Himmelstein MCRT 48200V User manual

1

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

MCRT®48200V NON-CONTACT DIGITAL TORQUEMETER

INSTALLATION, OPERATION,AND TROUBLESHOOTING GUIDE

MCRT®48200V NON-CONTACT DIGITAL TORQUEMETER

INSTALLATION, OPERATION,AND TROUBLESHOOTING GUIDE

& COMPANY

2490 Pembroke Avenue, Hoffman Estates, IL 60169 • 847-843-3300

www.himmelstein.com

Revision C • August 2021

CDTM

MCRT®48200V Non-Contact Digital Torquemeter

Installation, Operation, and Troubleshooting Guide

Customer:

Model Number:

Serial Number:

Factory Reference Number:

Rated Torque (lbf-in):

Torque Overload

Capacity (lbf-in):

Maximum Speed (rpm):

Performance Coade:

Special Features:

Speed Pickup Supplied: ❑None ❑Coda A ❑Code Z

Installed Scaling, Analog Output, Unit of Measure, and Filter Cutoff Frequency

Torque Range:

Torque Unit of Measure:

Analog Output Voltage:

Filter Cutoff Frequency:

Password Protection: ❑On ❑Off

Note: Unless specied differently when ordered, default values are as follows:

Sensor Full Scale ...................±10 Volts

Torque Unit of Measure ..............lbf-in

Filter Cutoff Frequency...............10 Hz

Password Protection ................Off

These selections can be changed with the included software.

The attached Calibration Certicate lists actual calibration data. The calibration was done in Himmelstein’s NVLAP Accredited

Laboratory (NVLAP Lab Code 200487-0). For details, visit www.himmelstein.com or the ‘laboratory accreditation’ link @

www.nist.gov. Cal values are loaded on power up. Calibration data can be accessed using a PC and the supplied software.

& COMPANY

2490 Pembroke Avenue, Hoffman Estates, IL 60169 • 847-843-3300

www.himmelstein.com

3

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Contents

I. Introduction ....................... 4

A. Mechanical Installation ............. 5

A.1 Applicability................................. 5

A.2 Coupling Selection ........................... 5

A.3 Coupling Installation.......................... 5

A.4 End-to-End Orientation........................ 5

B. Electrical Installation ............... 6

B.1 Applicability ................................. 6

B.2 Stator Connectors ............................ 6

B.2.1 Earth Ground Connection .................. 6

B.2.2 Power Input; 2 Pin Connector............... 6

B.2.3 Analog Outputs, Cal Enable,Torque Zeroing;

4 Pin Connector .......................... 6

B.2.4 Speed Signal Connector ................... 7

B.2.5 Com Port Connector; 3 Pins ................ 7

C. DT482 PC Interface Software ........ 9

C.1 DT482 PC Software Overview .................. 9

C.2 Change Sensor/Test Setup ..................... 9

C.3 DisplayTorque Data........................... 9

C.4Test Control ................................. 9

C.5 Perform Dead Weight Calibration ............... 9

C.6 Calibration Intervals .......................... 9

D. Operating & Safety Considerations ... 10

D.1 Applicability................................ 10

D.2 AllowableTorque Loads ...................... 10

D.2.1 Overload Considerations ................. 10

D.2.2 Fatigue Considerations ................... 10

D.2.3 Starting High Inertias with Electric Motors ... 10

D.3 Allowable Bearing Loads ......................11

D.4 Allowable Extraneous Loads ...................11

D.4.1 Allowable Bending Loads ..................11

D.4.2 AllowableThrust Loads....................11

D.5 Operating Speeds ........................... 12

D.6 Contaminants .............................. 12

E. Troubleshooting................... 12

E.1 Scope ..................................... 12

E.2 Preliminary Inspection ....................... 12

E.2.1Torquemeter ............................ 12

E.2.2 Cabling and Earth Grounding.............. 12

E.2.3 Readout Instrument/Data Acquisition System/

Controller .............................. 12

E.3Torque Subsystem ........................... 12

E.3.1 No Output When Torque is Present ......... 12

E.3.2 Constant Output Regardless of ShaftTorque . 13

E.3.3 Apparent Zero Drift ...................... 13

E.3.4 Signal Instability ........................ 13

E.3.5 System Will Not Zero..................... 13

E.4 Speed Pickup Replacement ................... 13

E.4.1 Removing A Defective Pickup .............. 13

E.4.2 Installing A Replacement Pickup ........... 13

E.4.3 Replacement Part Numbers ............... 13

Appendix I: MCRT® 48200V

Torquemeter Specication ............ 14

Appendix II: Belt and Chain Drive

Considerations ..................... 15

Appendix III: Mating Stator Connector

Part Numbers ...................... 15

Appendix IV: Serial Communications

for the MCRT®Compact Digital

Torquemeter ....................... 16

General Conventions Used InThis Document........ 16

General information ............................ 16

4© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

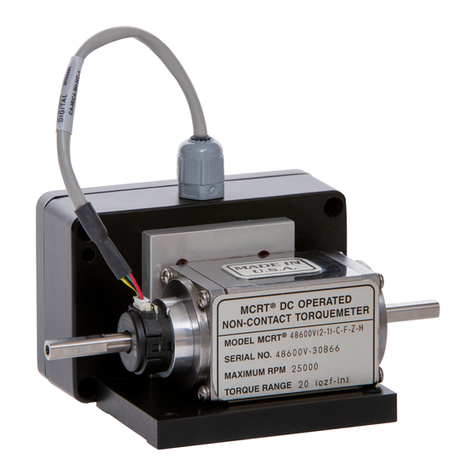

MCRT®48200V TORQUEMETERS measure and output

shaft torque and speed; speed is an option. Manual adjust-

ments and noisy pots are eliminated. Null, scaling and

unit of measure are stored in non-volatile memory. Ten

common units of torque are supported. Bessel response

signal lters avoid delay distortion and overshoot and

assure optimal measurement response. You may choose

from eleven (11) lter cutoff frequencies; 0.1 to 200 Hertz

in 1-2-5 steps. Input power is a single, unregulated dc

supply.The torquemeter has reverse polarity protection.

