Hino Series 155 Instruction manual

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks.

Applicable for HINO 155, 155h, 195, 195h series, equipped with J05E engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owner's Manual.

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors Sales U.S.A., Inc. reserves the right to make changes at any time without prior notice.

Please note that the publications below have also been prepared as relevant workshop manuals for the components and sys-

tems in these vehicles.

Manual Name Pub. No.

Chassis Workshop Manual S1-LXJE03A

S1-LXJE03A EWD

J05E Engine Workshop Manual S5-LJ05E04A

Trouble shooting Workshop Manual

S7-LXJE03C 1/7

S7-LXJE03C 2/7

S7-LXJE03C 3/7

S7-LXJE03C 5/7

S7-LXJE03C 6/7

S7-LXJE03C 7/7

MENU

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

CHAPTER

MANUAL No. S7-LXJE03C 4/7 (U.S.A.), S7-LXJE04C 4/7 (CANADA)

MODELS HINO 155, 155h, 195, 195h

Production Code XFC710, XFC720, XFC740, XJC700, XJC710, XJC720, XJC740

HYBRID 3-001

ENGINE

HYBRID

TRANSMISSION

CLUTCH

PROPELLER SHAFT

AXLE

DIFFERENTIAL

BRAKE

STEERING

FRAME AND FRAME ACCESSORY

CAB MOUNTING AND CAB SUSPENSION

BODY CONSTRUCTION

INDEX: TROUBLE SHOOTING GROUP 1/2

SUSPENSION

WORKSHOP

MANUAL

All rights reserved. This manual may not be

reproduced or copied in whole in part, with-

out the written consent of Hino Motors, Ltd.

