HIOS PG Series User manual

Brushless Screwdriver with Built-in Torque Sensor

PG Series

PG-3000 / PG-5000 / PG-7000

Control Unit

PG-01

User's Manual

ET-A034 22A

Table of Contents

03 Important Safety Instructions

04 Checking Supplied Accessories

05 Setting Up the Device

■Connect the Cords

■Install the Bit

Remove the Bit

■Turn On the Power

06 Parts and Their Functions

■PG-3000/PG-5000/PG-7000

■PG-01

09 Start and Stop

■Start the Screwdriver

■Stop the Screwdriver

09 Adjust Torque

■Reference Table of Output Torque

10 Set Learning Values (Teaching)

■About Learning Values

11 Evaluation of Screw Tightening

■OK/NG Judgment of Tightening Torque Value

■Evaluation of Operation Time

■Flowchart of Judgment

14 Connect the ScrewDriver to PC

■Check the Port

In Case of Windows 10

■Data Output Format by Either RS-232C or USB Connection

Error-related Output

Measurement Judgment Output

■PC Input

Hyper terminal (Example: Windows XP)

Example of a Measurement OK Message

Abnormal Conditions

■Data Taking-in Sheet (HIOS-PG-0611-V2-2_5)

Operating Environment

Conguration of the Screen

Other Sheet

■Collection of Screwdriver Data (Application)

20 Troubleshooting

21 After-sales Service

21 Specications

■External Dimension Drawing

■Specications of PG-01

03

Installation

◦Do not install the device at the places described

below. Otherwise, it may cause a re or a failure.

A place of high humidity or with a lot of dust

・A place where it becomes high temperatures

・A place of re

・A place of direct sunshine

・A place containing corrosive gas in the air

・Unstable place

◦Do not use the device where the ambient

temperatures are out of the range of 5 to 40 °C.

Power Supply

◦Be sure to install an earth leakage breaker and a

safety breaker on the commercial power source

before using it.

◦Connect the earth wire to the earth wire

terminal of the outlet. You may have an electric

shock without the earth wire connection in case

of an electric leakage.

◦Avoid the octopus foot wiring and use of an

extension cord. Otherwise, it may cause a re or

an electric shock.

◦Do not connect anything other than specied to

the connection part of this device. Otherwise, it

may cause an electric shock or a failure.

Handling

◦Do not wear clothes with ippers on the cus,

gloves, neckties etc. Otherwise, they may get

caught in the rotating screwdriver and cause an

injury or a failure.

◦Wear suitable clothing and protective eye-wear

for work. Cover long hair with a hat etc. so that

you can work safely.

◦Turn o power when you leave the workplace,

or when you attach / remove a bit / an optional

item.

◦If static electricity is charged, you need to

neutralize it before use.

◦Avoid an unstable place or an unreasonable

posture for work. Otherwise, it may cause an

injury.

◦Long-time work or some types of work may

cause strain on your hands, neck, arms or waist,

causing an injury. Avoid long-time work and take

a break regularly.

◦We recommend use of a balancer to prevent the

device from falling and to protect cords / wires.

◦Hold the plug when you attach / remove the

power cord, screwdriver and so on.

◦Protect cords / wires by not giving damages to

them; not remodeling them; not pulling them;

not bending them forcibly; etc. Also, do not

place heavy items on the power cord.

Otherwise, it may cause a re or an electric

shock.

◦If you detect an uneven rotation, strange noises,

overheating or activation of a breaker, etc., stop

using the device immediately and have it

repaired. However, note that the device may be

overheated depending on the frequency of the

workpiece or screw types. As a countermeasure,

prepare spare screwdrivers of the same model

to extend the tact time and use them alternately,

or review the selection of screwdriver models.

◦Do not overload the device so much that it

cannot clutch. Otherwise, it may cause a failure

of the motor.

◦Do not touch the screwdriver while it is rotating.

Otherwise, it may cause an injury or a failure.

◦Keep your hands and face away from the

rotating section while in use. Otherwise, it may

cause an injury.

◦Remove the bit from the screwdriver when you

Important Safety Instructions

Please read this manual and the power supply unit manual carefully before use to ensure proper operation. In

addition, do not use the product in the way not described in this manual. Please note that we are not responsible

for any problems caused by using the product in a manner that does not conform to the contents of this manual,

using it improperly, or repairing / modifying by a third party except by us or someone specied by us.

04

Checking Supplied Accessories

If an item is missing or damaged, contact the store where you purchased the product.

◦Screwdriver

◦Bit

◦Screwdriver Cord (2m)

◦Sensor Cord (1.7m)

◦PG-01

◦AC Adapter

◦RS-232C Cable

◦USB to RS-232 Conversion Cable*

◦Manual

◦User Software CD-ROM

* Please download and install the device driver for the USB to RS-232 conversion cable from the ATEN

website.

are not working.

◦If you cannot attach / remove the bit in the way

described in this document, please make

contact with our service section.

◦Fix the workpiece with jig / clump while in

working.

◦Do not use the switch lever as a hanger.

Otherwise, it may cause an accident or an injury.

◦Do not give a strong impact or excessive force.

Otherwise, it may cause a failure.

