Hillsboro 2500 Series User manual

Rev. C (8-16)

Form 223

Dominating in Quality, Excelling in Class

220 Industrial Road

Hillsboro, KS 67063

FX 620.947.3127

PH 800.835.0209

Hillsboro

Industries

Series 2500/3500

Aluminum Truck Bed

Owner’s Manual

w w w . h i l l s b o r o i n d u s t r i e s . c o m

Note: new bed installation instructons

For SN 38000 & UP

SERIES 2500/3500 ALUMINUM TRUCK BED

OWNER'S MANUAL

Table of Contents

GENERAL SAFETY RULES ............................................................................................................Page 1

HITCH RATINGS.......................................................................................................................... Page 2-3

SERIES 3500 TOOL BOX INFORMATION ....................................................................................Page 3

COMPLIANCE WITH SAFETY STANDARDS.................................................................................Page 4

Notes on FMVSS 105 ..........................................................................................................Page 4

Notes on FMVSS 108 ..........................................................................................................Page 4

Notes on FMVSS 111 ..........................................................................................................Page 4

BED INSTALLATION .......................................................................................................................Page 5

Adjusting Stinger Width........................................................................................................Page 5

Attaching Bed to Truck Frame .............................................................................................Page 6

Headache Rack Height & Adjustment .................................................................................Page 7

WIRING.............................................................................................................................................Page 7

Wiring Harness Diagram......................................................................................................Page 8

LED Lighting ........................................................................................................................Page 9

Adapter and LED Reference Chart....................................................................................Page 10

FUEL DOOR AND FILLER INSTALLATION.................................................................................Page 11

WARRANTY ...................................................................................................................................Page 12

Copyright 2016 by Hillsboro Industries

Manufacturer's Notice: All specifications are subject to change without notice

and without incorporating them into prior units.

This Manual contains cautions that are marked with the safety alert symbol. All

cautions should be carefully read and obeyed!

WARNING: This unit is not designed to provide protection for fuel

tanks mounted outside of the vehicle frame. Do not mount this unit

on a vehicle equipped with fuel tanks mounted outside of vehicle

frame.

GENERAL SAFETY RULES

Read and understand the Owner's Manual and all safety signs before installing or operating this product.

DO NOT modify truck bed length, width, or height nor obscure lighting provided on the truck

bed.

Observe all warnings and recommendations as specified in the vehicle manufacturers manual or

incomplete vehicle manual.

Use caution when working around fuel tanks and fuel lines. Avoid ignition sources.

Always wear protective clothing and eyewear when operating tools. Observe safe weld procedures and

also safe tool operation as specified in tool operating instructions.

Check that all lights are functioning properly before operating vehicle.

Page 1

Hitch Ratings

Truck Bed Gooseneck Hitch Ratings

If this truck bed is equipped with a factory-installed gooseneck hitch, when the truck bed is

properly mounted to a truck, this hitch has the following ratings:

Maximum Gross Trailer Weight = 30000 lbs.

Maximum Vertical Tongue Load = 6000 lbs.

Hitch Ball Size = 2-5/16 in.

These ratings apply to the hitch components only. Actual towing capacity may be lower de-

pending on the tow vehicle or installed equipment. Refer to the tow vehicle (truck) documen-

tation for vehicle towing capacity ratings.

Do not exceed the towing ratings of this hitch or the tow vehicle.

Do not cut, drill, weld or modify any hitch components except as defined in

the bed mounting instructions.

Optional B&W Accessory Compatibility and Ratings

This Hillsboro truck bed can be equipped with the Hillsboro B&W socket kit which provides

compatibility with available B&W accessory items. This kit may be purchased separately.

The Hillsboro B&W socket kit includes the B&W 2-5/16 turnover ball which projects from the

bed surface.

Hillsboro B&W Socket Kit - Hillsboro part number 74790

Maximum Gross Trailer Weight = 30000 lbs.

Maximum Vertical Tongue Load = 6000 lbs.

Hitch Ball Size = 2-5/16 in.

B&W has several accessory items available for use with the Hillsboro B&W socket kit. The

tow ratings of the Hillsboro truck bed with these items installed will never exceed the ratings

above and may be lower as defined below. Never exceed the rating stated by B&W for any

accessory item. Do not exceed the towing ratings of the tow vehicle

Approved B&W accessory items for use with the Hillsboro B&W socket kit:

MGTW = Maximum Gross Trailer Weight, lbs.

MVTL = Maximum Vertical Tongue Load, lbs.