If you re-calibrate, previous calibration values are

archived. Pin strapping and serial commands enable

traceable* torque calibrations, and remote zeroing. Pass-

word protection may be invoked if needed.

* NIST traceable calibration performed in our accredited Cal Lab

(NVLAP LAB Code 200487-0). For details visit www.himmelstein.com or

www.nist.gov.

Torque is sensed by one or more metal foil strain gage

bridges. The rotating bridges are excited, amplied and

converted by proprietary circuitry which produces coded

data unaffected by amplitude variations.That data is then

transmitted to the stator as infrared (IR) energy where it

is detected and output in industry standard analog and

digital formats.

The IR transmission is inherently tolerant of electrical

and magnetic noise. Because MCRT®48200Vs are fully

enclosed, they are immune to sunlight and virtually all

airborne contaminants. Power is transferred to the rotor

inductively, without contact. Elimination of slip rings,

brushes, radio transmitters and other limited-life, noise-

generating and noise susceptible elements provides long

life and high data reliability.

I. Introduction

DETAILS ABOUT INCLUDED SOFTWARE

Included standard software operates on Windows-based PCs. Use it to:

• Display CurrentTorque with Unit of Measure on the PC screen

• Display PeakTorque with Unit of Measure on the PC screen

• DisplayTorque Minimum with Unit of Measure on the PC screen

• DisplayTorque Spread with Unit of Measure on the PC screen

• Select ±5 Volt or ±10 Volt analog output

• Select lter cutoff frequency

• Select from ten Units of Measure without recalibration

• Remotely invoke a CW or a CCW Cal Check

• Remotely Zero theTorque Signal

• Turn Password Protection On and Off

• Re-dead weight calibrate the torquemeter

• Torque vs time screen plot

• Set High and Low torque limits with on screen status indicator

• Save data to disk

• StoreTest setup parameters

5

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

A. Mechanical Installation

A.1 Applicability

This discussion is applicable to all MCRT®48200V torqueme-

ters, i.e, MCRT®48201V, MCRT®48202V, etc.

A.2 Coupling Selection

Your torquemeter installation method dictates the type of

coupling needed. There are two installation methods, i.e., a

oating shaft and a base (or foot) mount.

In oating shaft installations, a single ex coupling is installed

at each shaft end. It takes out angular misalignment, and the

torquemeter “tilts” to take out parallel misalignment. Use a ex-

ible strap to prevent housing rotation and to strain relieve the

torquemeter electrical cable. Caution: when conduit is required

for electrical connections, the conduit must be exible. If rigid

conduit must be used, then use a foot mounted installation as

described below.

Install a foot mounted Torquemeter between double ex

couplings as shown. The double ex couplings accommodate

both parallel and angular misalignments.

For either installation method, choose couplings that will handle the:

• Expected shaft end oat

• Parallel and angular misalignments

• Maximum expected shaft speed

• Maximum expected shaft torque

• Expected extraneous loading

A.3 Coupling Installation

Use a slight interference t (0.0005 inches per inch of shaft

diameter) and follow the coupling manufacturers’ instructions.

Before installation, lightly coat the torquemeter shaft with an

anti-seizing compound suitable for use at 400 deg. F.

Next, heat the coupling hub, not the torquemeter, to

approximately 400 deg. F. Then, install the coupling.

The heated coupling hub should “slip” on the

torquemeter shaft without signicant resistance.

That is, coupling installation force shouldn’t

exceed a few pounds of axial force. Next, allow the

assembly to cool to room temperature.Then, repeat

the process for the second coupling.

If desired, use forced air to accelerate cooling.

Air cooling avoids contaminating the torque-

meter with anti-seizing compound. If cooling is

speeded with water dampened rags, orient the

torquemeter to prevent entry of water mixed

with anti-seizing compound. Otherwise, internal

damage can occur.

After coupling installation, verify that:

• Clearance exists between the coupling and

the torquemeter stator, and

• The shaft-to-coupling t is snug enough to

prevent vibration induced coupling motion.

To Avoid Damage Or Injury

• Use xturing to support the hot shaft.

• Use insulated gloves when handling hot parts.

• Stop the hub installation if the pressing force

exceeds a few pounds. Remove the coupling.

Cool all parts, and then inspect for burrs on

the coupling bore, shaft, keys and keyways. If

the parts are burr free, check the bore size and

verify the coupling keyway squareness.

• Don’t allow uids to enter the torquemeter.

A.4 End-to-End Orientation

MCRT®torquemeters are bi-directional.Their output

signal polarity reverses when the direction of

transmitted torque reverses. Himmelstein uses the

following convention for dening torque direction.

CWTorque: the shaft turns CW, when viewed

from the driven end

CCWTorque: the shaft turns CCW, when viewed

from the driven end

Reversing a torquemeter end-for-end doesn’t

change the torque direction or magnitude. There-

fore, it will have no effect on the torquemeter output

signal. When in doubt about shaft torque direction,

observe the output signals during normal machine

operation. A positive signal output indicates CW

torque per the above denition. A negative output

signal signies a CCW torque.

LoadDriver

Torquemeter

Single-Flex Coupling Single-Flex Coupling

Flexible Strap

Figure 1. Floating Shaft Installation.

LoadDriver Torquemeter

Double-Flex Coupling Double-Flex Coupling

Figure 2. Foot Mounted Installation.

6© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

B. Electrical Installation

B.1 Applicability

This section applies to all MCRT®48200VTorquemeters.

B.2 Stator Connectors

Three stator connectors are used, as follows:

• Input Power (2 Pins)

• Analog Output/Cal Enable/Zero (4 Pins)

• Com Port (3 Pins)

If an optional speed pickup is furnished, it will have an

integral 2 pin (Code A) or 3 pin (Code Z) connector. The

Code Z Zero Velocity Pickup is recommended for use

at low operating speed and for electrically noisy envi-

ronments. Mating connectors are supplied except if a

complete cable is furnished for the Com Port.

Before wiring mating connectors, refer to Figure 5 for the

connector pin number identication(s).That Figure shows

the stator connector looking down at the torquemeter.

Mating connector pin sequence is their mirror image.

