Signal SOLAR 4 Series User manual

ISSUE 1.07

SERIES 4

SOLAR

HEATED FID VOC ANALYSER

OPERATING MANUAL

Raising gas analysis to new levels

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 2of 42

DOCUMENT HISTORY

ISSUE

AMENDMENT

DATE

1.02

DRAFT

February 2015

1.03

Added wiring info

August 2015

1.04

Formatting, correct fig 8, added sample and air

pressures to spec, added more calibration detail

October 2018

1.05

Reformatted, added additional figures and tables,

Flow schemes updated

February 2020

1.06

Front cover, Relay and Chart Output Pinouts

updated

August 2020

1.07

Front cover update, MCERT-related updates

April 2021

Table 1 : Document history table

© Signal Group Ltd.

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system or

transmitted in any form or by any means - electronic, mechanical, photocopying, recording or

otherwise - without the prior written permission of Signal Group Ltd.

While we believe that the information and guidance given in this manual is correct, all parties must

rely upon their own skill and judgment when making use of it. Signal Group Ltd. will not assume any

liability to anyone for any loss or damage caused by any error or omission in the manual, whether

such error or omission is the result of negligence or any other cause. Any and all such liability is

disclaimed.

The information contained within this document is subject to change without notice.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 3of 42

Contents

1What’s in the box ................................................................................................................4

2Important safety instructions ..............................................................................................6

2.1 Wiring and Installation.................................................................................................6

2.2 Handling and Storing Pressurised Gases...................................................................6

2.3 Operation and Maintenance........................................................................................7

2.4 Competent Personnel .................................................................................................8

3Quick-start ..........................................................................................................................9

4Introduction.......................................................................................................................11

5The Principle of Flame Ionisation.....................................................................................12

5.1 Sample System.........................................................................................................12

6Flow Schemes..................................................................................................................13

7Operation..........................................................................................................................23

7.1 Services.....................................................................................................................23

7.2 Start...........................................................................................................................23

7.3 Control.......................................................................................................................27

7.4 Remote Control.........................................................................................................29

7.5 Connectivity...............................................................................................................30

8Routine Maintenance........................................................................................................34

8.1Introduction................................................................................................................34

8.2 Sample Filter.............................................................................................................34

8.3 Dual FID Cutter Cartridge Replacement...................................................................37

9Routine Servicing .............................................................................................................39

9.1 Schedule....................................................................................................................39

9.2 Service Manual..........................................................................................................39

9.3 Sample Capillary.......................................................................................................39

10 Table of Figures............................................................................................................42

11 Table of Tables.............................................................................................................42

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 4of 42

1 What’s in the box

‒Signal Series 4 SOLAR analyser

‒Signal Series 4 Wireless Tables (Optional)

‒Signal USB Drive containing:

•Operating Manuals

•S4i installation (Optional)

•Datasheet

•Test Reports

‒Shipping kit containing –Signal Part No. 3000/370010:

•2m Mains lead cable

•Sample filter key (MC/318011)

•9/16” Wrench

•7/16” Wrench

•USB drive with related documents

‒Analogue output connection cable –Signal Part No. MI/995 (Optional)

‒Relay output connection cable –Signal Part No. MI/996 (Optional)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 5of 42

Read This First

Signal Group Ltd designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using and maintaining Signal Group Ltd products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of

life; personal injury; property damage; damage to this instrument; and warranty invalidation.

‒Read all instructions prior to installing, operating, and servicing the product.

‒If you do not understand any of the instructions, contact your Signal Group Ltd

representative for clarification.

‒Follow all warnings, cautions, and instructions marked on and supplied with the product.

‒Inform and educate your personnel in the proper installation, operation, and maintenance

of the product.

‒Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

‒To ensure proper performance, use qualifiedpersonnel to install, operate, update, program,

and maintain the product.

‒When replacement parts are required, ensure that qualified people use replacement parts

specified by Signal Group Ltd. Unauthorised parts and procedures can affect the product’s

performance, place the safe operation of your process at risk, and VOID YOUR

WARRANTY. Substitutions may result in fire, electrical hazards, or improper operation.

‒Ensure that all equipment doors are closed, and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock and

personal injury.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 6of 42

2 Important safety instructions

2.1 Wiring and Installation

The following safety instructions apply to all EU member states and should be followed

according to Low Voltage Directive. It is recommended that non-EU areas should also comply

with these instructions unless superseded by other local or national standards.