◦Do not operate the screwdriver with wet or oiled

hands.

◦Do not operate the FOR / REV switch before the

screwdriver completely stops. Otherwise, it may

cause a failure.

◦Do not disassemble / remodel this device.

Otherwise, it may cause a failure.

◦High torque has a large recoil on the hand or

arm. Hold the driver rmly to avoid being swung

around.

Maintenance and Inspections

◦Turn o power and remove the power plug from

the outlet when the device is not in use for a

long time.

◦Remove the accessories from the screwdriver

and store them in the package box when it is

not in use them for a long time.

◦Inspect the device regularly to conrm there are

no damages. If you use it with damages, it may

cause a re or an electric shock.

◦When you clean the device, turn o the power

and remove the power plug from the outlet.

Otherwise, it may cause a re or an electric

shock.

◦Use dry cloth to wipe of dust or stains. The dust

may absorb moisture to allow current to ow,

causing a re.

◦Store the device in a place where the

appropriate temperatures and humidity are

controlled.

◦Do not store the device in an unstable place or a

place with vibrations. Otherwise, it may cause a

failure.

◦Keep the device out of reach of anyone but

people involved in the workpiece.

◦We recommend genuine HIOS parts for

replacement.

05

Setting Up the Device

■Connect the Cords

Connect all the attached cords.

After all cords are successfully connected, put the power plug into an outlet.

CAUTION

◦Make sure the combination of the screwdriver and the power supply is appropriate.

◦Make sure the power is o.

❶Connect the plug and screwdriver cord to the power supply.

❷

Connect the screwdriver and sensor cords to the screwdriver and connect the sensor cord to

PG-01.

❸Connect the AC adapter to PG-01.

■Install the Bit

CAUTION

◦Do not install or remove the bit with the power on. It may cause an accident.

❶Insert the bit while pushing the joint shaft collar into the body.

❷Release the collar and check if the bit is locked.

◦Pull the bit gently to conrm it does not come out.

Remove the Bit

❶Pull out the bit while pushing the collar against the body.

■Turn On the Power

❶Turn on T-70BL and PG-01.

CAUTION

PG-01 automatically performs zero-adjustment when the power is turned on. Do not apply a load to

the tip of the screwdriver or do not start the screwdriver during the adjustment.

06

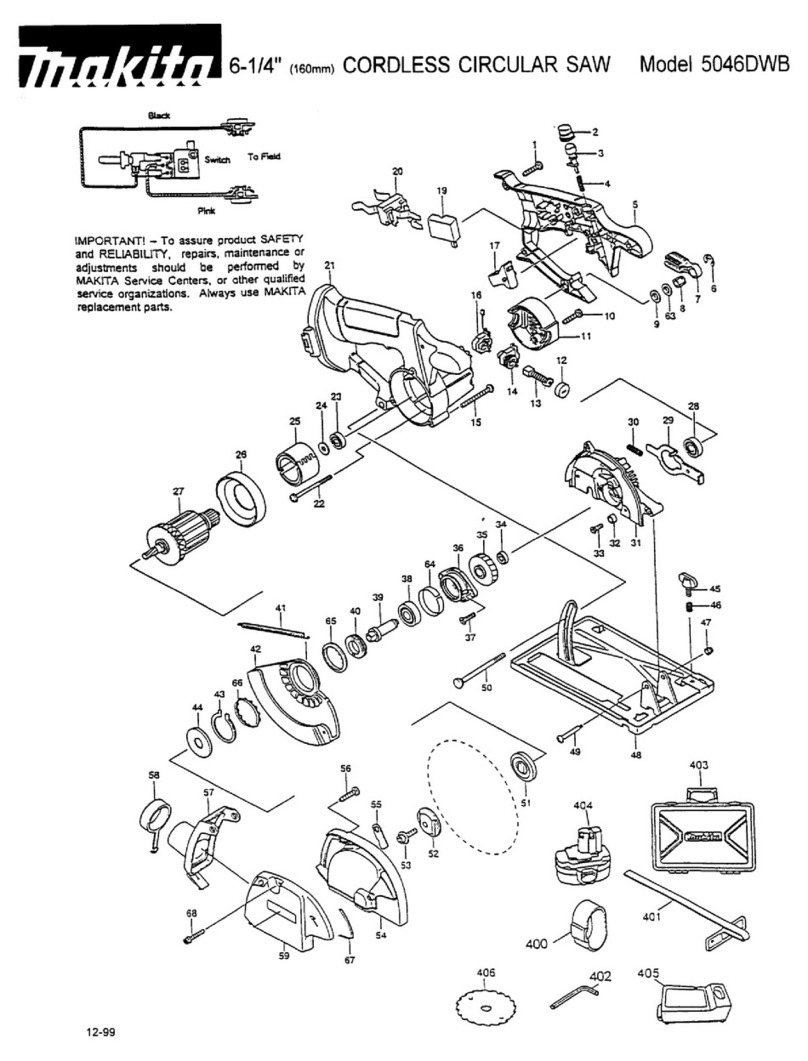

Parts and Their Functions

■PG-3000/PG-5000/PG-7000

❶ ❽❼❻❸❷ ❹ ❺

❶ ❽ ❼❻❸❷ ❹ ❺

❶ ❽❼❻❸❷ ❹ ❺

❶Joint shaft collar

Operate the collar to install or remove the bit.

