Hinowa GOLDLIFT 14.70 Instruction manual

MUGL147020409

MANUAL USE AND MAINTENANCE

SELF

SELF-PR

-PROPELLED TRA

OPELLED TRAC

CKED PL

KED PL A

ATF

TFORM

ORM

GOLDLIFT

GOLDLIFT 1

14.70

4.70

Valid from serial number G23

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

INDEX

CHAPTER 1 FOREWORD........................................................................................................Page 05

CHAPTER 2 OPERATOR’S MANUAL .................................................................................Page 05

2.1 DESCRIPTION OF THE MACHINE ................................................................Page 05

2.1.1 MACHINE IDENTIFICATION PLATE............................................................Page 06

2.1.2 OVERALL DIMENSIONS OF THE MACHINE .............................................Page 07

2.1.2.1 GOLDLIFT 14.70 DIMENSIONS.......................................................................Page 07

2.1.3 TECHNICAL DATA............................................................................................Page 08

2.1.3.1 PLATFORM TECHNICAL DATA.....................................................................Page 08

2.1.3.2 PETROL ENGINE TECHNICAL DATA ..........................................................Page 09

2.1.3.3 DIESEL ENGINE TECHNICAL DATA ............................................................Page 09

2.1.3.4 HYDRAULIC SYSTEM TECHNICAL DATA..................................................Page 09

2.1.3.5 ELECTRIC SYSTEM TECHNICAL DATA.......................................................Page 10

2.1.4 TERMINOLOGY..................................................................................................Page 10

2.1.4.1 GOLD LIFT 14.70 KEY........................................................................................Page 11

2.2 GENERAL SAFETY RULES ...............................................................................Page 12

2.3 SAFETY ADVICE ................................................................................................Page 14

2.3.1 GENERAL ADVICE ............................................................................................Page 14

2.3.2 PICTOGRAMS SITUATED ON THE MACHINE ..........................................Page 14

2.3.3 NOISE AND VIBRATIONS................................................................................Page 23

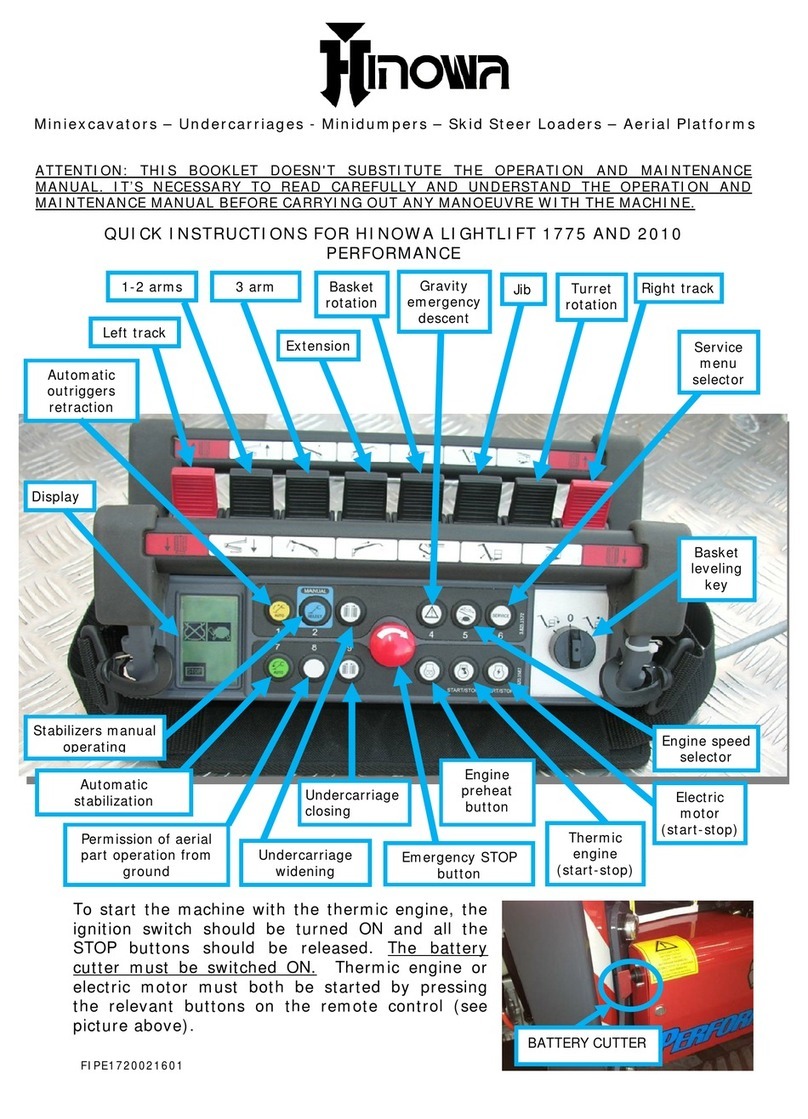

2.4 INSTRUMENTS AND CONTROLS .................................................................Page 23

2.4.1 BASKET CONTROL DEVICE............................................................................Page 23

2.4.1.1 BASKET ELECTRIC PANEL..............................................................................Page 23

2.4.1.2 BASKET HYDRAULIC CONTROLS FOR MODEL 14.70 .................................Page 26

2.4.1.4 CRAWLER HYDRAULIC CONTROLS ..............................................................Page 28

2.4.1.5 GROUND EMERGENCY CONTROLS SITUATED ON THE REVOLVING TURRET .....Page 31

2.5 SAFETY DEVICES...............................................................................................Page 33

2.5.1 BATTERY CUTOUT ............................................................................................Page 34

2.5.2 DISTRIBUTOR OVERPRESSURE VALVES .....................................................Page 34

2.5.3 CYLINDER STOP VALVES ................................................................................Page 35

2.5.4 PHOTOELECTRIC CELL AND SWITCH ALIGNMENT OVERHEAD

PART OF THE FRAME AND MACHINE BASE ...........................................Page 35

2.5.5 ENABLING DEVICE OF THE FRAME OVERHEAD PART ........................Page 36

2.5.6 SENSOR OF CONTROL CAR LOAD...............................................................Page 36

2.5.7 CONTROL GUARDS..........................................................................................Page 37

2.5.8 THE WATER LEVEL ..........................................................................................Page 37

2.5.9 LOCKING PIN SCREWS AND NUTS .............................................................Page 38

2.6 EMERGENCY DEVICES ....................................................................................Page 38

2.6.1 EMERGENCY STOP PUSHBUTTON...............................................................Page 39

2.6.2 SWITCH ENABLING EMERGENCY CONTROLS.......................................Page 39

2.6.3 HAND PUMP ......................................................................................................Page 40

