HIOS BLOP-STC 3 User manual

Screw counter series

BLOP-STC 3

CLT-70STC 3

Operation Manuals

(March, 2017)

1-16-5 Akiyama, Matsudo City,

Chiba Pref., Japan

TEL: 81 (Japan) 47-392-2001

FAX: 81 (Japan) 47-392-7773

CLT-70STC 3

BLOP-STC 3

17A Operation manual No. ET-A012

Utilizing 100%post-consumer

recycled paper pulp

HIOS Inc.

Table of Contents

Introduction.............................................................................................................................2

■Summary ...........................................................................................................................2

■Counting function ..............................................................................................................2

■Other functions ..................................................................................................................2

■Precautions concerning installation location .....................................................................3

■Precautions during use......................................................................................................3

■ Specication ......................................................................................................................4

■Compatible screwdriver.....................................................................................................5

■Primary functions and description of terms .......................................................................5

■Description of name and function for each section ..........................................................7

Front panel ........................................................................................................................7

Rear panel.......................................................................................................................10

Function setting table ......................................................................................................13

■Initial settings...................................................................................................................14

■Quick installation .............................................................................................................17

1. Normal power mode...................................................................................................17

2. Continuous counter mode ..........................................................................................17

3. Counter mode.............................................................................................................18

4. Multiple counter mode................................................................................................20

■Timing chart.....................................................................................................................23

■Troubleshooting...............................................................................................................27

- 1 -

Introduction

Thank you for purchasing the BLOP-STC 3, CLT-70STC 3 screw counter. Prior to use,

please read through this operating manual to enable proper use of the equipment. After use,

keep this manual in a safe place.

■Summary

When tightening screws, it is necessary to verify that the operator has tightened the stipu-

lated number of screws for 1 work piece to prevent forgetting to tighten screws. The Screw

counter has been developed as a power supply unit with a screw counting function to relieve

theburdenonoperators,toimproveoperatingefciencyandtopreventcarelessmistakes.

■Counting function

1. This device can be set to tighten between 1 and 99 screws, depending on the work

piece, and for each screw tightened, the display of the number of screws remaining is

reduced by one.

2. Whenthenalscrewistightened,abuzzersoundstopreventforgettingtotightening

ascrew.Thisalsopermitsconrmationofcompletionofwork.

3. After completion of tightening screw, the display of the number of screws is automati-

cally renewed using an auto reset function, and the electric screwdriver will not oper-

ateuntilthesetsignalforconrmationoftheworkpieceisreceived.

* Screwdriver operation in standby mode can be prevented.

4. Preventscountingofconrmationtighteningandadditionaltightening(tightening

screws a second time).

5. The equipment can be set not to count cases where a screw is not fully seated,

obliquelytightenedorwheretighteningisinsufcient*.

* Depends on type of work being performed.

■Other functions

1. Theexternaldevicecontrolfunctionenablessolenoidvalvecontrolofajigtoxwork

in place, and utilization of a commercially available total counter to count the total

number of work pieces completed.

2. In multiple counter mode using the external connection function, careless mistakes

can be prevented independently of the operator by operating several electric screw-

drivers for different numbers of screws or with different output torques in order of the

work being performed, for example in cell manufacturing, etc.

3. This equipment also has a normal power mode, where the counter function is disabled

and it functions as a normal power supply unit.

- 2 -

■Precautions concerning installation location

●Install a short circuit breaker or safety breaker in conjunction with commercial power

supply.

●Install the equipment where it is not exposed to dust, dirt and pieces of metal.

●Install in a location where it will not come into contact with water and oil.

●Do not place or stack heavy objects on top of this equipment.

●Install this equipment in a stable location that will not cause vibration.

● Forinstallationinahighlocation,xtheequipmentrmlytoexcludetheriskoffalling.

●Do not install near high voltage equipment or in noisy environments.

