Hinowa HP 1100 Instruction manual

Contents

DECLARATION OF CONFORMITY Page 4

INTRODUCTION Page 5

MINI-DUMPER IDENTIFICATION DATA Page 6

CLASSIFICATION Page 7

TERMINOLOGY Page 7

SAFETY WARNINGS Page 8

PICTOGRAMS Page 9

SAFETY AND ACCIDENT PREVENTION

1. GENERAL WARNING Page 11

1.1 Read carefully safety instructions Page 11

1.2 Follow safety instructions Page 11

1.3 Clothing and protective wear Page 11

1.4 Unauthorised alterations Page 12

1.5 Safety valves Page 12

OPERATING SAFELY

2. MEASURES TO TAKE BEFORE STARTING THE ENGINE Page 13

2.1 Safety in the working area Page 13

2.2 Fire prevention Page 13

2.3 Warning against exhaust fumes Page 14

3. MEASURES TO TAKE WHILE WORKING Page 15

3.1 Precautions when starting engine Page 15

3.2 Precautions when driving Page 15

3.3 Precautions when transporting the crawler Page 15

3.4 Transporting the machine Page 15

3.5 Parking the machine safely Page 16

3.6 Be prepared in case of emergency Page 16

3.7 Wear protective garments Page 16

3.8 Protect yourselves against noise Page 16

1

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNEE

EENN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

Courtesy of Machine.Market

4. OPERATING INSTRUCTIONS Page 17

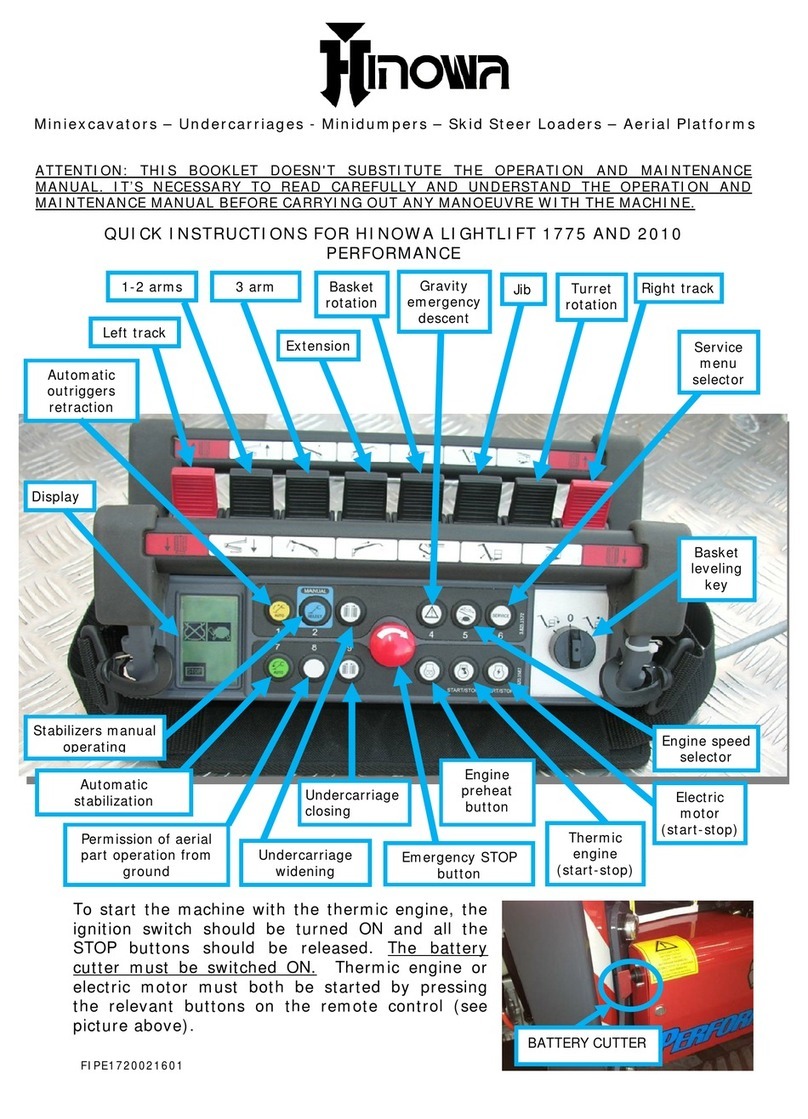

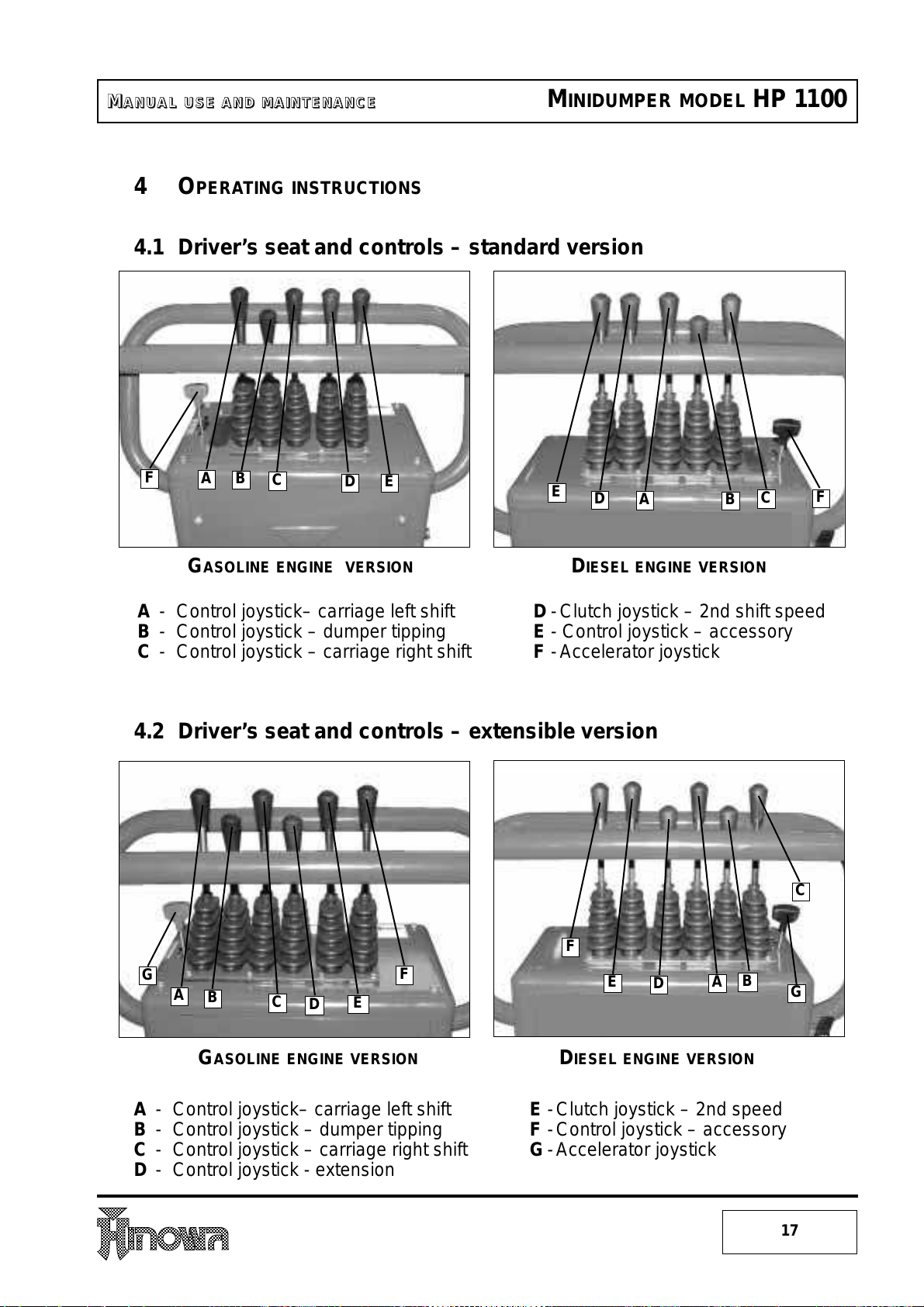

4.1 Driver’s seat and controls- standard undercarriage Page 17

4.2 Driver’s seat and controls – extensible undercarriage Page 17

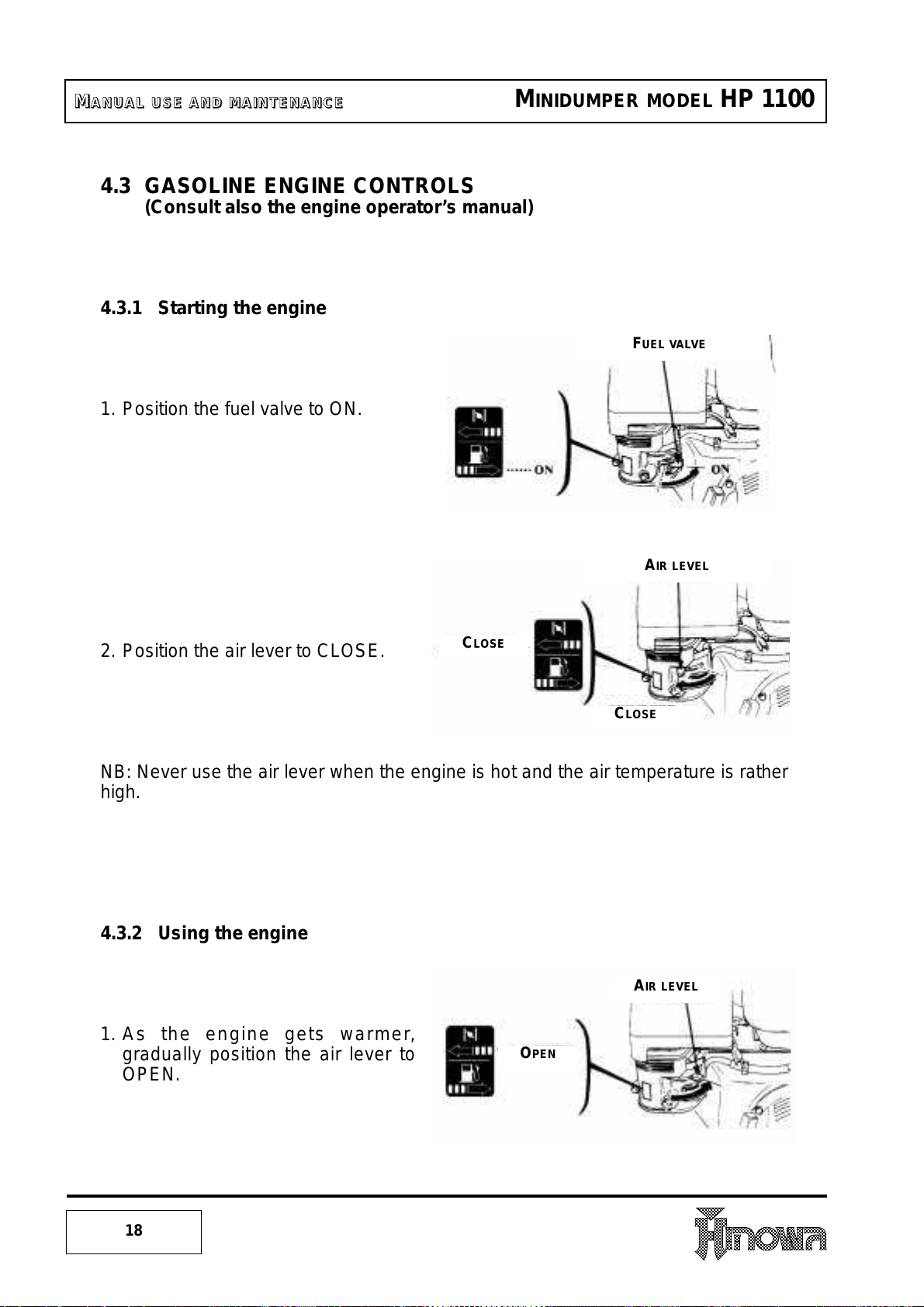

4.3 Gasoline engine controls Page 18

4.3.1 Starting the engine Page 18

4.3.2 Using the engine Page 18

4.3.3 Stopping the engine Page 20

4.4 Diesel engine controls Pag. 21

4.4.1 Motor Start Pag. 21

4.4.1.1 Manual start trough self-winding system Pag. 21

4.4.1.2 Electrical start Pag. 22

4.4.2 Motor functioning Pag. 23

4.4.2.1 Motor functioning Pag. 23

4.4.2.2 Checks to be done while the motor is working Pag. 23

4.4.3 Motor stop Pag. 23

4.5 Moving the machine Page 25

4.5.1 Operating the undercarriage – standard versionl Page 25

4.5.1.1 Operating hydraulic tilting Page 26