BODY INSIDE ACCESSORY

BODY OUTSIDE ACCESSORY

AIR BAG AND SEAT BELT

HEATER AND AIR CONDITIONER

GENERAL INTRODUCTION

CONTROL SYSTEM

INDEX: TROUBLE SHOOTING GROUP 2/2

ELECTRICAL

HYBRID 3–1

3

HYBRID

3-001

TROUBLE SHOOTING .................................... 3-4

HYBRID CONTROL SYSTEM......................................3-4

TROUBLE SHOOTING STEPS

FOR HYBRID SYSTEM ..........................................3-4

SAFETY MEASURES

FOR HIGH-VOLTAGE WORK ...............................3-12

LIST OF CONNECTOR SYMBOLS ......................3-15

HV SYSTEM WIRING DIAGRAM .........................3-19

HEARING SHEET.................................................3-21

HYBRID ECU .............................................................3-22

DIAGNOSIS CODE TABLE...................................3-22

FREEZE FRAME DATA LIST ................................3-30

LIST OF DATA MONITOR ITEMS .........................3-33

COMMON INSPECTION CHART .........................3-36

DTC: P0500 (TC51) ..............................................3-41

DTC: P0501 (TC5B)..............................................3-51

DTC: P0562 (TC71) ..............................................3-57

DTC: P060B (TCB2) .............................................3-66

DTC: P0617 (TC59) ..............................................3-69

DTC: P062F (TCB3)..............................................3-78

DTC: P0810 (TC9C)..............................................3-81

DTC: P0810 (TC9D)..............................................3-85

DTC: P0A01 (TC7B) .............................................3-89

DTC: P0A02 (TC78)..............................................3-98

DTC: P0A03 (TC79)............................................3-106

DTC: P0A06 (TC7F)............................................3-113

DTC: P0A07 (TC7E) ...........................................3-125

DTC: P0A0F (TC31)............................................3-129

DTC: P0A1D (TC12) ...........................................3-133

DTC: P0A1D (TC17) ...........................................3-136

DTC: P0A78 (TC21)............................................3-139

DTC: P0A78 (TC22)............................................3-142

DTC: P0A7E (TC48) ...........................................3-145

DTC: P0A82 (TC67)............................................3-151

DTC: P0A84 (TC66)............................................3-164

DTC: P0A85 (TC65)............................................3-177

DTC: P0A90 (TC2A) ...........................................3-183

DTC: P0A92 (TC29)............................................3-195

DTC: P0A93 (TC7A) ...........................................3-210

DTC: P0AFD (TC6B)...........................................3-217

DTC: P0BCA (TC68)...........................................3-221

DTC: P0C73 (TC80)............................................3-227

DTC: P3000 (TC42) ............................................3-234

DTC: P3001 (TC41) ............................................3-243

DTC: P3001 (TC43) ............................................3-246

DTC: P3001 (TC44) ............................................3-249

DTC: P3001 (TC45) ............................................3-252

DTC: P3001 (TC46) ............................................3-255

DTC: P3001 (TC47) ............................................3-259

DTC: P3001 (TC4A)............................................3-263

DTC: P3001 (TC4B)............................................3-267

DTC: P3001 (TC4C)............................................3-270

DTC: P3009 (TC49) ............................................3-273

DTC: P3128 (TC7D)............................................3-289

DTC: P3129 (TC7C)............................................3-301

DTC: P314C (TC82)............................................3-306

DTC: P314D (TC81)............................................3-311

DTC: P324B (TC62)............................................3-323

DTC: P324C (TC61)............................................3-328

DTC: P33B1 (TC64)............................................3-334

DTC: P33B2 (TC63)............................................3-339

DTC: U0073 (TC11) ............................................3-345

DTC: U0074 (TC16) ............................................3-350

DTC: U0100 (TC13) ............................................3-354

DTC: U0101 (TC18) ............................................3-358

DTC: U0110 (TC14) ............................................3-365

DTC: U0111 (TC15) ............................................3-373

DTC: U0121 (TC24) ............................................3-381

DTC: U0155 (TC25) ............................................3-388

DTC: U110A (TC26)............................................3-395

DTC: U1136 (TC27) ............................................3-402

INVERTER................................................................3-409

DIAGNOSIS CODE TABLE .................................3-409

FREEZE FRAME DATA LIST ..............................3-415

DATA MONITOR ITEM LIST................................3-417

CONNECTION DIAGRAM ..................................3-420

INSULATION RESISTANCE MEASUREMENT

PROCEDURE FOR HYBRID MOTOR

[ROTATION MACHINE] .......................................3-421

DTC: P0562 (TC96) ............................................3-423

DTC: P0562 (TCA0)............................................3-433

DTC: P0604 (TC18) ............................................3-443

DTC: P0604 (TCD2)............................................3-445