●Do not make input or output wires longer than necessary, and do not bundle with

power supply wiring. This may cause a malfunction.

■Precautions during use

●Connect the equipment to ground and operate at the rated power supply voltage.

●When connecting loads to the output terminals on the terminal block on the rear panel,

do not exceed the rated load. Exceeding the rated load may cause a failure.

●If an external device connected to the +24V DC output or other input or output termi-

nals on the terminal block on the rear panel is affected by electromagnetic induction

effects, such as a relay or a coil for an electromagnetic valve, use noise countermea-

sures such as diodes for absorbing reverse voltage. If noise countermeasures are not

used, this may be the cause of malfunction or failure.

●Do not connect the +24V DC terminal to any of the output terminals (COMP, VALVE,

BZ, ER BZ) or ground terminals on the terminal block on the rear panel. This con-

nection will cause failure of the unit.

●Do not connect the +24V DC terminal to any of the input terminals (RESET, SET) of

the terminal block on the rear panel. This connection will cause failure of the unit.

●When using the functions of the equipment for external equipment with an external

power supply, make the ground terminals common. If ground terminals are not com-

mon, this may cause malfunction or failure.

●

Do not apply voltage to the input terminals or output terminals. Connection to voltage

may cause a failure.

●

Do not change For/Rev SW while your running the screwdriver by either pressing

Lever SW, for Lever start type, or pushing the screwdriver, for Push start type.

It may cause either wrong count or damage internal SW of screwdriver.

When you change For/Rev SW, stop pressing the Lever or stop pushing the screw-

driver and wait until motor stops.

●Use in a temperature range from 5℃- 40℃and at a humidity of less than 80% (free

from condensation).

●Hold the plug when attaching or removing a power cord or screwdriver cord.

●Do not drag the cords or allow them to come into contact with oil or sharp edges, etc.,

or to come underneath heavy objects. This may cause a break or failure.

●If the electric screwdriver locks up, or if there is an overload, the overload protection

function operates. If the overload protection operates several times, it may be because

- 3 -

* External dimensions do not include protruding points such as screws and terminal block.

the work exceeds the load capability of this equipment or the electric screwdriver. If it

is being used correctly and the overload protection is actuated frequently, immediately

stop use, turn off the main power switch, remove the power supply cord from the outlet

and return the equipment to the supplying dealer.

●If overheating occurs, turn off the main power switch, remove the power supply cord

from the outlet and allow the equipment to cool naturally. After cooling, if the unit over-

heats while being used again, immediately stop use, turn off the main power switch,

remove the power supply cord from the AC outlet and return the equipment to the sup-

plying dealer.

●When tightening screws in plastics and other materials that store static electricity

easily, discharge any static electricity prior to starting work. If static electricity is not

discharged,itmaycauseamalfunctionduetostaticelectricityowingfromthetipof

the bit.

●Do not expose to severe shock such as dropping.

●Do not connect other makers' electric screwdrivers, except for HIOS inc., . This may

cause a failure.

●When equipment will not be used for a long period, turn off the main power switch and

remove the plug from the power outlet.

●Do not disassemble or modify the design of the equipment. This may cause a failure.

In this case, the warranty may be voided and you may not be able to get the equip-

ment repaired.

■ Specication

Power supply model number BLOP-STC3•CLT-70STC3

Primary

Input Power Supply AC100-240V

Fuse capacity

(Inside AC inlet) 3A/250V (one spare)

Power consumption 15W under no load

Secondary Output voltage

HI : 31V DC 2 stage

LOW

: 20V DC

Overload protection function included

External dimensions* (mm) 127(W) × 208(D) × 76(H)

Weight (kg) 1.8

AC cord length AC100VSpecication:1.8m(Standard3L3P)

AC220Vspecication:1.8m(basedonspecication)

Attachments Operator's manual 1 copy, one AC power supply cord

Crimp contacts, 8 pieces

- 4 -

■Primary functions and description of terms

1. Conrmation of tightening

• Toconrmthatascrewisreliablytightandtoperformadditionaltightening,tightenfor

a2ndand3rdtimeaftertighteningforthersttime.Thisisalsoreferredtoassecond

tightening and additional tightening.