4.5.1.2 Operating 2nd translation speed Page 26

4.5.1.3 Optional control lever Page 26

4.5.1.4 Operating external tool Page 27

4.5.2 Operating undercarriage – extensible undercarriage Page 28

4.5.2.1 Operating hydraulic tilting Page 29

4.5.2.2 Operating extensible undercarriage Page 29

4.5.2.3 Operating 2nd translation speed Page 30

4.5.2.4 Optional control level Page 30

4.5.3 Manoeuvring on soft soil Page 31

4.5.4 Avoiding manoeuvring on inclined slopes Page 31

4.5.5 Parking and stopping on inclined slopes Page 31

4.5.6 Transporting the machine Page 31

4.5.7 Lifting the machines Page 33

4.5.8 Using rubber tracks Page 33

5 MAINTENANCE Page 34

5.1 Correct machine inspection and maintenance procedures Page 34

5.2 Engine maintenance Page 35

5.2.1 Oil level check Page 35

5.2.2 Engine oil replacement Page 35

5.2.3 Air filter check Page 35

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

2

Courtesy of Machine.Market

5.3 Hydraulic system Page 35

5.3.1 Hydraulic oil Page 36

5.3.2 Hydraulic oil filter Page 36

5.3.3 Oil reduction translator Page 37

5.4 Electric system Page 38

5.4.1 Battery Page 38

5.5 Rubber tracks maintenance Page 39

5.5.1 Checking track tension Page 39

5.5.2 Track loosening/tightening procedures Page 39

5.5.3 Checking rubber tracks Page 40

5.5.4 Replacing rubber tracks Page 42

5.6 Checking nuts & bolts tightness Page 44

5.7 Storing the machine Page 45

6. TECHNICAL SPECIFICATIONS Page 46

6.1 Technical data Page 46

6.2 Hydraulic system diagram-standard version-gasoline motor Page 48

6.2.1 Hydraulic system diagram legend Page 48

6.3 Hydraulic system diagram-extensible version-gasoline motor Page 49

6.3.1 Hydraulic system diagram legend Page 49

6.4 Hydraulic system diagram-standard version-diesel motor Page 50

6.4.1 Hydraulic system diagram legend Page 50

6.5 Hydraulic system diagram-extensible version-diesel motor Page 51

6.5.1 Hydraulic system diagram legend Page 51

7. IDENTIFYING MALFUNCTIONS Page 52

Appendix Page 54

3

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

Courtesy of Machine.Market

INTRODUCTION

