Hills Portable 120 User manual

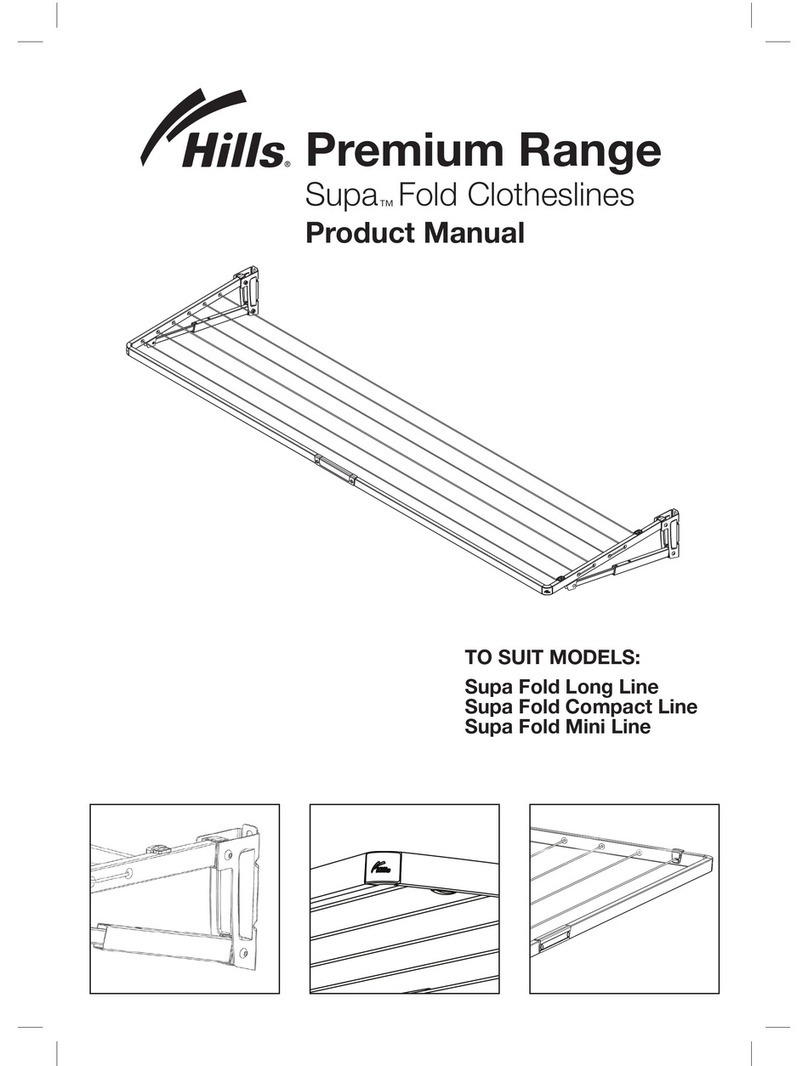

Premium

120 and 170

Portable

Clotheslines

Product Manual

2Introduction

Congratulations

Congratulations on the purchase of your new

Hills Portable Clothesline, which will bring you

many years of trouble-free and ecient drying,

both indoors and outdoors. It is important that

you read this product manual thoroughly before

assembly and use. In this way, you will benefit

from all of the design features and enjoy safe

use of the product. Thank you for choosing Hills.

Warning

• Caution: Do not push or pull your Portable

Clothesline across the floor as this could lead

to breakage of the legs.

• To move the clothesline, lift it completely from

the floor (it may require two persons to avoid

injury to yourself or damage to the product).

• Do not allow children or pets to swing on the

Portable Clothesline or items of laundry.

• Ensure when opening and closing your

Portable Clothesline that your hands are

positioned where they will provide support

and will not be caught in moving parts.

• Do not use for any purpose other than to

hang and dry washing.

• Not to be used as a child’s toy.

• Do not use your Portable Clothesline if parts

are worn or damaged.

• Inspect regularly – do not use if damaged.

• Dispose of packaging thoughtfully.

Please retain this Product Manual. Record the following

information for future reference.

Product number:

Date of purchase:

Name and location of store:

Made in China

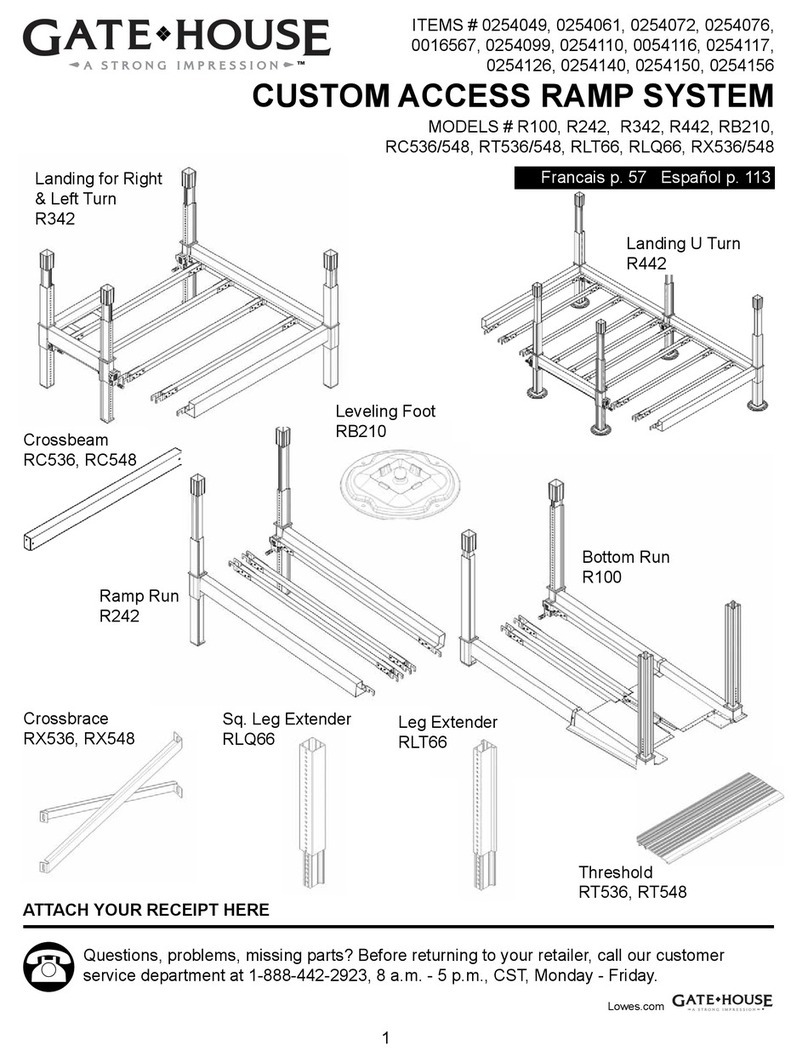

Carton contents

Part name Qty.

Spreader and Hinge Assembly 1

Arm Assembly 2

Leg Assembly - LH 2

Leg Assembly - RH 2

Leg Brace 2

Hanging Bracket 1

Door Adaptor 1

Line 2

Accessory pack contents (Fig. 2).

(includes):

4 x M6 x 12 low profile screw

8 x M6 x 16 countersunk screw

4 x M6 x 30 button head screw

4 x M6 nyloc nut

1 x Door Adaptor screw

1 x Hex Key – 4mm

1

3

Introduction

FD12000 - LINE ART

Fig 1

Spreader and Hinge Assembly

Arm Assembly

Leg Brace

Line

Leg Assembly LH Leg Assembly RH

Door Adaptor

Hanging Bracket

FD12000 - LINE ART

Fig 1

Spreader and Hinge Assembly

Arm Assembly

Leg Brace

Line

Leg Assembly LH Leg Assembly RH

Door Adaptor

Hanging Bracket

FD12000 - LINE ART

Hex Key - 4mm

M6 x 12 low prole screw

M6 x 16 countersunk screw

M6 x 30 button head screw

Door Adaptor screw

M6 nyloc nut

(Always ensure

nyloc nut is

screwed on

as shown)

Fig. 1

Fig. 2

Spreader and Hinge Assembly

Arm Assembly

Leg Assembly LH

M6 x 12 low profile screw

M6 x 16 countersunk screw

Leg Assembly RH

Leg Brace

Line

Hanging Bracket

Door Adaptor

M6 x 30

button head

screw

M6 nyloc nut (Always ensure

nyloc nut is screwed on as

shown)

Door Adaptor screw

Hex Key - 4mm

FD12000 - LINE ART

Hex Key - 4mm

M6 x 12 low prole screw

M6 x 16 countersunk screw

M6 x 30 button head screw

Door Adaptor screw

M6 nyloc nut

(Always ensure

nyloc nut is

screwed on

as shown)

FD12000 - LINE ART

Hex Key - 4mm

M6 x 12 low prole screw

M6 x 16 countersunk screw

M6 x 30 button head screw

Door Adaptor screw

M6 nyloc nut

(Always ensure

nyloc nut is

screwed on

as shown)

Note: Parts are not drawn to scale.

FD12000 - LINE ART

Hex Key - 4mm

M6 x 12 low prole screw

M6 x 16 countersunk screw

M6 x 30 button head screw

Door Adaptor screw

M6 nyloc nut

(Always ensure

nyloc nut is

screwed on

as shown)

4Installation

The Hills Portable Clothesline is quick and easy to assemble. Just follow the steps below

which are suitable for both the 17m (10 line) and 12m (8 line) models.

Note: All diagrams in this manual show the Portable 120 model.

