Hills Premium Rotary 6 User manual

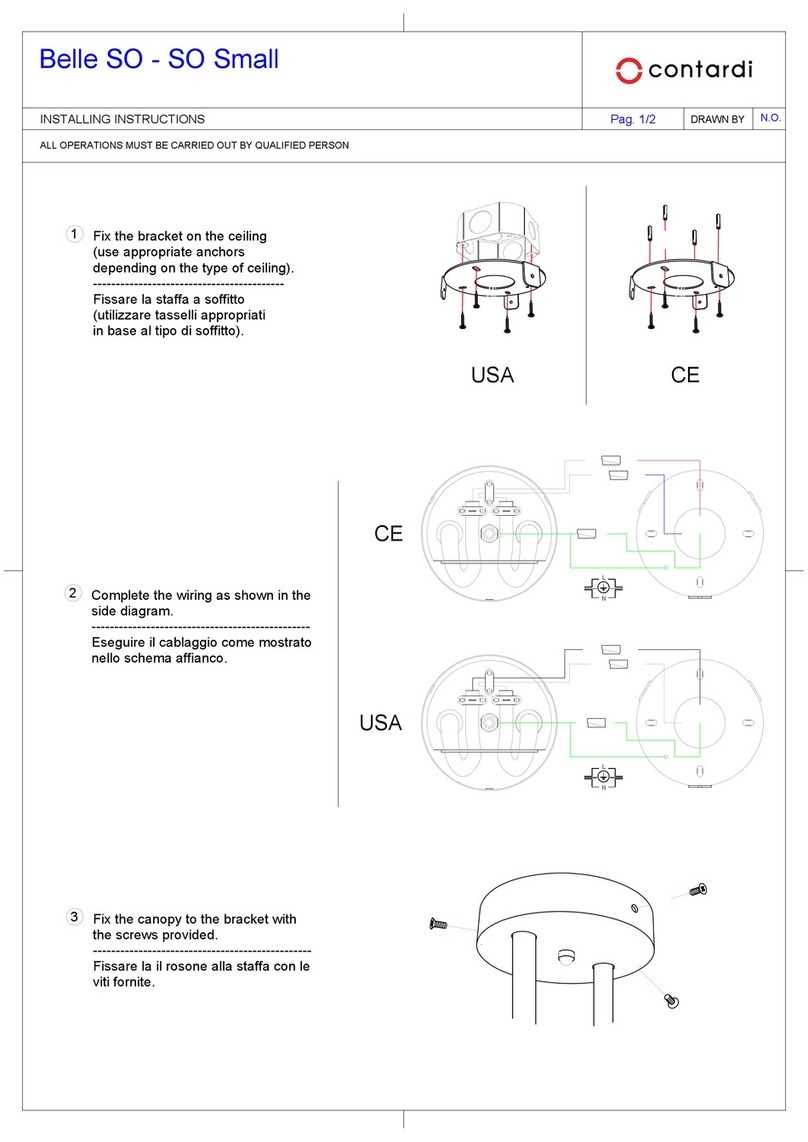

TO SUIT MODELS:

Rotary 6

Rotary 7

Rotary 8

PremiumTM

Product Manual

Rotary Folding Head Hoists

2

Congratulations

Congratulations on the purchase of your new Hills Premium Rotary Folding Head Hoist,

which will bring you many years of trouble free and efficient outdoor drying.

It is important that you read this Product Manual thoroughly before installation and use.

In this way you will benefit from all of the design features and enjoy safe use of the product.

Thank you for choosing Hills.

Warning

• DonotallowchildrenorpetstoswingontheRotaryHoistoritemsoflaundry.

• Donotuseforanypurposeotherthantohanganddrywashing.

• DonotuseyourRotaryHoistifpartsarewornordamaged.

• FoldupyourRotaryHoistintheeventofextremewindstoavoidanyproductdamage.

• TheassemblyoftheheadintotheMainStandardispermanent.Thetwopieceslock

together and cannot be separated when assembled.

Carton Contents

Part name Qty.