Dear customer,

First of all, thank you for choosing a Hinowa Minidumper HP1100 and we hope

that you will be satisfied by your recent purchase.

You have now a working instrument you can rely on as long as you follow the

operating and maintenance instructions.

Carefully read this manual before starting, operating, maintaining, refuelling

or doing any other operations on the machine.

We always have safety in mind when designing and manufacturing our machines.

Unfortunately, our effort is void when the machine is not operated safely.

Preventing accidents is also connected to paying attention, being careful and to

have properly trained people operating, transporting and maintaining the

equipment.

Among the operator’s responsibilities is to read and understand all the safety

instructions given in this manual and to apply them strictly.

Only allow properly trained staff to operate the minidumper. Working with

equipment of which you ignore the technical specifications can cause errors with

subsequent danger to health and safety. In order to acquire all the necessary

preparation, read carefully this manual before starting the machine. In any case the

owner’s responsibility (even if the machine is lent or hired) is to make sure that,

before starting work, all operators read and understand this operator’s manual and

are properly trained to operate this equipment.

This manual is part of the machine and must be always kept with it.

Our machines are constantly been improved and could therefore show

characteristics different from the ones shown in this manual; contact your Hinowa

dealer to have updated information.

Do not hesitate to contact your Hinowa dealer for all useful information or repair; he

is always informed on the best way to operate your machine and will advise you on

suitable equipment. He will also supply you with original spare parts, which is the

only guarantee of quality and perfect replacement. When ordering parts, please

specify the machine serial number if you want to make sure to get the right parts.

Good work with Hinowa!