B&W Part # Description MGTW MVTL

RVK3050 Companion Flatbed 5th Wheel 22000 5500

GNXA4000 Kingpin 30000 6000

GNXA4085 4” Extender 20000 5000

GNXA4075 Eyelet 30000 6000

GNXA4025 Inverted Ball 30000 6000

GNXA2050 Hi-Rise Ball 2-5/16” 20000 5000

Page 2

Hitch Ratings

Truck Bed Receiver Hitch Ratings

If this truck bed is equipped with a factory-installed receiver hitch, when the truck bed is properly

mounted to a truck, this hitch has the following ratings:

Weight Carrying Hitch Configuration

Maximum Gross Trailer Weight = 18000 lbs.

Maximum Vertical Tongue Load = 1800 lbs.

Weight Distributing Hitch Configuration

Maximum Gross Trailer Weight = 18000 lbs.

Maximum Vertical Tongue Load = 1800 lbs.

These ratings apply to the hitch components only. Actual towing capacity may be lower depend-

ing on the tow vehicle or installed equipment. Refer to the tow vehicle (truck) documentation for

vehicle towing capacity ratings.

Do not exceed the towing ratings of this hitch or the tow vehicle.

Do not cut, drill, weld or modify any hitch components except as defined in

the bed mounting instructions.

Page 3

Series 3500 Tool Box Information

WARNING: Do not place flammable, combustible or living object in tool

boxes. Proximity to vehicle exhaust can create high temperatures in tool

boxes.

Maximum allowable weight in tool boxes is 200lbs. Weight must be uniformly distributed over the box

floor.

CAUTION: Do not place corrosive objects in tool boxes.

COMPLIANCE WITH SAFETY STANDARDS

It is the responsibility of the final stage manufacturer (installer) to certify that the completed

vehicle complies with applicable Federal Motor Vehicle Safety Standards (FMVSS) by

properly completing and applying a final stage manufacturer certification label to the vehicle.

Notes on FMVSS 105

Installation of a Hillsboro Truck Bed must be in compliance with FMVSS 105 with respect to

vertical and horizontal Center of Gravity. Refer to the Incomplete Vehicle Manual and the

table below. The weights listed below include the weight of the hitch ball plate assembly. It

adds 90# to the bed weight. The vertical Center of Gravity is 2” below the top surface of the

bed floor. Determine the horizontal Center of Gravity from the following table:

Notes on FMVSS 108

Installation of a Hillsboro Aluminum Truck Bed results in a vehicle with an overall width

greater than 80 inches. To comply with FMVSS 108, "Lamps, Reflective Devices and

Associated Equipment", the completed vehicle must have identification lights, amber facing

front and red facing rear, centered on the vertical centerline of the vehicle. Identification

lights consist of three lights on the same level, as close as practicable to the top of the vehicle

with lamp centers spaced not less than 6 inches or not more than 12 inches. Your Aluminum

Truck Bed is equipped with red identification lights facing rearward.

Notes on FMVSS 111

Installation of a Hillsboro Aluminum Truck Bed may affect compliance with FMVSS 111,

"Rearview Mirrors". Information concerning rearview mirrors and compliance with FMVSS

111 may be obtained from the vehicle manufacturer's Incomplete Vehicle Manuals and Body

Builder's Books.