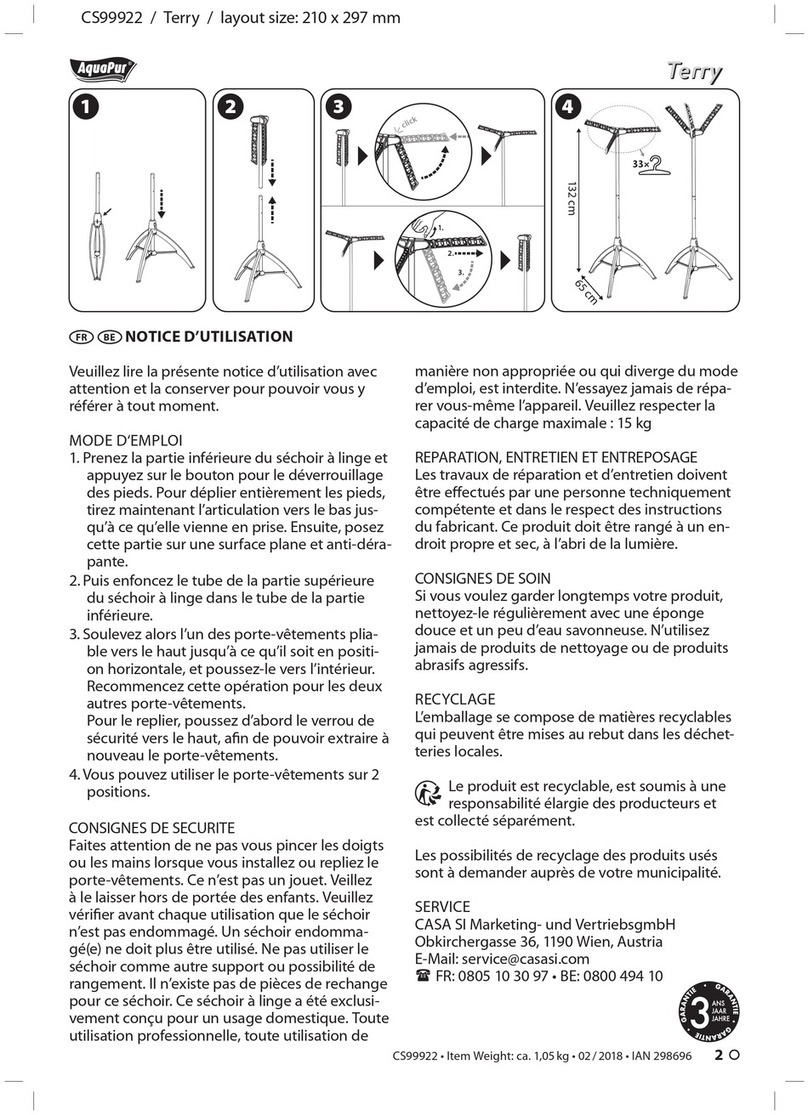

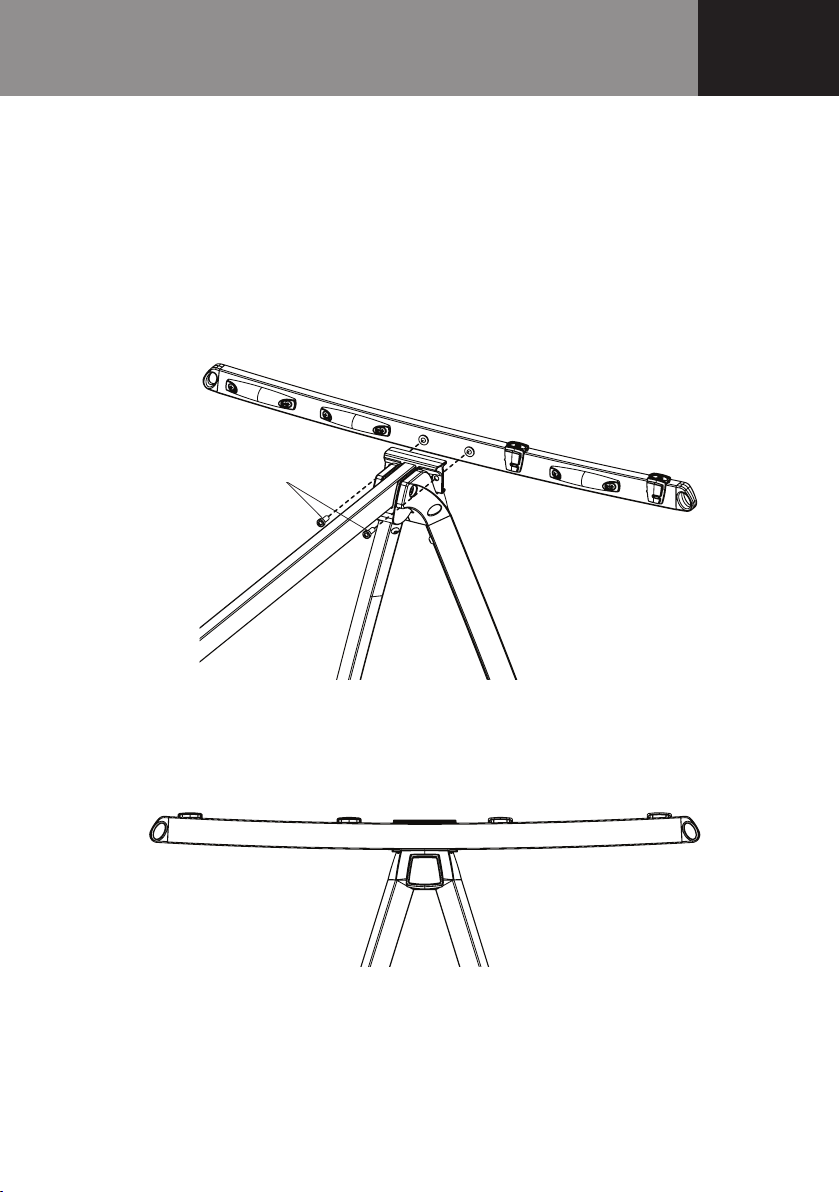

Step 1 – Rotate the Hinges into the open position

1.1 Place the spreader and hinge assembly on a flat surface.

1.2 Pull the latch out firmly (Fig. 3).

1.3 Whilst holding the latch out, rotate the hinge to the ‘open’ position

until the latch ‘clicks’ into place (Fig. 4).

1.4 Repeat at other end.

FD12000 - LINE ART

Pull out latch

Rotate hinge

Closed position

Fig 3

FD12000 - LINE ART

Latch

‘click’

into place

Open position

Fig 4

Pull out latch

Rotate hinge

