Section 000-0000

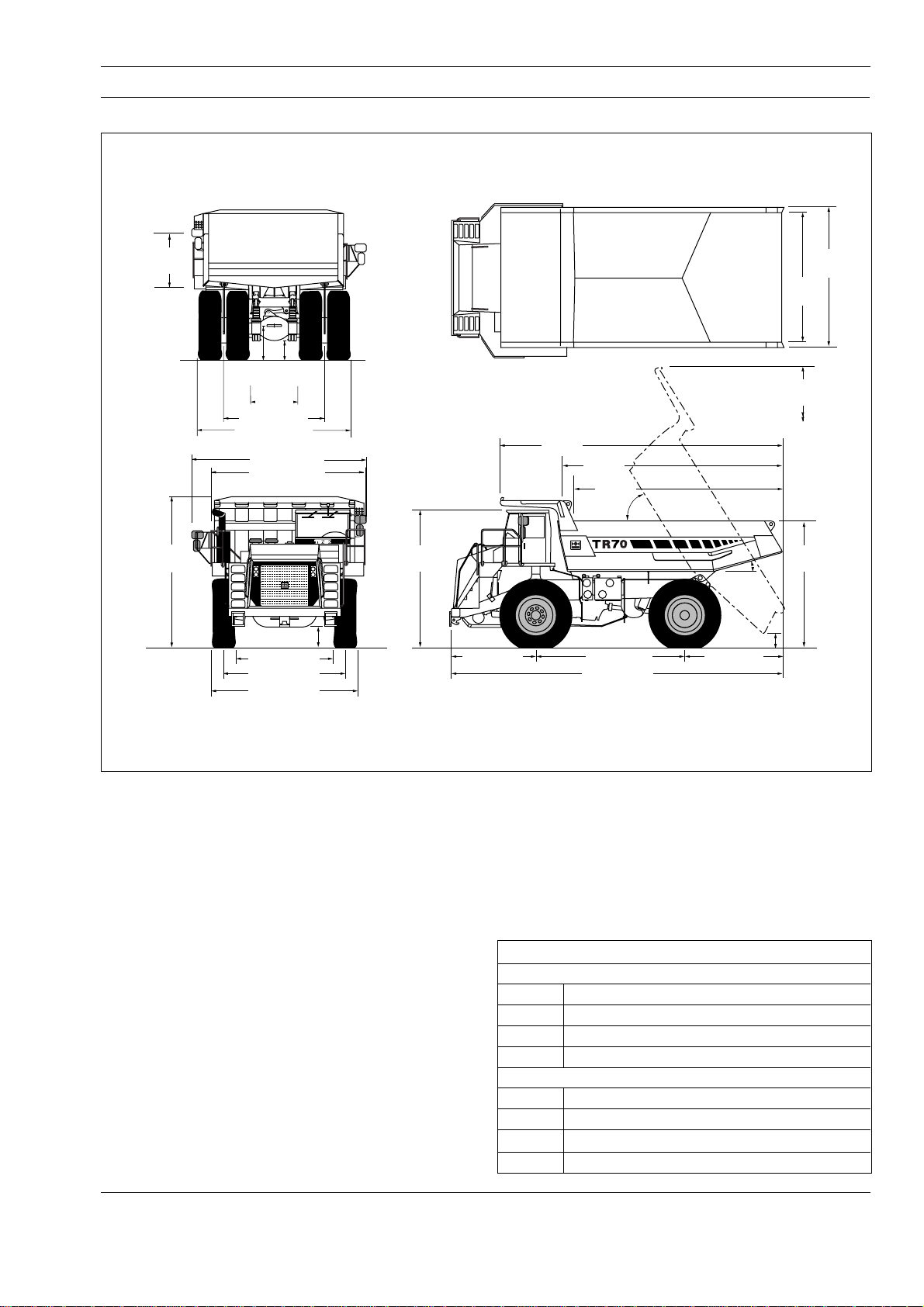

General Information - TR70 Off HighwayTruck

SM 1911 7-00

2

DRIVE AXLE

Heavy duty axle with single reduction spiral bevel gear

differential, full floating axle shafts, and planetary reduction

at each wheel.