Model Weight

Horizontal Center of Gravity

from Rear of Bed

ALT 81W X 86L S2500 548 39-3/4

ALT 81W X 102L S2500 608 46

ALT 81W X 112L S2500 623 51

ALT 96W X 86L S2500 592 39-3/4

ALT 96W X 102L S2500 658 46

ALT 96W X 112L S2500 675 51

ALT 96W X 136L S2500 763 61-1/4

Page 4

BED INSTALLATION

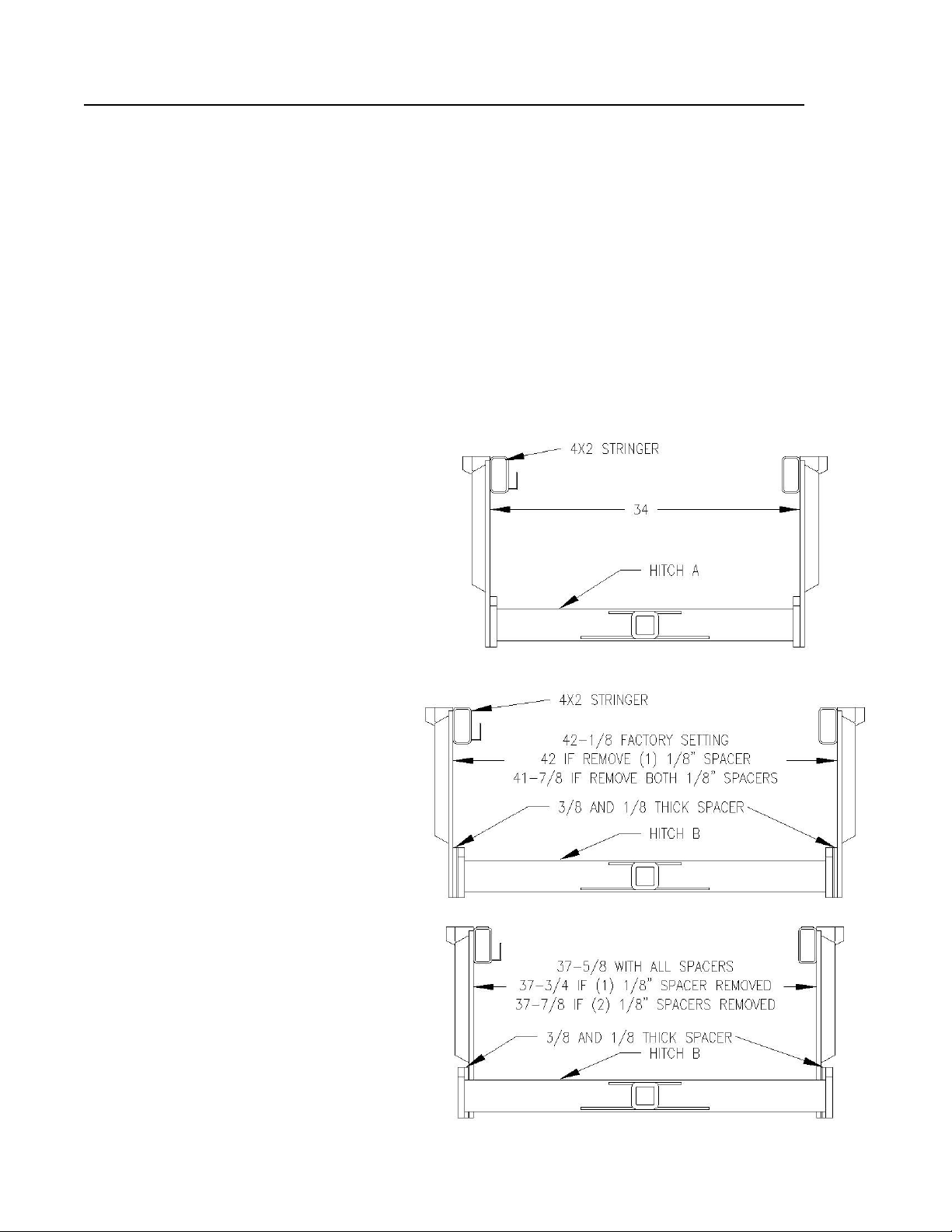

Adjusting Stringer Width

The series 2500 truck bed comes with adjustable width 4”x2” stingers. On 86” and 102”

long beds (for pickup box removals), the stringers are factory set for the 42” frame width

trucks. On 112” and longer beds, stingers are factory set for 34” frame width trucks.

Before installation, verify truck frame width. The truck frame should measure roughly 34”,

37-5/8” or 42”, depending on make and year of truck. Outside surfaces of the stingers

must match truck frame width. On most trucks, the 1/2” rear receiver hitch plates that

drop from the stingers will overlap the truck frame at the rear and at installation they will

be bolted to the truck frame. Therefore, the stingers need to be just wide enough to allow

the 1/2” plates to clear the truck frame. Even if the stingers are already in the correct po-

sition, the hitch bolts and the bed mounting bolts may need to be temporarily loosened to

allow the bed to freely slide over the rear of the truck frame.

On some trucks it will be necessary to

adjust stinger width. First, remove the

(8) 5/8” bolts and remove the receiver

hitch assembly and spacer plates.

Next, remove the 1/2” bolts that attach

stingers to the gooseneck plate and to

the aluminum bed. The aluminum bed

mount brackets and gooseneck plate

have holes for all 3 width settings.

Move stingers to the appropriate loca-

tion and reinstall 1/2” hardware.

The drawing on this page shows the

rear receiver hitch and how to position it

and the spacer plates to match the truck

frame width. “Hitch A” (34” wide) can

only be used in the 34” setting and does

not use spacer plates. “Hitch B” (41”

wide) is used for the 37-5/8 and the 42”

setting and uses spacer plates. As the

drawing shows, the 1/8” spacer plate on

each side can be removed as needed to

exactly match the truck frame width.