Main standard 1

Head assembly 1

Groundsocketwithcover 1

Plastic spacers 3

Patents and registered designs apply to this product.

Introduction

Please retain this Product Manual. Record the following

information for future reference.

ProductNumber(printedoncarton):FD

Dateofpurchase:

Name and location of store:

Made in China

Designed and tested under a

Quality System that meets Hills

demanding quality specifications.

®

3

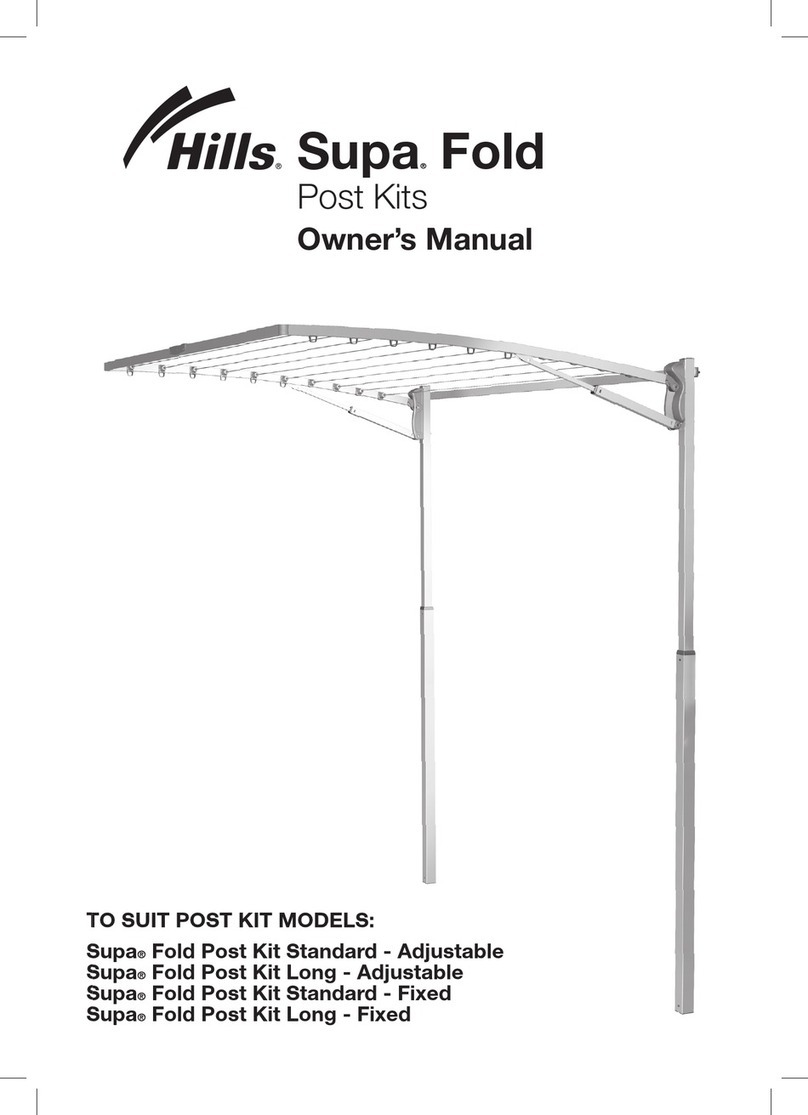

Step 1

Select a Suitable Location

1.1 Selectasuitableareaforinstallation.

1.2 Allow a minimum of (1'7")

clearance

around your Rotary Hoist (Fig. 1).

Step 2

Install the Ground Socket

2.1 Digahole250mm(10")diameterby

approximately650mm(26")deep(Fig. 2).

2.2 Placeapproximately200mm(8")

ofcoarsegravelintothehole.

2.3 Insert the main standard into the ground

socket. Engage the locking collar and lock

into position.

Make surethetabsareclosedtoprevent

concrete entering the locking recess.

2.4 Place the ground socket and main

standard into the hole.

Push the base of the ground socket into

thegravel.