❷Nut protection cover

This protects the torque adjustment nut. Turn it counterclockwise for removal.

❸Torque adjustment nut

Use this for adjustment of the output torque.

❹Switch lever

Start the screwdriver with the lever.

❺Forward / reverse switch

You can switch the screwdriver’s rotational direction.

: Clockwise

OFF: no rotation(PG-5000/PG-7000)

: Counterclockwise

❻Screwdriver cord connector

To connect the screwdriver cord.

❼Hanger

To hang the screwdriver on the balancer or like.

❽Sensor cord connector

To connect the sensor cord.

PG-3000

PG-5000

PG-7000

07

■PG-01

The measurement result of tightening a screw will be informed by the indicator and sound.

Control Unit

❶

❽ ❼ ❻❾❿⓫

❸❷ ❹ ❺

⓬ ⓭

⓮⓯

❶L.NG Indicator

This indicator is lit when the measured value is no good (smaller than the minimum pass value).

❷L.G Indicator

This indicator is lit when the measured value is good (larger than the minimum pass value and below

the minimum learning value).

❸GOOD Indicator

This indicator is lit when the measured value is good (larger than the minimum learning value and

smaller than the maximum learning value).

❹H.G Indicator

This indicator is lit when the measured value is good (larger than the maximum learning value and

below the maximum pass value).

❺H.NG Indicator

This indicator is lit when the measured value is no good (larger than the maximum pass value).

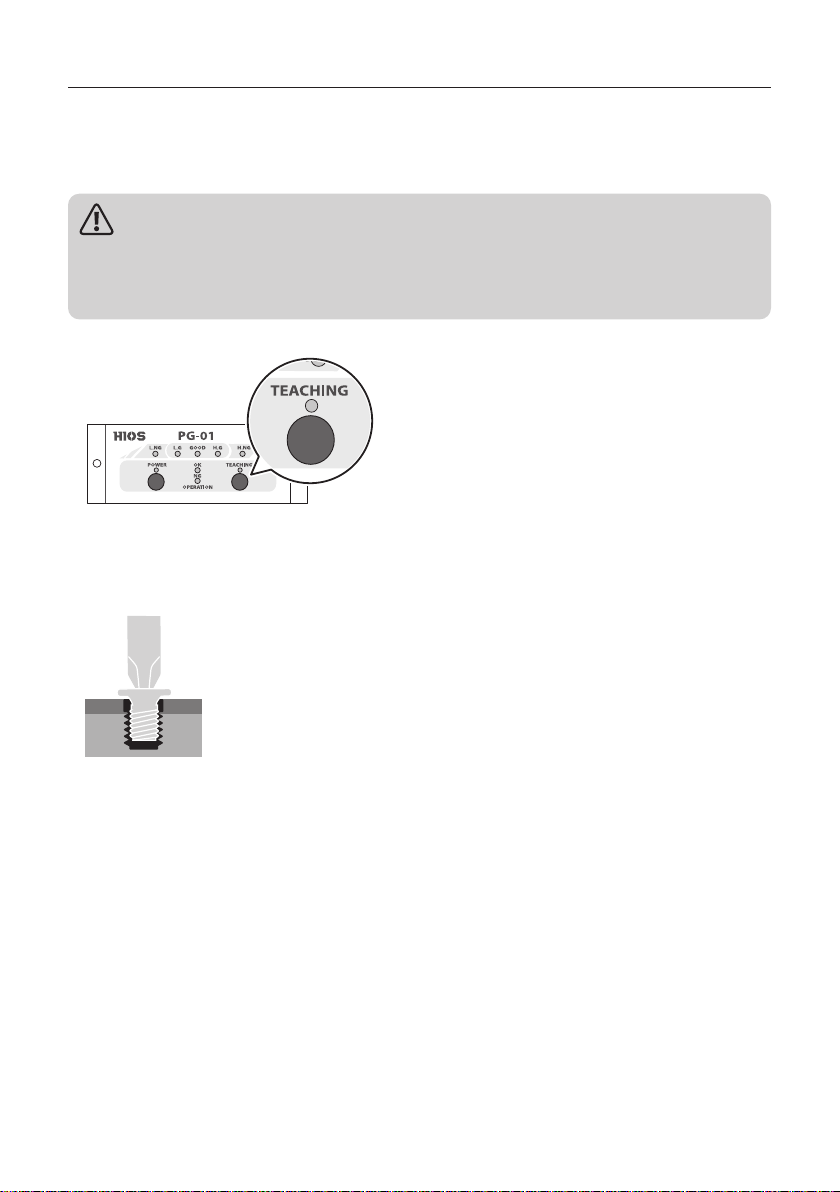

❻Teaching Indicator

This indicator is lit when in the teaching mode (for setting of learning values).

❼Teaching Button

This is for setting to the teaching mode. Pressing and holding this button (2 seconds or longer) in the

teaching mode will cancel the mode. For details of teaching, refer to "Set Learning Values (Teaching)"

(P.10).