Latch

'click'

into place

Closed position

Open position

Fig. 3

Fig. 4

5

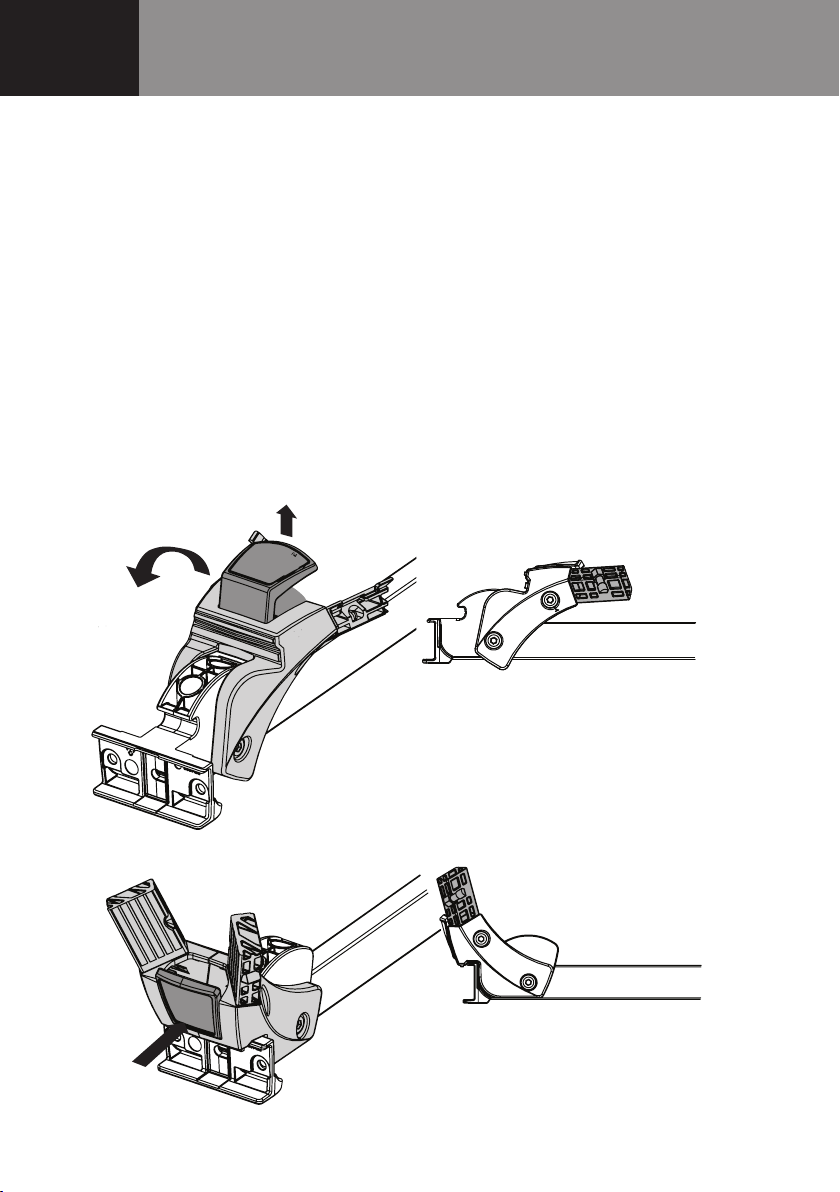

Step 2 – Attach the Legs to the Hinge Assemblies

2.1 Fasten the legs as shown in Steps 1-4.

Step 1 Locate the M6 nut on the moulded leg section of the hinge moulding (Fig. 5).

*Nylon ring of the nut must face outward.

Step 2 Fit the leg tube (ensuring mount hole is oriented as shown in Fig. 6).

Note: Check leg orientation (as per diagram in Fig. 7) to ensure the threaded

inserts for securing the leg brace are facing each other.