Checklevelvertically.

The top of the ground socket must sit

approximately6-12mm(1/4"-1/2")above

groundlevel.

2.5 Supportthemainstandardandconcrete

into position.

Concrete should be damp enough

to ‘hold together’ when squeezed

in your hand.

Settleconcretebypushingathinstickinto

themixseveraltimes.

Leave the main standard in the

ground socket until the concrete

has set.

Keep concrete out of the locking

recess in the ground socket.

2.6 Allow24hoursfortheconcretetoset

before final assembly and use of your

Rotary Hoist.

Checkforlevel

Main standard

Locking collar

Engage into

ground socket.

Rotate to lock.

Close tabs to

prevententry

of concrete

Ground

socket

450mm(18")

concrete

200mm(8")

gravel

650mm(26")

Fig. 1

Fig. 2

500mm(1'7")

500mm(1'7")

Installation

Top of socket

approximately

6-12mm(1/4"-1/2")

abovegroundlevel

3.0m (9'8")

Rotary6

3.6m (11' 9")

Rotary 7

4m (13')

Rotary8

250mm(10")

4

3.3 To engage, raise the head assembly

byapproximately100mm(4")and

lower until a ‘click’ is heard.

3.4 Check the head assembly is locked in

position by lifting upwards (it should

notmove).Iftheheadassemblyisnot

engaged,repeatStep3.3.

Note: there is a small amount of

rotationalmovementbetweenthewind

brake and the lower cross latch.

This is normal.

Note: once the head is engaged

into the main standard it cannot be

removed.

Step 3

Assemble the Hoist

3.1 Place the main standard in the

ground socket.

3.2 Place the bottom of the head

assembly into the top of the

main standard and lower it

gently until it stops (Fig. 3).

Fig. 3

Assembly

GENERAL ASSEMBLY DETAILS

ALL DIMENSIONS ARE EQUAL ABOUT

C

L

UNLESS

1.

OTHERWISE STATED.

DIMENSIONS BOUNDED BY ARE CRITICAL FOR

2.

ASSEMBLY WITH OTHER COMPONENTS.

THE DIMENSIONS SHOWN ON THIS DRAWING PLUS

3.

THE 3D CAD DATA FULLY DEFINE THE FINISHED PART.

ALL COMPONENTS TO BE CLEAN AND FREE FROM

4.

SHARP EDGES, BURRS AND DEFECTS.

IF IN DOUBT ASK

5.

GENERAL TOLERANCES:

Unless Otherwise Stated:

0 Dec. place

0.5mm

1 Dec. place

0.25mm

2 Dec. place

0.10mm

Holes: +0.25mm -0mm

Angles:

0.25

FIG 3.

OPEN MID WAY

6

D

C

B

A

E

F

G

H

E

A

B

C

D

F

5

4

3

2

1

7

8

9

10

11

12

1

2

3

4

5

6

7

8

G

9

10

11

12

H

Project:

X. Xxxxxxxx

DO NOT SCALE DRAWING.

DIMENSIONS IN MILLIMETRES.

Third Angle

Projection.

Approved:

Date:

Date:

XX.XX.XX

Checked:

24.09.10

P. Stevens

Date:

Drawn:

Issued / Received

1

Issue:

Sheet 1 of 1

TM

Colour:

Material:

Finish:

Description

A2

Drawing Number

Estimated Mass:

Project Number

Sheet

size

FD88000

ROTARY 8

REFER TO INDIVIDUAL COMPONENTS

16851 (grams)

REFER TO DRAWING SPECIFICATION

REFER TO COLOUR TABLE

SCALE:1:2

Volume

3957580 (mm)

D423

D423

Hills Industries Limited

ABN 35 007 573 417

Home & Hardware Products

Unit H, 5 Butler Boulevard

Burbridge Business Park

Adelaide Airport

South Australia 5950

Copyright

©

2010

Revision4 - 09.02.10 - DHN

Additives:

Insert head

assembly

Main

standard

Head

assembly

Groundlevel

Lower

cross Latch

Engage by

raising and

lowering head

assembly until a

‘click’ is heard

Wind

brake

5

Step 4

Operating the Hoist

4.1 To adjust the height of your Rotary

Hoist, wind the handle and head

assembly down and then fit one

or more of the plastic spacers in

the ground socket. The suggested

operating height is the user’s head

height+25mm(1")(Fig. 4).