B.2.1 Earth Ground Connection

Connect theTorquemeter stator directly to earth ground, a

buildings’ structural steel or a oor rod. If neither is avail-

able, drive a six foot copper rod into the oor. Then run

separate ground straps between it, the drive motor frame,

the machine base, the torquemeter housing, the load

device and the data acquisition/computer system ground.

Don’t “daisy chain” the connections. See Figures 3 and 4.

If an IGBT-based variable frequency drive (VFD) is used,

follow its installation manual. Improperly installed VFD’s

can cause premature motor and cable failures, and

reading errors from excessive noise. VFD’s should have

shielded power and motor cables. Belden Types 29500

thru 29507 cable are designed for VFD use. See “Cable

Alternatives for PWM AC Drive Applications” available at

www.belden.com. Himmelstein recommends the connec-

tion in Figure 20. For best results, use a differential input

amplier in these electrically noisy environments.

B.2.2 Power Input; 2 Pin Connector

The power connector has two pins with pinout as follows:

Pin 1 Power Return

Pin 2 + Power In ( 10 to 15 VDC)

Spare mating connectors can be ordered from the factory;

P/N: 320-1285.

Reverse polarity protection is standard. Although any wire

may be used for connections, shielded cable will perform

best in noisy environments and is recommended. Note:

the shield should oat at the Torquemeter end. The other

end should be tied to earth ground; see Figure 5.

Caution: Don’t connect a Torquemeter to a

Power Supply that also drives inductors or

solenoids. Induced switching transients may

cause damage or noise.

B.2.3 Analog Outputs, Cal Enable, Torque

Zeroing; 4 Pin Connector

Shielded cable is recommended for these connections.

The shield should oat at the Torquemeter end and tied

to earth ground at the other end; See Figure 5. Spare

mating connectors can be ordered from the factory; P/N:

320-1287.

B.2.3.1 Analog Outputs

An analog ofTorque is output on the four pin connector.

Pin connections are as follows:

Pin 1 Analog Output

Pin 2 Analog Ground

The analog signal may have full scale values as

follows:

Torque CW = +10V, CCW = -10V, or

CW = +5V, CCW = -5V

The default value is 10 Volts.The user may reas-

sign the output voltage selection with the use of

a PC and supplied software. CW torque causes

the shaft to turn CW when viewed from the

driven end. CCW torque causes the opposite

rotation.

B.2.3.2 Cal Check Enable

Internal Calibration Check Circuitry may be

remotely enabled by pin strapping and/or via

Load Device

DAS/Controller

Machine Base

Drive Motor Torquemeter

Earth Ground

NOTE: Use separate

ground straps.

Figure 3. Correct System Earth Grounding.

7

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

the com port using furnished software. Pin strapping is

accomplished by shorting the designated pin on the four

pin connector, to Analog Ground (Pin 2).

CW Cal: Short Pin 3 to Pin 2

CCW Cal: Short Pin 4 to Pin 2

The calibration signal will remain on until the short is

released. For that reason it should be invoked while the

driveline torque is at zero; if locked-in torque is present,

break one of the shaft couplings. When the driveline

torque isn’t zero, the calibration signal will add algebra-

ically with the driveline torque.

Calibration can also be invoked from a remote computer

using the furnished software.

Equivalent calibration values, in engineering unit of

measure, are listed on the Calibration Certicate which

documents NIST traceability. Calibration values were

determined in S. Himmelstein and Company’s accredited*

(NVLAP Lab Code 200487-0) calibration laboratory. They

can also be accessed using the furnished software. The

user may perform a dead weight calibration and store the

results in memory, using furnished software.The original

cal data is archived.

*For details visit www.himmelstein.com or follow the accreditation link at

www.nist.gov.

B.2.3.3 Torque Zeroing

TORQUE ZEROING SHOULD ONLY BE DONE WHEN

THE DRIVELINE TORQUE IS ZERO. If locked-in torque is

present, break one of the shaft couplings to remove it.

The Torquemeter can be remotely zeroed by simultane-

ously strapping the CW and CCW Cal enable lines (Pins

3 & 4) to Pin 2, and holding that condition for ve (5)

seconds. When this is done, any residual system offsets

will be removed.

Torque Zeroing can also be invoked from a remote

computer using the furnished software.

B.2.4 Speed Signal Connector

B.2.4.1 Zero Velocity (Code Z) Pickup

Code Z Zero Velocity Speed Pickups have three pin

connectors. They require external power (6 to 15VDC).

Connections are as follows:

Pin A +Power In (6 to 15VDC)

Pin B Output Signal (60 pulses/rev)

Pin C Common

Zero Velocity Speed Pickups produce 60 pulses/revolu-

tion. The pulse amplitude is independent of speed and is

approximately equal to the external supply voltage. Code

Z pickups are recommended for low speed service and for

electrically noisy environments.

Replacement Code Z Pickups can be ordered from the

factory; P/N: 900-1007. Spare mating connectors can also

be ordered; P/N: 224-5361.

B.2.4.2 Standard (Code A) Pickup

Code A Standard Speed Pickups have two pin connectors.

They are self generating, i.e., they do not require external

power. Connections are as follows:

Pin A Signal

Pin B Signal

Standard Speed Pickups produce 60 pulses/revolution.

The pulse amplitude is approximately proportional to

shaft speed. Therefore, outputs are low at low speeds. If

you must measure speeds below 100 rpm or, if you are in

an electrically noisy environment, you should use a Code

Z Pickup.

Replacement Code A Pickups can be ordered from the

factory; P/N: 900-1001. Spare mating connectors can also

be ordered; P/N: 224-3897.

B.2.5 Com Port Connector; 3 Pins

Torquemeters are shipped with a 20’ Sensor to PC cable.

The cable is made per Figure 5. If required, we can supply

a 50 foot cable. RS232 runs greater than 50 feet require a

repeater.

The Baud rate is xed at 115,200. Eight data bits are used

without parity. Neither handshaking or an ID is employed.

If you wish to write your own software, see Appendix

IV for serial communication commands. Spare mating

connectors can be ordered; P/N: 320-1286. Call the factory

should you need a spare cable assembly.

Load Device

DAS/Controller

Machine Base

Drive Motor Torquemeter

Earth Ground

Load Device

DAS/Controller

Machine Base

Drive Motor Torquemeter

Figure 4. Examples of Incorrect Earth Grounding.

8© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Figure 5.Torquemeter Cable Connections.

Torquemeter Stator Housing

Analog

Outputs

Mating Connector

(viewed from side

wires connect to)

Belden 9940

or equivalent.

Belden 8761

or equivalent.

Note: To Zero, connect

pins 3 and 4 to pin 2

for 5 seconds.

Mating Connector

(viewed from side

wires connect to)

Mating Connector

(viewed from side

wires connect to)

Power

In

COM

Port

1

2

34

1

2

1

2

3

Optional Speed Pickup:

Type A: Pin A +Signal

Pin B -Signal

Type Z: Pin A +POWER IN

Pin B Output Signal

Pin C Common

Notes:

1. A dot appears next to Pin 1 on

all connectors.

2. All cables are shielded.

3. Shields Float atTorquemeter end.

4. Shields terminated at Data

Acquisition/Controller end.

5. Shields must be continuous.

Do not cut or splice them.

6. Body ofTorquemeter should be

strapped to earth ground.

See ¶B.2.1.

Pin 1

Pin 2

Pin 3

Pin 4

Analog Output

To Customer

Data

Acquisition

System or

Controller

Earth

Ground

Analog Ground

CW CAL

CCWCAL

{

To

Customer

Furnished

Power

(10-15VDC)

To

Computer

COM

Port

{

Pin 1

Pin 2

Power Return

+Power In

{

Pin 1 TXD

Pin 2 GND

Pin 3 RXD

RED RXD

GRN TXD

WHT GND

BLK

Pin 2

Pin 3

Pin 5

9

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

C. DT482 PC Interface Software

C.1 DT482 PC Software Overview

Sensors are shipped with standard Windows-based PC

interface software (Titled: DT482). That software provides

for several valuable functions as follows:

• Change Setup; Units of Measure, etc.

• Display Current MeasuredTorque

• Display PeakTorque

• Display MinimumTorque

• DisplayTorque Spread

• Make Real-timeTorque Plots

• Store Data

• StoreTest Setup

• ControlTest Functions

• Perform dead weight calibration and archive cal data

All PC operated functions are accomplished by selecting

options shown on the screen. The following paragraphs

summarize the functions available. Page 1 lists the

installed setup, when shipped. If desired, a user may

write his own communication software; see Appendix IV

for information on the serial command structure.

C.2 Change Sensor/Test Setup

• Select any of 10 units of measure. Default units are:

lbf-in. See Appendix I for a complete listing.

• Select any of 11 data lter cutoff frequencies; 0.1 to

200 Hz in 1-2-5 steps. Data lters have neither delay

distortion or overshoot errors.

• Select ±5V or ±10V full scale analog output.

• Set High and Low Torque Limits and display their

status on PC screen.

• Save data to disk.

• Store test setup.

• Adjust the value of the analog output voltage. This is

factory set at ±5.000V and ±10.000V and should not be

re-adjusted without accurate measuring equipment.

• Invoke or disable password protection and enter

a new password. Default condition is password

protection disabled. The default password is SHC.

You can change the password to any string but,

record the new one in a secure place.

Setup changes made with the Interface Software don’t

require recalibration. Any change will automatically

recongure dependent parameters. For example, if units

are changed from lbf-in to Nm, torque data and Cal Checks

will be correct without further adjustments.

C.3 Display Torque Data

• Displays Current Torque numeric data with unit of

measure.

• Displays Torque Peak and Valley numeric data with

unit of measure.

• Displays Torque Spread numeric data with unit of

measure.

• Classies status of user set High and Low Torque

Limits.

• Displays real time plots ofTorque.

C.4 Test Control

You can initiate the following actions from a PC:

• Invoke CW and CCW Cal Checks.

• InvokeTorque Zeroing.

• Save current setup parameters.

• Save Data to disk.

C.5 Perform Dead Weight Calibration

Units are shipped with an NIST traceable dead weight

calibration performed in our accredited laboratory; a Cali-

bration Certicate is shipped with the sensor. The results

of that calibration are stored in non-volatile memory and

automatically loaded on power up. Remote, initiated

either via PC (per ¶C.4) or by strapping (per ¶B.2.3.2), Cali-

bration Checks are referenced to it.

The user can perform a dead weight calibration and store

it in memory.The interface program prompts you through

the process. If done, the original factory calibration will

be archived as will subsequent dead weight calibrations.

However, unless you have accurate, accredited calibra-

tion facilities, you should not substitute a eld calibration

for the factory calibration. Rather, you can perform a

eld calibration for use as a rough check of operation. If

an inaccurate or erroneous calibration is inadvertently

stored, the factory calibration(s) may be recovered.

C.6 Calibration Intervals

For continuous or intermittent service, make periodic

Calibration Checks per ¶B.2.3.2 or ¶C.4, above.

In applications requiring high accuracy, perform a dead

weight calibration in a accredited torque calibration labo-

ratory at intervals specied by your QC Procedures. If

you do not have an established QC procedure, then we

recommend an initial one year interval.

If the MCRT®Torquemeter is overloaded or operates

abnormally, then calibrate/inspect it at once.

Himmelstein offers certied dead weight calibration

service, traceable to NIST, for all its products. Its calibra-

tion laboratory is accredited (Laboratory Code 200487-0)

by NVLAP, an arm of the NIST. For further information

visit our website at www.himmelstein.com or, follow the

accreditation link at www.nist.gov

10 © 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

D. Operating &

Safety Considerations

D.1 Applicability

The following paragraphs apply to all MCRT®products.

D.2 Allowable Torque Loads

Operate an MCRT® torquemeter within its’ full scale; see

booklet cover for rating of this device.

D.2.1 Overload Considerations

The overload rating of an MCRT©Compact DigitalTorque-

meter is 2 times full scale.This torquemeters’ overload is

listed on the cover sheet. The torquemeter will not yield

(evidenced by a non-return to zero) or fail if subjected to

an instantaneous peak torque up to its’ overload value.