DTC: P0605 (TC17) ............................................3-447

DTC: P0605 (TCD1)............................................3-449

DTC: P060B (TC1A) ...........................................3-451

DTC: P060C (TC1C) ...........................................3-454

DTC: P062F (TC41) ............................................3-456

DTC: P0A0D (TC20) ...........................................3-458

DTC: P0A1B (TC16) ...........................................3-465

HYBRID3–2

DTC: P0A1B (TC92)............................................3-472

DTC: P0A1B (TC97)............................................3-474

DTC: P0A1B (TC3F) ...........................................3-476

DTC: P0A1B (TCA1) ...........................................3-478

DTC: P0A1B (TCA2) ...........................................3-480

DTC: P0A1B (TCA3) ...........................................3-482

DTC: P0A1B (TCA4) ...........................................3-484

DTC: P0A1B (TCA5) ...........................................3-486

DTC: P0A1B (TCA6) ...........................................3-488

DTC: P0A1B (TCA7) ...........................................3-490

DTC: P0A1B (TCA8) ...........................................3-492

DTC: P0A1B (TCA9) ...........................................3-494

DTC: P0A1B (TCAA)...........................................3-496

DTC: P0A1B (TCBB)...........................................3-503

DTC: P0A1B (TCBC)...........................................3-505

DTC: P0A1B (TCBD)...........................................3-507

DTC: P0A1B (TCBE)...........................................3-509

DTC: P0A1B (TCBF) ...........................................3-511

DTC: P0A1B (TCD3) ...........................................3-513

DTC: P0A1B (TCD4) ...........................................3-515

DTC: P0A1B (TCD5) ...........................................3-517

DTC: P0A1D (TC21) ...........................................3-519

DTC: P0A2B (TCE9) ...........................................3-523

DTC: P0A2B (TCED)...........................................3-534

DTC: P0A2C (TCDA)...........................................3-545

DTC: P0A2D (TCDB) ..........................................3-555

DTC: P0A2F (TC33)............................................3-566

DTC: P0A3C (TC34) ...........................................3-573

DTC: P0A3F (TCB7) ...........................................3-593

DTC: P0A41 (TCC0) ...........................................3-602

DTC: P0A42 (TCC1) ...........................................3-614

DTC: P0A51 (TCD6) ...........................................3-626

DTC: P0A51 (TCD7) ...........................................3-629

DTC: P0A78 (TC13) ............................................3-632

DTC: P0A78 (TC14) ............................................3-645

DTC: P0A78 (TC15) ............................................3-664

DTC: P0AA1 (TCD8) ...........................................3-671

DTC: P0AA4 (TCD9) ...........................................3-678

DTC: P0ADB (TC1F)...........................................3-687

DTC: P0ADC (TC93)...........................................3-694

DTC: P0ADF (TC1E)...........................................3-702

DTC: P0AE0 (TC95)............................................3-709

DTC: P0AE6 (TC1D) ...........................................3-717

DTC: P0AE7 (TC94)............................................3-724

DTC: P0AEE (TC22) ...........................................3-732

DTC: P0AEE (TC23) ...........................................3-735

DTC: P0AEF (TC24) ...........................................3-738

DTC: P0AF0 (TC25)............................................3-742

DTC: P0BEA (TCB3)...........................................3-746

DTC: P0BEA (TCB4)...........................................3-749

DTC: P0BEB (TC9A)...........................................3-752

DTC: P0BEC (TC9B)...........................................3-755

DTC: P0BEE (TCB5)...........................................3-758

DTC: P0BEE (TCB6)...........................................3-761

DTC: P0BEF (TC9C)...........................................3-764

DTC: P0BF0 (TC9D) ...........................................3-767

DTC: P3126 (TC12) ............................................3-770

DTC: U0073 (TC91) ............................................3-783

DTC: U0074 (TC3E)............................................3-788

DTC: U0293 (TC31) ............................................3-792

BATTERY ECU .........................................................3-801

DIAGNOSIS CODE TABLE .................................3-801

LIST OF FREEZE FRAME DATA.........................3-804

LIST OF DATA MONITOR ITEMS .......................3-806

CONNECTION DIAGRAM...................................3-809

DTC: P0562.........................................................3-810

DTC: P0604.........................................................3-816

DTC: P0605.........................................................3-819

DTC: P060B ........................................................3-822

DTC: P062F ........................................................3-825

DTC: P0A1F ........................................................3-828

DTC: P0A7D........................................................3-831

DTC: P0A7F ........................................................3-835

DTC: P0A80 ........................................................3-840

DTC: P0A95 ........................................................3-845