Reinstall and tighten hardware. Torque

nuts to 65 ft. lbs. for 1/2” hardware and

110 ft lbs for 5/8” hardware.

Special applications may require the

other hitch than what is included with

the bed. These are available as kits

through Hillsboro Industries and our

dealers.

Page 5

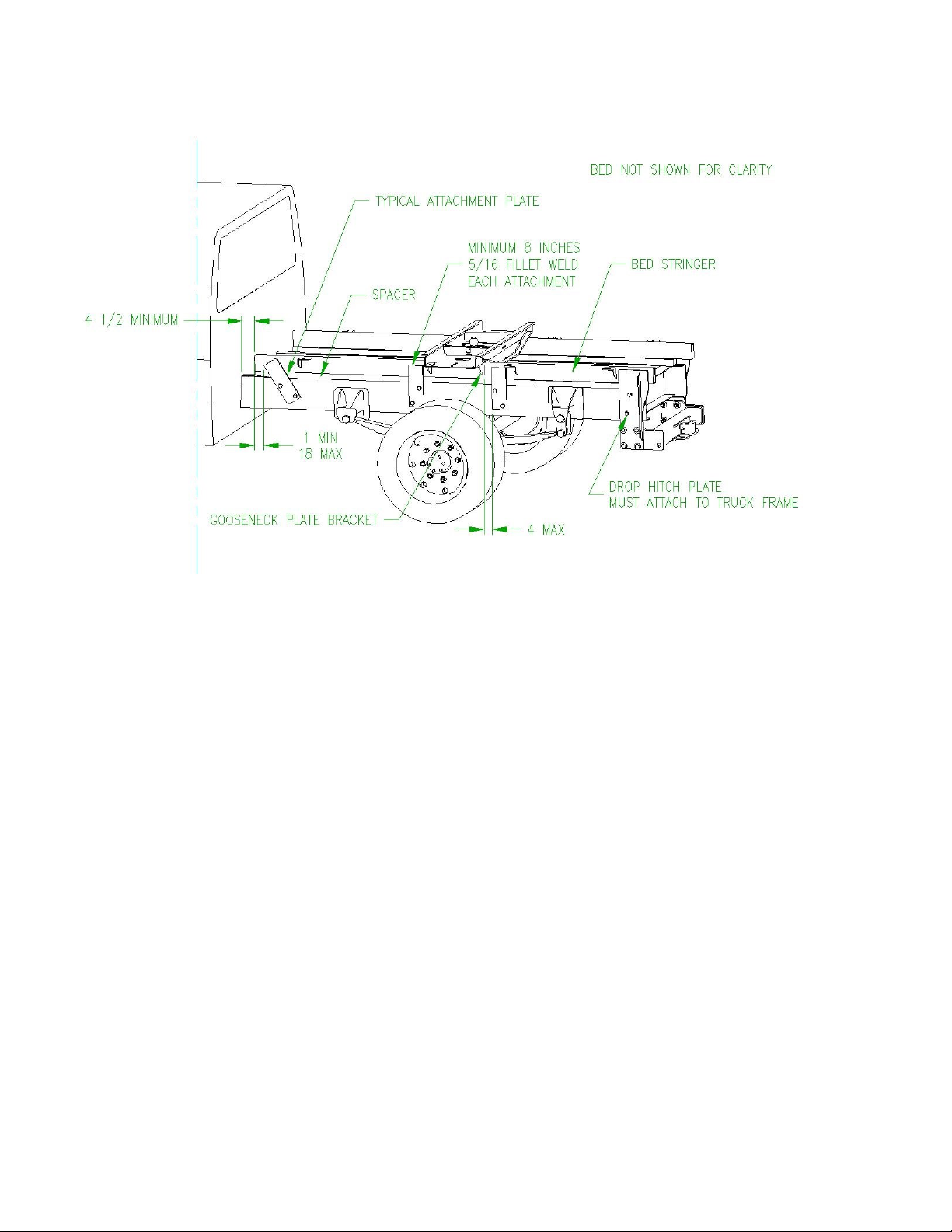

Attaching Bed to Truck Frame

Position the bed on top of the truck frame. The front of the stringers shall be no closer than 4 1/2”

to the vehicle cab. This should create a 3” gap between the headache rack and the cab. (This is

the truck OEM recommended minimum distance) Stringers may need to be spaced off the frame

to allow adequate clearance for vehicle components operating under the bed. Refer to the truck

manufacturer’s Body Builder Guide for spacer recommendations. Check for proper clearance to

vehicle components located under the bed.