2. Torque-up

• Referstonaltighteningofthescrewwherethetorquereachesthetorquetightening

setting and the electric screwdriver clutch disengages.

• Thisdevicedenesthersttorque-upafterthenormalrotation*counttimerstopsas

thetorque-upforthenishofscrewtightening.Setthecounttimersothatitdoesnot

countdownfortorque-upsusedforconrmationtightening.

* Normal rotation count timer is abbreviated to count timer in the rest of this document.

3. Input type

•The signal input method for this equipment is a photo coupler input. The maximum

input current is of 10 mA.

•When connecting an open collector, connect the collector to the input terminal and the

emitter to the GND terminal.

<Caution>

Do not apply voltage to the input terminals.

Add a diode or equivalent to relay coils that are connected to inputs to absorb reverse

voltage.

Provide some type of noise reduction measures when using external devices. (See Fig.

1, p. 20)

4. Output type

•The signal output type for this equipment is an open collector output with a maximum

rated load of 30V DC/80 mA.

■Compatible screwdriver

BLOP-STC 3

compatible driver

Number

of con-

trollable

units

CLT-70STC 3

compatible driver

Number

of con-

trollable

units

BLG-4000ZERO1, BLG-5000ZERO1 series

BLG-4000BC2, BLG-5000BC2 series

BLG-4000BC1, BLG-5000BC1 series

BLG-4000-OPC, BLG-5000-OPC serirs

BL-2000-OPC, BL-3000-OPC

BL-5000-OPC, BL-5020-OPC,

BL-7000-OPC

1

CL-2000 CL-3000 CL-4000

CL-6000 CL-6500 CL-7000

α-4500 α-5000 α-6500

SS-2000 SS-3000 SS-4000

SS-6500 SS-7000

1

- 5 -

<Caution>

Do not apply voltage to the output terminals.

For use of external equipment with relays or solenoid valve coils, add a diode, etc., to

absorb reverse voltage.

5. Overload protection function

•The overload protection unit of this equipment interrupts the output if a high current

causedbyoverload,forexampleduetolockingoftheelectricscrewdriver,owsforlon-

ger than a stipulated period and is intended to protect this unit and the electric screw-

driver.

•If the overload protection function operates, turn the power off and let the unit rest for

one minute or longer, and then turn the unit back on.

<Caution>

If the overload protection function operates several times, it may be because the work

exceeds the load capability of this equipment or the electric screwdriver.

6. Finish of screw tightening vs. completion of screw tightening

• Inthisoperator'smanual,"nishofscrewtightening"referstonormaltighteningofone

screw.

•In this operator's manual "completion of screw tightening" refers to normal tightening

work that is performed for 1 work piece.

7. Electric screwdriver operation control function

•The counter mode and multiple counter mode for this equipment are functions that

permit or prohibit operation of the electric screwdriver based on a set signal.

8. Counter mode

•Operating mode where the set number of screws to be tightened is displayed, and this

display is reduced by 1 each time a screw is tightened.

9. Multiple counter mode

•In addition to the counter mode function, this is an operating mode for using relays for

multiple electric screwdrivers that are set at different torques or use different bits for 1

work piece.

•Connect an equivalent number of electric screwdrivers and main units using a daisy

chain method. (See Fig. 2, p. 22).

<Caution>

When using an electric screwdriver in its order of operation, the other electric screw-

drivers will not work and their operation is prevented.