DTC: P0A9D........................................................3-850

DTC: P0A9E........................................................3-854

DTC: P0AAE .......................................................3-858

DTC: P0AAF........................................................3-862

DTC: P0ABF........................................................3-866

DTC: P0AC0........................................................3-873

DTC: P0AC1........................................................3-880

DTC: P0AC2........................................................3-887

DTC: P0AC7........................................................3-894

DTC: P0AC8........................................................3-898

DTC: P0ACC .......................................................3-902

DTC: P0ACD .......................................................3-906

DTC: P0AEA .......................................................3-910

DTC: P0AEB .......................................................3-914

DTC: P0AFC .......................................................3-918

DTC: P0B25 ........................................................3-921

DTC: P0B3D........................................................3-925

DTC: P0B42 ........................................................3-930

DTC: P0B47 ........................................................3-935

DTC: P0B4C........................................................3-940

DTC: P0B51 ........................................................3-945

DTC: P0B56 ........................................................3-950

DTC: P0B5B........................................................3-955

DTC: P0B60 ........................................................3-960

DTC: P0B65 ........................................................3-965

DTC: P0B6A........................................................3-970

DTC: P0B6F ........................................................3-975

DTC: P0B74 ........................................................3-980

DTC: P0B79 ........................................................3-985

DTC: P0B7E........................................................3-990

DTC: P0B83 ........................................................3-995

DTC: P0B88 ......................................................3-1000

DTC: P0B8D......................................................3-1005

HYBRID 3–3

DTC: P0B92 ......................................................3-1010

DTC: P0B97 ......................................................3-1015

DTC: P0B9C .....................................................3-1020

DTC: P0BA1......................................................3-1025

DTC: P0C30......................................................3-1030

DTC: P3004 ......................................................3-1036

DTC: P3011 ......................................................3-1039

DTC: P3012 ......................................................3-1044

DTC: P3013 ......................................................3-1049

DTC: P3014 ......................................................3-1054

DTC: P3015 ......................................................3-1059

DTC: P3016 ......................................................3-1064

DTC: P3017 ......................................................3-1069

DTC: P3018 ......................................................3-1074

DTC: P3019 ......................................................3-1079

DTC: P301B ......................................................3-1084

DTC: P3020 ......................................................3-1087

DTC: P3021 ......................................................3-1092

DTC: P3022 ......................................................3-1097

DTC: P3023 ......................................................3-1102

DTC: P3024 ......................................................3-1107

DTC: P3025 ......................................................3-1112

DTC: P3026 ......................................................3-1117

DTC: P3027 ......................................................3-1122

DTC: P3028 ......................................................3-1127

DTC: P3029 ......................................................3-1132

DTC: P302F ......................................................3-1137

DTC: P3065 ......................................................3-1142

DTC: P308A ......................................................3-1147

DTC: U0074 ......................................................3-1152

DTC: U0293 ......................................................3-1156

HYBRID/TROUBLE SHOOTING3–4

TROUBLE SHOOTING

HYBRID CONTROL SYSTEM

TROUBLE SHOOTING STEPS FOR HYBRID SYSTEM

EN01H03ZZZ030602002001

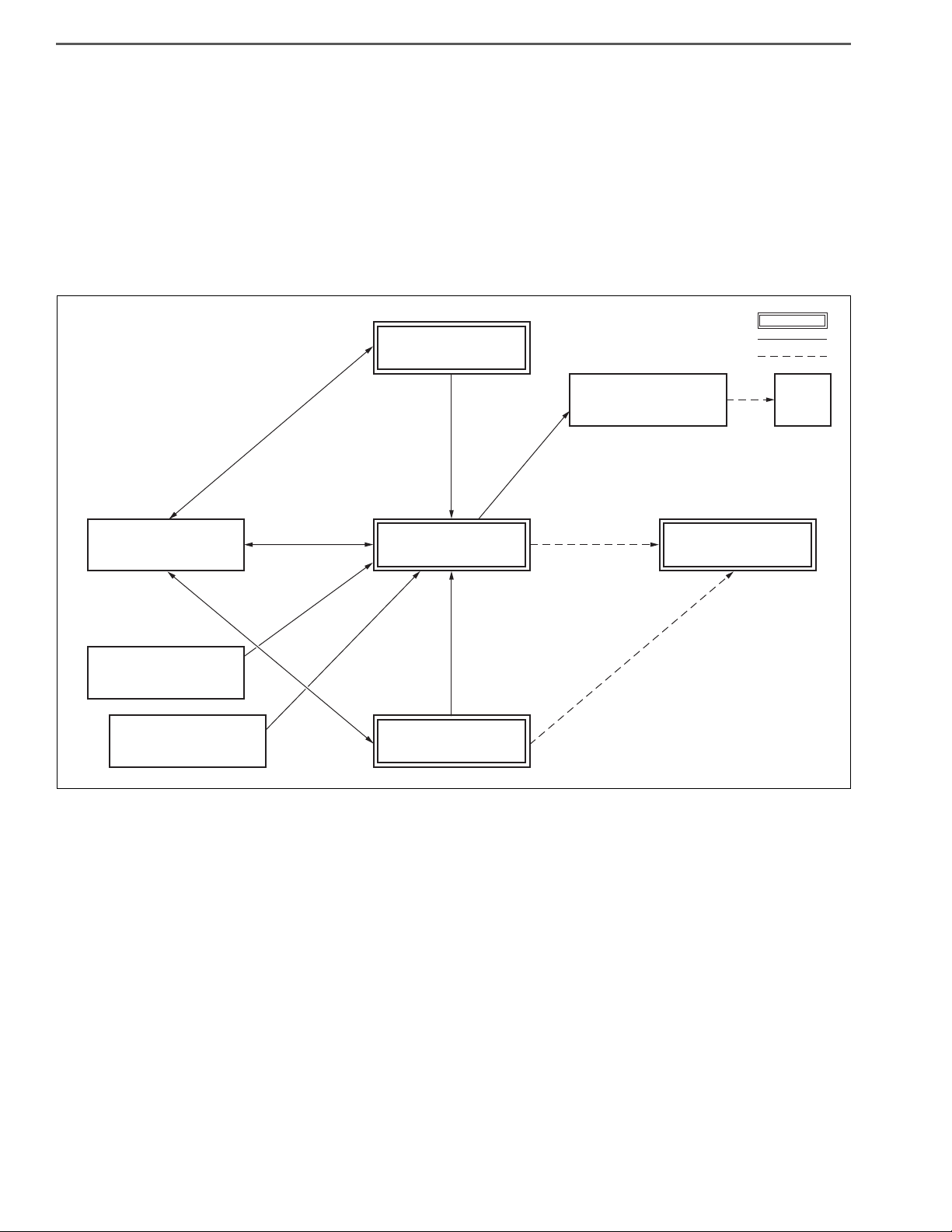

CONFIGURATION DIAGRAM OF HYBRID TROUBLE SHOOTING SYSTEM

HV BATTERY ECU

HV SYSTEM ALARM

HV WARNING LIGHT

ENGINE ECU

VEHICLE CONTROL ECU

CLUTCH ECU

MIL

HV ECU OR COMMUNICATION

FUNCTION PERFORM

ALARMING ONLY WHEN THE

FUNCTION FAILS.

INVERTER

MALFUNCTION INFORMATION

MIL ON REQUEST

MALFUNCTION INFORMATION

MIL ON REQUEST

MALFUNCTION

INFORMATION

MIL ON

REQUEST

MIL ON REQUEST

HV ECU

READ CODE AND

DIAGNOSE

READ CODE AND DIAGNOSE

READ CODE AND

DIAGNOSE

SERVICE TOOL

HYBRID CONTROL SYSTEM:

CAN:

SIGNAL LINE:

SHTS03ZZZ0300001

HYBRID/TROUBLE SHOOTING 3–5

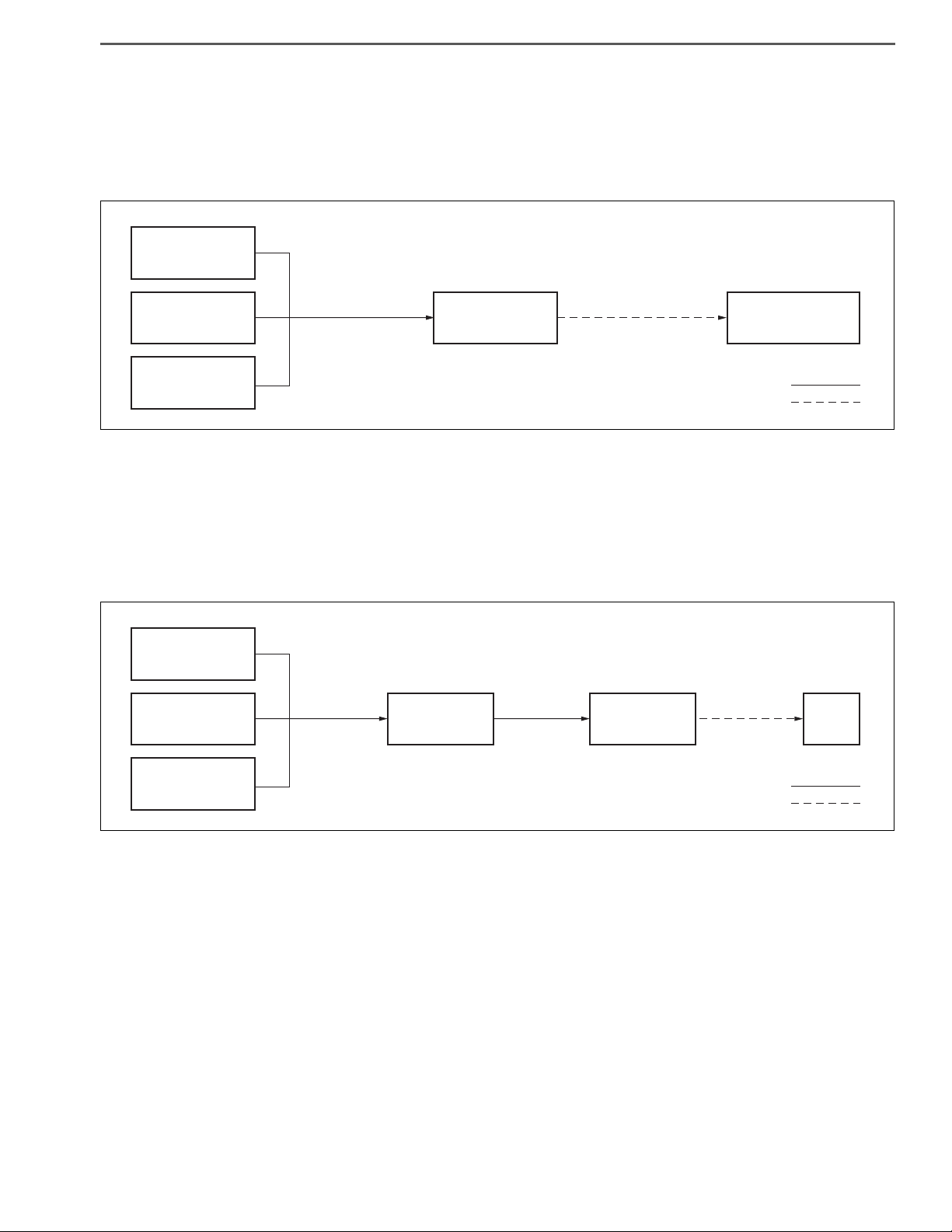

1. HV WARNING LIGHT LIGHTING PROCESS

(1) The HV ECU controls the HV warning light.