Back Side

Front Side

08

❽OPERATION OK Indicator

This indicator is lit while the screwdriver is rotating positively.

❾OPERATION NG Indicator

This indicator is lit when the operation ends without torque up. This blinks when the operation ends

due to an abnormal measurement time.

❿Power Button

This switch turns power on and o. Press and hold the button for 2 seconds to turn o the power.

⓫Power Indicator

This indicator is lit when power is supplied.

⓬Sensor Cord Connector

This is used to connect the sensor cord.

⓭I/O Connector

The I/O at cable is connected here for the evaluation result to be output. The output format is an open

collector. Use this when you cannot connect with RS-232C.

111

1919

19

22

2202020

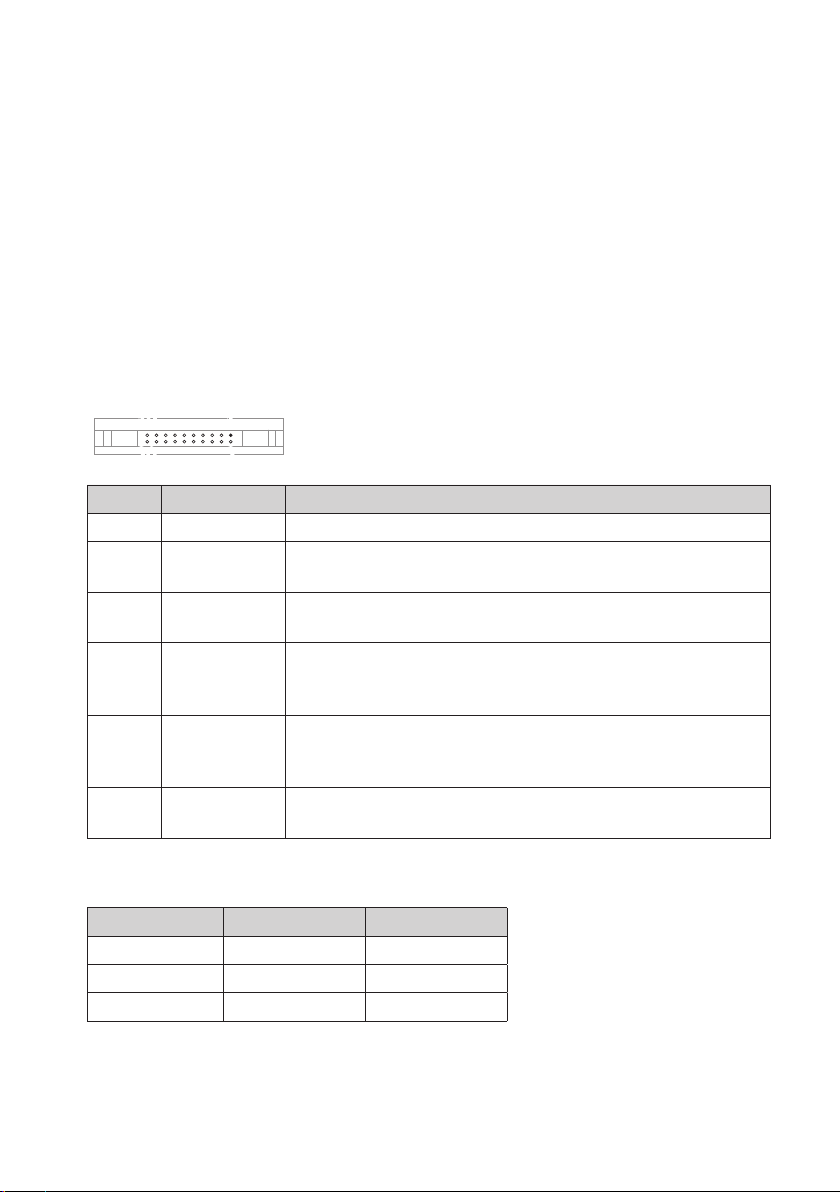

PIN No. Output signal Description

12 COM GND —

13 L.NG (NG) Output when the measurement value is NG (below the minimum pass

value)

14 L.G (OK) Output when the measurement value is OK (equal to or larger than the

minimum pass value and smaller than the minimum learning value)

15 GOOD (OK)

Output when the measurement value is OK (equal to or larger than the

minimum learning value and smaller than the maximum learning

value)

16 H.G (OK)

Output when the measurement value is good (equal to or larger than

the minimum learning value and smaller than the maximum learning

value)

17 H.NG (NG) Output when the measurement value is no good (larger than the

maximum pass value).

⓮RS-232C Connector

An RS-232C cable is connected here.

PIN No. Signal name I/O

2 RXD OUT

3 TXD IN

5 GND

⓯AC Adaptor Connector

An AC adaptor is connected here. Power will be automatically supplied when an AC adaptor is

connected.

09

Start and Stop

■Start the Screwdriver

❶Pull the switch lever to start the bit turning. Release it to stop turning.

■Stop the Screwdriver

❶When the set torque is reached, the clutch in the screwdriver works to stop turning.

Adjust Torque

CAUTION

The "reference table of output torque" and the torque adjustment scale are approximate and do not

guarantee actual setting values.