Step 3 Insert and fasten securely the M6 x 30 button head screws using the hex key (Fig. 8).

Step 4 Repeat for all legs.

Installation

FD12000 - LINE ART

M6 Nyloc nut*

Threaded inserts Threaded inserts

Fig 5

Fig 7

Step 1 Step 2

Step 3 Step 4

Fig 6

Fig 8

Mount hole

FD12000 - LINE ART

M6 Nyloc nut*

Threaded inserts Threaded inserts

Fig 5

Fig 7

Step 1 Step 2

Step 3 Step 4

Fig 6

Fig 8

Mount hole

Step 1

Step 3

Fig. 5

Fig. 7

FD12000 - LINE ART

M6 Nyloc nut*

Threaded inserts Threaded inserts

Fig 5

Fig 7

Step 1 Step 2

Step 3 Step 4

Fig 6

Fig 8

Mount hole

FD12000 - LINE ART

M6 Nyloc nut*

Threaded inserts Threaded inserts

Fig 5

Fig 7

Step 1 Step 2

Step 3 Step 4

Fig 6

Fig 8

Mount hole

Step 2

Step 4

Fig. 8

Fig. 6 Mount Hole

Threaded inserts

Threaded inserts

M6

Nyloc

nut*

6Installation

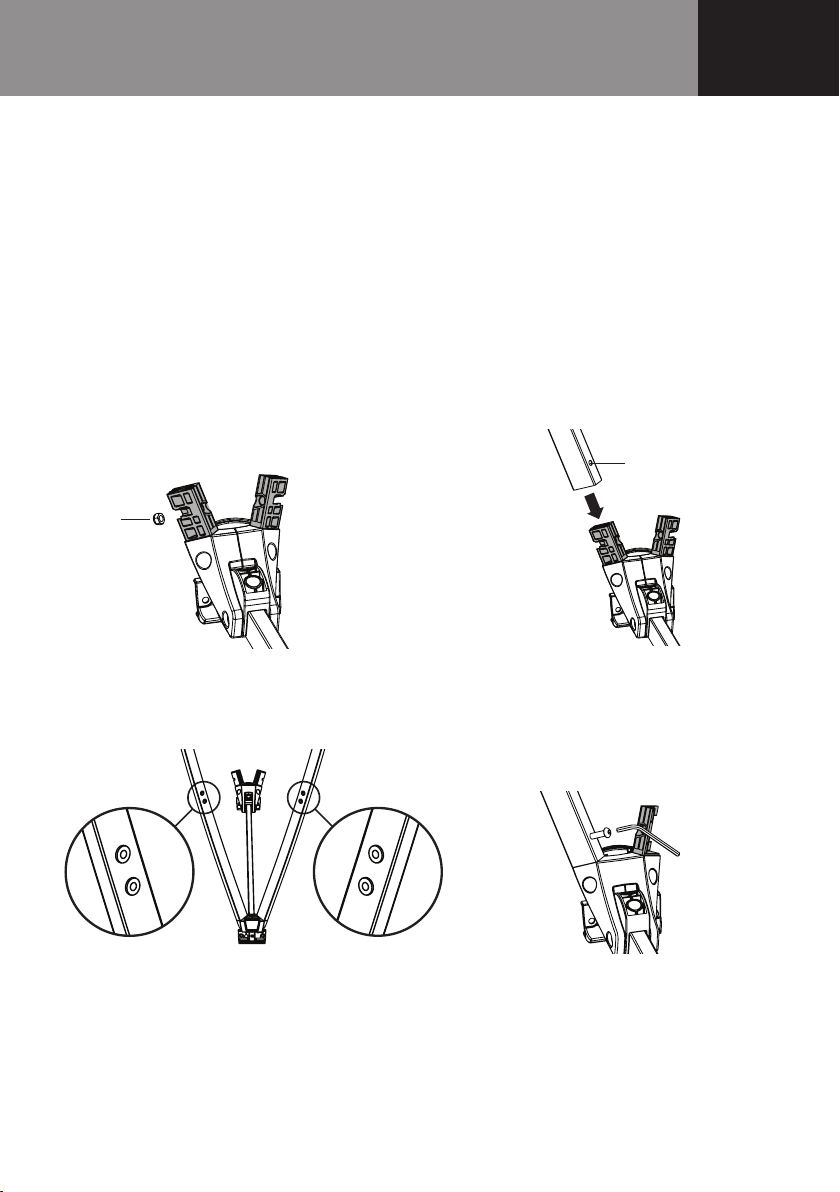

Step 3 – Attach the Brace to the Legs

3.1 Using the M6 x 16 countersunk screws, attach the Leg Brace to the 4 threaded inserts,

using the hex key (Fig. 9).

3.2 Fasten securely.

3.3 Repeat at other end.

Step 4 – Turn the Portable Clothesline over and stand on the ground

as shown (Fig. 10).