2.6.4 SOLENOID VALVES FOR EMERGENCY DESCENT....................................Page 41

2.7 SAFETY REGULATIONS TO OBSERVE BEFORE USING THE PLATFORM ......Page 42

2.7.1 DANGER OF ELECTRIC FULMINATION .....................................................Page 42

2.7.2 DANGER DUE TO BAD WEATHER CONDITIONS ....................................Page 43

2.7.3 DANGER DUE TO THE WORKING AREA ...................................................Page 43

2.8 PROCEDURES FOR A PROPER USE...............................................................Page 44

2.8.1 OPERATOR’S RECAPITULATORY TABLE OF SAFETY REGULATIONS .....Page 44

2.8.2 GOLD LIFT 14.70 WORKING AREA ...............................................................Page 45

2.9 USE OF THE OVERHEAD PLATFORM..........................................................Page 46

2.9.1 PRELIMINARY CHECKS BEFORE STARTING OPERATING ....................Page 47

2.9.2 START OF THE PETROL/DIESEL (OPTIONAL) ENGINE ..........................Page 48

2.9.3 START OF THE ELECTRIC ENGINE ..............................................................Page 49

2.9.4 TRANSLATION...................................................................................................Page 49

2.9.4.1 PARKING OF THE MACHINE ON A SOLPE OR DISCONNECTED GROUND....Page 51

2.9.5 STABILISING AND LEVELLING THE MACHINE.......................................Page 51

2.9.6 MOVING THE CONTROL CAR.......................................................................Page 52

2.9.7 MANUAL LEVELLING OF THE CONTROL CAR .......................................Page 54

2.9.8 MANOEUVRING THE BASKET EMERGENCY DESCENT........................Page 55

2.9.8.1 ACTIVATING THE BASKET EMERGENCY DESCENT...............................Page 55

2.9.8.2 ACTIVATING THE GROUND EMERGENCY DESCENT WITH

THE MACHINE IN PERFECT WORKING ORDER......................................Page 56

1

2.9.8.3 ACTIVATING THE GROUND EMERGENCY DESCENT WITH THE

HAND PUMP IN CASE OF ALL THE ENERGY SYSTEMS BREAKDOWN ....Page 56

2.9.9 MAIN USES PLANNED FOR THE PLATFORM ...........................................Page 58

2.9.9.1 SYSTEMS ..............................................................................................................Page 58

2.9.9.2 CLOSED PREMISES............................................................................................Page 58

2.9.9.3 USING FOR PRUNING......................................................................................Page 58

2.9.9.4 USE FOR REPAIRS AND MAINTENANCE OF ROOFS AND RAIN PIPES......Page 58

2.9.9.5 USE FOR PAINTING, SAND BLASTING AND PLASTERING...................Page 59

2.9.9.6 USE IN SALTY ENVIRONMENT....................................................................Page 59

2.10 REMOVAL OF THE BASKET............................................................................Page 59

2.11 TRANSPORT SAFETY REGULATIONS..........................................................Page 60

2.11.1 LOADING AND UNLOADING ON RAMPS.................................................Page 60

2.11.2 LIFTING THE MACHINE .................................................................................Page 61

2.11.2.1 HOW AND WHERE TO HOOK THE PLATFORM.......................................Page 62

2.11.2.2 WHAT TO USE FOR HOOKING THE PLATFORM......................................Page 62

2.11.3 TRANSPORT OF THE MACHINE...................................................................Page 63

CHAPTER 3 SPECIFICATIONS FOR GREASING AND LUBRICATING ...................Page 63

3.1 SAFETY RULES FOR GREASING AND LUBRICATING .............................Page 63

3.2 LUBRICATING POINTS ....................................................................................Page 64

3.3 GREASING POINTS ..........................................................................................Page 64

3.3.1 GREASING THE TELESCOPIC ARM..............................................................Page 65

CHAPTER 4 MAINTENANCE OF THE MACHINE ..........................................................Page 65

4.1 SAFETY REGULATIONS FOR MAINTENANCE OPERATIONS...............Page 65

4.2 PERIODIC GENERAL CONTROL ...................................................................Page 66

4.2.1 PERIODICAL MAINTENANCE TIMES..........................................................Page 67

4.3 RUBBER TRACK MAINTENANCE.................................................................Page 69

4.3.1 CHECKING TRACK TENSION........................................................................Page 69

4.3.2 OPERATIONS TO LOOSEN OR TIGHTEN TRACK.....................................Page 69

4.3.3 CHECKING RUBBER TRACKS ........................................................................Page 70

4.3.4 REPLACING RUBBER TRACKS.......................................................................Page 72

4.4 CHECKING BOLTS AND NUTS TIGHTNESS...............................................Page 74

4.5 CHECKING HYDRAULIC OIL LEVEL...........................................................Page 75

4.6 CHECKING LEAKS FROM THE HYDRAULIC SYSTEM............................Page 75

4.7 CHECKING FILTER CARTRIDGE...................................................................Page 75

4.8 CHECKING THE MACHINE PLATES INTEGRITY ...................................Page 76

4.9 CHECKING WORKING PRESSURES OF THE HYDRAULIC SYSTEM....Page 76

4.10 CHECKING THE TIGHTENING OF THE FIXING SCREWS OF

THE PIN STOPS AND THE RING NUTS ...........................................................Page 77

4.11 CHECKING WEAR AND TEAR OF THE TELESCOPIC ARM

SLIDING BLOCKS ..............................................................................................Page 77

4.12 CONTROL OF WEAR AND TEAR OF THE INTERIOR SLIDING RING EXTENSION.Page 77

4.13 BATTERY: CHECKS AND MAINTENANCE.................................................Page 78

4.13.1 CHECKING ELECTROLYTE.............................................................................Page 78

4.13.2 RECHARCHING THE BATTERY.....................................................................Page 78

4.13.3 REPLACING THE BATTERY ............................................................................Page 79

4.13.4 DISCARDING THE BATTERY..........................................................................Page 79

4.14 ENGINE MAINTENANCE................................................................................Page 79

CHAPTER 5 TROUBLESHOOTING .....................................................................................Page 80

CHAPTER 6 CHECKING THE MACHINE AFTER REPAIRS .........................................Page 81

6.1 CHECKING THE PROPER WORKING OF THE CONTROLS....................Page 81

6.2 CHECKING THE PROPER WORKING OF THE SAFETY DEVICES.........Page 81

CHAPTER 7 HYDRAULIC SYSTEM .....................................................................................Page 82

7.1 GOLDLIFT 14.70 HYDRAULIC SYSTEM........................................................Page 82

7.2 KEY DIAGRAM GOLDLIFT 14.70 HYDRAULIC SYSTEM..........................Page 83

7.3 GOLDLIFT 14.70 HYDRAULIC SYSTEM WITH 2ND SPEED........................Page 84

7.4 KEY DIAGRAM GOLDLIFT 14.70 HYDRAULIC SYSTEM WITH 2ND SPEED .....Page 85

CHAPTER 8 ELECTRIC SYSTEM ..........................................................................................Page 86

2

3

FOREWORD

The aim of this manual is to provide the customer with all the necessary instructions and

operating procedures essential for the proper use of the machine in order to avoid serious

damages to the machine or others.