Both the full scale and overload ratings are based on the

peak stress seen by the transducer.They are independent

of stress duration, except for cyclical (or fatigue) loading

considerations; see ¶D.2.2. Virtually all rotary power

producing and absorbing devices produce pulsating

rather than smooth torque and power.

Thus, in addition to its’ average torque and speed values,

the driveline torque usually includes a fundamental

(driving) frequency and superimposed harmonics.

Torsional vibration magnitudes can be amplied by the

driveline. See Bulletin 705 for further information. The

Figure 6 waveform is typical of what occurs in the real

world.

For these reasons, a conservative design approach

dictates the torquemeters’ overload => twice the probable

peak torque. Reserve the region between the peak instan-

taneous torque and the torquemeters’ overload rating as

a safety margin for unexpected loads. Do not knowingly

operate in the overload region. If you expect torques in

the overload region, then change to a torquemeter with a

higher overload rating.

D.2.2 Fatigue Considerations

If the peak torque seen by an MCRT®torquemeter is less

than half its overload rating, it can handle full torque

reversals with innite fatigue life. When peak torques

are cyclical, and exceed 50% of the overload rating, then

fatigue failure can occur.

D.2.3 Starting High Inertias with Electric Motors

When started across the line, during the start, a motors’

developed torque can be several times its’ rated torque.

Thus, a Digital Torquemeter sized to handle the motors’

rated load torque, can be overloaded during starting.

Drivelines are particularly vulnerable when oversized

motors drive light duty, high inertia loads.

Load

J2

Driver

J1

J1 & J2 ARE ROTATING INERTIAS

Torquemeter

To avoid damage when starting high inertia loads, use

a torquemeter rated for the starting torque or, limit the

starting torque to a safe value.Techniques to limit electric

motor starting torques include:

• Use reduced voltage starting.

• Electronically limit the maximum motor current.

• Add inertia to the input side of the torquemeter.

Before operating, verify the motor can safely start

the increased load inertia.

• Use “shock absorbing” couplings. Careful coupling

selection and thorough analysis is essential. Under

some conditions, such couplings can aggravate

rather than improve the situation.

Figure 6. Reciprocating Machine Torque Prole.

Figure 7. Motor Start Torque Prole.

11

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

D.3 Allowable Bearing Loads

MCRT®torquemeter bearing design provides long life,

smooth running, and avoids bearing torque measure-

ment errors. In a oating shaft installation, the stator

must be exibly restrained so total loads, including the

stator restraint and shaft runout, don’t exceed its bearing

rating. A stranded wire or braided cable will provide this

exible restraint and strain relieve the electric cable.

When the stator is foot mounted, the coupling end oat

must be sufcient to take up axial shaft motions and

hold the bearing loads within the limits specied in the

following table.

When using shaft torquemeters in belt/chain drives,

pillow blocks are usually needed to isolate them from

radial bearing and bending loads (see ¶D.4). Consider

pulley or wheel type torque sensors for such service.

Their bearings are isolated from the belt loads, and they

accept large radial and bending loads without damage or

measurement errors.

Model

Bidirectional

Bearing Load (lbs)

Radial Axial

MCRT®48201V 50 20

MCRT®48202V 50 20

MCRT®48203V 75 30

MCRT®48204V 75 30

D.4 Allowable Extraneous Loads

Any moment or force a torquemeter sees, other than the

transmitted torque, is an extraneous load. Depending on

the installation, these could include bending moments and

axial thrust. Crosstalk errors from such loads, expressed

in pound-inches, are typically 1% of the applied pound-

inches of bending or, 1% of the applied pounds of thrust.

D.4.1 Allowable Bending Loads

When it is applied without thrust, a standard MCRT®

Torquemeter, mounted as a oating shaft, can handle a

shaft bending moment equal to one half its’ torque rating.

Such bending may be applied simultaneously with rated

torque.

The allowable bending input to a foot mounted torque-

meter (Figure 8) is dictated by its’ bearing radial load

ratings (see ¶D.3), and by the need to prevent coupling

“lock-up”. When a coupling locks-up, it no longer provides

one or more needed degrees of freedom and, ultimately

causes a driveline failure.

Caution

Use pillow blocks to isolate a foot mounted

torquemeter from excessive bending and

radial loads. When applying such loads, don’t

exceed a torquemeters’ bearing load ratings;

see Appendix II for explicit details.

D.4.2 Allowable Thrust Loads

Drive and

Thrust Bearing

THRUST

Torquemeter

When applied without bending, most MCRT®Torque-

meters, when mounted as a oating shaft, can handle a

thrust load (tension or compression) in pounds, applied

to its’ shaft (see Figure 9 ), equal to its’ torque rating in

pound-inches. Some units may have different thrust

capacities; refer to the applicable Specication or Descrip-

tive Bulletin. Such thrust may be applied simultaneously

with rated torque.

Caution

Large thrust loads are only allowable in

oating shaft installations. Bearing axial loads

limit the thrust capacity of foot mounted

torquemeters; see ¶ D.3.

Figure 8.Torquemeter With Bending Load.

Figure 9.Torquemeter With Thrust Load

Driver

Foot Mounted

Torquemeter Blower Wheel

UnderTest

WEIGHT OF

BLOWER WHEEL

APPLIES

BENDING LOAD

Double-Flex

Coupling

12 © 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

D.5 Operating Speeds

Operate MCRT®DigitalTorquemeters within the maximum

speed rating published in the pertinent specication and

appearing on the cover of this booklet. The ratings are

bi-directional. Standard torquemeters do not require

external lubrication.

Caution

If a driveline part fails, dynamic balance is

lost and the resultant forces can cause other

part failures.Therefore, it is an essential safety

requirement that guard covers, substantial

enough to contain any separated mass, be

installed.

D.6 Contaminants

Don’t ood a torquemeter with liquids—they can inter-

fere with IR signals and cause heat buildup from viscous

losses at high speeds.

MCRT®devices are immune to spray from mineral based

oils and natural, hydrocarbon hydraulic uids.When using

synthetic uids, verify they are compatible with plastic,

electronic components, and electrical insulation. Protect

the torquemeter from contact with uids that attack insu-

lation or plastics. Warranties are void for damage caused

by such materials.

Airborne abrasive can cause premature bearing failure.