Note: The height adjusting winding

mechanismhasanautomaticdevice

Fig. 4

Operation

to disengage the handle at the

maximumandminimumheights.

A slight ‘clicking’ noise will be heard

when this system is operating.

4.2 To Open: Undo the line retainer (see

page6)andguideitbackintothe

hoist. Make sure the lines are tangle

free. Push the lower cross and arms

up until the latch engages.

Locking collar

Spacers

Cover

Groundlevel

Ground

socket

Usersheadheight+25mm(1")

Note: In transit or use, you

may find one or more of your

lines has been pulled, causing

your hoist to not open.

To free the arms, pull the

line(s) that are tight through

theotherthreenon-tensioning

armstoeven-outthecircuit's

line tension. Your hoist will

then open as intended.

Refer to our website

www.hills.com.au for

avideodemonstration.

6

Operation

4.3 To Fold:

1. Pull down the latch gently to release

(Fig. 5).

2.Lowerthearmandcrossassembly

until closed.

4.4 Wrap the line retainer around

thehoisttopreventlinesfrom

becoming tangled.

1.Pulllineretaineroutfromabovethe

latching mechanism (Fig. 6).

2.Wrapretaineraroundthehoistto

captureall4arms(Fig. 6a).

3. Clip the blue retainer back onto the

retaining line to secure hoist (Fig. 6b).

4.5 To Remove from the ground socket:

Unlock the locking collar by rotating

anti-clockwise.LifttheRotaryHoist

from the ground socket and store in a

suitableplace.Insertthecoverintothe

top of the ground socket.

Step 4

Operating the Hoist (continued)

Fig. 5 Fig. 6

Fig. 6a

FIG 6b.

GENERAL ASSEMBLY DETAILS

ALL DIMENSIONS ARE EQUAL ABOUT

C

L

UNLESS

1.

OTHERWISE STATED.

DIMENSIONS BOUNDED BY ARE CRITICAL FOR

2.

ASSEMBLY WITH OTHER COMPONENTS.

THE DIMENSIONS SHOWN ON THIS DRAWING PLUS

3.

THE 3D CAD DATA FULLY DEFINE THE FINISHED PART.

ALL COMPONENTS TO BE CLEAN AND FREE FROM

4.

SHARP EDGES, BURRS AND DEFECTS.

IF IN DOUBT ASK

5.

GENERAL TOLERANCES:

Unless Otherwise Stated:

0 Dec. place

0.5mm

1 Dec. place

0.25mm

2 Dec. place

0.10mm

Holes: +0.25mm -0mm

Angles:

0.25

FIG 6a.

FIG. 6

6

D

C

B

A

E

F

G

H

E

A

B

C

D

F

5

4

3

2

1

7

8

9

10

11

12

1

2

3

4

5

6

7

8

G

9

10

11

12

H

Project:

X. Xxxxxxxx

DO NOT SCALE DRAWING.

DIMENSIONS IN MILLIMETRES.

Third Angle

Projection.

Approved:

Date:

Date:

XX.XX.XX

Checked:

24.09.10

P. Stevens

Date:

Drawn:

Issued / Received

1

Issue:

Sheet 1 of 1

TM

Colour:

Material:

Finish:

Description

A2

Drawing Number

Estimated Mass:

Project Number

Sheet

size

HD10054

HEAD ASSEMBLY - ROTARY 8 - S3

REFER TO INDIVIDUAL COMPONENTS

8792 (grams)

REFER TO DRAWING SPECIFICATION

REFER TO COLOUR TABLE

SCALE:1:2

Volume

1927628 (mm)

MID MARKET ROTARY

D423

Hills Industries Limited

ABN 35 007 573 417

Home & Hardware Products

Unit H, 5 Butler Boulevard

Burbridge Business Park

Adelaide Airport

South Australia 5950

Copyright

©

2010

Revision4 - 09.02.10 - DHN

Additives:

Fig. 6b

7

Line Tensioning

Step 5

Tensioning the Lines

Thelinesarepre-tensionedinthefactory.