IMPORTANT

ALL THE INFORMATION IN THIS MANUAL IS MANDATORY AND MUST BE READ

CAREFULLY AND UNDERSTOOD BEFORE STARTING ANY OPERATION ON THE

MACHINE.

Being an important working tool, this manual must always be kept in a safe and easy to

reach place to be available at any time for further explanations.

Since it is not possible for the manufacturer to check the application of the machine and its

operation.

THE OPERATOR IS RESPONSIBLE to observe the safety instructions described in this

manual.

Before delivery, each machine is checked and tested carefully so that the operator does not

need to do any further adjustments.

IT IS ABSOLUTELY FORBIDDEN AND THE RESPONSIBILITY IS AT THE OPERATOR’S

OWN RISK to do any alterations and/or adjustments without any prior authorisation from

HINOWA SPA.

IT IS THE EMPLOYER’S RESPONSIBILITY TO MAKE SURE THE OPERATOR HAS THE

NECESSARY SKILLS AND ABILITIES TO OPERATE PROPERLY THE MACHINE AND

THAT HE HAS READ AND UNDERSTOOD THE CONTENTS OF THIS INSTRUCTION

AND OPERATING MANUAL.

IT IS ALSO THE EMPLOYER’S RESPONSIBILITY TO TRAIN THE OPERATOR ACCOR-

DING TO NATIONAL LAWS WHICH MIGHT BE SUPPLEMENTARY TO THE CONTENTS

OF THIS MANUAL.

If this manual gets damaged or lost, ask directly HINOWA SPA for a replacement copy.

Note: all the pictures and drawings in the manual have been added to simplify the com-

prehension of the texts. The machine in your possession may differ from the pictures and the

drawings in some details.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

APPLIED STANDARDS

This machine has been planned, built and tested according to the prescribed harmonised

regulations EN280 which supplies the presumption of conformity to the Essential Safety

requirements of the Machine Directive 98/37/CE although it is a type C Voluntary Technical

Rule. According to what prescribed in EN280 the platform GOLDLIFT has been classified in

GROUP B, as the vertical projection of the load centre of gravity always remains outside the

overturn lines and in TYPE I as the translation is only allowed when the platform is at rest.

CUSTOMER SERVICE

In case of repairs or overhauls of the following parts of the machine:

- Locking valves;

- Sensors (microswitches, photoelectric cells, loading sensors etc.);

- Main part of the electric system (PLC).

IT IS OBLIGATORY to contact the dealer where the platform has been purchased or directly

HINOWA SPA Customer Service. They have highly qualified staff and above all the suitable

equipment to carry out the necessary operations in complete safety.

When doing ordinary maintenance or repairs, ONLY USE ORIGINAL SPARE PARTS pur-

chased from the dealer where the platform has been bought or directly from HINOWA Spa

Spare parts Department.

WARRANTY

When purchasing a platform GOLDLIFT you are given a warranty and test certificate where

the warranty terms are clearly stated and where there must be specified any interventions on

the machine.

LIABILITY

HINOWA SPA declines any responsibility or obligations for any damages caused to people

or things due to the following reasons:

• Not observing the instructions indicated in this INSTRUCTION AND OPERATING

MANUAL with regard to the operating, use and maintenance of the machine;

• Any sudden or violent actions or wrong manoeuvres in the use and maintenance of the

machine;

• Any alterations done to the structure and the components of the machine without any

prior authorisation from HINOWA SpA and/or without using proper equipment;

• Any foreign events not related to the ordinary and proper use of the machine as descri-

bed in this INSTRUCTION AND OPERATING MANUAL;

• Using non original and non authorised manufactured spare parts.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

4

5

1. INTRODUCTION

In this manual, you can see safety-warning signs used to bring the reader’s attention to some

warnings of particular importance.

The warning signs comes under two main types identified and described below.

DANGER

This sign accompanied by the word DANGER indicates that the situation descri-

bed below, if not avoided, can cause serious injuries or even death to the people

concerned (operator, ground staff, people near the platform, people assigned to

maintenance etc.).

WARNING

This sign accompanied with the word WARNING indicates that the situation

described below indicates a potential risk to the structure of the machine. This

condition could cause dangerous conditions (even injuries and death) to the peo-

ple concerned.

2. OPERATOR’S MANUAL

2.1. DESCRIPTION OF THE MACHINE

The GOLD LIFT machine is a self-propelled hydraulic lifting device, equipped with a

working control car situated at the top of a rotating and extensible articulated structure. The

lifting device GOLD LIFT is meant for PLACING PEOPLE AND THEIR TOOLS AND

MATERIALS IN PLACES HIGHER THAN GROUND LEVEL.

The main control station of all the movements of the lifting device GOLD LIFT is situated on

the control car. Thanks to the main control station the operator can drive the machine, lift or

lower the extensible structure and rotate it towards the left or the right for an overall 300°

angle.

The machine GOLD LIFT is equipped with a ground control station that excludes the main

control station by means of a switch. The ground controls check the movements of the exten-

sible structure and are used in case of emergency to bring the control car back to the ground

when the operator is not able to do it.

The ground emergency controls can be used when doing control checks before starting ope-

rating.

The machine GOLD LIFT is a self-propelled machine able to move easily on any type of

ground, able to overcome big slopes and, seen its contained dimensions, to enter into narrow

places. The control car is the only control location planned by the manufacturer that prevents

the operator from being injured during all the translation operations of the machine. In fact,

the controls have been studied to be used from the said position to have a proper sight of the

involved area.

The travel function can be controlled from the ground position only when the machine has to

pass pass through reduced-height or narrow spaces. In these cases, to allow the machine to

access these spaces, the two-place cage must be removed. The machine must travel only

lengthwise and must be controlled by a specialist operator.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

When controlling the translation of the machine from the control car, take the maximum care

of elements like cornices, terraces, lintels, branches etc. that could come into contact with the

operator.

If the machine translation is controlled from the ground (see the a.m. admitted cases),

remember that the machine must be orientated with the control car part towards the back so

that, in case of a wrong manoeuvre, the operator does not come into contact with the rubber

tracks.

Controlling the travel of the machine from the ground with the cage removed is conside-

red an extraordinary procedure that should be adopted only when the work area cannot be

reached in any other way.

It is absolutely forbidden to do manoeuvres different from the above mentioned ones by con-

trolling translation from the ground as a possible sharp movement of the machine could

crush the operator between itself and the elements present on the manoeuvring area or make

the operator come into contact with the rubber tracks or the platform stabilisers.

After reinstalling the cage, put back the iron caps immediately.