- 6 -

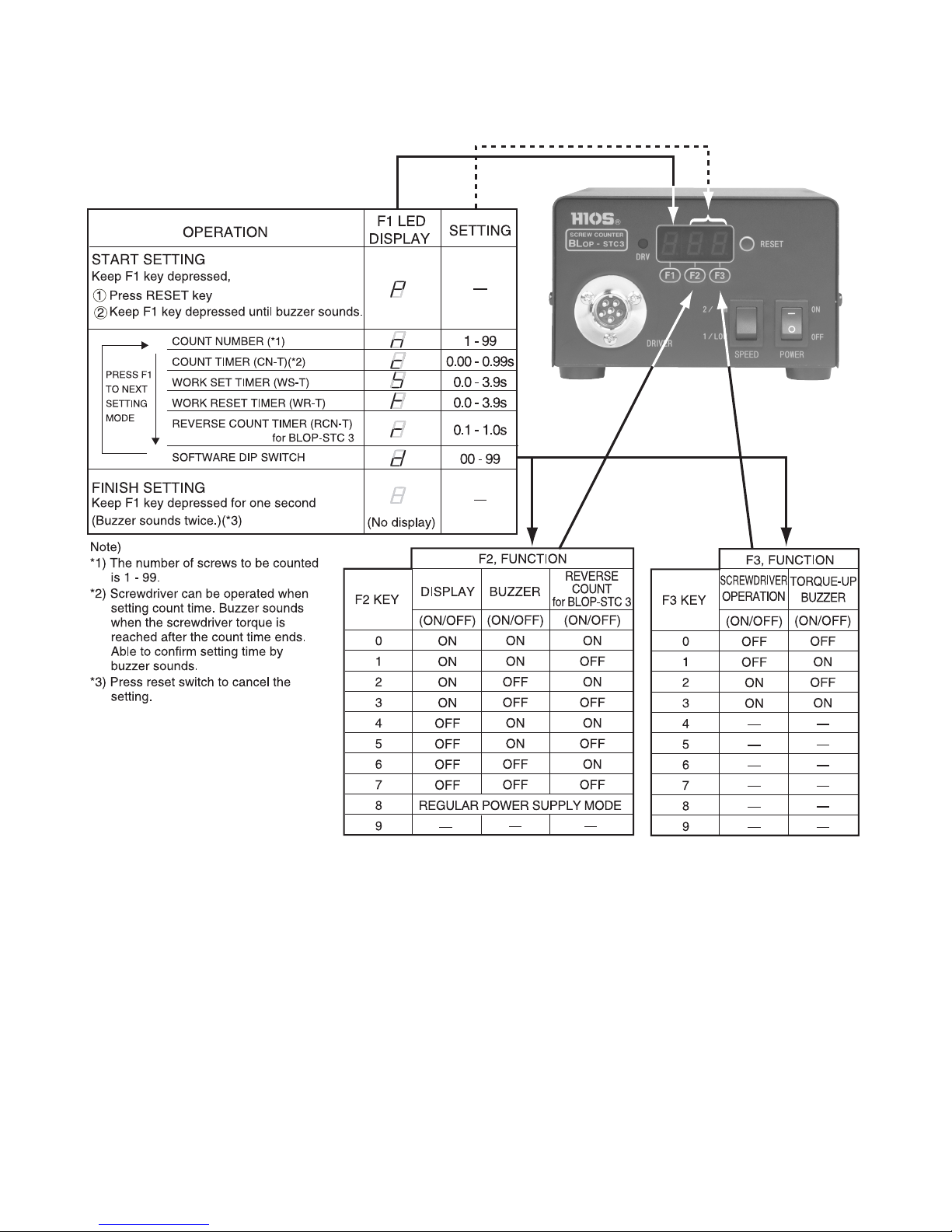

<Description of front panel>

●Main power switch (POWER)

•Turns the power supply on and off.

•When the power supply is “on”, the LED inside the switch lights.

•The protection circuit automatically operates and turns off the power supply if the elec-

tric screwdriver locks and causes an overload.

In this case, turn off the main power switch and turn it back on after one minute.

If this measure fails, please check the fuse.