No initial tensioning is required.

Ifovertime,thelinedoesneedtensioning,

the Rotary Hoist must be in the open

position.

With the Rotary Hoist open, follow the

tensioning instructions below.

5.1 To begin tensioning: Although all the

arms look the same, only one is the

tensioning arm. This is the arm directly

left of the latch. It is highlighted by an

arrow pointing to it on the bottom of

the lower cross (Fig. 7).

Note:Avideodescribingthis

operationcanbeviewedonthe

Hills website at www.hills.com.au

Fig. 7

Removecovercap.

Step 1

Removelinefromunderlockinglip.

Step 3

Pull line out of arm.

Step 2

Pull line out from tensioner.

Step 4

Tensioning arm

8

Line Tensioning

Keeping the tension on the line, feed it back through

the tensioner. Pull to retain tension.

Feed line back into arm through central hole. Cut off

excessivelineifrequiredpriortoputtingintoarm.

Pushlinermlyintoarmtogiveaushresult. Replacecoverwhennished.

Startingatthefurthestarmfromthetensioning

arm,pullthelinetightandmovefromarmtoarmto

generate desired line tension.

Swingthelinebackunderthetensionerliptosecure.

TIP: Keep pressure on bottom left edge to stop

tension loss.

Step 5

Step 7

Step 9 Step 10

Step 6

Step 8

Step 5 (continued)

9

Handy Hints

Hills Handy Hints

One of the benefits of a Rotary Hoist is that

it spins naturally in the breeze, allowing the

sun to shine on all your clothes and speed

up drying time.

Raiseyourhoistformaximumdrying

efficiency and to ensure clearance for

longer items.

The wind brake assists in the pegging and

unpegging of clothes on windy days by

restricting the free rotation of the clothesline.

It can be engaging by winding the ‘head’ of

the hoist fully down.

Place smaller items of clothing on the lines

nearest the centre and work your way

outwards for larger items.

When hanging thick or bulky items, you may

hangtheitemovermorethanoneline.

Whenyoudonotexpecttollthecapacity

of your hoist, hang your clothes on the outer

lines, this will allow your clothesline to spin

more easily.

Care and Maintenance

It is a good idea to occasionally inspect all

components and check for wear and tear

or damage. If there is any damage, parts

should be replaced with original Hills spares

or the Hoist repaired before using again.

The hoist should be periodically wiped clean

with a damp cloth and mild detergent.

To maintain appearance and durability

of coating on metal components, we

recommend a twice yearly application of a

reputablebrandofcarpolishorwax.

Your Rotary Hoist can be easily folded and

removedfromthegroundsockettogiveyou

extragardenspace.

Thehoistshouldbeeasytoremovefrom

the ground, but if left for a period of many

years it may become more difficult. It is

recommended the hoist is lifted out of the

groundatleasteverysixmonths.

Hills Smart Pegs

Available from leading retailers

•Stylish,contemporaryclothespegs

•Dualmouldedforcomfortandgrip

•UVstabilisedforsunprotection

•Rust-resistantstainlesssteelspring

•Selectionoffashioncolours

WARNING:CHOKINGHAZARD!

Smallparts.Notforchildrenunder3yrs.

Not to be used as a toy.

10

Warranty

Hills Warranty

1.HillsprovidesconsumerswiththefollowingwarrantyinrelationtothisProduct,

inadditiontocomplyingwiththerequirementsofanyrelevantlegislation,including

theCompetitionandConsumerAct2010(Cth)inAustraliaandtheConsumer

Guarantees Act 1993 in New Zealand (the Acts),exceptwhereaNewZealand

consumeracquirestherelevantProductforthepurposesofabusiness.