FD12000 - LINE ART

Fig 10

FD12000 - LINE ART

Leg

Threaded insert

Leg brace

M6 x 16 countersunk screws

Fig 9

Fig. 9

Fig. 10

Leg

Leg Brace

M6 x 16

countersunk screws

Threaded insert

7

Installation

Step 5 – Attach the Arms

5.1 Locate the arms into the recess in each end of the Hinge Assemblies, ensuring the screw holes

and insert fasteners align.

5.2 Insert the M6 x 12 low profile screws and fasten securely using the hex key (Fig. 11).

Note: Ensure the arms are assembled with the curve up (Fig. 12).

FD12000 - LINE ART

Low prole screws

Fig 11

FD12000 - LINE ART

Arms correctly assembled curve up

Fig 12

Low profile screws

Arms correctly assembled curve up

Fig. 12

Fig. 11

8

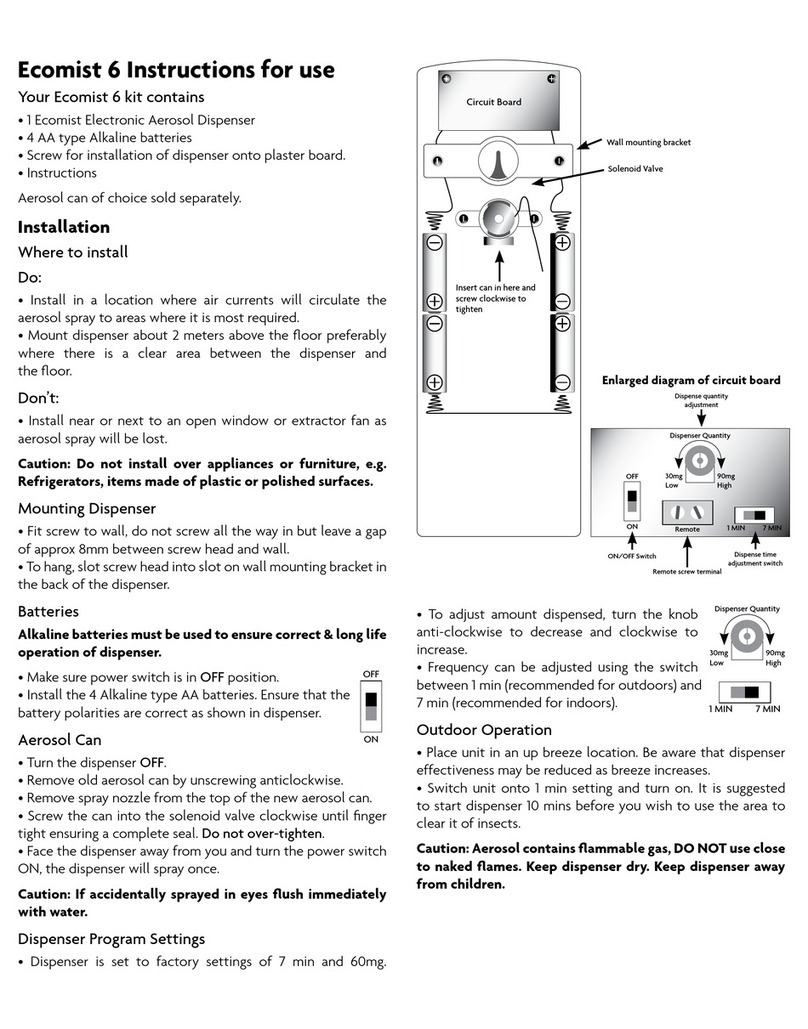

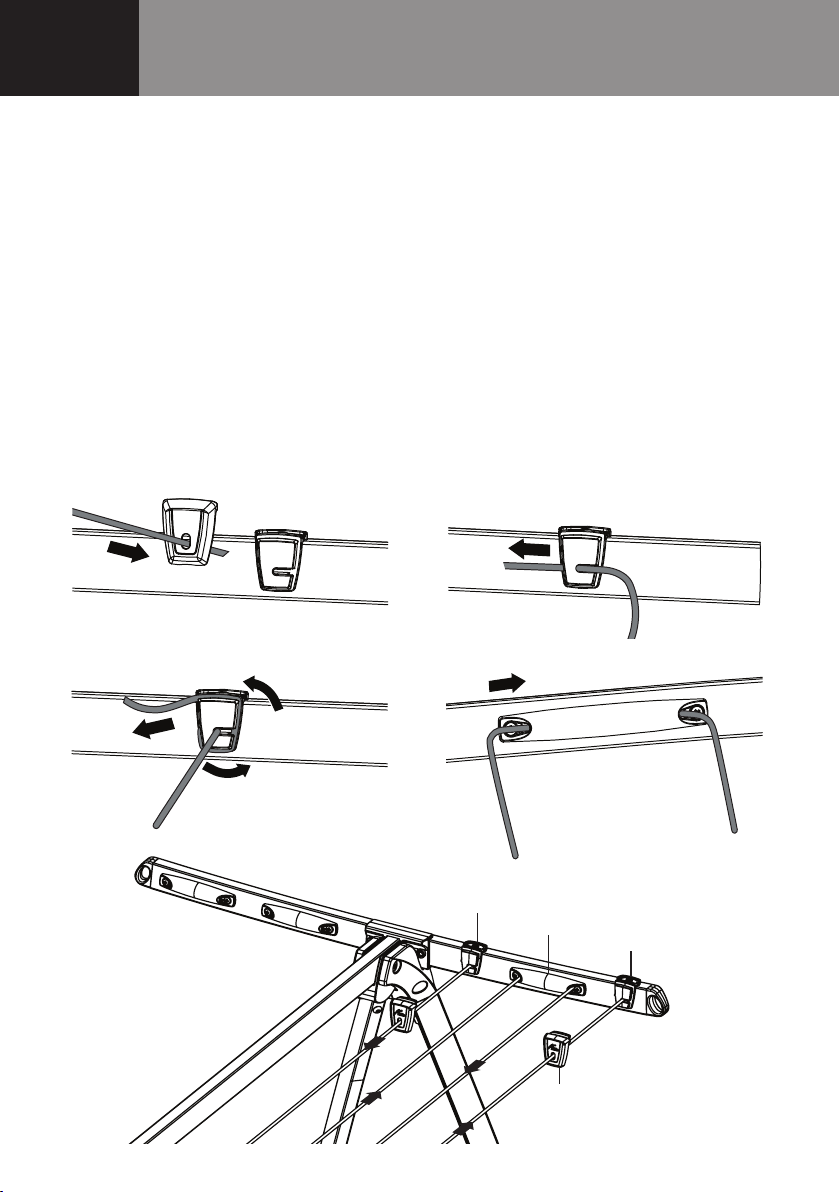

Step 6 – Attach the Line

6.1 Fasten the line to the innermost line tensioner as shown in steps 1-11.

Step 1 Thread a line tie o cap onto one end of the PVC line (Fig. 13).

Step 2 Insert the line into the slot of an inner line tie o saddle and through the side

(Fig. 14). Pull through 15cm+ of excess line for tensioning.

Step 3 Loop the line around the groove in the line tie o saddle (Fig. 15).

Pull tight to prevent the line from slipping.

Step 4 Feed the line through the line’s sleeves (Fig. 16).

Note: It is useful to kink or twist the line when feeding it through the line sleeves

to make assembly easier.

Step 5 Continue feeding the line through the line sleeves’ ensuring all lines are parallel.

Refer to Fig. 17 for the threading pattern for your product.

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

Installation

Fig. 13

Fig. 15

Fig. 14

Fig. 16

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

Fig. 17

Line tensioner inner

Cover cap

Line sleeve

Line tensioner outer

9

Step 6 When you reach the tie o end of the line, thread another line tie o cap (Fig. 18).

Step 7 Insert the line into the slot of the last line tie o saddle (Fig. 19).

Warning: Do not tighten the line yet.

Step 8 Repeat steps for the other side.

Step 9 Tighten the line on each side by pulling it ‘through’ the line sleeves and repeating