Ifthefusehasfailed,tareplacementfuse.

Spare fuses are stored inside the AC inlet (rear panel).

●HI/LOW switch (switching of rotational speed) (HI/LOW)

•Sets the output voltage to high or low.

•This switch changes the rotational speed of the electric

screwdriver.

●Metal connector (DRIVER)

•Connects the driver cord.

•BLOP-STC 3 uses a 6P (pin) connector type and CLT-70STC 3 uses a 5P (pin).

<Front Panel>

Spare fuses

Operating

display LED

Number of screws

display

* Metal connector HI/LOW

switch

Power supply

main switch

Reset switch

Function switch (F3)

Function switch (F2)

Function switch (F1)

■Description of name and function for each section

(Rear panel)

- 7 -

●Operating display LED

•Lights green when the power is switched on.

•Lights orange when operation of the electric screwdriver is enabled.

●Number of screws display

•Displays the set number of screws to be tightened initially and displays the remaining

number of screws to be tightened after counting starts.

•Each time a screw is tightened, the remaining number of screws to be tightened is

reduced by one.

●Reset switch (RESET)

•This resets the counter functions, interrupts output of the valve signal and releases the

work piece held by an external device.

•If operated during or after setting the set switch, the display returns to the number that

was set.

•Performs the same function as the reset on the terminal block on the rear panel.

●Function switch (F1)

•Enters change function mode if pressed for more than 1 second after reset (Display " ").

•Pressing the button for longer than 1 second while in Change Function Mode will cause

a buzzer to sound, shutting down the Change Function Mode.

●Function switch (F2, F3) (x10, x1 Setting Switch)

•Numbers increase in increments of 1 as the button is pressed.

A limit may be imposed depending on the setting being changed.

1) Count Setting Mode (Display " ")

•Set the number of screws to be tightened from 1 to 99.

•Set the position for 10 and 1 .

A setting of 00 cannot be entered (warning buzzer will sound).

2) CN-T (Count Timer) Setting Mode (Display " ")

•Setting range from 0.01 second to 0.99 second.

• ThisSWsettingpreventscountingthesecondtighteningofascrewduetoconrmation

or additional tightening.

•The buzzer will sound for a short time while countdown is possible.

Usethebuzzerwhileconrmingthetightnessofscrewsthathavebeentightenedasa

guide to setting the count timer operating time.

(The screwdriver will only operate while the count timer is running, regardless of other

settings)

- 8 -

➜

3) WS-T (Work Set Timer) Setting Mode (Display " ")

•Setting range from 0.1 second to 3.9 seconds.

•This setting changes the time allotted until the screwdriver is operational, as well as

generating a valve signal when the set signal is received by the terminal block.

•Use the time taken for the LED to light after receiving the set signal as a guide to set-

ting the Work Set Timer.

4) WR-T VR (Work Set Timer) Setting Mode (Display " ")

•Setting range from 0.1 second to 3.9 seconds.

•Set the time between the end of the valve signal after work has been completed, and

the time for which the screwdriver is not operational.

•Use the time taken between the start and end of the buzzer sound after work has been

completed, as a guide to setting the Work Reset Timer.

5) REV-T (Reverse Timer) Setting Mode (Display " ") for BLOP-STC 3

•Setting range from 0.1 second to 1.0 second.

•Set the time taken until reverse counting starts.

•Use the time taken to the start reverse counting as a guide to setting the Work Reset

Timer.

6) System Setting Mode (Display " ")

•Settings for the following features are available.

a) Controls display of remaining number of screws, see page 12 : ON=display,

OFF=no display

b) Controls buzzer sound: ON=buzzer noise, OFF=no buzzer noise

c) Controls reverse count: ON=on, OFF=off

d) Controls the normal counter operating mode with a signal on set terminal, see page

10 : ON=on, OFF=off

e) Controls buzzer sound during torque-up: ON=on, OFF=off

f

) Stops all counting features: power supply only

Note: REV-T(Reverse Timer) is valid only for BL-OPC and BLG-OPC type screwdrivers.