‒It is essential that suitable grounding connections be made at all connectors provided for

this purpose.

‒All safety covers and grounding connections must beproperly reinstated after maintenance

or troubleshooting. The integrity of all earth terminals must always be maintained.

‒To ensure safe operation ofthis equipment,connection to the mains supply should be made

through a circuit breaker which will disconnect all circuits carrying conductors in the case

of a fault. These circuit breakers should comply with a recognised standard such as

IEC947. All wiring must conform to any local or national standards.

2.2 Handling and Storing Pressurised Gases

This instrument requires pressurised gases for use. Some general safety precautions are

outlined below; however, it is advisable that operators are properly trained in the handling and

storage of pressurised gas containers:

‒Never drop cylinders or permit them to strike each other violently.

‒Cylinders may be stored in the open, but in such cases should be protected against

extremes of weather and, to prevent rusting, from the dampness of the ground. Cylinders

should be stored in the shade when located in areas where extreme temperatures are likely.

‒The valve protection cap should be left on each cylinder until it has been safely secured

against a wall or other solid structure or placed is dedicated cylinder stand.

‒Avoid dragging, rolling or sliding cylinders, even for a short distance –they should be

moved using a suitable transportation device (e.g. bottle trolley).

‒Never tamper with the safety devices in valves or cylinders.

‒Avoid storage of full and empty cylinders together. Serious suck-back can occur when

empty cylinders are attached to pressurised systems.

‒No part of a cylinder should be exposed to a temperature higher than 52°C (125°F), or a

naked flame or incandescent material.

‒Do not place cylinders where they could become part of an electric circuit.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 7of 42

2.3 Operation and Maintenance

On leaving the Signal Group Ltd factory, this product conformed to all applicable safety

directives. The operator must take care to follow the instructions given in this manual to

preserve this condition.

Before switching on the instrument, ensure that the local supply voltage is within the limits

indicated in this manual.

Any interruption of the protective earth connections, whether inside or outside of the unit, or

removal or interruption of its ground line connection, may result in reduced instrument

performance and exposure to the risk of electrocution. It is therefore strictly forbidden to

deliberately disconnect the protective earth.

The removal of covers and panels may expose electrical components. Connectors may also

be energised even if no mating connector is present. The unit should therefore be

disconnected from all electrical supplies before any kind of maintenance or repair is carried

out. Only trained personnel who are aware of the risk are permitted to energise an open unit.

Fuses may only be replaced with identical items. It is forbidden to use repaired fuses or to

bypass fuses.

Substances hazardous to health may escape from the unit’s gas outlets. It is advisable to

exhaust the gas outlets to a safely ventilated area.

The safety of the personnel operating this equipment is paramount. All efforts should be taken

to ensure their protection.

Our analysers are checked and tested using state of the art equipment and techniques.

Despite this, an element of risk remains to the user when using any gas analyser. Even when

operated as intended and observing all applicable safety instructions and standards, some

risks remain, including but not limited to the following:

‒An accidental interruption of the protective earth line, e.g. In an extension cable, may result

in a risk to the user;

‒Electrically live components may be exposed if operating the instrument with covers

removed;

‒The emission of hazardous gases may be possible even if all connections have been made

correctly and according to the manufacturers’ instructions.

Avoid exposure to the dangersof these residual risksby taking care when installing,operating,

maintaining and servicing the analyser.

If unsure about anything in this manual, please contact your local Signal Group Ltd

representative for further guidance.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 8of 42

2.4 Competent Personnel

Specialist knowledge of this instrumentation is a necessity for working with and on the unit.

Authorised personnel for installing, operating, servicing, and maintaining the analyser are

instructed and trained personnel of the operating company, Signal Group Ltd or their local

representatives.

‒It is the responsibility of the operating company to:

‒Ensure their staff have adequate training.

‒Observe safety regulations.

‒Follow this instruction manual.

‒Operators must:

‒Have been properly trained.

‒Have read and understood all relevant sections of the instruction manual before

commencing use of the instrument.

‒Know all the applicable safety mechanisms and regulations.

To avoid personal injury and loss of property, do not install, operate, maintain or service this

instrument before reading and understanding this manual and receiving appropriate training.

Do not dispose of this instruction manual.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 9of 42

3 Quick-start

Please read all safety instructions before operating the analyser

This section is intended as a quick guide for trained personnel. See the Operation section for

detailed instructions.