5

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

Courtesy of Machine.Market

CLASSIFICATION

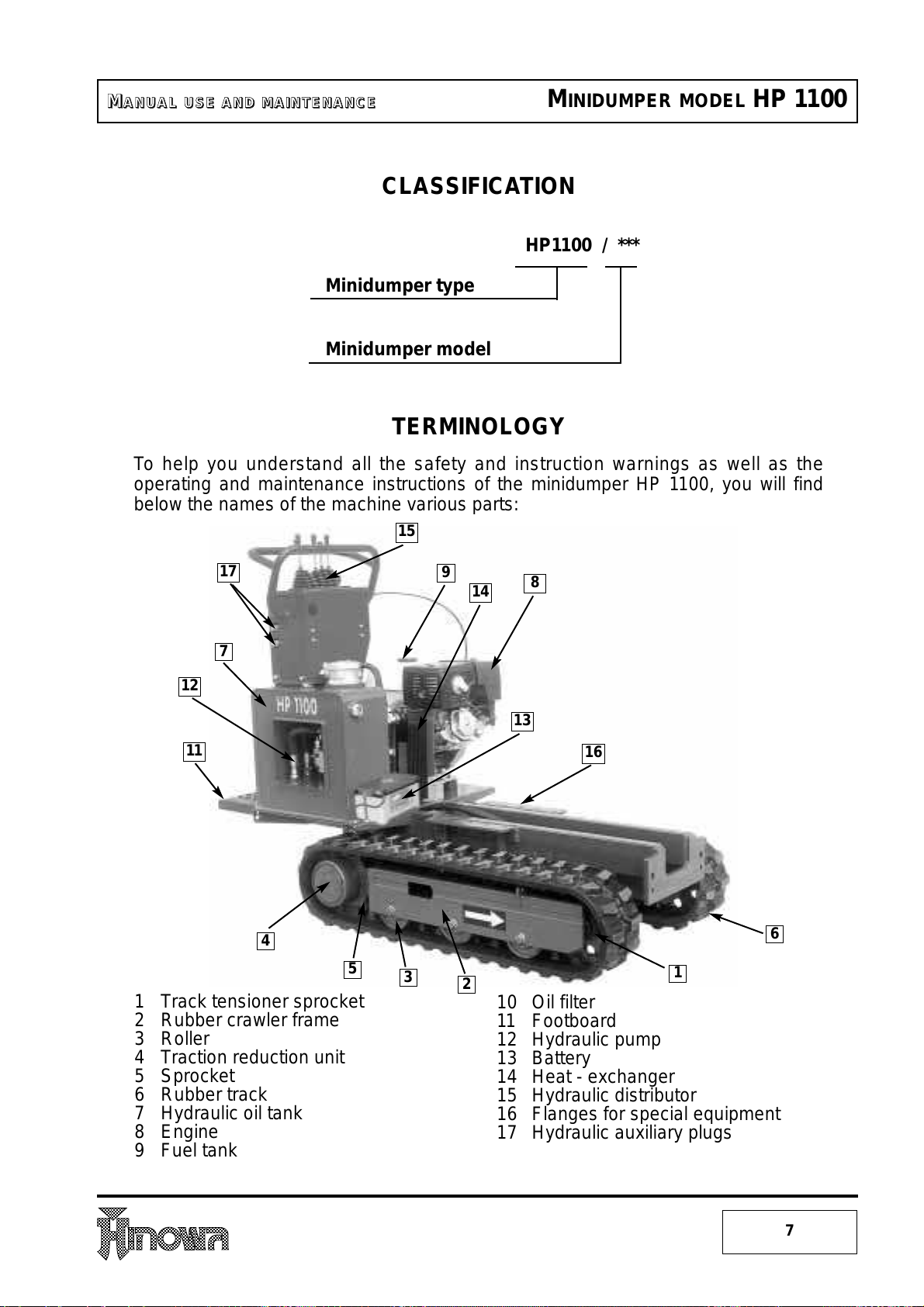

TERMINOLOGY

To help you understand all the safety and instruction warnings as well as the

operating and maintenance instructions of the minidumper HP 1100, you will find

below the names of the machine various parts:

7

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

HP1100 / ***

Minidumper type

Minidumper model

1 Track tensioner sprocket

2 Rubber crawler frame

3 Roller

4 Traction reduction unit

5 Sprocket

6 Rubber track

7 Hydraulic oil tank

8 Engine

9 Fuel tank

10 Oil filter

11 Footboard

12 Hydraulic pump

13 Battery

14 Heat - exchanger

15 Hydraulic distributor

16 Flanges for special equipment

17 Hydraulic auxiliary plugs

1

2

3

4

5

6

7

98

16

17

12

13

14

15

11

Courtesy of Machine.Market

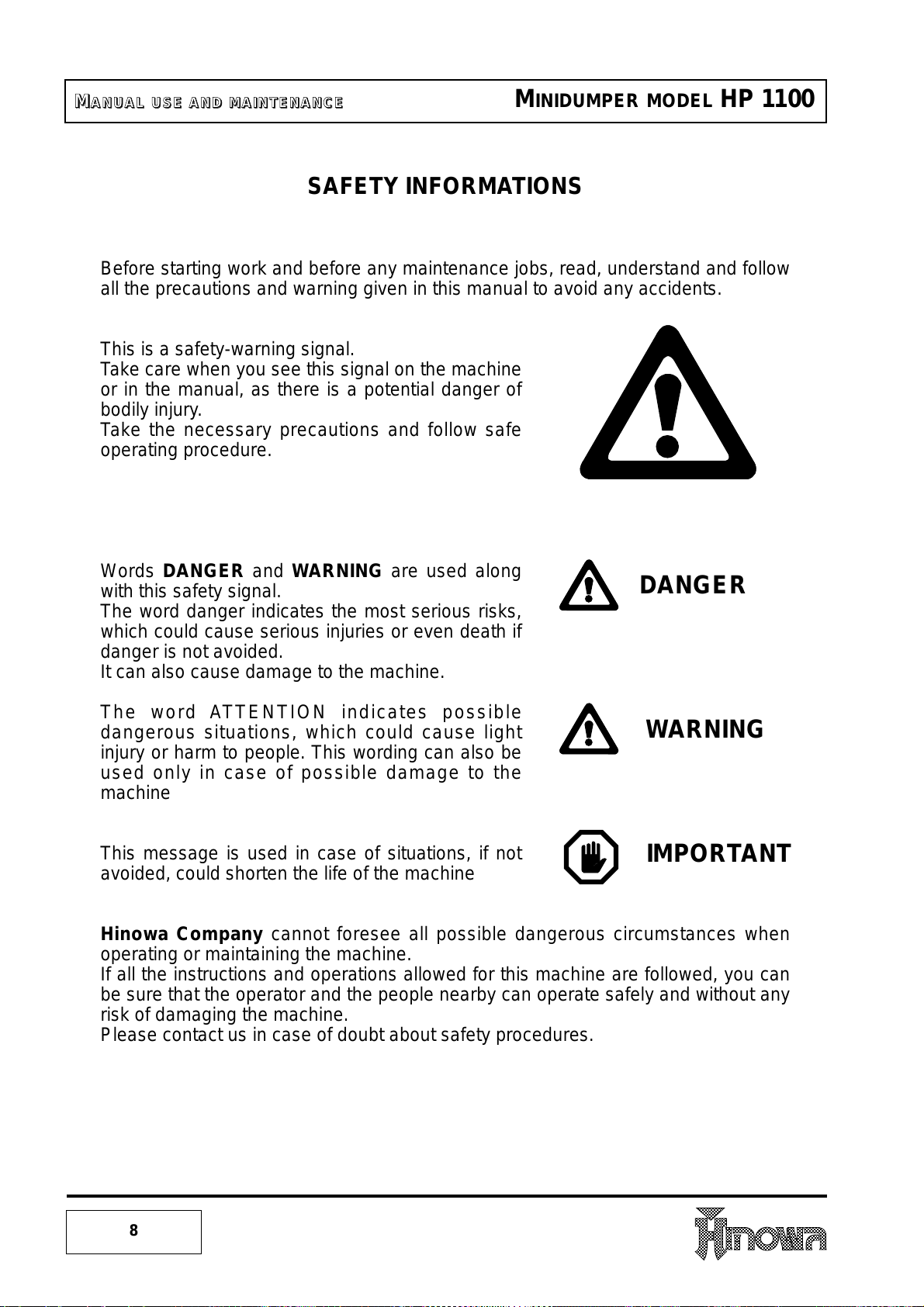

SAFETY INFORMATIONS

Before starting work and before any maintenance jobs, read, understand and follow

all the precautions and warning given in this manual to avoid any accidents.

This is a safety-warning signal.

Take care when you see this signal on the machine

or in the manual, as there is a potential danger of

bodily injury.

Take the necessary precautions and follow safe

operating procedure.

Words DANGER and WARNING are used along

with this safety signal.

The word danger indicates the most serious risks,

which could cause serious injuries or even death if

danger is not avoided.

It can also cause damage to the machine.

The word ATTENTION indicates possible

dangerous situations, which could cause light

injury or harm to people. This wording can also be

used only in case of possible damage to the

machine

This message is used in case of situations, if not

avoided, could shorten the life of the machine

Hinowa Company cannot foresee all possible dangerous circumstances when

operating or maintaining the machine.

If all the instructions and operations allowed for this machine are followed, you can

be sure that the operator and the people nearby can operate safely and without any

risk of damaging the machine.

Please contact us in case of doubt about safety procedures.