*ReverseTimeristodenethetimewethercount-upornotwhilereversingthescrewdriver.

* The counter count-up when the screwdriver is reversed longer than this timer.

<Caution>

•Note: Even the slightest reverse rotation will be considered as loosening and result in a

count-up from the last screw of the operation with a count of 00, regardless of the time

set for the reverse count timer.

•The reverse count feature cancels the countdown of the preceding torque-up operation.

Once reverse count-up has started, further count-up will not occur until count-down

from a normal rotation torque-up operation has occurred.

- 9 -

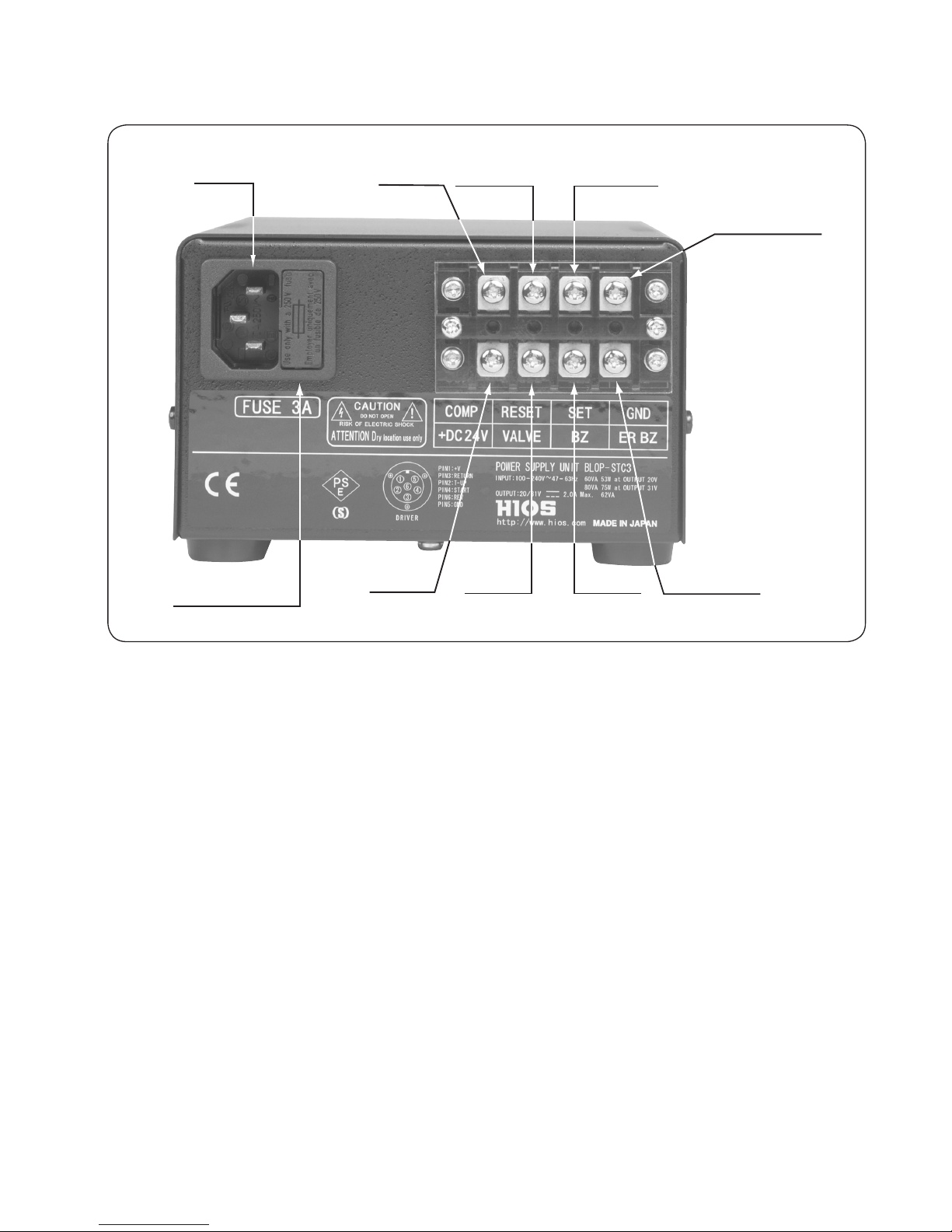

<Description of rear panel>

●Ground terminal (GND)

•Ground terminal

●Set terminal (SET)

•Input terminal for work set signal.

•After the period set for the work set timer elapses from input of the set signal, the op-

eration LED is turned on and operation permission is provided for the electric screw-

driver. The VALVE signal is generated at the same time.

•Connect the detection switch so that there is a set signal input when there is no voltage

between the set terminal and the ground terminal.

<Caution>

In order to prevent incorrect operation, operation of the electric screwdriver is not per-

mitted until after the operating display LED lights orange.

●Reset terminal (RESET)

•Input terminal for reset signal.

•This resets the counter functions, interrupts generation of the valve signal and releases

the work piece being held by an external device.

AC inlet

Fuses and spare

fuses

<Rear Panel>

- 10 -

COMP

terminal

Reset

terminal Set terminal

Ground terminal

+24V DC

terminal

Valve

terminal

Buzzer

terminal

Error buzzer

terminal

•Display is renewed when reset terminal and ground terminal are connected during or

after setting of the count set switch.

•Performs the same function as the reset on the front panel.

•Connect the reset switch so that there is an input on the reset signal when there is no

voltage between the reset terminal and the ground terminal.

●COMP terminal (COMP)

•Output terminal for the completion of work COMP signal (completion of work).

•Output for 0.1 second after work reset timer stops.

•The output type is open collector output, and the maximum rated load is 30V DC/80

mA.