For accurate torque check, please use an HIOS torque meter and Fidaptor.

❶If the torque is determined beforehand, turn the torque adjustment nut and nut xing ring

referring to the "reference table of output torque".

◦Turn the torque adjustment nut clockwise to increase the torque and turn

it counterclockwise to decrease the torque.

◦Adjust it so that the end face of the nut xing ring is right above the scale.

◦After the nut xing ring is positioned, t the torque adjustment nut

accordingly.

❷Try to fasten a screw and check how it is fastened after the screwdriver stops and adjust the most

appropriate torque.

■Reference Table of Output Torque

PG-3000PG-3000

Torque Scale

1

0.3

0.2

0.5

0.55

0.4

N·m

2345678

PG-5000PG-5000

Torque Scale

1

0.4

0.6

1.0

0.8

1.2 N·m

2345678

PG-7000PG-7000

Torque Scale

1.0

1.4

1.2

1.6

2.0

1.8

2.6

2.2

2.4

2.8 N·m

21 3 4 5 6 7 8 9 10

10

Set Learning Values (Teaching)

Measure the "tightening torque" and "working time" by using screws and materials actually used to set

the reference values for work. The two values recorded are the minimum and maximum, respectively.

Also, after teaching, it is possible to change the error tolerance of the learning values and the learned

values in the attached application or Excel le.

CAUTION

Teaching should be done under the same conditions as actual operation.

An error may occur in the measured value if the screw to be used, the materials to be fastened, the

attaching method of the screw, etc., are different from actual operation.

❶Press and hold the teaching button.

Control Unit

◦A buzzer sounds in about 2 seconds and the teaching mode is enabled.

◦The teaching indicator is lit.

◦L.NG indicator and H.NG indicator blinks.

❷Using the screws and materials to be actually used, perform tightening more than 3 times.

◦Every time after tightening is completed, a buzzer sounds once, and the measured value is recorded.

◦

The measured values of the third to tenth trials are recorded and the values after the eleventh trial

will overwrite the old values.

❸Press and hold the teaching button.

◦A buzzer sounds in about 2 seconds and the teaching mode ends.

◦The teaching indicator, L.NG indicator and H.NG indicator turn o.

■About Learning Values

◦The learned values do not disappear even when the power is turned o.

◦To reset the learned values, perform teaching again. The previous learned values will be deleted when

the teaching mode is enabled.

◦After purchasing, please perform teaching with PG-01 for the rst time. Otherwise, it is not possible to

set learning values with the attached application.

11

Evaluation of Screw Tightening

◦

It measures actual screw tightening work in real time, compares the measurement with the learning

value, and informs the user of the evaluation result with a indicator and sound.

◦The reverse rotation of the screwdriver is not evaluated.

◦The allowable error range at the time of purchase is set to 10% for both upper and lower limits. If you

want to change it, please use the attached application.

■OK/NG Judgment of Tightening Torque Value

If no error is detected in the screw tightening work, one of L.G, GOOD or H.G indicator is lit and the buzzer

sounds.

NG NGOK

Learning

value

Allowable error range

Lower limit value

Allowable error range

Upper limit value

Threshold valueThreshold value

If the torque is within the learning values, the GOOD indicator will be lit, and if it falls within the allowable

error range, either L.G or H.G indicator will be lit. Conversely, when the torque is less than the lower limit

value, the L.NG indicator will be lit, and when the torque exceeds the upper limit value, the H.NG indicator

will be lit, which means fail.

12

■Evaluation of Operation Time

◦

The operation time from start of rotation to stop of the screwdriver is evaluated against the learning

values.

◦

The blinking and lighting of the OPERATION NG indicator will turn o when the START signal is entered

again.

Control Unit

Main reasons why OPERATION NG indicator is lit

◦No torque up signal is sent because of reasons like screwdriver idling.

Main reasons why OPERATION NG indicator blinks

◦

A torque up signal was not sent during the learning measurement period.

If it is not necessary to strictly measure the operation time, by using the application, change the setting

value so that the learning interval will become larger.

◦Continuous ON/OFF operations at the end of tightening (pushing the button twice or three times in a

row)

CAUTION

There is a nonintervention time of 100mS for torque measurement and evaluation after the START is input.

Nonintervention time of 100mS

If the screwdriver output is given to a screw even after tightening, the value will be larger than the

measuring value and not the expected tightening value.

To perform proper screw tightening, please do not perform continuous operations.