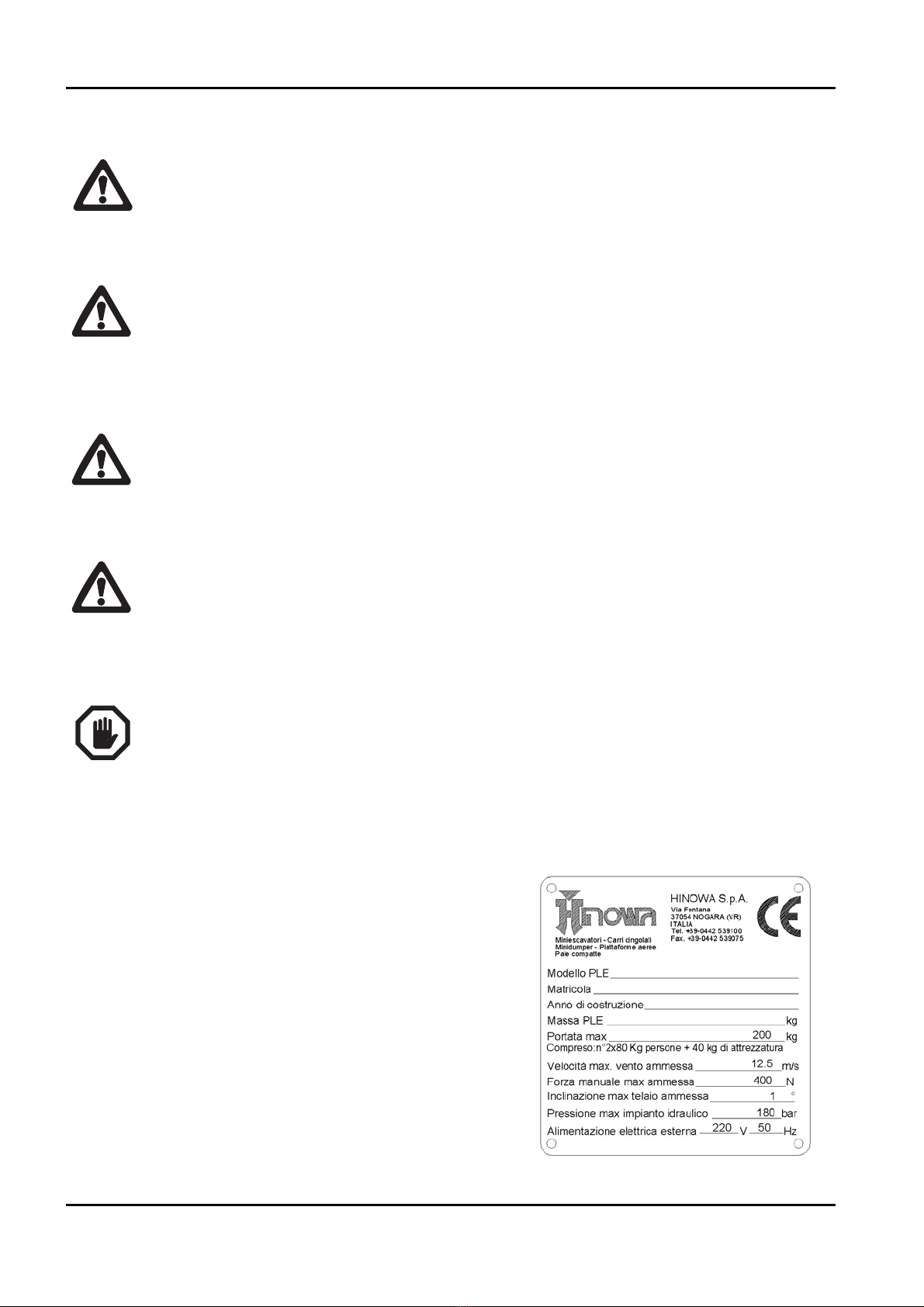

2.1.1 MACHINE IDENTIFICATION PLATE

The Manufacturer plate is situated on the right

side of the metallic frame sustaining the transla-

tion/stabilising controls. You can see the drawing

below.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

6

7

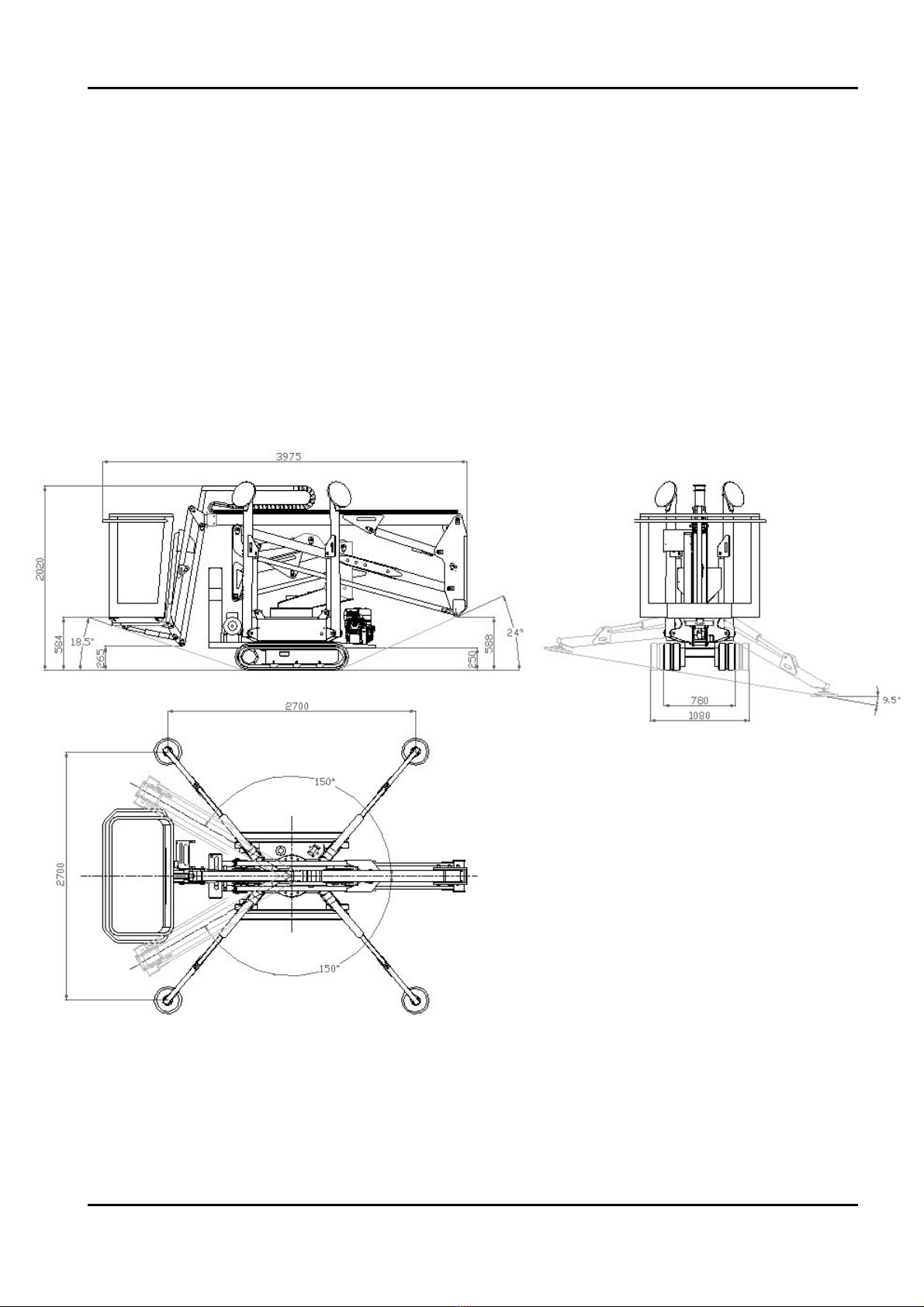

2.1.2 OVERALL DIMENSIONS OF THE MACHINE

2.1.2.1 DIMENSIONS 1470

Maximum length in running conditions........................3975 mm

Carriage width ..................................................................780-1080 mm