the tie o procedure with the outer line tensioner.

Note: Do not over tighten the line, as you can distort the frame.

Step 10 Trim o excess PVC line at dotted line (Fig. 20). Make sure the line is firmly pulled

back into the line tie o saddle.

Step 11 Push the PVC line end securely into the saddle (Fig. 21).

Step 12 Fit the line tie o caps over the line tie o saddles (Fig. 22).

Your Portable Clothesline is now ready to use.

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

Fig. 21

Fig. 19Fig. 18

Fig. 22

Fig. 20

FD12000 - LINE ART

Fig 13 Fig 14 Fig 18 Fig 19

Fig 20

Fig 22

Fig 21

Fig 15

Fig 17

Fig 16

Line tensioner inner

Line sleeve

Cover cap

Line tensioner outer

Installation

10

Step 7 – Line tensioning

To re-tension lines if required:

7.1 Remove either cover cap on the arm.

7.2 Untie the existing line.

7.3 Repeat steps as described on pages 8 and 9.

Note: Do not over tighten the line, as you can distort the frame.

Step 8 – Folding and Unfolding

8.1 To fold away your Portable Clothesline, pull the latch out firmly with one hand,

while supporting and rotating the legs up and around with your other hand.

Keep rotating until the latch ‘clicks’ back into place, locking the legs closed (Fig. 23).

FD12000 - LINE ART

Fig 23

Pull to

release

latch

Fig. 23

Installation

Pull to

release

latch

11

8.2 Place the folded end on the ground (Fig. 24).

8.3 Release the latch at the other end, and fold the legs, while bringing the product

to a vertical position (Fig. 25).

Note: Check the legs are not caught in the lines before trying to unfold.

Always ensure your hands are positioned where they will provide support

and will not be caught in moving parts.

FD12000 - LINE ART

Fig 22

FD12000 - LINE ART

Fig 23

Fig. 24

Fig. 25

Installation

12

Step 9 – Hanging Bracket

To hang your Portable Clothesline for convenient storage, a hanging bracket has been

included (Fig. 26).

9.1 The hanging bracket can be fastened to almost any wall or vertical surface, using appropriate

fasteners (not supplied).

The hanging bracket and door adaptor can be used over most doors.

