it on the ground.

2. Remove the Handle Assembly as per Item 6.

3. Remove the screw in the Main Standard located behind the Handle Assembly. This screw

secures the Winding Mechanism within the Main Standard (Fig. 45).

4. Using a screwdriver and hammer, remove the Windbrake from the top of the Main

Standard (Fig. 46).

5. Carefully slide the Main Standard completely off the Secondary Standard, ensure that the

Winding Mechanism does not become dirty, and the Ground Socket Locking Collar does

not fall off. If the saddle or pinion gear become dislodged, clean and lubricate them with

Vaseline before replacing (Fig. 48).

6. Use a hacksaw to cut the bard off the top of the Worm (Fig. 47).

7. Fit a new Winding Mechanism into the Main Standard and secure with the screw (Fig. 49).

8. Push a new or the removed Windbrake into the top of the Main Standard, ensuring that

the moulding is aligned with the punched details in tube. Centre punch the tube in the

nibbed areas to re-secure (Fig. 50).

9. Slide the Main Standard over the Secondary Standard then stand hoist upright in the

Ground Socket to re-engage the worm with the Secondary Standard.

10. Re-attach the handle assembly as per Item 6.

Fig. 45 Fig. 46 Fig. 47

Fig. 48 Fig. 49 Fig. 50

14

Line Length Chart

This chart shows the length of line to cut for each section. It gives the required length plus

200mm to allow easy installation

Hills Rotary 400TM

970

mm 1

197

mm

Hills Rotary 450TMHills Rotary 500TM

2827mm

2580mm

2333mm

2086mm

1832mm

1578mm

1329mm

970mm

2580mm

2333mm

2086mm

1832mm

1578mm

1329mm

970mm

2086mm

1832mm

1578mm

1329mm

15

Notes

Issue – November 2007

This manual suits for next models

2

Table of contents

Other Hills Household Appliance manuals

Hills

Hills Hoist 8-Line User manual

Hills

Hills Supa Fold 230 User manual

Hills

Hills Supa Fold Post Kit Standard - Adjustable... User manual

Hills

Hills FD52007 User manual

Hills

Hills Premium Supa Fold Long Line User manual

Hills

Hills Everyday Rotary 37 User manual

Hills

Hills Supa Fold 230 User manual

Hills

Hills Portable 120 User manual

Hills

Hills HILLS HERITAGE 5 User manual

Hills

Hills Traditional Rotary 42 Hoist User manual