Maximum height in running conditions........................1980 mm

Maximum ramp angle ......................................................18.5°

Maximum stabilising angle..............................................10°

Stabiliser base side ............................................................2700 mm

N.B. Standard version with two-seater basket.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

2.1.3 TECHNICAL DATA

2.1.3.1 PLATFORM TECHNICAL DATA

GOLDLIFT 14.70

....................................................................................................LOAD 200 kg ....LOAD 120 kg

PLATFORM HEIGHT (tread level ) ......................................10,58 m ..........11,94 m

MAXIMUM WORKING HEIGHT ............................................12,63 m ..........14,00 m

STANDARD CONTROL CAR DIMENSIONS ..............................1330x694 H1100 mm

HORIZONTAL RANGE ..........................................................5,16 m ............6,24 m

MAXIMUM WORKING HORIZONTAL RANGE ..........................5,61 m ............7,00 m

ROTATION (non continuous) ....................................................300°................300°

PLATFORM CAPACITY ..........................................................200 kg, ............120 kg

MAX GROUND REACTION PER STABILISER ..............................................1330 daN

MAX GROUND PRESSURE PER STABILISER ..........................................1,9 daN/cm2

OPERATORS N° ............................................................................2 ....................1

OPERATOR N° IN SINGLE- SEATER BASKET (OPTION) ..................1 ....................1

JIB-TYPE ARTICULATION ............................................................../ ......80° (+0°/-80°)

MAX WORKING INCLINATION....................................................................1°/2,2%

MAX STABILISING INCLINATION......................................................................10°

OVERALL WEIGHT IN TRANSPORT POSITION..............................................1700 kg

THERMIC ENGINE....................................................HONDA GX270-9 CV-3000 rpm

............................................................HONDA GX390-13 CV-3000 rpm (Optional)

....................................................................................HATZ 1B30-7 CV-3000 rpm

ELECTRIC ENGINE......................................................1,5 kw/220V/50Hz 1500 rpm

..................................................................1,5 kw/110V/50Hz 1500 rpm (Optional)

TELECTRIC SYSTEM VOLTAGE..........................................................................12 V

PUMPS ....................................................................................................2x3,15 cc

MAX TRANSLATION SPEED (thermic engine) ............................................1,4 km/h

MAX TRANSLATION SPEED (thermic engine) with 2nd speed (optional) ........1,4/2,8 km/h

STAB/TRANSLATION SYSTEM PRESSURE ....................................................175 bar

OVERHEAD PART PRESSURE ......................................................................180 bar

MAX UPPER SLANT IN RUNNING CONDITIONS..........................................24°/53%

MAX WIND SPEED....................................................................................12,5 m/s

MAX ADMITTED MANUAL FORCE ..................................................................40 kg

RUBBER CRAWLER WIDTH- OPEN/CLOSE ........................................780/1080 mm

NB: The side range is measured from the centre of the fifth wheel to the outer

side of the control car.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

8

9

It is absolutely forbidden to translate and/or manoeuvre on transversal slopes with the craw-

ler not extended as the machine could turn over and cause serious damages to the operator.

2.1.3.2 PETROL ENGINE TECHNICAL DATA

Make/ModelHONDA GX270

Fuel/coolant ........................................................................PETROL/AIR

Power SAEJ1349 ................................................................6.6 kW (9 CV) / 3600 Giri/min

Max regulated rpm............................................................3000 giri/min

Maximum torque ..............................................................19.1 Nm/2500 Giri/min (80/1269/EC)

Cylinder n° ..........................................................................1

Cubic capacity....................................................................270 cm3

Make/Model ......................................................................HONDA GX390

Fuel/coolant ........................................................................PETROL/AIR

Power SAEJ1349 ................................................................9.6 kW (13 CV) / 3600 Giri/min

Max regulated rpm............................................................3000 giri/min

Maximum torque ..............................................................26.5 Nm/2500 Giri/min (80/1269/EC)

Cylinder n° ..................................................................................1

Cubic capacity....................................................................389 cm3

2.1.3.3 DIESEL ENGINE TECHNICAL DATA

Make/Model ......................................................................HATZ 1B30

Fuel/coolant ........................................................................DIESEL/AIR

Power SAEJ1349 ................................................................5,0 kW (6,8 CV) / 3600 Giri/min

Max regulated rpm............................................................3000 giri/min

Maximum torque ..............................................................18,2 Nm/2000 Giri/min (80/1269/EC)

Cylinder n° ........................................................................1

Cubic capacity....................................................................347 cm3

2.1.3.4 HYDRAULIC SYSTEM TECHNICAL DATA

Hydraulic oil tank capacity..............................................25 litres

Pump ..................................................................................double 2x3.15cm3

Hydraulic system max pressure......................................180 bar

For further information please consult the hydraulic diagram annexed to this manual or the

paragraph relative to the maintenance of the relative components.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

DANGER

2.1.3.5 ELECTRIC SYSTEM TECHNICAL DATA

Battery ................................................................................35 Ah - 125 A - 12V

Alternator: - petrol engine..............................................10 A (3000rpm)

- diesel engine ..............................................14 A (3000rpm)

Electric engine: - electrical connection..........................220 V

- frequency............................................50 Hz

- power ..................................................1.5 kW

For further information please consult the electric diagram annexed to this manual or the

paragraph relative to the maintenance of the relative components.

2.1.4 TERMINOLOGY

To make this manual easier to understand, there is a diagram that gives all the exact terms

identifying the different parts of the platform.

