SS7081C961-00

Contents

Introduction........................................................................................................................................................ 1

Confirming Package Contents ......................................................................................................................... 1

Safety Information ............................................................................................................................................. 2

Usage Notes ....................................................................................................................................................... 3

1 Overview ..................................................................................................................................................... 5

1.1 Overview ..................................................................................................................................................... 5

1.2 Features ...................................................................................................................................................... 5

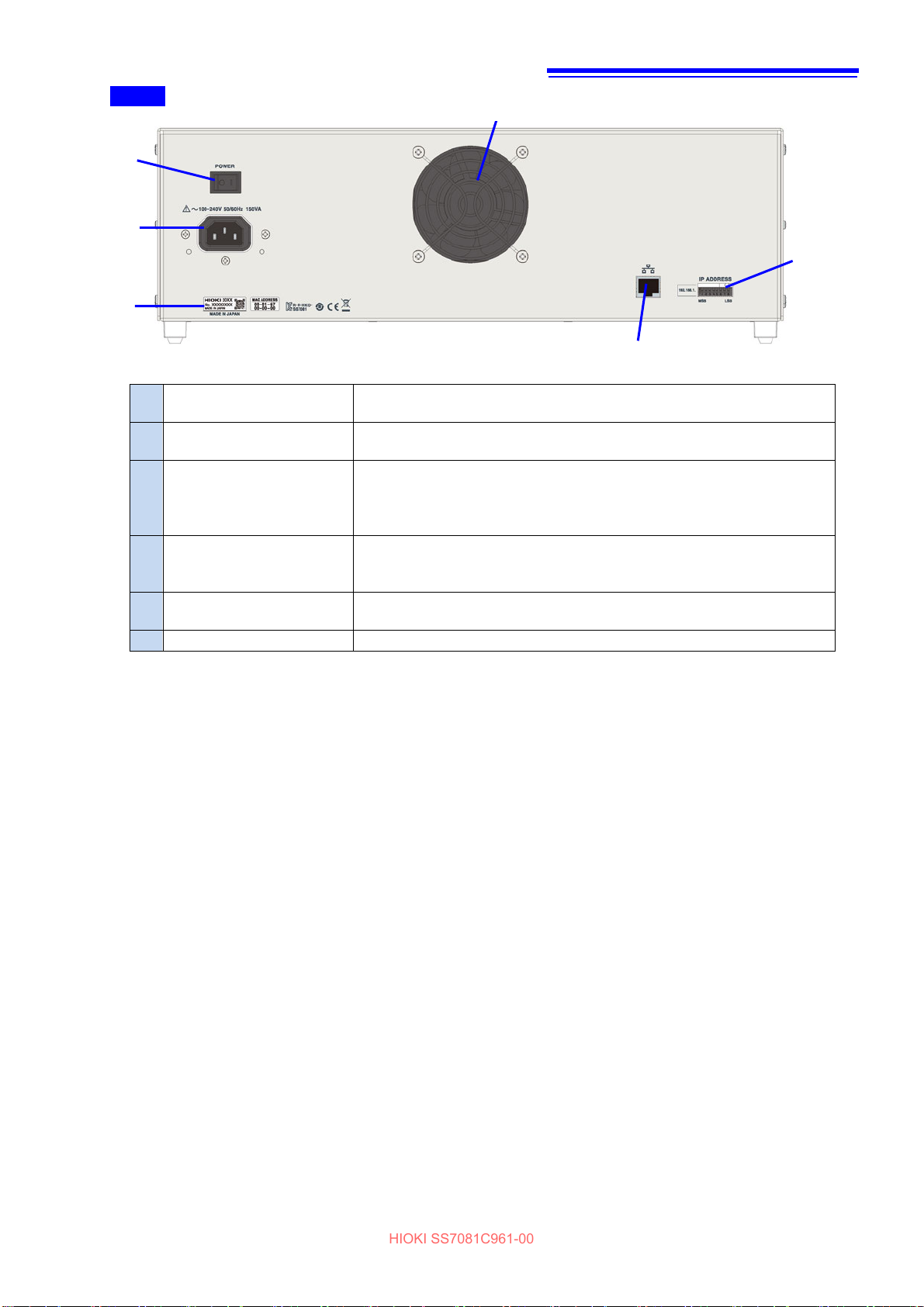

1.3 Name and Function of Each Part ............................................................................................................. 6

1.4 Lamp Display.............................................................................................................................................. 8

Channel status display.................................................................................................................................. 8

Other (error display) ...................................................................................................................................... 8

1.5 Control Methods ........................................................................................................................................ 9

2 Preparations ............................................................................................................................................. 11

2.1 Preparation Process ................................................................................................................................ 11

2.2 Connecting the Power Cord.................................................................................................................... 11

2.3 Connecting the Output Cable ................................................................................................................. 12

Connecting wires to the terminal block..................................................................................................... 12

Connecting channels .................................................................................................................................. 13

Connecting multiple instruments............................................................................................................... 14

2.4 Setting the IP Address............................................................................................................................. 15

2.5 Connecting the LAN Cable...................................................................................................................... 16

2.6 Turning the Instrument On and Off ........................................................................................................ 17

3 Generation and Measurement................................................................................................................. 19

3.1 Voltage Outputs........................................................................................................................................ 19

Output constant voltage ............................................................................................................................. 19

Changing the output voltage at high-speed (memory output function) ................................................ 20

3.2 Switching Output Terminals ................................................................................................................... 21

Output terminals for each channel ............................................................................................................ 21

Output expansion terminal (CHAIN terminal) ........................................................................................... 23

3.3 Voltage and Current Measurements ...................................................................................................... 24

Switching the current measurement range............................................................................................... 24

Acquiring stable measured values (smoothing function) ....................................................................... 25

Saving, collating, and acquiring measured values (logging function) .................................................. 26

4 Error Detection Function......................................................................................................................... 27

Overcurrent error ......................................................................................................................................... 27

Output voltage error .................................................................................................................................... 27

Abnormal temperature inside the case ..................................................................................................... 28

5 Communication Command ..................................................................................................................... 29

5.1Commands Overview .............................................................................................................................. 29

Message format............................................................................................................................................ 29

Output queue and input buffer ................................................................................................................... 32

Status byte registers ................................................................................................................................... 32

Event registers ............................................................................................................................................. 33

Communications errors .............................................................................................................................. 36