(2) The HV warning light turns on in case of malfunction of the HV ECU, the HV battery ECU, the inverter, or the

clutch ECU.

(3) The HV ECU receives information regarding malfunction of the HV battery ECU, the inverter, and the clutch ECU

via CAN.

2. ABOUT MIL

(1) The engine ECU controls whether to turn on or turn off MIL.

(2) When a malfunction relevant to emission occurs in the HV system or vehicle control ECU, the MIL light ON

request is sent from the HV ECU to the engine ECU using CAN.

(3) HV battery ECU, inverter and vehicle control ECU send the MIL light ON request to the engine ECU using CAN

via HV ECU.

LIGHT ON OR LIGHT OFF

HV WARNING LIGHT

HV ECU

MALFUNCTION

INFORMATION

HV BATTERY ECU

INVERTER

CLUTCH ECU CAN:

SIGNAL LINE:

SHTS03ZZZ0300002

LIGHT ON OR

LIGHT OFF MIL

HV ECU

MIL ON

REQUEST

ENGINE ECU

MIL ON

REQUEST

HV BATTERY ECU

INVERTER

VEHICLE CONTROL

ECU CAN:

SIGNAL LINE:

SHTS03ZZZ0300003

HYBRID/TROUBLE SHOOTING3–6

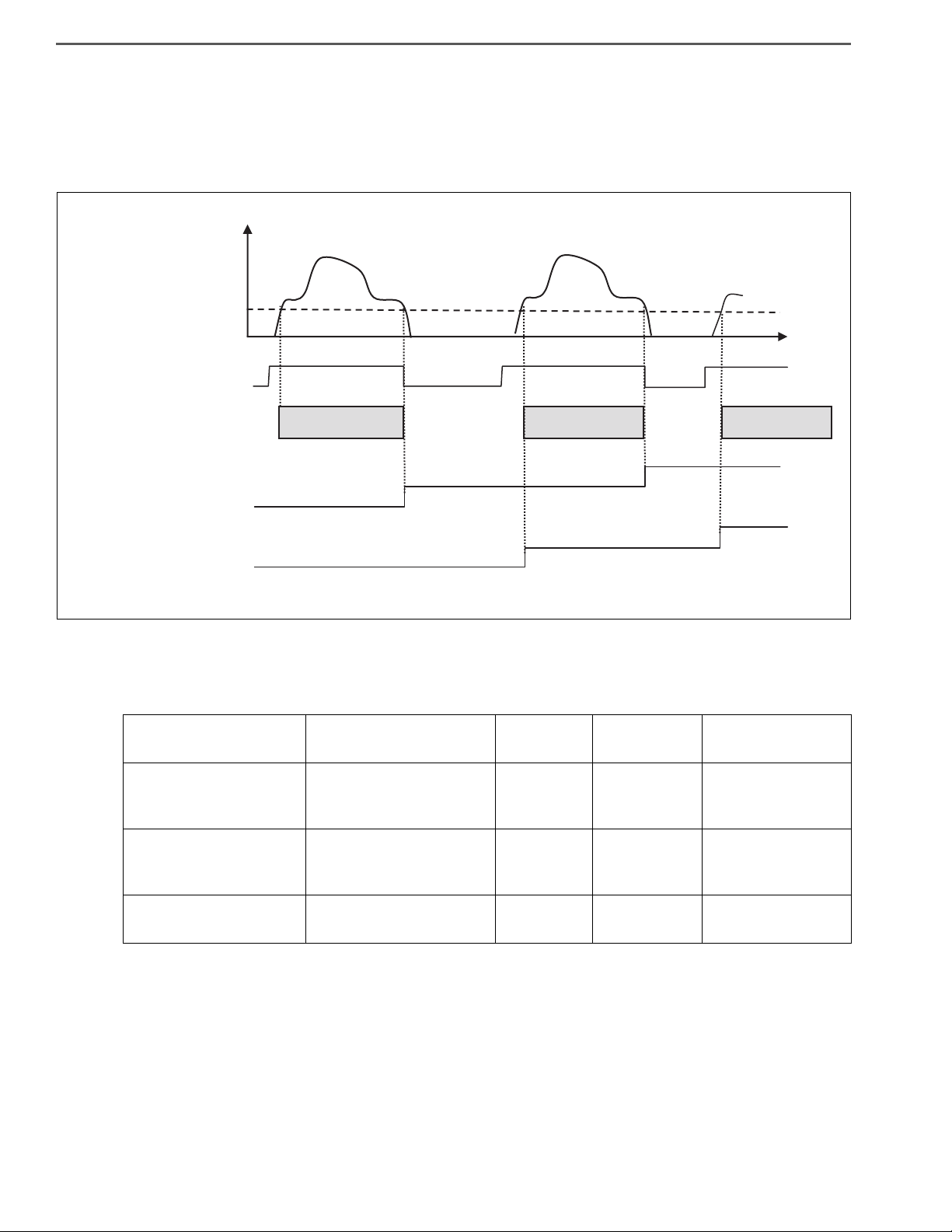

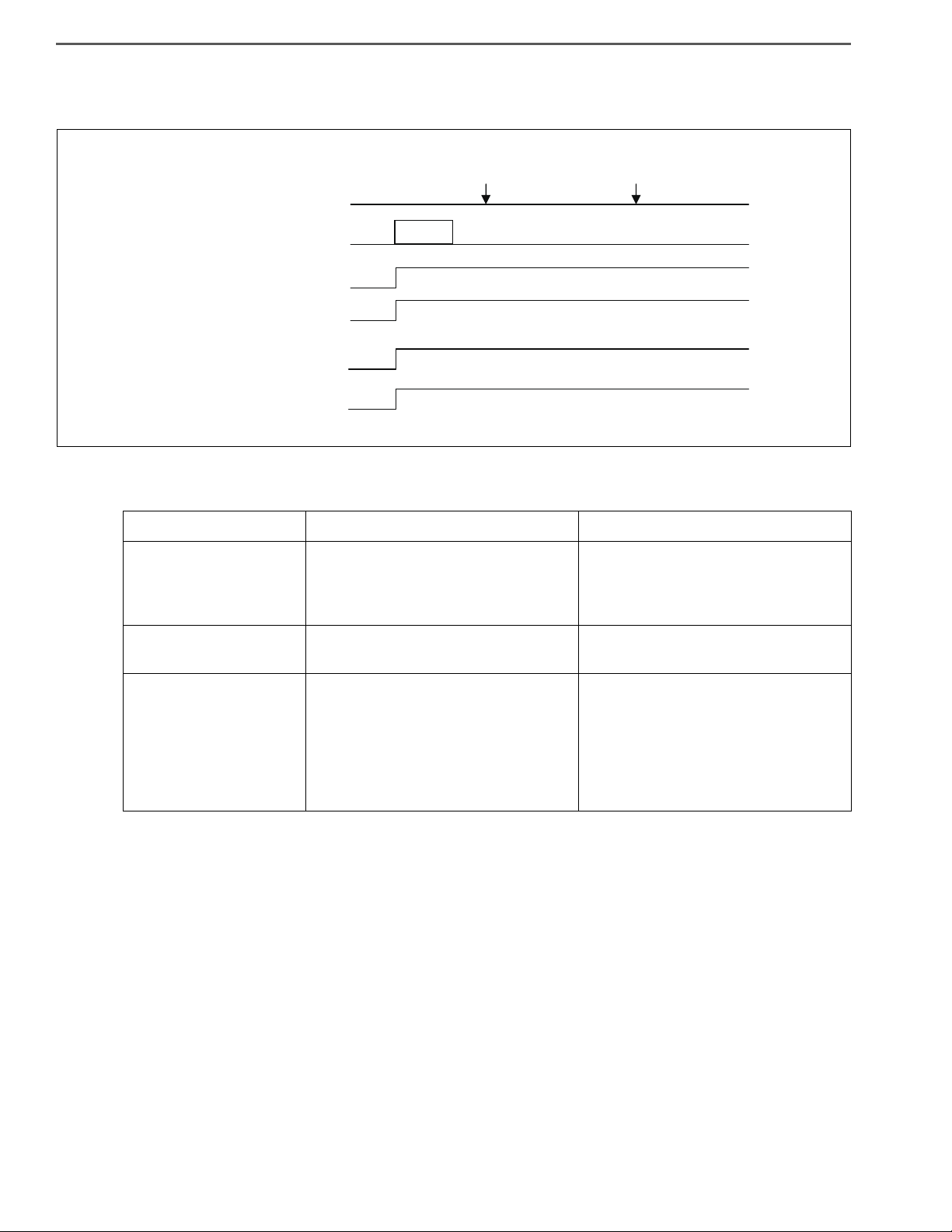

3. DEFINITION OF MALFUNCTION

(1) Driving cycle

The driving cycle (hereinafter referred to as "DCY") is confirmed when the engine revolution becomes equal to or

more than the value calculated using the following formula [idling speed minus 150 r/min] after the starter key is

turned to the "ON" position. DCY is completed when the starter key is turned to the "LOCK" position.

* Completion of DCY is the timing to delete the Permanent diagnosis code and Pending diagnosis code.

(2) Definition of diagnosis code

The following table shows malfunctions that are displayed on the service tool.

*1 This light lights for malfunctions relevant to emission.

*2 If a malfunction is recovered, control is switched from failsafe control to normal control; however the

Confirmed diagnosis code is not deleted.

Code name Definition of diagnosis

code

HV warning

light MIL Effect on vehicle

Pending diagnosis code

Diagnosis code that is

being detected (malfunc-

tion is not confirmed).

Light OFF Light OFF Normal control

Confirmed diagnosis

code

Diagnosis code in which

the malfunction is con-

firmed

Light ON Light ON *1 Failsafe control *2

Permanent diagnosis

code Stored diagnosis code Light OFF Light OFF Normal control

DCY#3

CONFIRMATION TIME

t

COMPLETION

OF DCY#2

COMPLETION

OF DCY#2

COMPLETION

OF DCY#1

COMPLETION OF

DCY#1

DCY#1

CONFIRMATION TIME

DCY#2

CONFIRMATION TIME

ON

LOCK

[r/min]

IDLING SPEED-150 [r/min]