13

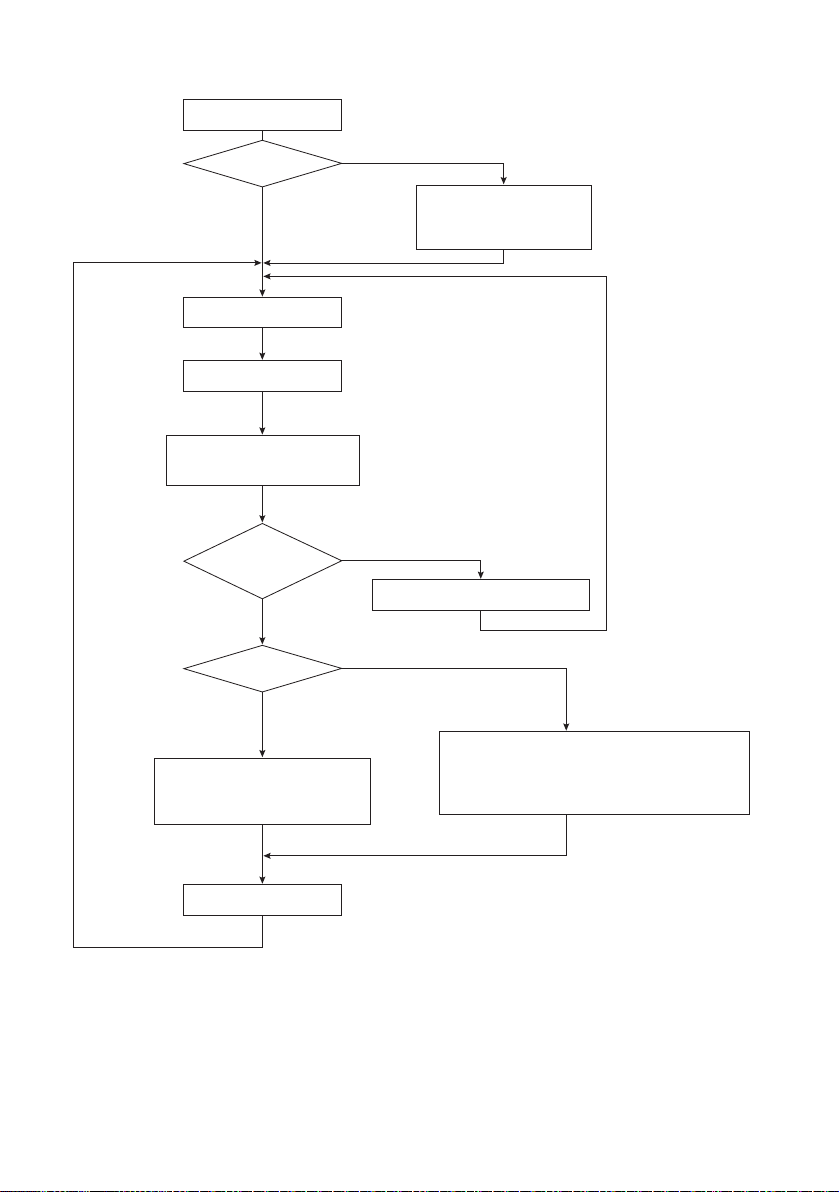

■Flowchart of Judgment

Evaluation

End of tightening

(Torque up signal)

Power ON

Select an operation

Normal operations

Set the judgment value (TEACHING)

Set the evaluated value

TEACHING LED is lit (red)

L.NG & H.NG LED blinks (red)

L.NG, and H.NG blinks

if no teaching value is set.

The set value can be

changed later from the

tabulation software on the

connected PC.

Initial resetting of PG-01

No torque up signal

NG

OK

Tightening ON

LED OFF at completion

OPERATION NG LED ON (red)

OPERATION OK LED ON (green)

One beep

L.G, GOOD or H.G LED ON (green)

One beep

Signal output

L.NG LED or H.NG LED ON (red)

If measurement time is NG, OPERATION NG LED blinks (red)

Two beeps

Signal output

End

14

Connect the ScrewDriver to PC

❶Connect the RS-232C cable to PG-01.

❷Connect the USB to RS-232C conversion cable to the RS-232C cable.

❸Connect the USB to RS-232C conversion cable to PC.

❹Download the device driver from the ATEN website and install it on PC.

Check the website for how to install and supported OSs.

https://www.aten.com/global/en/products/usb-peripherals/usb-converters/uc232a/

❺Turn on PG-01.