When they are present, consider using an air purge to

prevent invasion of such materials.

E. Troubleshooting

E.1 Scope

These discussions suggest procedures for identifying a

defective system component.They are an aid for operating

personnel. Special training and adequate inspection, test

and assembly xtures are needed for extensive service.

The installation, the torquemeter, the cabling and the

terminal device are all potential faults.The best procedure

is to isolate the problem part, then correct or replace it.

Otherwise, return the defective part to the factory.

E.2 Preliminary Inspection

E.2.1 Torquemeter

Inspect the sensor for physical damage. If the shaft

is locked or a rub exists, remove the speed pickup, if

present, per instructions contained in ¶E.4.3. If the fault

clears, reinstall the pickup following ¶E.4.3 instructions.

Otherwise return the unit to the factory.

E.2.2 Cabling and Earth Grounding

Make electrical checks for continuity and shorts; see

¶B.2 and Figures 3, 4 and 5 for connections. Verify that

the mating connectors are installed and secured. Erratic

connections, omission of shields and poor grounds can

produce noise. If noise is a problem, then replace the cable

with one that is shielded and provide a good earth ground

to the motor, machine base and torquemeter housing per

¶B.2.1. Examine all cables for damage. Replace damaged

cables. Clean connectors with an approved contact

cleaner.

E.2.3 Readout Instrument/Data Acquisition

System/Controller

Examine for physical damage, blown fuses and/or loose

parts. Correct any defects; refer to the manufacturers’

manual, as necessary.

E.3 Torque Subsystem

E.3.1 No Output When Torque is Present

Verify input power is present, its’ polarity is correct, and

the cable is intact, i.e., between 10 and 15 VDC appears

at the torquemeter terminals. Finally, verify the power

supply is properly sized. That is rated for 10 to 15 VDC

output and will handle at least 250 mA and preferably 500

mA.

Operate the Cal Check. If the analog output has the correct

Cal Signal but the PC does not, then check the PC cable

connections and verify the port is set per ¶B.2.5. If all

checks are negative, the problem is in the sensor. Return

it for factory service.

13

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

E.3.2 Constant Output Regardless of Shaft

Torque

If the ¶E.3.1 above Cal Checks are performed and found

normal, then the problem is the sensor. Return it for

factory service.

E.3.3 Apparent Zero Drift

• Check the Cabling. See ¶E.2.2.

• Check for Driveline Torque Offsets. Torquemeters

installed in a drive which has hysteresis or friction

torques, may appear to have long term drift when

there is none. For example, when installed between

a pump and a gear drive, the torque reading may not

return to zero after a test because of locked-in fric-

tion torque.The sensor sees and reads that locked-in

torque. Always zero the torquemeter with no torque

on the driveline—in the case cited, with a coupling

disassembled. At the end of the test, the shaft should

be mechanically “shaken” or a coupling broken, to

return to zero torque. Otherwise, the sensor will

read locked-in torque. A rub between any rotating

and stationary part is a common cause of friction.

Verify the shaft couplings and other rotating parts

have adequate clearance.

E.3.4 Signal Instability

• Check the Cabling. See ¶E.2.2 above.

• Check For Driveline Torque Variations. The driveline

may have a low frequency oscillation which the

sensor reads (seeTech Memo 8150). Use theTorque-

meters’ low frequency lter to suppress signals

above 1 Hertz. If the readings become steady, then

you may wish to identify the physical cause of the

shaft torque variation or, remove it with mechanical

ltering techniques. Oscillographic signal analysis

is often helpful under these conditions. Use the 200

Hertz lter for this analysis. If very large, high inertia

machines are used, or large machines are used in a

control loop, torque and speed oscillations can be

present below 1 hertz.

E.3.5 System Will Not Zero

• Check the Cabling. See ¶E.2.2 above.

• Verify the Torque Input is Zero. If the sensor is

installed in a driveline, break or remove one of the

couplings. If the system still can’t be zeroed, then

the problem is either the cable, system grounding

or theTorquemeter. Verify cable integrity, congura-

tion and connections and check theTorquemeter per

¶E.2.1.

• Verify A Good Earth Ground, per ¶B.2.1, is present.

E.4 Speed Pickup Replacement

Speed pickups are threaded into the sensor stator housing

and locked with a jam nut.

E.4.1 Removing A Defective Pickup

• Disconnect the mating cable.

• With shaft motion stopped, loosen the jam nut.

• Back out the defective speed pickup.

E.4.2 Installing A Replacement Pickup

• With shaft motion stopped, screw in the new pickup

until it makes contact with the rotor assembly.

• Back off the pickup one quarter of a turn.

• Tighten the jam nut.

• Slowly rotate the shaft to verify no rub occurs. It you

detect a rub, re-adjust the pickup.

• Reconnect the mating cable.

E.4.3 Replacement Part Numbers

• Standard (Code A) Speed Pickup P/N: 900-1001

• Zero Velocity (Code Z) Speed Pickup P/N: 900-1007

14 © 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Appendix I

MCRT®48200V Torquemeter Specication

General Specications Code N Performance Code C Performance

Accuracy (combined nonlinearity, hysteresis and nonrepeatability, % of Range) <= ±0.20 <= ±0.10

Remote Calibration Accuracy* (% of Range @ 75 °F/23.9 °C, traceable to NIST) <= ±0.10 <= ±0.05

Temperature Effects

Zero Drift (% of Range/°F)/(% of Range/°C) <= ±0.004/<= ±0.007 <= ±0.0017/<= ±0.003

Span Drift (% of Reading/°F)/(% of Range/°C) <= ±0.004/<= ±0.007 <= ±0.0017/<= ±0.003

Compensated Range (°F)/(°C) +75 to +150/+23.9 to +66

Useable Range (°F)/(°C) +32 to +175/0 to 79.4

Analog Output

(Resolution: 0.02% on ±10V

& 0.04% on ±5V output)

(Source Impedance: < 1Ω)

CW/CCW Output at Full Scale +10V/-10V or +5V/-5V, user selectable. Default is +10V/-10V.