COMPLETION OF

HV BATTERY ECU DCY

COMPLETION OF

INVERTER DCY

STARTER KEY

DCY

COMPLETION OF

HV ECU DCY

ENGINE

SPEED

0

0

0

SHTS03ZZZ0300004

HYBRID/TROUBLE SHOOTING 3–7

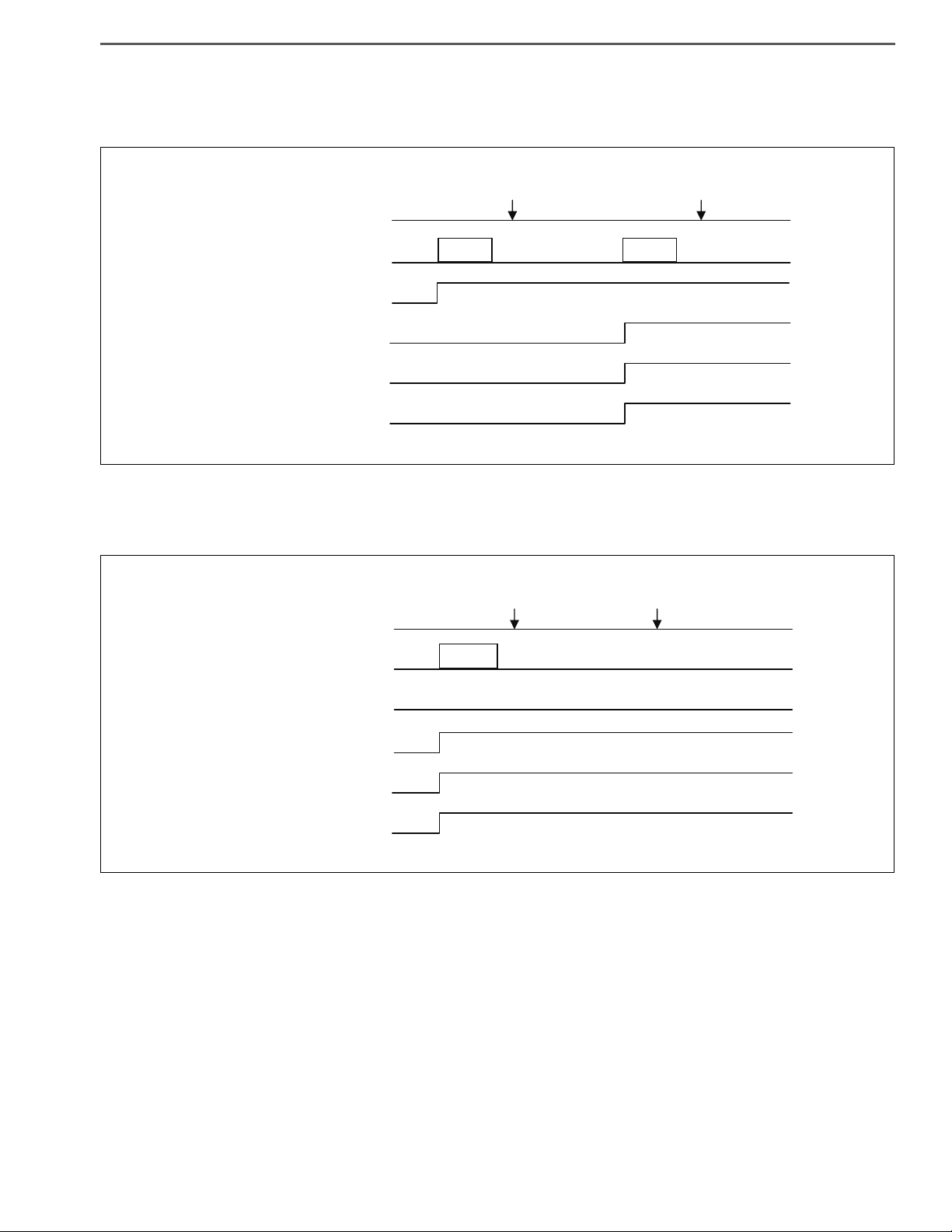

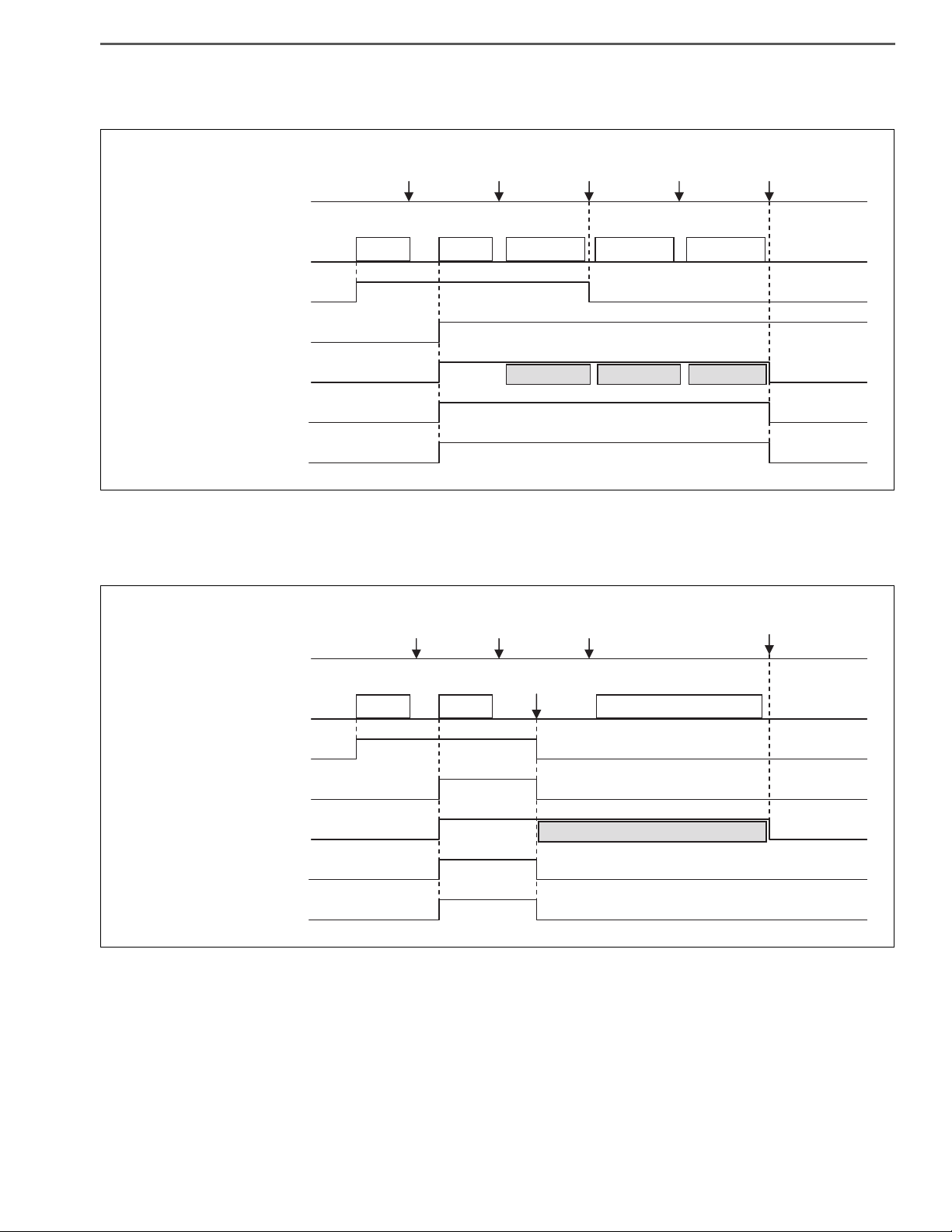

(3) Pending diagnosis code

Represents the diagnosis code in which the malfunction is confirmed by detecting the malfunction in 2DCY or

more. The following table shows examples in which the malfunction is confirmed in 2DCY.

(4) Confirmed diagnosis code

Represents the diagnosis code in which the malfunction is confirmed by detecting the malfunction in 1DCY.

*1 For the malfunction in which the Confirmed malfunction is confirmed in DCY, the Pending malfunction

is not confirmed.

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

DETECTION OF

MALFUNCTION

CONFIRMATION

DETECTION OF

MALFUNCTION

CONFIRMATION

LIGHT ON

LIGHT ON

DCY

VEHICLE CONDITION

PENDING MALFUNCTION

CONFIRMED MALFUNCTION

HV WARNING LIGHT

MIL

SHTS03ZZZ0300005

CONFIRMATION

LIGHT ON

LIGHT ON

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

PENDING MALFUNCTION *1

CONFIRMED MALFUNCTION

HV WARNING LIGHT

MIL

SHTS03ZZZ0300006

HYBRID/TROUBLE SHOOTING3–8

(5) Permanent diagnosis code

Permanent malfunction is confirmed by confirming the Confirmed malfunction.

(6) Deletion of diagnosis code

*1 Refer to the following figure and 4. Procedure for deleting the Permanent malfunction for details.

Code name Deletion from vehicle condition Deletion using the service tool

Pending diagnosis code

This code is deleted when condition

to be judged normal is satisfied and

malfunction detection condition is

not satisfied in 1DCY

Instant deletion

Confirmed diagnosis

code None Instant deletion

Permanent diagnosis

code

This code is deleted when condition

to be judged normal is satisfied in

3DCY. *1

This code is deleted after performing

the predetermined operation when

condition to be judged normal is sat-

isfied and malfunction detection con-

dition is not satisfied in 1DCY after

deleting the diagnosis code using

the service tool. *1

CONFIRMATION

CONFIRMATION

LIGHT ON

LIGHT ON

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

CONFIRMED MALFUNCTION

PERMANENT MALFUNCTION

HV WARNING LIGHT

MIL

SHTS03ZZZ0300007

HYBRID/TROUBLE SHOOTING 3–9

•The following figure shows deletion of the Pending diagnosis code and deletion of the Permanent diagnosis

code in 3DCY.

•The following figure shows clearing of Pending malfunction code, Confirmed malfunction code, and Perma-

nent malfunction code by using the service tool.

*1 Refer to 4. Procedure for deleting the Permanent malfunction (1).

CONFIRMATION

DELETION

DELETION

LIGHT OFF

LIGHT OFF

LIGHT ON

LIGHT ON

CONFIRMATION

CONFIRMATION

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

COMPLETION OF

DCY#3

COMPLETION OF

DCY#4

COMPLETION OF

DCY#5

DETECTION OF

MALFUNCTION

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

PENDING MALFUNCTION

CONFIRMED MALFUNCTION

PERMANENT MALFUNCTION

HV WARNING LIGHT

MIL

NORMAL JUDGMENT #1 NORMAL JUDGMENT #2 NORMAL JUDGMENT #3

NORMAL JUDGMENT

DCY#1

NORMAL JUDGMENT

DCY#2

NORMAL JUDGMENT

DCY#3

SHTS03ZZZ0300008

CONFIRMATION

DELETION

DELETION

DELETION

DELETION OF THE MALFUNCTION

CODE USING THE SERVICE TOOL

LIGHT OFF

LIGHT OFF

LIGHT ON

LIGHT ON

CONFIRMATION

CONFIRMATION

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

COMPLETION OF

DCY#3

COMPLETION OF

DCY#4

DETECTION OF

MALFUNCTION

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

PENDING MALFUNCTION

CONFIRMED MALFUNCTION

PERMANENT MALFUNCTION

HV WARNING LIGHT

MIL

NORMAL JUDGMENT #1

*1

SHTS03ZZZ0300009

HYBRID/TROUBLE SHOOTING3–10

4. PROCEDURE FOR DELETING THE PERMANENT MALFUNCTION

There are two procedures for deleting the Permanent diagnosis code.