‒Connect your power supply to the mains IEC connector on the rear panel (for standard AC

operation);

‒Connect your gases to the rear panel at the following pressures, using tubing as indicated

below:

Gas

Tube

Pressure

Air

(not required for internal air

pump option)

1/4ʺPTFE or similar

0.75Bar ±0.25Bar

Separate FID Air (Optional)

1/4ʺPTFE or similar

0.75Bar ±0.25Bar

Fuel

(H2He or H2- refer to analyser

configuration to ensure that

correct fuel is used)

1/8ʺPTFE or similar

1.5Bar ±0.5Bar

Calibration gas

(CH4, C2H6,C3H8)

1/8ʺPTFE or PFA

0.4Bar ±0.2Bar

Sample

1/4ʺPTFE or similar

(Heating to 200°C optional)

-0.6 to 0.4Bar

(with internal sample pump)

or

0.2 to 0.5Bar

(without internal sample pump)

Table 2 : Quick-start setup

‒Switch on the power using the switch on the rear panel (AC operation only). At this stage

you should seea solid blue LEDon the frontpanel, indicating that theunit is in Sleep mode.

An internal fan may also be audible;

‒Your instrument is now powered up and ready for general use. The various internal heated

components require time to warm up. Depending on your chosen options, this may be as

long as 45 minutes. Use your chosen operating interface (front panel display or S4i. See

the appropriate user guide for detailed information) to proceed and initiate the warmup

procedure;

‒The following options will initiate warmup:

Standby –the unit will go to a state ready for measurement. No gas valves will be open.

Zero –the unit will automatically initiate ignition, and once the flame is lit,open the zero valve

to begin measuring zero gas.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 10 of 42

Span –as Zero but for Span. Dual FIDs may use Span 1 or Span 2.

Sample –as Zero but the unit will begin measuring Sample gas once lit.

Pause –as Zero but the Span, Zero and Sample Solenoids will all be closed.

‒For optimal performance you need to calibrate your instrument. (It is recommended to do

this daily) You can calibrate from the following modes:

Zero –calibration in this mode will adjust the zero offset only.

Span –calibration in this mode will adjust the span coefficient only.

Sample –calibration in this mode will adjust the zero offset, followed by the span coefficient.

NOTE –it is advisable to leave your instrument lit for at least an hour before first

calibration.

Further details regarding calibration can be found in Section 7 (Including calibration

through the sample port).

‒Once calibrated and stable, your instrument is ready for accurate measurement. Use the

relevant user interface guide for further information regarding instrument features such as

analogue outputs and data logging, and how to configure and use them.

Front Panel Light codes

Light

Status

Red Blink

Heating

Purple

Loading Config File

Yellow

Standby

Yellow Blink

Purge

Green

Measurement Mode

White

No Config

Red/Blue

Alarm

Blue

Sleep

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 11 of 42

4 Introduction

The Signal SOLAR range of gas analysers uses reference-method Flame Ionisation Detector

(FID) technology to determine the Total Hydrocarbon (THC) content of gas samples.

Specifically designed to be versatile and reliable, and function equally well in tough

applications, such as Continuous Emissions Monitoring (CEM), engine certification and gas

turbine research and development, the SOLAR range has the performance to meet your

analysis requirements. Proprietary digital flow and temperature control, together with Signal’s

world-class Series 4 electronics package, provides superior performance across the board.

•Standard SOLAR analysers allow optional:

•Measurement ranges as low as 1ppm CH4equivalent up to as high as 10% C3H8

equivalent;

•Heating (to 200°C);

•Internal combustion and zero air generation;

•Hydrogen or mixed hydrogen/helium fuel;

•Fully automated calibration and flame optimisation;

•Internal heated sample pump;

•Continuous measurement of Total Hydrocarbons (THC), methane (CH4) and Non-

Methane Hydrocarbon (NMHC) using dual detectors;

•10 user-programmable analogue outputs for monitoring concentrations, ranges,

pressures and/or temperatures;

•Up to 35 user-programmable relay outputs for alarm or external valve operation;

•Remote control and data logging over Ethernet or RS232;

•On-board data logging;

•24VDC power supply.