Bandwidth (Hz.); has Bessel Response Data Filter(s) DC to 0.1 thru 200 in 1-2-5 steps

Noise and Ripple (rms, % of Range) <= 0.1

Overrange (% of Full Range) 30

Maximum Allowable Resistive and Capacitive Loads 10kΩ Minimum and 0.05uF Maximum

Rotational Effect on Zero (% of Range) <= ±0.05 <= ±0.025

RS232C Port (115,200 Baud) Outputs Torque in Engineering Units. Inputs units of measure, scaling, signal lter selection, zero, span, cal data and commands.

Supply Voltage 10 to 15 VDC @ 200 mA, nominal. Has reverse polarity and 25 Volt overvoltage protection.

Available Options

Enhanced Performance - Code C, Code N is standard performance.

60 PPR Speed Pickup Options: Code A is standard type, Code Z is Zero Velocity type, Code N denotes no pickup.

A Type Z pickup is recommended for low speeds and/or operation in electrically noisy environments.

Supported Units of Measure lbf-in, lbf-ft, ozf-in, ozf-ft, N-m, kN-m, N-cm, kgf-m, kgf-cm, gf-cm

MCRT®

MODEL TORQUE RANGE TORQUE OVERLOAD SPEED RATING* (RPM)

SHAFT

STIFFNESS**

ROTATING

INERTIA

MAX

WT.

[lbf-in] [n–m] [lbf-in] [n–m] Code N Code C [lbf-in/rad] [ozf-in s2] [lbs]

48201V(25-0) 25 2.82 50 5.65 0 to ±8,000 0 to ±15,000 1,800 0.031 10

48201V(5-1) 50 5.65 100 11.3 0 to ±8,000 0 to ±15,000 5,000 0.031 10

48201V(1-2) 100 11.3 200 22.6 0 to ±8,000 0 to ±15,000 12,000 0.031 10

48201V(2-2) 200 22.6 400 45.2 0 to ±8,000 0 to ±15,000 26,000 0.031 10

48202V(5-2) 500 56.5 1,000 113 0 to ±7,000 0 to ±12,000 66,000 0.032 10

48202V(1-3) 1,000 113 2,000 226 0 to ±7,000 0 to ±12,000 85,000 0.032 10

48203V(2-3) 2,000 226 4,000 452 0 to ±6,500 0 to ±8,500 288,000 0.080 10

48204V(5-3) 5,000 565 10,000 1,130 0 to ±6,000 0 to ±8,500 545,000 0.100 11

48204V(1-4) 10,000 1,130 20,000 2,260 0 to ±6,000 0 to ±8,500 684,000 0.100 12

*Ratings are for continuous operation without external lubrication. **Stiffness is conservatively rated and includes the torsion section and shaft ends.

15

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Appendix II

Belt and Chain Drive Considerations

Appendix III

Mating Stator Connector Part Numbers

Function Number of Pins Part Number

Power Connector 2 320-1285

Analog Output/Cal

Enable/Zero

4 320-1287

Com Port Connector 3 320-1286

Type A Speed Pickup 2 224-3897

Type Z Speed Pickup 3 224-5361

MCRT®48200V Torquemeters are furnished with mating connectors and cable. Mating

Connectors are supplied for Power (2 Pins) and for Analog Outputs and Cal Enable (4

Pins). Additionally, a Com Port-to-PC cable is also provided.That cable has connectors

at each end. When a speed pickup option is ordered, the appropriate mating connector

is supplied; 2 pins for aType A pickup and 3 pins for aType Z pickup.

To order spare connectors, use the following part numbers (P/N).

When the bearing load ratings don’t meet the above criteria, use pillow blocks and a

jack shaft to isolate the pulley/belt loads; see Figure 10 example. Alternatively, consider

a pulley or wheel type torquemeter.Their bearings are isolated from the belt loads, and

they can accept large radial and bending loads without damage or measurement errors.

Caution. Don’t install a pulley or

sprocket on the torquemeter shaft

unless the torquemeters’ radial

bearing load rating, from ¶D.3, is :

≥[Torque Rating] / [4*L]

and,

≥[T1+T2]*[1 + L/H]

These criteria assure safe torque-

meter bending and bearing loads.

To simplify your analysis, assume

T2= 0 and calculate T1= [Torque

Rating*2/D]. Then, make [T1+ T2] =

1.1 times the calculated value ofT1.TORQUE = (T1 -T2) * (D/2)

T1 +T2 T1

H

T2

D

L

JACKSHAFT

PILLOW BLOCKS

FLEXIBLE COUPLINGS

TORQUEMETER

PULLEY

OR

GEAR

16 © 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Appendix IV

Serial Communications for

the MCRT®Compact Digital Torquemeter

This specication of the serial communications for the MCRT®48200V is

subject to change at any time without notice.

• Lines that end in “ =a.b” apply only to version a.b

• Lines that end in “ >c.d” apply only to versions >c.d

• Lines that end in “ <e.f” apply only to versions <e.f

General Conventions Used In This Document

<OK> stands for the string “OK”

<index> is an alphanumeric character (A-Z or 0-9)

<CR> is a carriage return (^M / 13 decimal / 0D hexadecimal / 15 octal)

<LF> is a line feed (^J / 10 decimal / 0A hexadecimal / 12 octal)

<int> is a integer (e.g. “1234”)

<oat> is a oating point number string (e.g. “1234.57”)

<string> is a string (e.g. “LB-IN”)

<hex> is a hexadecimal *string* (e.g. hex could be “8FC4”)

<base64> is a base-64 *string* with “0-9A-Za-z@_”

<Bool> is either a ‘0’ which means false, or ‘1’ which means true.

<HF> is an 8 character hexadecimal string that represents a IEEE-oat. (A 1-bit

sign, 8-bit exponent biased by 126, and a 23-bit mantissa with an implied

MSB of 1)

• 0x80000000 : Sign (0 = positive, 1 = negative)

• 0x7F800000 : Exponent

• 0x007FFFFF : Mantissa

o if (sign = 0) then value = (2 ^ (Exponent - 24)) * (Mantissa + 0x800000)

o else value = -(2 ^ (Exponent - 24)) * (Mantissa + 0x800000)

General information

• All messages to and from the

MCRT48200V are terminated

with a <CR> or <LF>.

o The default termination

character is <CR>.