2.Inthiswarranty,wehaveusedthefollowingdenitions:

(a) Hills, our or wemeansHillsHoldingsLimited(ABN35007573417)

of159PortRoadHindmarshSouthAustralia5007;

(b) Products means the following goods manufactured by Hills (including products

manufactured for Hills by its contract manufacturers): Hills Premium Rotary

Folding Head Hoist;

(c) Material means a material or component used by Hills in the manufacture

oftheProducts;

(d) Warranty Periodmeans10yearsfromthedateofpurchaseoftherelevant

Product and, in relation to polycore line, means a period of 1 year from the date of

purchase of the Product. If the Product or part (as the case may be) is repaired or

replaced,therewillbenoextensiontotheoriginalwarrantyperiod;and

(e) Workmanship means the handling, assembly and manufacturing processes

performed by or on behalf of Hills in order to manufacture the Products.

3. Hills warrants that for the duration of the Warranty Period, all Products will be free

of faults arising from defects in Workmanship or Materials, on the terms and conditions

set out in this warranty.

4.HillsundertakesthatifduringtheWarrantyPeriodanyProduct,oranypart

ofaProduct,hasfailedtooperatecorrectlyduetofaultyWorkmanshipordefective

Material, it will repair or replace the Product or part (as the case may be) free of charge

providedthatthefollowingprocedureismet:

(a) The consumer must contact Hills upon becoming aware of any defect to a

Product. The contact details for Hills are set out in this warranty and under

the heading “Hills Contacts”.

(b) Following consultation with Hills, Hills will determine whether there is a defect,

and if so Hills agrees to (at Hills’ option):

i.inthecaseofgoods–repair,replaceorsupplyequivalentgoods,orpay

thecostofanyofthoseremediestotheconsumer;or

ii.inthecaseofservices–supplytheservicesagainorpaythecostofhaving

theservicessuppliedagain.

(c) If Hills requests the return of the applicable Product or part, Hills will be

responsible for the collection and freight costs of returning that Product or part.

The consumer agrees to assist Hills with any reasonable request to enable Hills

to collect such Product or part.

(d)HillsalsoagreestoberesponsibleforthefreightcoststodeliveranynewProduct

or replacement part to the consumer.

11

Warranty

5.Thiswarrantyisinadditiontoanynon-excludablelegalrightsorremediesconferred

ontheconsumerunderanyapplicableActandanysimilarlaws.Totheextent

permittedbylaw,Hills'liabilityforanynon-excludableconditionorwarrantyislimited

torectifyinganydefectatitsoption,assetoutinparagraph4(b).

6.SubjecttotherequirementsofanyapplicableActorlegislationandtotheextent

permittedbylaw,noliability(whetherexpressedorimplied)ofanynaturewhatsoever,

is accepted by Hills for any consequential loss, damage or injury arising as a result

of any fault in the Products.

7.ThiswarrantydoesnotextendtodamagetoProductswhichoccursduringtransit

or transportation, or which is caused by any abuse, accident or improper installation,

connection, use, adjustment or repair or use of goods otherwise than in accordance

with instructions issued by Hills.

8.ThewarrantyonProductsiswaivedifanyadditionorattachmenttotheProducts

donothaveHills'specicapprovalorarenotsoldasHillsproducts.TheProducts

are designed to perform specific tasks under established test loads and unauthorised

attachments may produce stresses for which the design is not appropriate.

9.ThefollowingappliestoconsumerswhopurchasedarelevantProductinAustralia:

OurgoodscomewithguaranteesthatcannotbeexcludedundertheAustralian

Consumer Law. You are entitled to a replacement or refund for a major failure

and compensation for any other reasonably foreseeable loss or damage.

Youarealsoentitledtohavethegoodsrepairedorreplacedifthegoodsfail

to be of acceptable quality and the failure does not amount to a major failure.