•Connects the total counter to permit counting of the number of work pieces completed.

●+ 24V DC terminal

•Power supply terminal for external devices. The power supply capability has a maxi-

mum rated output of 24V DC/0.2A.

●Valve terminal (VALVE)

•Output terminal for control signal of external devices.

• Usethistocontrolasolenoidvalve(24VDC)foranexternaldeviceusedtoxwork

pieces in place.

•Connect the (+) terminal of the solenoid valve for the external device to the +24V DC

terminal, and the solenoid valve ground terminal to the valve terminal.

•When an external device operates at a different voltage, connect the devices to a com-

mon ground and use an external power supply.

•Add a diode to the solenoid valve of external devices to absorb reverse voltage.

•The output type is open collector output, and the maximum rated load is 30V DC/80

mA.

●Buzzer terminal (BZ)

•Similar to the completion of work buzzer, signal output is synchronized with the work

reset timer.

•The output of the BZ terminal is provided regardless of the setting of the mode switch.

•When a separate power supply is used for the external device, connect the devices to a

common ground and use an external power supply.

•Add a diode to the solenoid valve of external devices to absorb reverse voltage.

•The output type is open collector output, and the maximum rated load is 30V DC/80

mA.

●Error buzzer terminal (ER BZ)

•Generated if the work set signal is interrupted, even for an instant, prior to completion

of screw tightening.

- 11 -

•However, operation of this device can be actuated normally by the number of screws

remaining to be tightened for completion.

•ER BZ output does not stop until there is a reset or count-down is completed.

•When a separate power supply is used for the external device, connect the devices to a

common ground and use an external power supply.

•Add a diode to the solenoid valve of external devices to absorb reverse voltage.

•The output type is open collector output, and the maximum rated load is 30V DC/80

mA.

- 12 -

<Function Setting Table>

- 13 -

■Initial settings

* Initial settings use the counter mode as an example, however settings other than

MODE are performed in the same manner. Set the initial settings prior to use for the

rsttime,andperformMODEsettingstosuitanyfollowingwork.