(1) Procedure for deleting the Permanent diagnosis code after deleting the diagnosis code using the service tool

a. Turn the starter key "ON".

b. Delete the diagnosis codes using the service tool.

- Delete diagnosis codes from the following systems.

•ECU of the HV system in which the Permanent diagnosis code is occurring.

(Deletion of engine ECU must be performed after performing deletion in the order of HV battery ECU

Inverter HV ECU.)

•Engine ECU

c. Set the starter key to the "LOCK" position and wait for 30 seconds or more.

d. Turn the starter key "ON".

e. Start the engine.

f. Idle the engine for 6 minutes or more.

g. Keep the engine revolution at 1,150 r/min or more for 6 minutes or longer.

h. Set the starter key to the "LOCK" position and wait for 30 seconds or more.

i. Turn the starter key "ON".

j. Start the engine.

k. Wait for 30 seconds or more.

l. Set the starter key to the "LOCK" position.

! CAUTION

•Trouble shooting the malfunction is conducted before following the above procedure, therefore the malfunction

does not occur or the malfunction does not occur while following the above procedure.

•The HV warning light must turn off when the diagnosis code is deleted at (b).

When the HV warning light turns off, it is possible to check that there is no malfunction in the HV system.

•Condition to be judged normal for the malfunction occurred in the above steps (d) to (g) must be satisfied.

Condition to be judged normal varies depending on malfunction.

(2) Procedure for deleting the Permanent diagnosis code in 3DCY

a. Turn the starter key "ON".

b. Start the engine.

c. Idle the engine for 2 minutes or more.

d. Set the starter key to the "LOCK" position.

e. Wait for 30 seconds or more.

f. Repeat the steps from (a) to (e) for 3 times in total (3DCY).

g. Turn the starter key "ON".

h. Start the engine.

i. Wait for 30 seconds or more.

j. Set the starter key to the "LOCK" position.

! CAUTION

•The above procedure is satisfied when making normal driving operation; therefore the Permanent diagnosis

code may be deleted when making similar driving operation if the malfunction is recovered.

•Trouble shooting the malfunction is conducted before following the above procedure, therefore the malfunction

does not occur or the malfunction does not occur while following the above procedure.

•Condition to be judged normal for the malfunction occurred in the above steps (a) to (d) must be satisfied. Con-

dition to be judged normal varies depending on malfunction.

Confirmed diagnosis code Permanent diagnosis code Deletion procedure

None Present Deletion using the procedure (1)

Present Present Deletion using the procedure (1) or (2)

Present None —

HYBRID/TROUBLE SHOOTING 3–11

5. TROUBLE SHOOTING PROCEDURE

(1) Trouble shooting procedure (when using genuine Hino service tool)

a. Check the DTC of the HV ECU using the service tool (trouble shooting tool).

b. Record the DTC and TC No. (detailed DTC) of freeze frame data.

c. Perform trouble shooting for the relevant DTC. For an inverter/HV battery line malfunction, read the DTC of

each ECU for trouble shooting according to the HV ECU diagnostic chart.

d. After trouble shooting, delete the DTC of each ECU using the service tool and conduct a trial running to check

that the malfunction does not recur.

! CAUTION

•When inspecting the high voltage line, wear insulating gloves because of a risk of electrical shock. Before per-

forming inspection, be sure to remove the service plug after the starter key is turned to the "LOCK" position.

When inspecting the HV battery, wear safety glasses.

Do not touch the terminals of the high voltage line for 7 minutes after removing the service plug.

•One diagnosis code (DTC) may contain more than 1 malfunction. Read TC No. (detailed DTC) of freeze frame

data with the trouble shooting tool and perform trouble shooting according to the relevant trouble shooting

chart.

•When inspecting the harness, first check the connector for fitting looseness, and the fitting surface for entry of

foreign matters.

•There may be irregular contact or temporary noise due to partial fitting of the connector if parts are returned to

normal without repairing or replacing parts using the diagnostic chart.

•The service tool or trouble shooting tool described in the trouble shooting chart indicates the genuine Hino ser-

vice tool.

•If the starter key is turned "ON" in the state that connectors, etc. are disconnected while performing the trouble

shooting chart, the malfunction may be recorded due to disconnection of a connector. In such case, be sure to

delete the diagnosis code using the trouble shooting tool.

HINT

If there is no malfunction and the engine does not stop with the idling stop function, the following cases are con-

ceivable.

•A vehicle is not running at vehicle speed of 5 km/h or more from the last idling stop.

•The change lever is located at a position other than "D" and "4".

•When the turn signal light and the hazard light are ON. (Even if the turn signal light switch signal and the hazard

light switch signal transmitted to the HV ECU are Low, the engine does not stop automatically by use of the

idling stop function.)

•When a vehicle stopped on a sloped road.

•While PTO is operating.

•While DPR is operating.

•Capacity of the HV battery is low.

•Engine coolant temperature is low.

•The engine is still running. (The engine is running at approximately 1 km/h or more.)

•When the status of the idling stop cancel switch is "ON".

•Brake vacuum pressure is low. (Even if the low brake vacuum pressure switch signal transmitted to the HV ECU

becomes Low, the engine does not stop automatically by use of the idling stop function.)