Signal is renowned for its ability to create instruments for special applications, so if the options

above do not cover your specific requirements then contact Signal or one of their local

representatives to discuss your application further.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 12 of 42

5 The Principle of Flame Ionisation

The detector in this instrument ionises carbon atoms in a hydrogen flame. Normally a

hydrogen flame produces very few ions. Any carbon-hydrogen bonded molecules carried into

the flame results in the formation of carbon ions. The detector can measure most compounds

with a carbon-hydrogen bond provided that they are in gaseous form.

Because the detector responds to carbon ions, a mixture of hydrocarbon compounds results

in an output proportional to the carbon count. 10 ppm CH4mixed with 10 ppm C3H8results in

an output of 40 ppm Methane equivalence (ppm), or 13.33 ppm Propane equivalence. These

are two of the ways that the hydrocarbon concentration can be expressed. The Signal Dual

FID SOLAR will always output methane equivalence.

Combustion exhaust gases normally contain some hydrocarbons that are liquid at ambient

temperatures. A heated sample system is necessary to maintain the sample at an elevated

temperature.

5.1 Sample System

The compact 3U19"rack unit includes a 191 °C heated sample handlingmodule which houses

the FID, a sample particulate filter, a sample selection solenoid, sample and fuel capillaries,

and connections to the zero and span selection valves.

The sample handling module allows the connection ofa heated sample line directly to the rear

panel preventing cold spots where sample condensation may occur. It uses the well proven

make-up air bypass system to prevent sample condensation problems at the regulator. Make-

up air is added to the sample path from the bypass air supply at a point down-stream of the

sample extraction point. This creates a constant flow at the sample dump port. The sample is

never in contact with the control components.

Optional internal pumps provide sample flow and/or bypass air. Alternatively, externally

pressurised sample and air supplies may be used.

A portion of the bypass air may be passed through an optional, internal catalytic purifier to

provide FID combustion air and zero grade air for calibration.

The dual FID uses a sophisticated and delicate air-bleed system to provide a very fast

response time for real time CH4and NMHC measurement and ensures that enough oxygen is

available for the necessary catalytic oxidation of non-methane hydrocarbons (NMHCs) even

with low-oxygen sample gas.