Hills Contacts

Wearecommittedtoprovidingyouwithcompletecustomersatisfaction.Ifyouhave

anyquestionsorcommentsaboutourproductsorservicespleasecontactyournearest

customerservicecentreduringtheirlocalbusinesshours:

Australia

1300300564

New Zealand

092623052

United States

8775341371(Eastern)

Europe

+44(0)1189738971(UK)

enquiries@greenergardensolutions.co.uk

South Africa

0214421540

info@stingray.co.za

Hills Websites

www.hills.com.au

Hills Branded Products

www.hillsholdings.com.au

Hills Holdings Limited

Hills Holdings Limited

A.B.N.35007573417

IssueSeptember2011

PD3067c

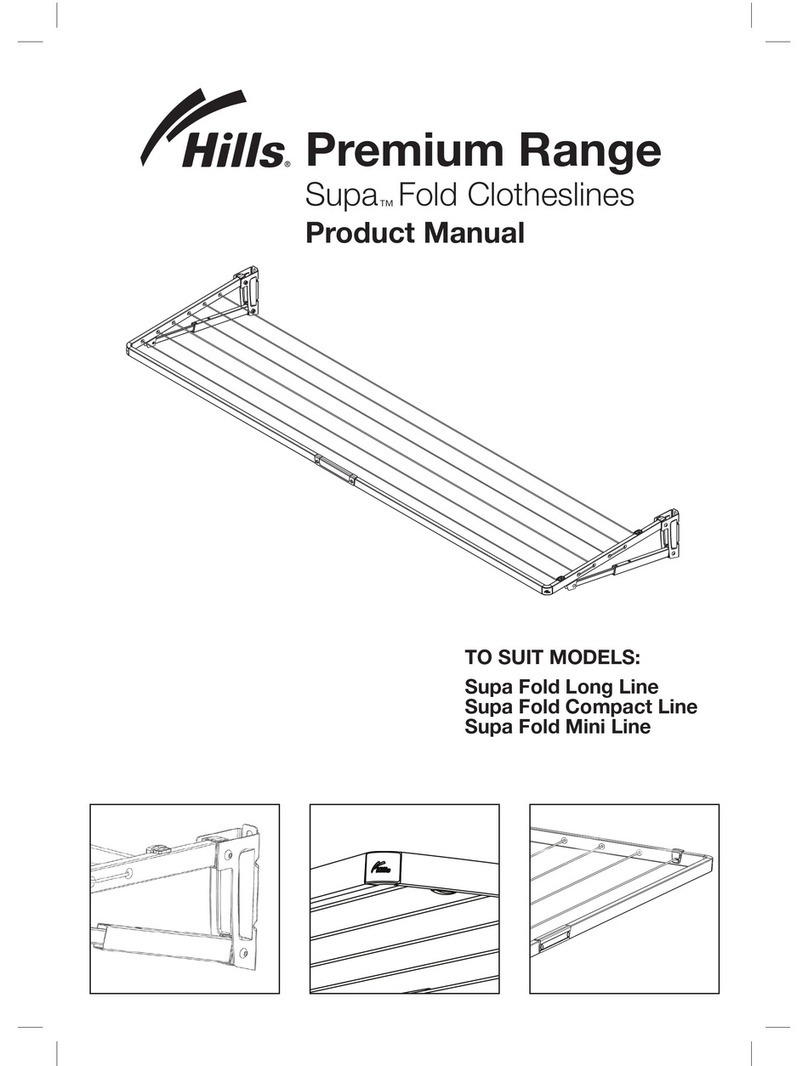

This manual suits for next models

2

Table of contents

Other Hills Household Appliance manuals

Hills

Hills HILLS HERITAGE 5 User manual

Hills

Hills Premium Supa Fold Long Line User manual

Hills

Hills Supa Fold 230 User manual

Hills

Hills Portable 120 User manual

Hills

Hills Traditional Rotary 42 Hoist User manual

Hills

Hills FD52007 User manual

Hills

Hills Supa Fold 230 User manual

Hills

Hills Hoist 8-Line User manual

Hills

Hills Supa Fold Post Kit Standard - Adjustable... User manual

Hills

Hills Everyday Rotary 37 User manual