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

8

PERICOLO

ATTENZIONE

IMPORTANTE

DANGER

WARNING

IMPORTANT

Courtesy of Machine.Market

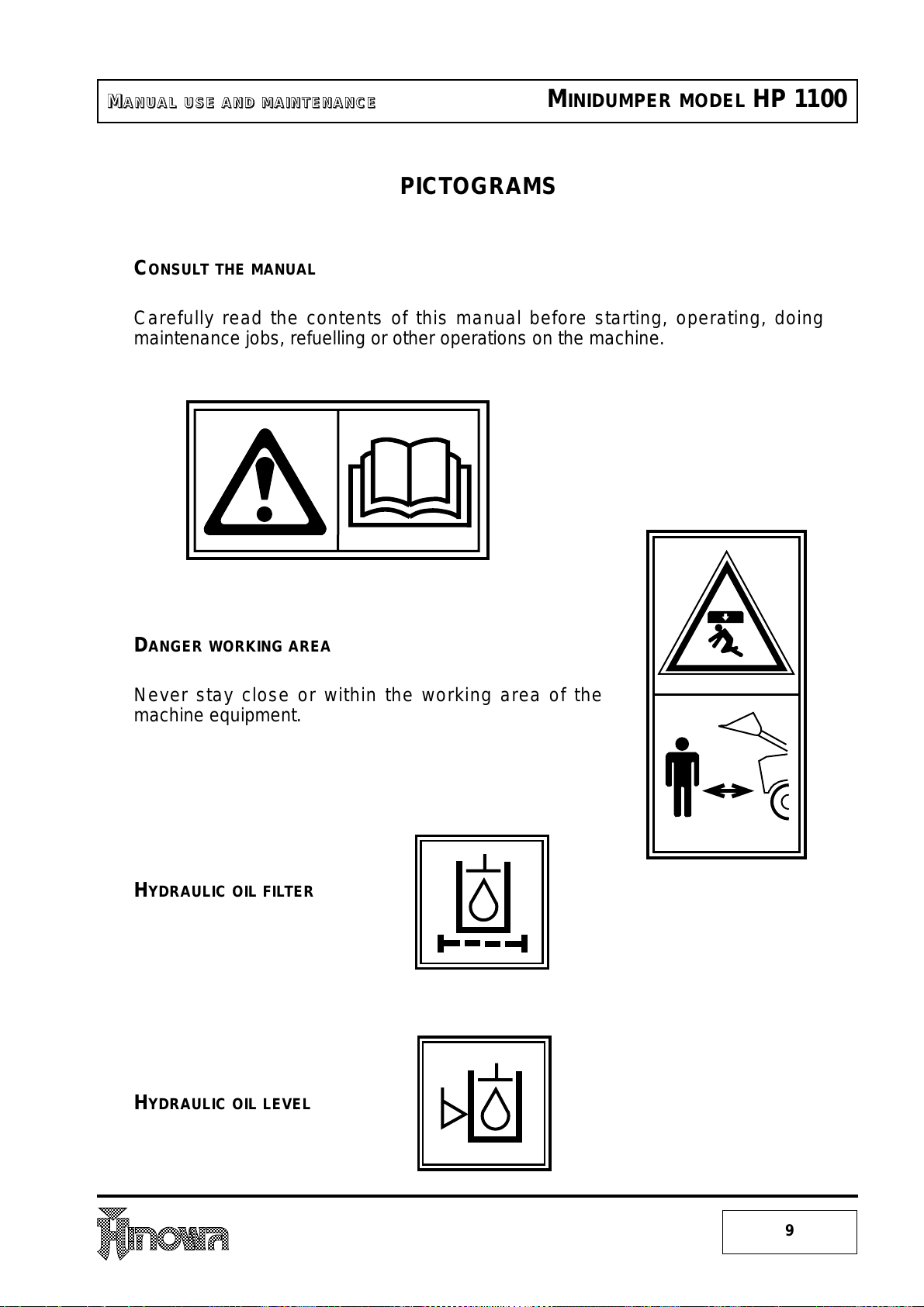

PICTOGRAMS

CONSULT THE MANUAL

Carefully read the contents of this manual before starting, operating, doing

maintenance jobs, refuelling or other operations on the machine.

DANGER WORKING AREA

Never stay close or within the working area of the

machine equipment.

HYDRAULIC OIL FILTER

HYDRAULIC OIL LEVEL

9

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

Courtesy of Machine.Market

11

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

SAFETY AND ACCIDENT PREVENTION

1GENERAL WARNING

1.1 Read the instructions carefully

Before doing any types of operations on the machine, follow all the safety rules,

warnings and instructions given in this manual.

1.2 Follow safety instructions

Read the meaning of all safety warnings in this manual and the safety signals on

the machine.

Check that all the safety signs are in proper working order, replacing the missing or

damaged ones.

Make sure that new equipment bear correct signs when replacing new parts or

tools.

Learn the proper way of operating the machine and the controls.

Never allow unauthorised and not properly trained people to operate the machine

or/and do maintenance jobs on it.

1.3 Clothing and protective wear

Avoid wearing loose clothes, rings, watches or anything that could get entangled

inside the rotating parts. Do not wear clothes stained with oil or fuel, as they can be

flammable.

When operating the machine or doing maintenance jobs, wear a helmet, safety

glasses and safety shoes, a mask, gloves and noise protection earmuffs.

When working for more than 8 hours with a 90 dBA acoustic level it is absolutely

necessary to wear protective earmuffs.

ATTENZION

E

DANGER

Courtesy of Machine.Market

1.4 Unauthorised alterations

It is absolutely forbidden to do any alterations on the machine, which could damage

its working and its safety. Hinowa declines any responsibility for injury or damage

caused by unauthorised alterations.

1.5 Safety valves

Never alter or/and tamper with the safety valves and the controls in the hydraulic

system.

Hinowa declines any responsibility for injury to people, damage to things and to the

machine if the hydraulic valve standard gauging has been tampered with.