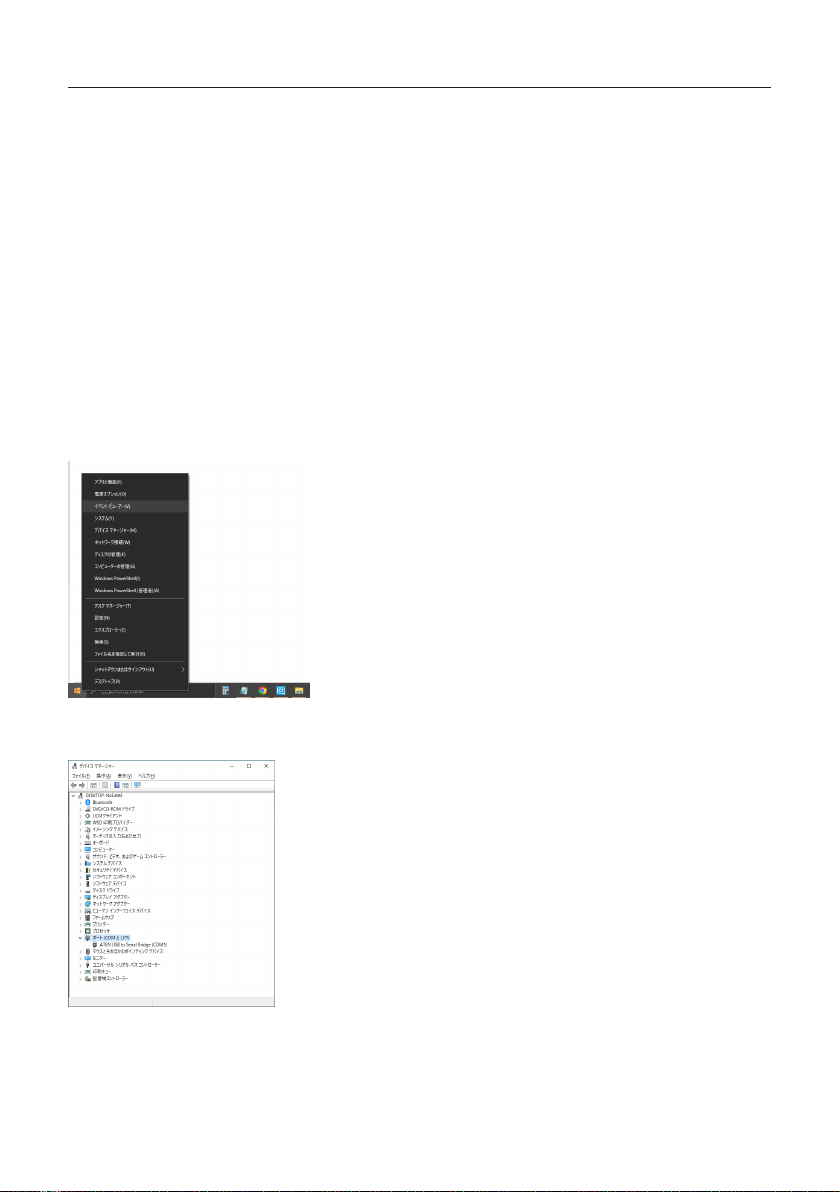

■Check the Port

Open the device manager to check which port PG-01 is connected to.

In Case of Windows 10

❶Right-click the Start button and select Device Manager.

❷Click the port (COM and LPT) in the list and check COM number displayed in <ATEN USB to Serial

Bridge (COMXX)>.

15

■Data Output Format by Either RS-232C or USB Connection

The data for judgment is output for each measurement in the three formats in the sequence below.

・Measurement Data

D10 XXXX XXXXX<LF>

❶ ❷

❶Torque conversion value – 4 digits

❷Measurement time – 5 digits (unit: mS)

・Recorded Learning Value

D00 XXXX XXXX XXXX XXXXX XXXXX<LF>

❸ ❹ ❺ ❻ ❼

❸Display learning number

❹Display learning minimum value

❺Display minimum learning measurement time

❻Display learning maximum value

❼Display maximum learning measurement time

・Judgment reference values

❽ ❾ ❿ ⓫ ⓬

D20 XX XXXX XXXX XXXXX XXXXX<LF>

❽Judgment error rate

❾Judgment minimum value

❿Judgment measurement time minimum value

⓫Judgment maximum value

⓬Judgment measurement time maximum value

Error-related Output

E90 End which cannot be detected by 0 areas, and judged [Zero area detection/Impossible

judgment ending]

E91 Abnormal termination at measurement time [The abnormally end at the

measurement time]

E92 Study shortage and end which cannot be judged

[The ending about which it is

impossible to judge by the

learning

lack]

E93 Judgment=LOW NG [Judgment = Low NG]

E94 Judgment=HIGH NG [Judgment = High NG]

Measurement Judgment Output

E00 Judgment=GOOD [Judgment = Good]

E01 Judgment=LOW OK [Judgment = Low OK]

E02 Judgment=HIGH OK [Judgment = High OK]

16

■PC Input

Hyper terminal (Example: Windows XP)

After the PC is turned on and the version information is displayed, auto-zero correction is performed. The

following messages for debugging are displayed that are not directly related to measurement.

Ver3.04 2022/05/25

[Zero Adj A/D=7C2 G=1EA F=200]

[Zero Adj A/D=806 G=1EB F=200]

[Zero Adj A/D=808 G=1EC F=200]

[Zero Adj A/D=803 G=1ED F=200]

[Zero Adjustment end A/D=7FF Gain=1ED]

Example of a Measurement OK Message

In general, messages are either operation check messages or measurement data.

[Job Num = 4]

S00

[Lever SW ON]

[Job Num = 6]

S02

[Torque UP ON]

Operation check message for debugging

D10026900668

D000005026903150033701891

D2002026303210033001928

Measurement data

M21[Judgment=LOW OK]

E01

[Judgment end]

Operation check message for debugging

Abnormal Conditions

This displays the condition when judgment results are abnormal.

[Job Num = 4]

S00

[Lever SW ON]

[Job Num = 6]

S02

[Torque UP ON]

Operation check message for debugging

D10028600590

D000006009600010000101894

D2002140513090131201931

Measurement data

[Abnormal termination at measurement time]

E91 Operation check message for debugging

17

■Data Taking-in Sheet (HIOS-PG-0611-V2-2_5)

By using the data taking-in sheet in the attached CD-ROM, you can check the OK/NG of screw tightening

on the PC or record the measurement data.