9.2 Simply place the hanging bracket and door adaptor over your door.

Place the Portable Clothesline on the hanging bracket, ensuring it is centred on the door and

does not make contact with door handles, surrounding furniture and walls, when the door is

opened and closed (Fig. 27).

Secure the door adaptor to the top of the door with the small screw provided.

Note: Check there is clearance between the top edge of the door and door frame for the

door adaptor and screw before fixing.

FD12000 - LINE ART

Fig 26

Check clearance

Installation

FD12000 - LINE ART

Fig 1

Spreader and Hinge Assembly

Arm Assembly

Leg Brace

Line

Leg Assembly LH Leg Assembly RH

Door Adaptor

Hanging Bracket

Hanging Bracket

Fig. 26

Fig. 27

Check clearance

13

Hills Handy Hints

Heavy or large items like thick towels, sheets and quilts can be dried on the Portable Clotheslines.

We recommend placing them over the inner lines, leaving the outer lines for smaller objects.

We also recommend spreading the load over two lines to allow more air circulation for faster

drying. Sheets can be folded in half and dried over two lines.

Quilts can be dried by laying them over the Portable Clothesline then pegging the ends/corners

together to lift them o the floor. When placing washing on the Portable Clothesline, ensure the

weight is balanced and washing is placed evenly on both sides.

The Hills Portable Clothesline can be used almost anywhere but should not be used in strong

wind conditions unless it is placed in a protected area and secured.

The Hills Portable Clothesline can be stored when not in use.

The brace that supports the legs includes holes that provide additional hanging space.

Place pegs over the seams in your clothing to avoid or minimise peg marks on the fabric.

Care and Maintenance

It is a good idea to occasionally inspect all components and check for wear and tear or damage.

The Portable Clothesline should be periodically wiped clean with a damp cloth and

mild detergent.

Handy Hints and Maintenance

14 Warranty

10-Year Warranty*

*In addition to other rights and remedies that

may be available under any applicable law,

AMES Australasia Pty Ltd warrantstothepurchaser

of the product (customer) that this Clothesline

will be free from defects in workmanship and

materials for 10 yearsand the Polycore Line

for 1 year from the date of purchase of the

product. If a defect in material or workmanship

becomes evident during that period, AMES

Australasia Pty Ltd will, at its option, either:

•replace the product; or

•refund tothe customer thepurchase price

paid by the customer for theproduct.

In the event of such a defect, the product

should be returned to the place of purchase

of the product bythecustomer, together

with proof of purchase, for replacement or

refund. Any handling and transportation (and

other expenses incurred in claiming under this

warranty) are not covered bythis warrantyand

will be borne by the customer, not AMES

Australasia Pty Ltd.

The obligation of AMES Australasia Pty Ltd under

this warranty is limited to the circumstances set

out above and is subject to:

•theproduct not having been altered,

tampered with or otherwisedealt with by any

person in a manner other than as intended in

respect of the relevant product; and

•theproduct not having been used or applied

in a manner that is contrary to customary

usage or application of the relevant product

or contraryto anystated instructions or

specification of AMES Australasia Pty Ltd (orits

related bodiescorporate).

For products purchased in Australia:

Our goods come with guarantees that cannot

be excluded under theAustralian Consumer

Law. You are entitled to a replacement or

refund for a major failure and compensation

for any other reasonably foreseeable loss or

damage. You are also entitled tohave the goods

repaired or replaced if the goods fail to be of

acceptable quality and the failure does not

amount to a major failure.

For products purchased in New Zealand:

Our goods come with guarantees that cannot

be excluded under theConsumer Guarantees

Act. AMES Australasia Pty Ltd will comply with

our obligations to youunder the Consumer

Guarantees Act.

AMES Australasia Pty Ltd

ABN 89169 427 061

Level1, 660 Doncaster Road,

Doncaster Vic3108

Phone: 1300 300 564

Email: hhl.enquiries@amesau.com

15

Hills Contacts

We are committed to providing you with

complete customer satisfaction. If you have any

questions or comments about our products or

services please contact your nearest Customer

Service Centre during their local business hours:

Australia

1300 300 564

New Zealand

0800 021 027

Email

Hills Websites

hillshome.com.au

Hills Home Living

hillshome.com.au/need-help/

Hills Consumer Advice

Contacts

AMES Australasia Pty Ltd

A.B.N. 89 169427 061

Issue Mar 2019

HD10777c

Other manuals for Portable 120

1

This manual suits for next models

1

Table of contents

Other Hills Household Appliance manuals

Hills

Hills Rotary 400 User guide

Hills

Hills FD52007 User manual

Hills

Hills Portable 120 User manual

Hills

Hills Hoist 8-Line User manual

Hills

Hills Supa Fold 230 User manual

Hills

Hills Premium Rotary 6 User manual

Hills

Hills Everyday Rotary 37 User manual

Hills

Hills HILLS HERITAGE 5 User manual

Hills

Hills Supa Fold Post Kit Standard - Adjustable... User manual

Hills

Hills Supa Fold 230 User manual