Determine the stringer attachment points on your vehicle. Attachment components are not

supplied. Each stringer must be attached to the vehicle frame at a minimum of four places. The

front attachment must locate between 1 and 18 inches from the end of the stringer. The center

attachments must be located from 0 to 4 inches from each end (front and rear) of the gooseneck

plate bracket. The rear attachment should be made through the 1/2” drop hitch plate. If the truck

frame is not long enough to attach through the drop hitch plate, extend the truck frame to reach

the drop hitch plate or add material to the front of the drop hitch plates to reach the truck frame.

Each attachment should be a minimum 3/8 inch thick hot rolled steel plate. Do not trim, notch or

alter attachment plates in any way that would weaken the attachment joint. The plates should be

welded to the stringers with a minimum of 8 inches of 5/16 fillet weld. Observe safe weld

procedures. The plates should be bolted to the truck frame. Most frames have existing holes that

can be used. If it is necessary to drill holes in the truck frame, refer to the truck manufacturer’s

Body Builder Guide for allowable size and location for holes. Each plate will require a minimum of

two 5/8” Grade 5 bolts. Bolts may be located no closer than 4 inches on-center and 1 inch from

any edge of the attachment plates or the rear hitch plate.

Page 6

Headache Rack Height Adjustment

If the headache rack is too tall for your truck, it can be lowered 2-1/2”. Remove the 2-1/2”

formed riser channel by removing the 8 bolts that secure it. Remove the 4 bottom bolts on

each side that bolt the diamond plate headache rack gusset to the headache rack mounts.

Lower the headache rack down to the bed and reinstall end bolts. Re-install the 4 bolts

that hold the headache rack panel to the bed.