GOLD LIFT 14.70

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

10

11

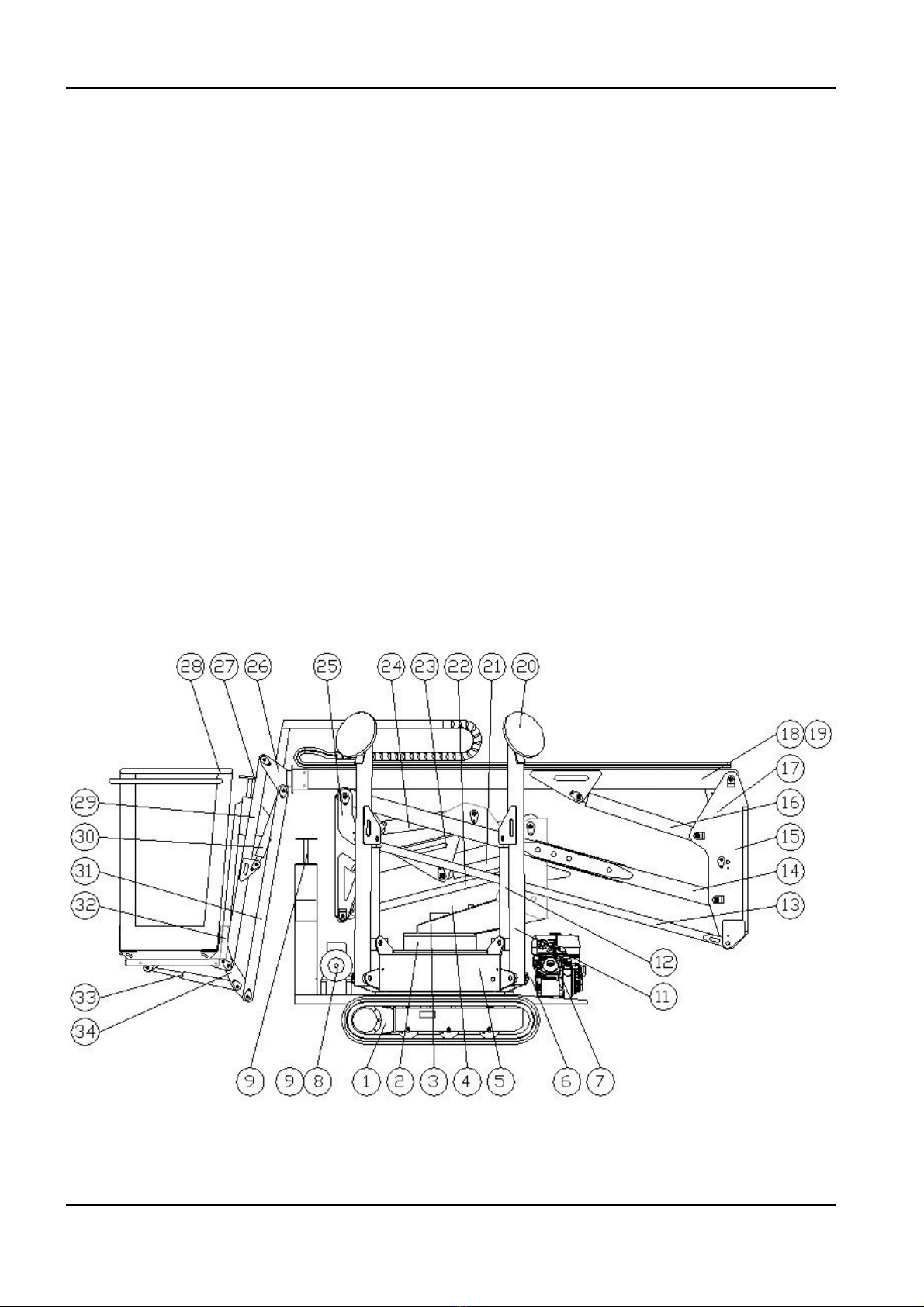

2.1.4.1 GOLD LIFT 14.70 KEY

1Extensible rubber crawler

2Fifth wheel + rotation engine

3Revolving turret

4Overhead part emergency controls

5Base + electric components box + oil tank

6Triple gear pump

7Diesel/petrol engine

8Electric engine

9Triple gear pump

10 Translation and stabilisers controls

11 Stabilizer

12 Stabilizer cylinder

13 Second arm tie-rod

14 Second arm

15 Second transmission

16 Third arm cylinder

17 Basket levelling cylinder on transmission

18 Third arm

19 Extraction cylinder

20 Stabilizer cap

21 First arm cylinder

22 First arm tie- rod

23 First arm

24 Second arm cylinder

25 First transmission

26 Extraction arm

27 Controls

28 Basket or control car

29 Jib arm

30 Jib cylinder

31 Jib tie-rods

32 Basket support

33 Basket levelling cylinder on jib

34 Jib transmission

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

2.2 GENERAL SAFETY RULES

NOT OBSERVING THE SAFETY PRECAUTIONS LISTED IN THIS SECTION AND

SHOWN ON THE MACHINE CAN CAUSE INJURIES OR DEATH TO THE STAFF AND

DAMAGES TO THE MACHINE AND IS A SERIOUS VIOLATION OF SAFETY RULES.

This section of this INSTRUCTION AND OPERATING MANUAL describes the dangerous

procedures or situations that could cause damages to things and/or people and what the

operator must do to avoid them.

• The operator must always work professionally, observing all the safety rules, taking care

not to underestimate their own responsibility towards themselves and all the things and

people around them.

• Before starting work it is essential that the operator makes sure the safety devices are in

perfect conditions, that they make the necessary checks on the machine and become fami-

liar with the ground conditions where they must manoeuvre and stabilise.

• When working it is essential that one specialised person with knowledge of the use of the

machine and the contents of this INSTRUCTION AND OPERATING MANUAL stays on

the ground.

• It is absolutely forbidden to do any alterations to the machine without any prior written

authorisation from HINOWA SPA as this could damage its functioning and its safety.

HINOWA SPA declines any responsibility for injury or damage caused by such beha-

viour.

Clothing and protective wear

Avoid wearing loose clothes, rings, watches or anything that

could get entangled inside the rotating parts.

When operating the machine or doing maintenance jobs,

wear a helmet, safety glasses and safety shoes, gloves and

noise protection earmuffs after checking their integrity.

Wear the homologated and certified safety belt

Before operating at height it is necessary to correctly wear the safety belts and to fasten them

to the anchorages of the basket.

The use of the safety belts is compulsory in connection with the local regulatins of every sin-

gle State. In those States where the law does not require the use of holding systems, the choi-

ce is of the employer or/and user.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

12

IMPORTANT

WARNING

13

Safety valves

Never alter and/or tamper with the safety valves and the controls in the main hydraulic

system. HINOWA SPA declines any responsibility for damages to people, things or the

machine when the hydraulic valve standard gauging has been tampered with.

Fire prevention

Keep the engine compartment clean. Remove any pieces of

wood, paper and other flammable products; clean properly

any fuel leaks as they can be potential fire risks.

Petrol is extremely flammable and explosive under certain

conditions. Refuel in a well-ventilated place and when the

engine is off.

Never smoke or cause sparks in the refuelling place or the fuel

storage place.

After refuelling, make sure that the cap is closed safely and

properly.