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

12

Courtesy of Machine.Market

OPERATING PRECAUTIONS

2P

RECAUTIONS TO TAKE BEFORE STARTING THE ENGINE

2.1 Safety in the working area

Before starting the engine, carefully check the conditions of the working ground to

find out any possible irregularities, which might make working dangerous.

Always take care of people entering within the working range of the machine.

Always warn people before moving the machine.

2.2 Fire prevention

Keep the engine compartment clean; remove any

pieces of wood, paper and other flammable

products; clean properly any fuel, oil or

flammable fluid leaks, as they can be potential

fire risks.

Petrol is extremely flammable and explosive

under certain conditions. Refuel in a well-

ventilated place and when the engine is off.

Never smoke or cause sparks in the refuelling

place or the fuel storage place.

Never fill the tank too much. After refuelling,

make sure that the cap is closed safely and properly.

Make sure there is no fuel leak when refuelling. Petrol fumes or possible leaks

might catch fire.

Make sure the area is dry before starting the engine.

The exhaust pipe gets overheated during work and remains hot even after the

engine has been turned off. Take care not to touch the exhaust pipe when it is hot.

To avoid burns, cool the engine before moving the carriage or starting it.

13

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

ATTENZIO

N

DANGER

Courtesy of Machine.Market

2.3 Warning against exhaust fumes

When working inside a building, make sure there is proper ventilation. If you are not

sure about ventilation, use an extension to evacuate exhaust fumes.

Exhaust fumes can cause death.

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

14

Courtesy of Machine.Market

15

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

3

M

EASURES TO TAKE WHEN WORKING

3.1 Precautions when starting the engine

Before starting the machine, check it properly by walking

around it.

Warn people nearby that you are starting the machine.

Do not allow anyone to climb onto the machine.

3.2 Precautions when driving

In order to avoid possible accidents or loss of control, never climb onto the carriage;

place yourself behind it and hold the handle firmly. To avoid any possible injury from

the machine, keep children and animals away from working area.

NEVER OPERATE THE MINIDUMPER AT NIGHT.