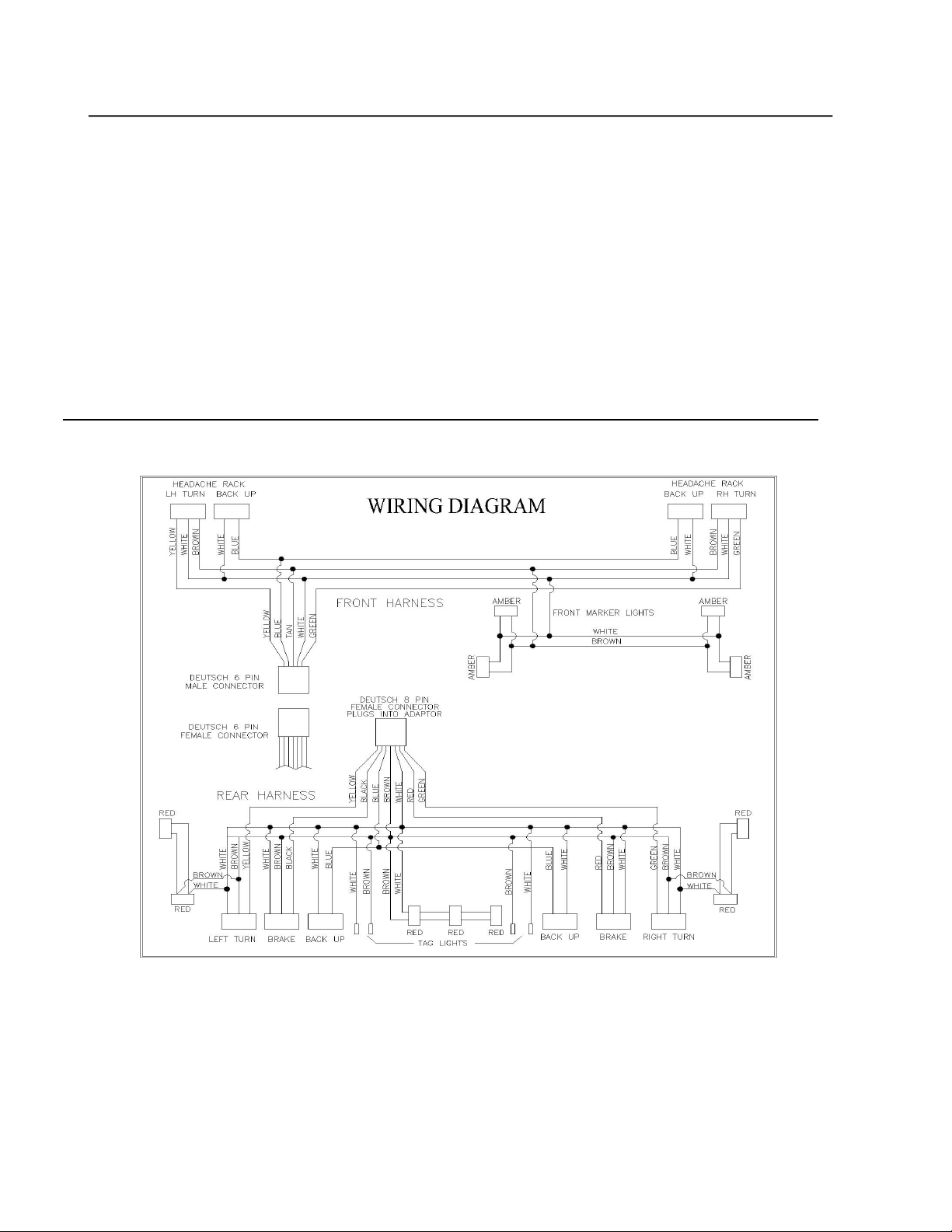

WIRING

NOTE: Observe all vehicle manufacturer recommendations when working with or

connecting to vehicle electrical system. Keep all lights turned off when making electrical

connections.

This harness is designed for either combined or separate stop/turn signals. To connect to

the harness, all trucks require a make specific adaptor. Although 1999-2010 Ford trucks

will plug into the harness, an adaptor is required for the lights to function properly. To

purchase an adaptor, contact the selling dealer or Hillsboro Industries. Please refer to

the chart on page 8 for adapter part numbers.

NOTE: On newer Dodge trucks (box removal), all truck harness wires cut during box

removal must be connected to a corresponding light in the bed. Failure to do so may result

in a “light out” message on the dash.

Verify that vehicle lighting systems function properly and comply with FMVSS 108 and

vehicle manufacturer recommendations.

Gooseneck Ball Plate Adjustment

When adjusting the stingers to match frame width you will need to un-bolt the

gooseneck ball plate. After the stingers have been adjusted to the correct width the goose-

neck ball plate should then be reattached using the same 1/2” hardware and torque to 65

ft. lbs. The ball should be oriented so it is closer to the headache rack, this is to provide

proper weight distribution of the trailer tongue weight.

Page 7

Wiring Harness Diagram

Separate Stop/Turn

Color Combined Stop/Turn (2003-2005 Dodge, 2003-2007 GM)

White Ground Ground

Brown Marker Rear Marker Rear

Tan Marker Front Marker Front

Blue Backup Backup

Green RH Turn/Brake RH Turn

Yellow LH Turn/Brake LH Turn

Red RH Turn/Brake Brake

Black or Purple LH Turn/Brake Brake

Page 8

Trailer Electrical Socket

Hillsboro extruded floor aluminum

truck beds are equipped with two holes in

the gooseneck ball plate. One of these holes

is to be used for running a pigtail with a trail-

er electrical socket on the end. This pig tail

should be 1-2 foot long so that it can be

coiled in the ball plate box and covered with

the gooseneck hitch lid when it is not being

used. The provided grommet should be

used in the hole selected for the pigtail, also

zip ties should be used on both sides of the

grommet to keep the desired length of plug

in the ball plate box to prevent dragging.

When a trailer is attached route the pigtail

so that is not damaged by the safety chains

or trailer coupler.

LED Lighting

Turn Signal Fast Flash Rate

Because LEDs draw significantly less current than traditional incandescent lamps (as low as

1/10th), using LED lights in a Hillsboro Truck bed can cause a fast flash rate of the turn signal

circuits. The fast flash rate can be corrected in a couple of different ways depending on the

make and year of the truck. Please refer to the table on the next page for more information.

LED Resistor Harness

Please refer to the table on the next page to see if resistor harnesses are needed to correct

the turn signal fast flash rate.

Hillsboro Industries has developed a LED resistor harness (part number 233805) that plugs in

between the LED light and the Hillsboro truck bed wiring harness. The resistor harness con-

tains a 6 ohm 50 watt power resistor. The resistor draws the same current (appx. 2 amps) as

the original incandescent light and therefore the turn signals flash at the correct rate.

To install the resistor harness, plug it in between the LED stop/turn/tail light and the Hillsboro

truck bed harness. The power resistor gets very hot during operation and needs to be mount-

ed to a metal surface (preferably aluminum) which acts as a heat sink. Make sure that

all wiring is kept clear of the resistor and heat sink.

Page 9

Adapter and LED Reference Chart

Page 10

FUEL FILLER INSTALLATION

WARNING: Keep all ignition sources away from vehicle when working with Fuel

Tank Filler Pipe.