Ratios: Standard Optional

Differential....................................... 3.73:1 3.15:1

Planetary......................................... 5.80:1 5.80:1

Total Reduction............................. 21.63:1 18.27:1

SUSPENSION

Front: King pin strut type independent front wheel

suspension by self-contained, variable rate, nitrogen/oil

cylinders.

Rear: Variable rate nitrogen/oil cylinders with A-frame

linkage and lateral stabilizer bar.

Maximum Strut Stroke

Front .......................................................235 mm (9.25 in)

Rear ..........................................................193 mm (7.6 in)

Maximum Rear Axle Oscillation..................... ± 7.5 Degrees

WHEELS AND TYRES

Wheel Rim Width .......................................................... 17 in

Standard Tyres (Front & Rear) ..............24.00 R 35** Radial

Optional Tyres (Front & Rear) ............ 24.00-35 (48 PR) E-3

Note: It is recommended that for tyres both listed and

unlisted, the user should consult the tyre manufacturer and

evaluate all job conditions in order to make the proper

selection.

BRAKES

Service

All hydraulic brake system. Transmission mounted pressure

compensating pump provides hydraulic pressure for brakes

and steering. Independent circuits front and rear. Each

circuit incorporates a nitrogen accumulator which stores

energy to provide consistent braking response.

Front Brake Circuit Pressure ............. 110 bar (1 600 lbf/in²)

Rear Brake Circuit Pressure ....................52 bar (750 lbf/in²)

Accumulators:

Nitrogen Precharge Pressure...............55 bar (800 lbf/in²)

Front:

Type............................ Dry Disc with 2 callipers per wheel

Disc Diameter ............................................710 mm (28 in)

Pad Area, Total.................................... 2 788 cm²(432 in²)

Rear:

Type...............................Oil cooled, multiple friction discs,

completely sealed from dirt and water.

Braking Surface, Total ..................67 390 cm² (10 445 in²)

Parking

Application of rear brakes by springs in brake disc pack.

Hydraulically released.

Hold-off Pressure ..................................83 bar (1 200 lbf/in²)

Retardation

Modulated lever control of rear disc pack.. 670 kW (900 hp)

continuous.

Retarder Actuation Pressure ......... up to 33 bar (480 lbf/in²)

Emergency

Push button solenoid control applies service and parking

brakes. Automatically applies when engine is switched off.

Parking brake applies should system pressure fall below a

predetermined level.

Brakes conform to ISO 3450, SAE J1473 OCT 90.

STEERING SYSTEM

Independent hydrostatic steering with closed-centre

steering valve, accumulator and pressure compensating

piston pump.

Accumulator provides uniform steering regardless of engine

speed. In the event of loss of engine power it provides

steering of approximately two lock-to-lock turns.

A low pressure indicator light warns of system pressure

below 83 bar (1 200 lbf/in²). Steering meets SAE J53.

Relief Pressure ...................................210 bar (3 000 lbf/in²)

Steering Cylinders ................... Double Acting, Single Stage

Accumulator:

Nitrogen Precharge Pressure...............55 bar (800 lbf/in²)

Steering Angle (Left and Right) .......................................42°

Pump:

Type......................................................................... Piston

Capacity at 2 100 rev/min..... 1.75 litres/s (32 US gal/min)

BODY HYDRAULICS

Two body hoist cylinders are mounted between the frame

rails. Cylinders are two-stage with power down in the

second stage.

System Relief Pressure ..................... 190 bar (2 750 lbf/in²)

Pump:

Type........................................................................... Gear

Capacity at 2 100 rev/min..................................6.1 litres/s

(97 US gal/min)

Control Valve ...................... Servo Controlled, Open Centre

Body Raise Time................................................ 13 Seconds

Body Lower Time ............................................ 11.5 Seconds

ELECTRICAL

Type ............................................. 24 Volt, Negative Ground

Battery......... Two, 12 Volt, 165 Ah each, Maintenance Free

Accessories................................................................ 24 Volt

Alternator ..................................................................70 Amp

Starter ........................................................................... 9 kW

Find manuals at http://best-manuals.com/search?&s=TEREX-SM1909