• To set a value on the

MCRT48200V, nd the mes-

sage that retrieves the data

you want to change. Then

append to that message the

desired value of the parame-

ter. The MCRT48200V should

respond with “OK”.

• All hexadecimal/binary data

from the MCRT48200V is in

big-endian (MSB rst) format.

In response to any command, the MCRT48200V returns one of the following:

• “string” where string is the data requested.

• “OK” operation was successful.

• “!Command:xx” command “xx” is not recognized.

• “!Channel” command is inappropriate for the given channel.

• “!Arg” parameter is malformed.

• “!Index” an index <index> is bad (see “CC” for example)

• “!Invalid” there is some other error.

• “!Unknown Error” an unknown error occurred.

• “!SignalToo Small” calibration signal is too small in magnitude.

• “!SignalToo Large” calibration signal is too large in magnitude.

• “!Signal has wrong sign” calibration signal is of the wrong sign for the requested calibration.

17

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Examples:

Remember *ALL* messages to and from the MCRT48200V series end with a <CR> or a <LF>.

• Retrieve data:

Send “DC” to the MCRT48200V.The “DC” is the data current command.The return message should look

something like “1234.56”.

• Retrieve the lter:

Send “FL” to the MCRT48200V. The return message should be something like “07” which implies (refer-

ring to the appropriate list under the “FL” message) the lter setting is 5 Hz.

• Set the lter to 100 Hz:

Refer to the list under the “FL” (lter) command to nd that a 100 Hz lter corresponds to the value 02.

Therefore, send “FL02” to the MCRT48200V.The MCRT48200V should respond with “OK” if the operation

was successful.

• Retrieve the version number of the MCRT48200V:

Send “VR” to the MCRT48200V.The return message should be something like “Model MCRT48200V v1.2”.

Informational Only Messages

• These messages can only retrieve information from the MCRT48200V—they can not change any data on the

MCRT48200V.

• The time returned is the number of 10kHz clock ticks since the MCRT48200V was powered on.

MESSAGE REPLY MEANING

DC oat Current engineering data for the torque.

XC hex Current hexadecimal data for the torque.

YC hex, hex Time and Current hexadecimal data for torque.

64 base64 Current base-64 data for the given channel.

65 hex, base64 Hexadecimal time and Current base-64 data for the given channel.

MX int, int The max and min of the torque. Multiply by the scaling constants (SC command) to get lbf-in.

SN string Serial number of the MCRT48200V.

SP string Scratch pad of the MCRT48200V.

MD string Model number of the MCRT48200V.

PP Bool

Is ash password protected?

See the “PC” command to change the protection password, and the “PS” command to set/unset the

protection.

VR string Version number of rmware.

AD int, int, int

A/D readings

o1st number: temperature sensor

o2nd number: F-coil voltage

o3rd number: Input voltage

SC hexoat, hexoat Positive/Negative Scaling Constants, lbf-in / counts

18 © 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Analog Output Messages

MESSAGE REPLY MEANING

AA int

o 5V vs 10V analog output

o 0: 10 V analog output

o 1: 5 V analog output

AI index OK

Analog output user tweak values

o index:

• A: DAC value to give +10V analog output

• B: DAC value to give +5V analog output

• C: DAC value to give 0V analog output

• D: DAC value to give -5V analog output

• E: DAC value to give -10V analog output

Miscellaneous Messages

MESSAGE REPLY MEANING

@@ OK Write data in RAM to non-volatile ash

PS

index

string

OK

Change Flash password protection

o string must match the current ash password

o index:

• A: Disable ash password protection.

• B: Enable ash password protection, but still allow taring of the torque.

• C: Enable ash password protection.

PC

string:

string:

string

OK

Change ash protection password.

o If the rst string equals the current password, and the second and third strings are equal, then

change the ash protection password to the second string.

19

© 2022 S. Himmelstein and Company—all rights reserved. www.himmelstein.com

Torque Specic Messages

MESSAGE REPLY MEANING

UN string Unit name of torque

TV int

Current Tare Value (16 bits)

o Chars 1- 4: Current Tare Value In raw counts

TT OK Tare Torque

SC HF HF

Positive and Negative Scaling Constants in lbf-in / raw counts

o Chars 1- 8: Positive scaling constant (IEEE-oat)

o Chars 9-16: Negative scaling constant (IEEE-oat)

DS HF

Display Scaling in eng units / lbf-in

o 0xFFFFFFFF : Display Scaling (IEEE-oat)

• The native units (lbf-in) for the channel’s data are multiplied by this number before being sent to

the user.

• Only data from the DC command is subject to this scaling.

FL int

FiLter (0-10) (4 bits)

o 2: 200 Hz

o 3: 100 Hz

o 4: 50 Hz

o 5: 20 Hz

o 6: 10 Hz

o 7: 5 Hz

o 8: 2 Hz

o 9: 1 Hz

o 10: 0.5 Hz

o 11: 0.2 Hz

o 12: 0.1 Hz

MXO OK Reset the max and min data to the current torque data

AS

index OK

Apply a Cal Check signal to the Torque data

o index:

• A: no-shunt applied

• B: Apply Positive Cal Check Signal (add full Scale to the reading)

• C: Apply Negative Cal Check Signal (subtract Full Scale from the reading)

CC

index HF

Calibration Constants

o index

• A: Full Scale

• B: Zero value -- LEAVE AT ZERO

• C: Positive Load value

• D: Negative Load value

CL

index long

Do a calibration. This message takes approximately 1.25 seconds to nish!

o index

• A: Do a Zero Calibration

• B: Do a Positive Load Calibration

• C: Do a Negative Load Calibration

& COMPANY

2490 Pembroke Avenue, Hoffman Estates, IL 60169 • 847-843-3300

www.himmelstein.com

CDTM

Table of contents

Other Himmelstein Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Beta

Beta 1651DGT user manual

Master Meter

Master Meter Madness PD Assembly instructions

Keysight Technologies

Keysight Technologies U1084A Startup guide

AGICO

AGICO PUMA user manual

Endress+Hauser

Endress+Hauser Teqwave F operating instructions

Wavetronix

Wavetronix smartsensor advance INSTALLER QUICK-REFERENCE GUIDE