CAUTION: Fuel Tank Filler Pipe must be installed according to vehicle

manufacturer requirements. Follow all warnings and cautions within the vehicle

manual.

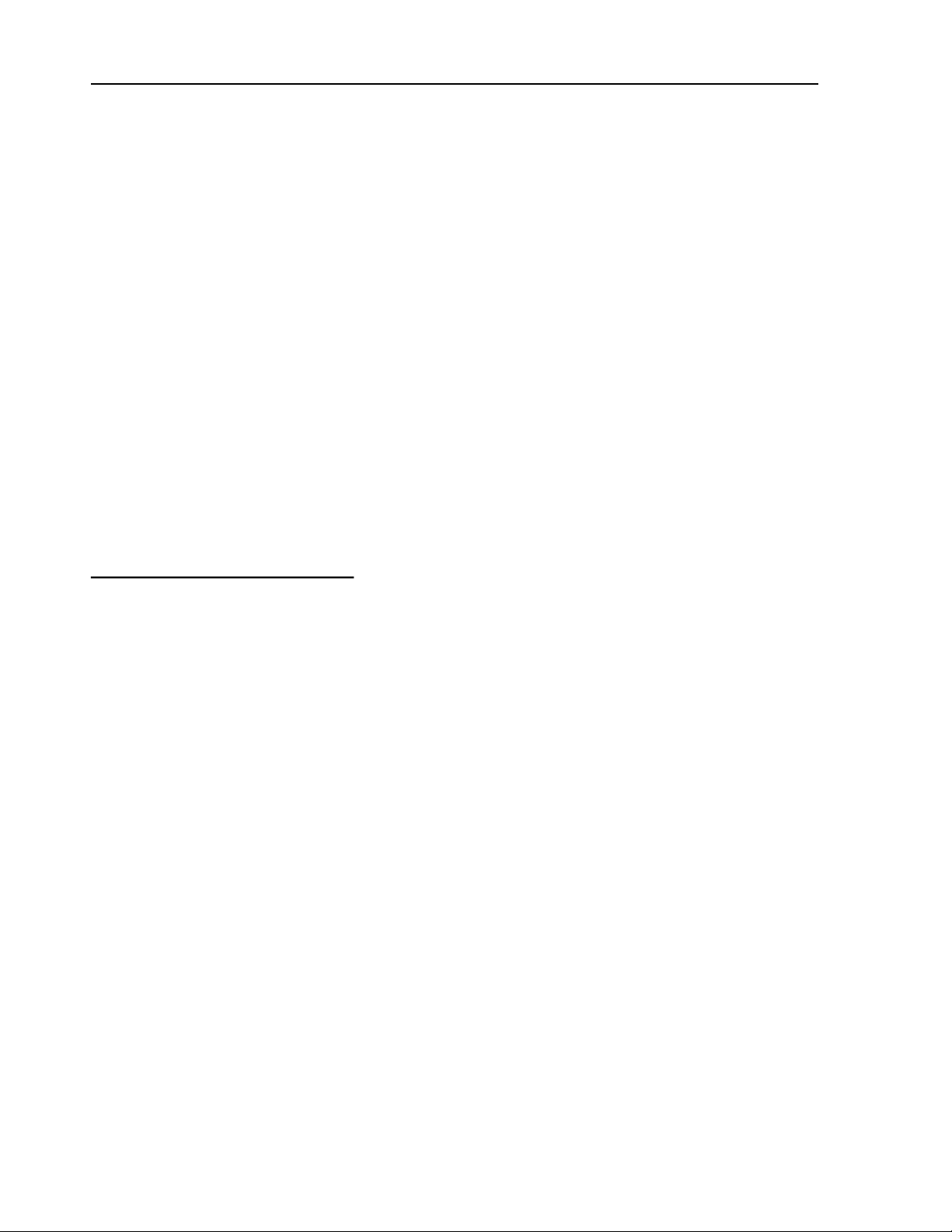

Locate and identify all components supplied with the Fuel

Filler Mounting Kit. Hardware is packaged in a padded

envelope. Determine the desired location along the side of

the bed for the fuel filler installation. Location must avoid

interference of fuel tank fill tube with bed crossmembers and

be no closer than 4 inches to any stake pocket. Mark

selected filler centerline on tie strap and bed.

Remove 4 1/2 inches of tie strap centered on fuel filler

centerline. Cut a 2 1/2 inch diameter hole in the side of the bed

located on fuel filler centerline and 2 5/8 inches downward from

the top surface of bed. Remove all burrs remaining after

cutting.