Take care not to touch the exhaust pipe when it is hot, as it remains hot during the working

of the machine and also after turning off the engine.

Preventing damages caused by washing the machine

When washing the machine do not direct high- pressure jets

onto the electric components. Do not use chemical or petrol

detergents that could cause serious damages to the plastic

components and the paint.

Preventing damages when the machine is at work.

When the machine has been stabilized and starts working, avoid entering in its working

range.

Manoeuvre systematically the controls slowly and regularly. Do not invert movements sharply.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

2.3 SAFETY ADVICE

2.3.1 GENERAL ADVICE

To avoid accidents, before starting work and before doing any

operations of maintenance, read, understand and follow all

the warnings and instructions given in this manual. The

machine operator/user cannot be held responsible if they have

not read this manual and learnt how to manoeuvre the machi-

ne under the supervision of a qualified operator.

Carefully read all the safety warnings in this manual and the

safety signs on your machine.

Keep the safety signs in proper order and replace them when

they are damaged.

Make sure that the new components on the machine have the proper safety signs.

2.3.2 PICTOGRAMS SITUATED ON THE MACHINE

You will find below the description, meaning and location of all the warning, indication and

instruction stickers placed on the machine.

1) Description:

WARNING! READ THE INSTRUCTION AND MAIN-

TENANCE MANUAL BEFORE USING THE MACHI-

NE AND APPROACH THE ELECTRIC COMPONENT

COMPARTMENT.

Location on the machine:

- on the electric component case

- on the basket.

2) Description:

WARNING: KEEP AT SAFETY DISTANCE FROM THE MACHINE.

Location on the machine:

- on the basket

- on the second transmission.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

14

15

3) Description:

WARNING! DANGER OF CRUSHING LOWER LIMBS.

Location on the machine:

- on the stabilisers

- on the crawler.

4) Description:

WARNING! OBJECTS FALLING.

Location on the machine:

- on the basket.

5) Description:

MACHINE FIXING POINTS FOR TRANSPORT.

Location on the machine:

- on fixing points.

6) Description:

FASTEN SEAT BELT.

Location on the machine:

- on the basket.

7) Description:

USE PERSONAL PROTECTION DEVICES.

Location on the machine:

- on the basket.

8) Description:

NEVER DO MAINTENANCE WHEN THE MACHINE IS IN THE

REST POSITION.

Location on the machine:

- on the basket.

9) Description:

NEVER FIX LADDERS, TOOLS OR OTHERS TO THE CONTROL

CAR OF THE PLATFORM TO INCREASE WORKING OUTPUT.

Location on the machine:

- on the basket.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

10) Description:

NEVER WORK NEAR ELECTRIC CABLES (Par. 2.7.1).

Location on the machine:

- on the basket.

11) Description:

NEVER USE THE WORKING PLATFORM AS A LIFT.

Location on the machine:

- on the basket.

12) Description:

WEAR THE PROTECTIVE GLOVES

Location on the machine:

- on the basket.

13) Description:

WEAR SAFETY SHOES

Location on the machine:

- on the basket.

14) Description:

WARNING! 230V.

Location on the machine:

- on the electric differential switch box.

15) Description:

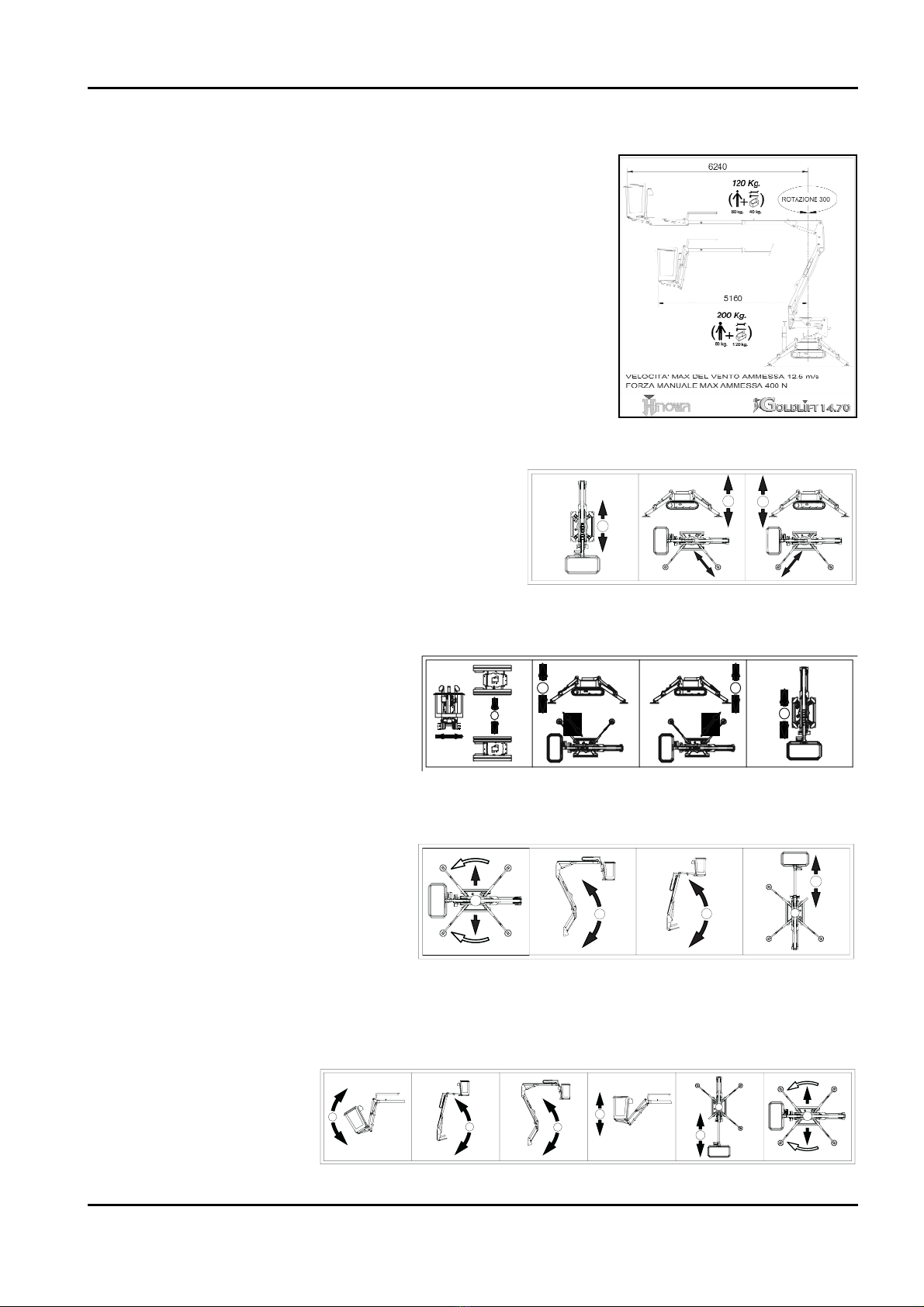

GOLDLIFT 14.70 MAX. LOADS AND ARM RANGES

WITH SINGLE-SEATER BASKET

Location on the machine:

- on the basket.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

16

17

16) Description:

GOLDLIFT 14.70 MAX LOADS AND ARM RANGES

WITH SINGLE-SEATER BASKET (OPTION)

Location on the machine:

- on the basket.