HYBRID/TROUBLE SHOOTING3–12

SAFETY MEASURES FOR HIGH-VOLTAGE

WORK

EN01H03ZZZ030602002002

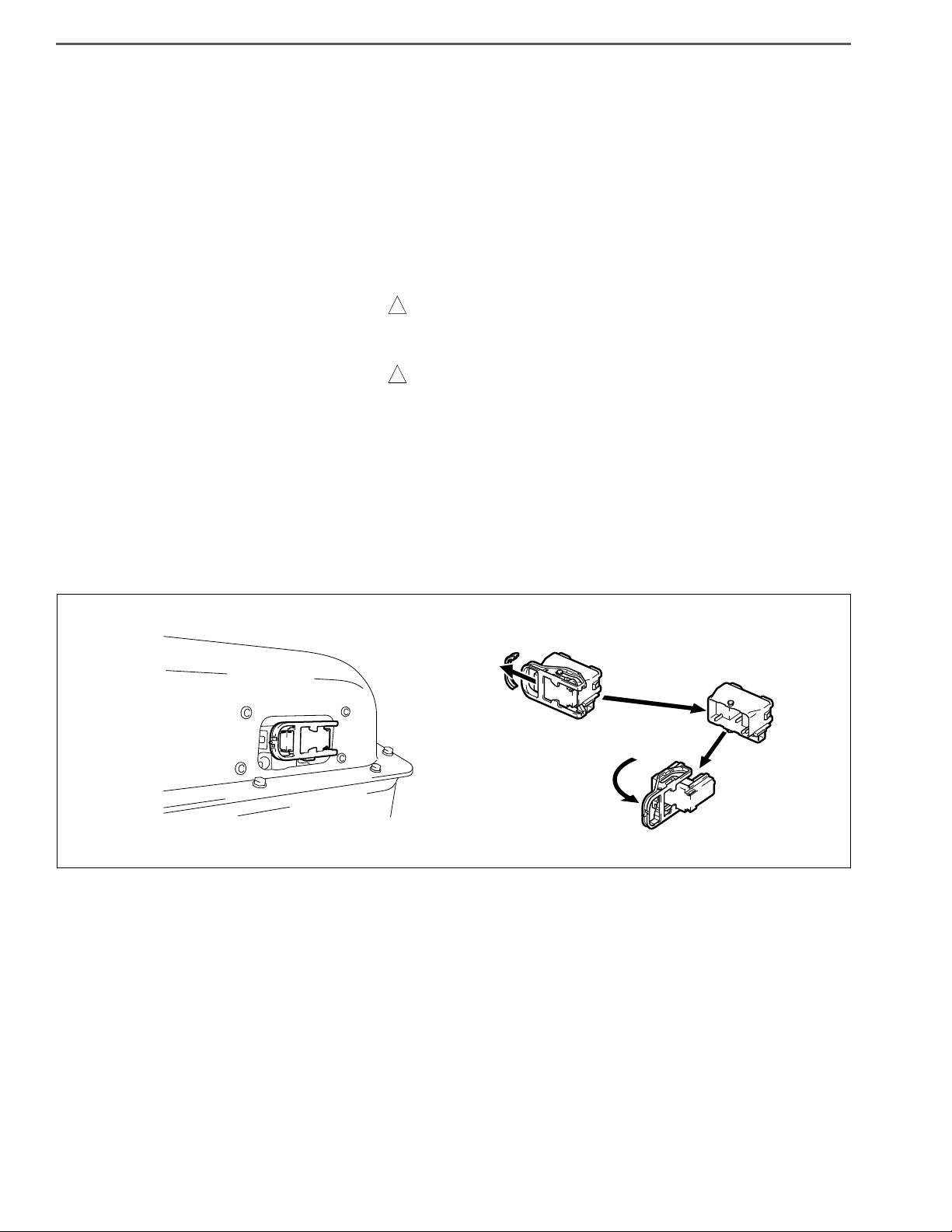

1. CAUTIONS ON INSPECTION OF HYBRID CONTROL SYSTEM

(1) To inspect the high-voltage system or disconnect the low-

voltage connector in the PCU box, be sure to take actions to

prevent electric shocks, i.e. wearing insulated gloves and dis-

connection of service plug. Removed service plug should be

put in a pocket so as to prevent other engineers from using it

by mistake during work.

!WARNING

Note that the SMR is turned "ON" and high-voltage circuit is acti-

vated when the starter key is turned to "ON."

!CAUTION

Since any failure may occur when the starter key is turned to "ON"

with the service plug removed, never turn the starter key to "ON"

unless otherwise instructed in this document.

(2) All wire harness connectors for the high-voltage circuit are

orange colored. Further, "HIGH VOLTAGE" caution label is

attached to high-voltage components such as the hybrid bat-

tery. Do not touch these wiring and components unnecessar-

ily.

(3) Turn the starter key "LOCK" and remove the service plug.

Then wait for at least 7 minutes before starting the work.

NOTICE

In the 7 minutes the high-voltage capacitor in the inverter dis-

charges.

1

2

3

SHTS03ZZZ0300010

HYBRID/TROUBLE SHOOTING 3–13

(4) Check the insulated gloves for damage such as cracks and

break before use. Also, do not use wet insulated gloves.

(5) Do not carry on any metal product such as a pen and scale

which may fall to cause short circuit while working.

(6) Be sure to wear insulated gloves when it is necessary to

touch any high-voltage terminal without insulating coating.

(7) After disconnecting high-voltage connectors and terminals,

insulate them with insulator tape without delay.

(8) After working on high-voltage components, check for any

component or tool left, tightening condition of high-voltage

terminals and connector conditions again before connecting

the service plug.

(9) Do not reserve the hybrid battery.

(10) Do not disassemble the hybrid battery.

! CAUTION

High voltage is applied to the hybrid battery even when the ser-

vice plug is disconnected. Further, high-alkaline electrolyte is

used.

(11) Make sure to use the insulated tools.

Recommended tools: FACON's Facom-quality insulated tools

(12) Turn the starter key to "LOCK" for resistance inspection.

(13) Turn the starter key to "LOCK" before removing/installing

connectors.

(14) Alert other workers with indication such as "High-voltage

work. Don't touch" on the vehicle during works on high-volt-

age components.

(The next page is an example of the indication. You may copy

and use it.)

INCORRECT

SHTS03ZZZ0300011

HYBRID/TROUBLE SHOOTING3–14

SHTS03ZZZ0300012

HYBRID/TROUBLE SHOOTING 3–15

LIST OF CONNECTOR SYMBOLS

EN01H03ZZZ030602002003

WHITE

WHITE

ORANGE

BLACK

BLACK

BLACK

DARK GRAY

WHITE

WHITE

WHITE

1

3

2

23

456789

11112

23

16

22

15

21

14

20

13

24

17

25

18

26

19

10

1

9 10111213141516

2345678

1

12 13 14 15 16 17 18 19 20 21 22

10 1123456789

1

5

23

67

4

8

11 12 13 14 15 16 17 18 19

23456789

20

2423 25 26 27 28 29

21 22

30

110

1234

1234

56789 10 11

30 31

12131415

1617181920

2122232425 26272829

3233343536 37383940

78910

11 12

34

13 14 15 16

17 18 19 20 21 22 23 24

12 56

1819

20 21 22 23 24 25 26

7 8 9 1011121314151617

123456

BATTERY ECU (CAN)A

B

F

GJ/C DIAG CAN

INVERTER COOLING WATER PUMP

BATTERY ECU (TEMPERATURE MONITORING)

CHHV ECU1

BATTERY ECU (VOLTAGE MONITORING)

DIHV ECU2

INVERTER

EJHV ECU3

INVERTER COOLING RADIATOR FAN

SHTS03ZZZ0300013

HYBRID/TROUBLE SHOOTING3–16

123456

16 17

78910

12 13 14 15 18 19 20 21

11

22

12 11 10

1

65

78

9

234

10 11 12

234

5678

9

1

21

17 16

34567

8

101112131415

181920212223

9

24

3456789

101112131415

1819 20 2122 2324

2

17

1

16

21

1234

12

34

GRAY BLACK

WHITE

(RELAY BLOCK SIDE)

BLACK

BLACK BLACK

BLACK

WHITE

WHITE

BLACK BLACK

1234

5678

9 101112

13 14 15 16

4321

8765

12 11 10 9

16 15 14 13

(RELAY BLOCK SIDE)

(COMPONENT SIDE)

(COMPONENT SIDE)

3

5

L

N

2

1

3

5

2

1

12

INVERTER START RELAY

L

NHV BATTERY START RELAY

O J/C CTRL CAN

P PCU HARNESS 16-PIN

RHV BATTERY COOLING FAN

SSMR DRIVE

SERVICE PLUG SWITCH

T

X PCU HARNESS 24-PIN

KCOOLANT TEMPERATURE SENSOR

PCU HARNESS 12-PINY

SHTS03ZZZ0300014

Other manuals for Series 155

1

This manual suits for next models

3

Table of contents

Other Hino Truck manuals

Popular Truck manuals by other brands

Armorgard

Armorgard rubble truck RT400 Operational And Maintenance Manual

Haklift

Haklift HAVA2500V Operation and installation manual

BACKSAFE

BACKSAFE STUGO 16810010 instruction manual

Daewoo

Daewoo Novus M2SEF manual

Chevrolet

Chevrolet 10 1971 Series Chassis Service Manual

Paccar

Paccar Peterbilt 587 owner's manual