Insert fuel tank fill pipe through hole in bed side. Connect fuel

tank fill pipe to tank according to vehicle manufacturer

requirements.

Slide fuel filler mount down from the top behind tie strap and

over fuel fill pipe, until the top of the mount is flush with the top of tie strap. Clamp fuel filler

mount in place. Drill upper 3/8 inch holes through tie strap, both flanges of filler mount, and bed.

Upper holes are centered vertically on the tie strap and 1/2 inch from cut edge, 2 places. Drill

lower 3/8 inch holes through filler mount and bed. Lower holes are 3/8 inch from bottom and

edge of filler mount, 2 places.

Install carriage bolts from outside. Install flat washer, lock washer and hex nuts, 6 places.

Tighten nuts to approximately 13 ft. lbs. Fasten fuel filler pipe flange to filler mount as required

by vehicle manufacturer specifications.

Page 11

MANUFACTURER’S WARRANTY

Aluminum Truck Bed Products from

Hillsboro

Industries

Hillsboro Industries (HI) warrants the aluminum frame of its aluminum truck bed product line against

structural failure (including weld failure) for (3) three years from the date of purchase by the original owner.

This includes weld failures and failure of extrusions, decking and headache rack.

Warranty on any HI product used by the customer in the transportation of goods for compensation or in

rental enterprises will be one-half of the above-stated length.

This warranty applies to the original owner only. All warranty claims must be submitted through an

authorized HI dealer for processing.

Hillsboro Industries will not be responsible for any damage caused by the abuse, misapplication or misuse

of their products.

Any part or workmanship, subject to this warranty, if defective, as determined solely by HI, will be repaired

or replaced, at the option of HI, without charge. Photos may be required by HI to assess extent of damage.

If repairs or replacements are made at a location other than HI, reimbursement to the original owner will be

made at an amount not to exceed the amount HI would charge for the parts and labor. All parts for

warranty consideration must be returned to Hillsboro Industries* freight prepaid. All warranty claims must

be filed with HI no later than 30 days after the warranty period expires.

COMPONENTS NOT MANUFACTURED BY HI MAY BE COVERED BY THE WARRANTY OF THEIR

RESPECTIVE MANUFACTURERS, BUT ARE NOT COVERED BY THE HI WARRANTY.

HOW TO FILE FOR WARRANTY:

• First contact the selling dealer and process the claim through the dealer.

• Any HI product found to have defective material or workmanship must be serviced or corrected through

an authorized HI dealer. All warranties must then be authorized by a Hillsboro Industries factory

representative. Hillsboro Industries will not make reimbursements for any repairs and or adjustments

made without prior written consent from the HI factory.

• Always provide the HI serial number of the truck bed

HI neither assumes nor authorizes any person to create or assume for it any obligation or liability in

connection with its products or to undertake any responsibility to any purchaser for representation or

warranty made by a dealer beyond those expressly set forth herein.

HI shall not be held liable for consequential commercial damages resulting from any breach of this

warranty or any other warranty, all of which are expressly disclaimed, for any delay in the performance of

this warranty due to causes beyond its control.

THESE EXPRESS WARRANTIES ARE IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. TO THE EXTENT THAT ANY LIMITATION CONTAINED HEREIN IS

PROHIBITED BY ANY STATE OR FEDERAL LAW, SUCH LIMITATION IS VOID.

For more information see your dealer or contact:

*Hillsboro Industries

220 Industrial Road

Hillsboro, Kansas 67063

Call toll free 1.800.835.0209

Page 12

This manual suits for next models

8

Table of contents

Popular Automobile Accessories manuals by other brands

Boyo

Boyo VTR107 user manual

Abrams

Abrams RUGEYE-X Series Installation and operation manual

Atera

Atera SIGNO 044 437 quick start guide

Fortin Electronic Systems

Fortin Electronic Systems EVO-CAN SUGGESTED WIRING CONFIGURATION

Kargo Master

Kargo Master 40474 installation guide

Classic Accessories

Classic Accessories OVER DRIVE 80-112-012401-00 quick start guide

iSimple

iSimple TranzIt BLU ISFM23 installation instructions

Metra Electronics

Metra Electronics 99-9223 installation instructions

Telefunken

Telefunken TF-DVR32FHD instruction manual

Tessera4x4

Tessera4x4 SOT-ROLL Series installation manual

Xiaomi

Xiaomi Mi 20W Wireless Car Charger quick start guide

Nav TV

Nav TV BMW12-DYNAMIC KIT Install manual