17) Description:

TRANSLATION DISTRIBUTOR CONTROL FUNCTIONS.

Location on the machine:

- near the translation controls.

18) Description:

TRANSLATION DISTRIBUTOR CONTROL FUNCTIONS.

Location on the machine:

- near the translation controls.

19) Description:

DISTRIBUTOR GROUND CONTROL FUNCTIONS OF THE OVERHEAD PART.

Location on the machine:

- near the ground platform con-

trols.

20) Description:

DISTRIBUTOR CONTROL FUNCTIONS OVERHEAD PART ON BASKET GOLDLIFT 14.70.

Location on the machine:

- near the overhead

part controls on the

basket.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

BB BB

21) Description:

OVERHEAD PART GROUND CONTROL SWITCH FROM BASKET.

Location on the machine:

- near the overhead part ground control switch from

basket .

22) Description:

HAND PUMP SWITCH.

Location on the machine:

- near hand pump switch.

23) Description:

GROUND REACTION AND PRESSURE CAUSED BY

THE WEIGHT OF THE MACHINE ON RESTING SURFA-

CES.

Location on the machine:

- on the rubber crawler.

24) Description:

MAXIMUM REACTION AND MAXIMUM PRESSURE INDUCTED

BY ONE STABILISER WITH CAP Diam.300 PLACED ON THE

GROUND.

Location on the machine:

- on the stabiliser.

25) Description:

WARNING: DANGER OF INJURING UPPER LIMBS.

Location on the machine:

- in front of the distributor of the overhead part ground control

and in front of the control place on the basket.

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

18

19

26) Description:

RESPECT THE GREASING INTERVARS OF THE INDICATED

PARTS (see page 67-78).

Position on the machine:

- on the thermic engine protection in correspondence with the grease

cup of the slew ring.

27) Description:

TRANSLATION STICKER: It is absolutely forbidden to use

the machine from a different position of the control on the

basket.

Position on the machine:

- Distributor support.

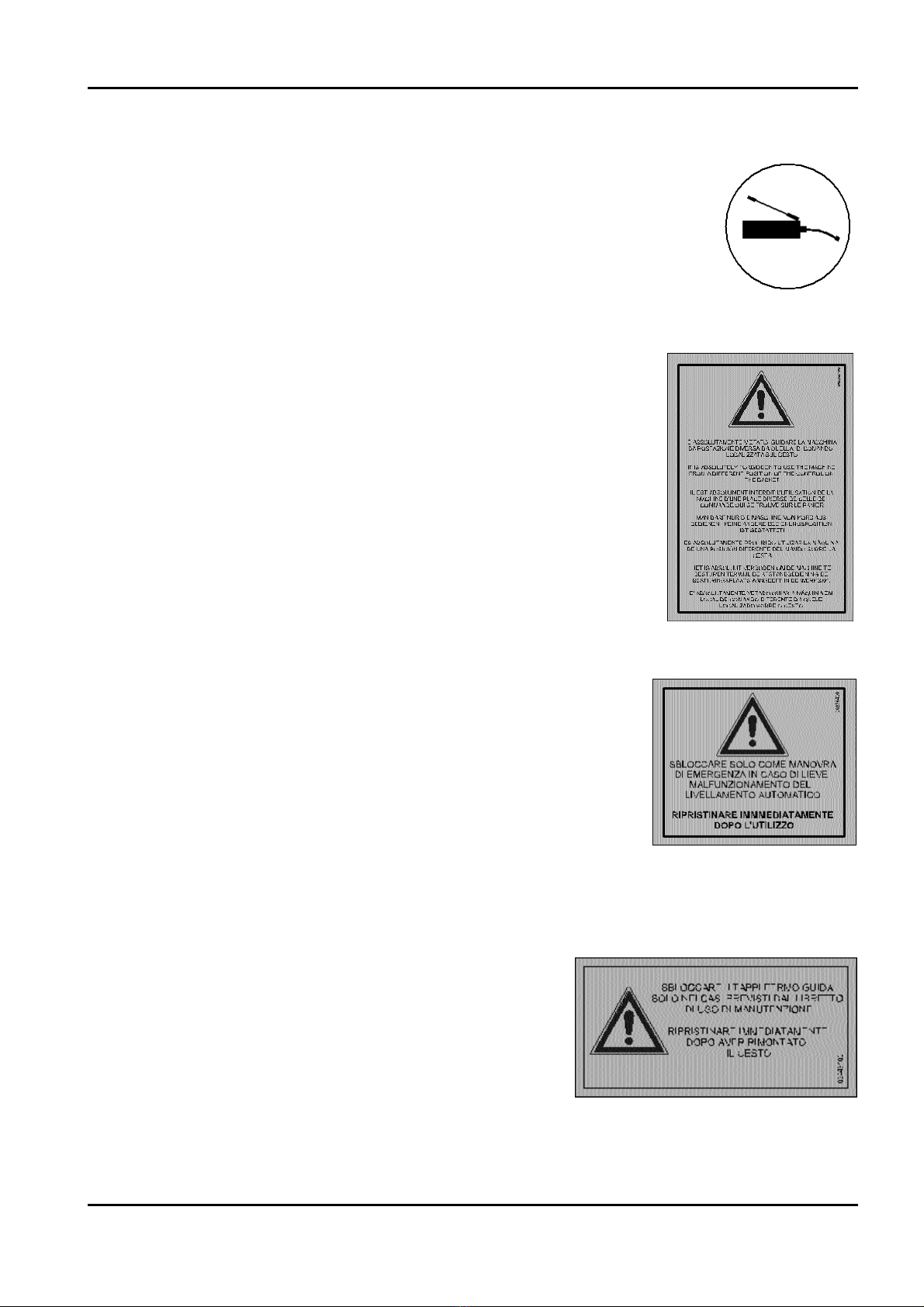

28) Description:

STICKER FOR THE CAGE LEVELLING LOCK

Release only in case of emergency, if the automatic

levelling function does not work correctly; after use,

restore immediately.

Location on the machine:

- overhead part distributor support.

29) Description:

STICKER FOR THE LOCKING OF THE CAGE GUIDE RETAINER CAPS

Release only in the cases specified in the operation

and maintenance manual; after reinstalling the

cage, put back the caps immediately.

Location on the machine:

- cage guide retainer caps

- cage support slide

SELF-PROPELLED TRACKED PLATFORM GOLDLIFT 14.70

HINOWA

Table of contents

Other Hinowa Lifting System manuals