3.3 Precautions when transporting loads

To avoid accidents or tipping over, follow the loads restrictions indicated on p.40

Make sure the load is properly secured and does not exceed the dimensions of the

carriage or obstruct the operator’s view.

To avoid overturning, never change directions with the transporting carriage when

operating on slopes. Never operate the carriage on upwards slopes with an over

25° slant and on downwards slopes with an over 25° slant.

Take care when reversing with the carriage, as there is an increased risk of falling

and skidding.

On steep downward slopes, always operate at minimum speed. Never reverse on

downward slopes.

3.4 Transporting the machine

Observe local regulations when transporting the machine on public roads.

Use a lorry or a trailer suitable for transporting the machine.

Always load or unload the machine on a flat or solid surface.

ATTENZIO

N

DANGER

Courtesy of Machine.Market

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

16

Always use a ramp or a loading platform when loading or unloading the machine.

Never use high-speed gears.

Avoid steering when driving up or down a ramp as it could be very dangerous. If

steering is absolutely necessary, first go back to the ground or the flatbed, change

direction and then start driving again.

Never operate any levers except the drive lever when driving up or down a ramp,

this is to avoid unbalancing the machine. There is a bump at the top of the ramp.

Take care when crossing it.

Fix chains and cables to the machine frame.

3.5 Parking the machine safely

Park the machine on a flat and solid surface with enough space for controlling. If

you have to park on a slope, put safety blocks under rubber tracks.

3.6 Be prepared in case of emergency

Be prepared in case of fire.

Keep handy a first aid kit and a fire extinguisher.

Keep emergency numbers for doctors, ambulance, hospital and fire brigade near

the telephone.

3.7 Wear protective garments

Wear tight fitting garments and safety equipment appropriate to the job you are

doing.

3.8 Protect yourselves against noise

Prolonged exposure to loud noise can cause ear damage or loss of hearing.

Wear a suitable noise protection device such as earplugs or earmuffs to protect you

against deafening or loud noises.

Courtesy of Machine.Market

4OPERATING INSTRUCTIONS

4.1 Driver’s seat and controls – standard version

4.2 Driver’s seat and controls – extensible version

17

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

ABD

CE

BCE

F

A- Control joystick– carriage left shift D-Clutch joystick – 2nd shift speed

B- Control joystick – dumper tipping E- Control joystick – accessory

C- Control joystick – carriage right shift F-Accelerator joystick

A- Control joystick– carriage left shift E-Clutch joystick – 2nd speed

B- Control joystick – dumper tipping F-Control joystick – accessory

C- Control joystick – carriage right shift G-Accelerator joystick

D- Control joystick - extension

FDCF

AB

D

C

G

E

F

G

GASOLINE ENGINE VERSION DIESEL ENGINE VERSION

GASOLINE ENGINE VERSION DIESEL ENGINE VERSION

EAB

AD

Courtesy of Machine.Market

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

18

4.3 GASOLINE ENGINE CONTROLS

(Consult also the engine operator’s manual)

4.3.1 Starting the engine

1. Position the fuel valve to ON.

2. Position the air lever to CLOSE.

NB: Never use the air lever when the engine is hot and the air temperature is rather

high.

4.3.2 Using the engine

1. As the engine gets warmer,

gradually position the air lever to

OPEN.

FUEL VALVE

AIR LEVEL

AIR LEVEL

CLOSE

CLOSE

OPEN

Courtesy of Machine.Market

2. Position the acceleration control lever

to obtain the desired rpm.

Oil alarm system (optional)

The oil alarm system is designed to prevent damages to the engine, as a result of

lack of oil in the sump. Before the oil level drops below the minimum level, the

alarm system stops the engine automatically. The engine switch remains in ON

position.

NB:

If the engine stops and does not start again, check the oil level in the engine

before checking any other parts.

Circuit switch

The circuit switch protects the battery recharging circuit. A short circuit or a wrongly

connected battery will make it suddenly trip.

In this case, before disconnecting the circuit switch, find the origin of the trouble

and put it right.

To disconnect the circuit switch, press CIRCUIT BREAKER button.

19

MM

MMAA

AANN

NNUU

UUAA

AALL

LLUU

UUSS

SSEE

EEAA

AANN

NNDD

DDMM

MMAA

AAII

IINN

NNTT

TTEE

EENN

NNAA

AANN

NNCC

CCEE

EEMINIDUMPER MODEL HP 1100

BUTTON CIRCUIT BREAKER

ACCELERATION CONTROL LEVER

HIGH LOW

Courtesy of Machine.Market

Table of contents

Other Hinowa Lifting System manuals

Popular Lifting System manuals by other brands

Schmalz

Schmalz VACUMASTER HHVM operating instructions

Braun

Braun NVL Vista A3 Series Service manual

VMB

VMB TE-074 PRO operating instructions

MaxJax

MaxJax M6K user manual

Nussbaum

Nussbaum JUMBO NT 3500 Operating Instruction and Documentation

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL 263 Original instructions