CAUTION

◦Enable macros.

◦Start settings after turning on PG-01 and connecting it to the PC.

◦When using USB, the PC may turn o PG-01 automatically in some cases. In that case, please

disconnect and reconnect the screwdriver.

◦There is no reaction to the reverse rotation of the screwdriver.

◦If you want to take in two types of data, create two les (for example, test1.xls and test2.xls) in

advance. Then, start up two applications, and then open each le.

If you open les by double-clicking them in Windows Explorer, two les are opened in the same

application and the application cannot be used.

Operating Environment

The data taking-in sheet was conrmed to be eective in the following environments:

・Microsoft Windows XP

・Microsoft Excel 2003

If it is not functioning, select application type “screwdriver data collection”.

Please be aware that maintenance and support services are unavailable since this is sample software.

Conguration of the Screen

❶ ❷ ❸ ❹ ❺

❻

❼

❽

❾

❿

⓫

⓬

❶Connection confirmation window

18

The login information is displayed.

❷Disconnect button

This ends data import.

❸Connect button

This makes the data import standby. If the previous data is necessary, please save the current data rst

and then connect the screwdriver. (The previous data will be cleared upon connection.)

❹COM port

Check the port number and enter it. Then, press [Enter] on the keyboard. Usually, select COM as the

port.

Cell colors

・Gray: the screwdriver is not connected.

・Yellow: the screwdriver is connected.

❺LAN settings

Optional

❻Judge On/Off

Errors E90/E91/E92 can be turned ON/OFF.

ON: the measured values are entered in the datasheet.

OFF: the measured values are entered in the irregular sheet.

❼Measurement settings processing table

The table shows commands and settings processing that are displayed in the log.

❽Judgment

This indicates OK/NG of screw tightening with colors.

❾Output data

Torque equivalent value: this indicates values taken during actual operation.

Measurement time: this indicates the time from screw tightening to torque-up.

Number of the learning: indicates the number of teaching operations performed.

Minimum of the learning: indicates the minimum teaching value (modiable).

Maximum of the learning: indicates the maximum teaching value (modiable).

Measurement time of minimum: indicates the teaching minimum time (modiable).

Measurement time of maximum: indicates the teaching maximum time (modiable).

After inputting a number, press [Enter] on the keyboard.

・These learning-related values will be sent to PG-01 by clicking the [Write learn-value] button after

entering a number.

・If the [Learned value change] button is not pressed, the memory in PG-01 won’t be updated and the

previous value will be recovered after the next torque-up operation.

❿Judgment comparison data

Torque value: indicates the value output on the graph sheet.

Judgment minimum value: indicates the amount minus the % setting for the learning minimum value.

Judgment maximum value: indicates the amount plus the % setting for the learning maximum value.

Meas. Time of judge minimum: indicates the amount of the time minus the % setting for the learning

minimum measurement time.

Meas. Time of judge maximum: indicates the amount of the time plus the % setting for the learning

maximum measurement time.

⓫Judgment error rate (%)

This sets the acceptable evaluation threshold before a screw tightening operation.

19

Selecting the judgment error rate while the screwdriver is connected transmits the selected rate to

PG-01. Even after disconnecting the PC, the selected rate will be retained.

The selectable rates: 0%, 2%, 5%, 10% or 20% (02=2%)

⓬Work On

Normally this turns on automatically when an operation is performed.

Other Sheet

データーシート

グラフシート

イレギュラシート

■Collection of Screwdriver Data (Application)

The operation data is collected in the same way as the data taking-in sheet. The data is saved in the CSV

format.

For details, click [Instructions] on the screen of screwdriver data collection.

20

Troubleshooting

If you have any problem while using this machine, please check the items in this section before making

inquiries.

Then, if the problem persists, please contact your dealer or us.

The L.NG or H.NG indicator blinks when the power is turned on.

There is a possibility that the learning values are not set correctly. Repeat teaching 3 times or more to set

the learning values.

The L.NG or H.NG indicator ashes even when the teaching mode is ended and

measurement cannot be performed.

There is a possibility that data for evaluation comparison is insucient. If the learning count is less than 3,

the indicator will keep ashing even if the teaching mode ends. Repeat teaching 3 times or more again to

set the learning values.

In the following cases it is dicult to make an evaluation, and it may not be counted as learning.

・Torque value is 10 or less ("E90" [Zero area detection/Impossible judgment ending])

・Idling of the screwdriver occurs or the measurement time is 100 mS or shorter. ("S01" [Lever switch

O(no torque up)])

Setting cannot be changed from the tabulation software.

Click the [Write learn-value] button after input of a number. The settings in PG-1 will be updated by

clicking the [Write learn-value] button.

The torque is abnormally low or high.

Turn o the power to check if the cords are connected correctly and then turn on the power again.

If the problem persists, replace the sensor cord.

When a Problem Cannot Be Solved

When contacting us, have the following information ready:

・Product name

・Description of the problem (detailed description of the operation performed and its result, etc.)

・Serial number (on the label of the product)

This manual suits for next models

4

Table of contents

Other HIOS Power Tools manuals