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com P a g e | 13 of 42

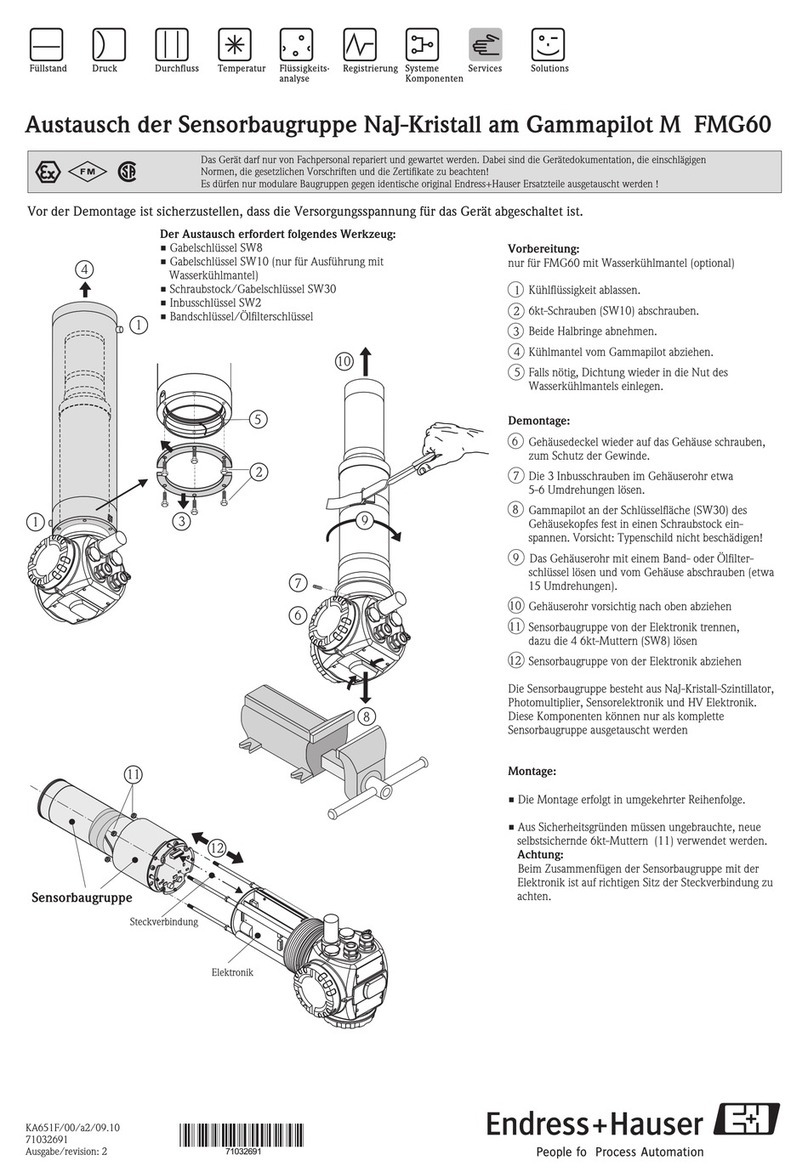

6 Flow Schemes

It is important to use the correct flow scheme for your analyser, there are nine variations to

the Solar analyser, five single channel analysers (HFID-THC) with differing pump

configurations and four Dual channel analysers (HFID-DNMHC) with differing pump

configurations.

The flow schemes can be found below in the following order;

‒Figure 1 : THC flow schematic (with air and sample pumps)

‒Figure 2 : THC flow schematic (without pumps)

‒Figure 3 : THC flow schematic (with an air pump and no sample pump)

‒Figure 4 : THC flow schematic (with no air pump and a sample pump)

‒Figure 5 : THC MCERT flow schematic (separate burner bulkhead with no air pump and a

sample pump)

‒Figure 6 : NMHC dual FID flow schematic (with pumps)

‒Figure 7 : NMHC dual FID flow schematic (with no pumps)

‒Figure 8 : NMHC dual FID flow schematic (with an air pump and no sample pump)

‒Figure 9 : NMHC dual FID flow schematic (with no air pump and a sample pump)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 14 of 42

Figure 1 : THC flow schematic (with air and sample pumps)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 15 of 42

Figure 2 : THC flow schematic (without pumps)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 16 of 42

Figure 3 : THC flow schematic (with an air pump and no sample pump)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 17 of 42

Figure 4 : THC flow schematic (with no air pump and a sample pump)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 18 of 42

Figure 5 : THC MCERT flow schematic (separate burner bulkhead with no air pump and a sample pump)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 19 of 42

Figure 6 : NMHC dual FID flow schematic (with pumps)

Series 4 Operating Manual - Solar Issue 1.07

www.signal-group.com Page | 20 of 42

Figure 7 : NMHC dual FID flow schematic (with no pumps)

Table of contents

Other Signal Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Michell Instruments

Michell Instruments Pura user manual

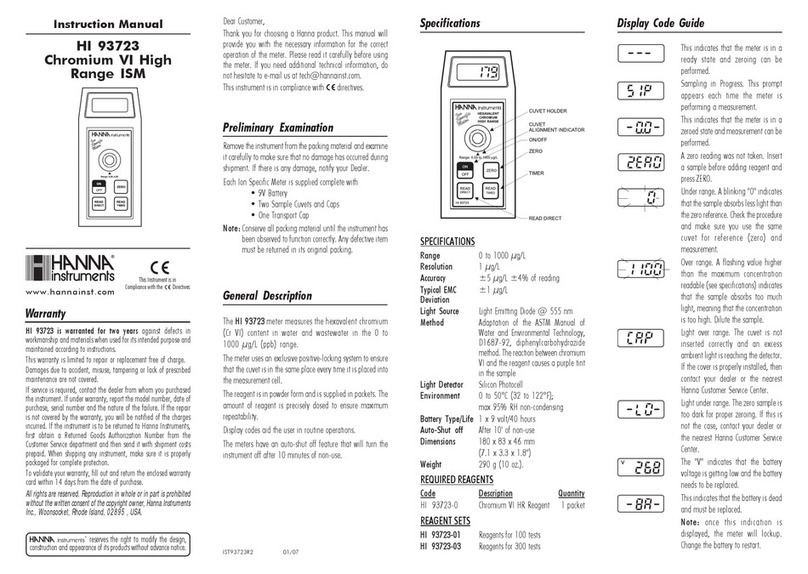

Hanna Instruments

Hanna Instruments HI 93723 instruction manual

Seaward

Seaward Europa Plus instruction manual

paratronic

paratronic PLV400 installation manual

Supelco

Supelco Spectroquant Prove Series quick guide

Midtronics

Midtronics EBT-965P user manual