1. Connections

1) Connect the screwdriver cord to the metal connector of the main unit.

2) Connect the unit's power supply cord to an outlet that supplies the rated power (AC

power outlet), and then connect to ground.

2. Setup instructions

1) ConrmMODEsettings(factorysettings)

•Turn the main power switch on while pressing the F1 switch.

(If the unit is already switched on, press the F1 and Reset switches together, before

releasing the Reset switch only)

A buzzer (beeping sound) will sound with the F1 switch. Continue pressing the switch (for

1 second or more) until " " is shown in the F1 display.

2) Press the F1 switch until " " is shown.

• Conrmthat"00"isshowninthesettingsdisplay.

3) Press the Reset switch.

3. Work instructions

1) Turn the main power switch on.

2) Settings for the Work Set Timer

•Press the F1 and Reset switches together, before releasing the Reset switch only. A

buzzer (beeping sound) will sound with the F1 switch. Continue pressing the switch (for

1 second or more) until " " is shown in the F1 display.

•Use the F1 switch to change to the Adjust Work Set Timer mode (F1 Display " ") and

set the timer settings with the x10, x1 switches.

(Setting range from 0.1 second to 3.9 seconds)

•After the Work Set Timer operation has completed (time up), the valve signal will be

generated.

(The signal will continue to be generated until the unit is reset or counting is completed)

•When settings have been completed, press the F1 switch to move to the next setting.

•When all settings have been completed, press the F1 switch for 1 second or more. The

buzzer will sound twice, and the setting mode will close.

3) Change to Counter Timer Setting mode (F1 Display " ") and set the count timer while

performingconrmationtighteningwiththex10andx1switches.

- 14 -

(Setting range from 0.01 second to 0.99 second)

The buzzer will sound for a short time if a torque-up operation is performed after the

count timer has expired.

Whilevariationsbetweendifferentoperatorsmayexist,performcontinuousconrma-

tion tightening before setting the time required for work without using a count-down.

(The factory setting for the count timer is 0.15 second)

•When settings have been completed, press the F1 switch to move to the next setting.

•When all settings have been completed, press the F1 switch for 1 second or more. The

buzzer will sound twice, and the setting mode will close.

<Caution>

•Countdown will not be performed if a count timer operating time longer than the actual

time required for tightening has been set. Take note of this when tightening screws with

a short thread.

4) Reverse Counter Timer Settings - for BL

•Change to the Reverse Counter Timer Setting mode (F1 Display " "), loosen the

screw, and set the reverse time of the electric screwdriver using the x10, x1 switches at

the point where the screw has been determined to be removed.

(Setting range is from 0.1 second to 1.0 second. The factory setting for the reverse

counter timer is 0.2 second)

•When settings have been completed, press the F1 switch to move to the next setting.

•When all settings have been completed, press the F1 switch for 1 second or more. The

buzzer will sound twice and the setting mode will close.

<Caution>

•Releasing the start lever after 0.1 second has elapsed for short threaded screws that

are removed in less than 0.1 second of starting reverse rotation can increase the count-

up by 1.

•Using the screwdriver in the reverse rotation for longer than the time set in the reverse

counter timer will increase the count-up by 1, even if the screw is not actually loosened.

5) Settings for the Work Reset Timer

•Change to the Work Reset Timer Setting mode (F1 Display " ") and set the work reset

timer operating time using the x10, x1 switches.

• Afterthetorque-upoperationiscompleteforthenalscrewonthecurrentworkpiece,

set the Work Reset Timer to the time taken for the DRV LED (operating display) to

change from orange to green for the current work piece.

•The output of the VALVE signal is stopped when the Work Reset Timer operation is

complete.

•After the Work Reset Timer operation has stopped, the COMP signal will be generated

for 0.1 second.

•When settings have been completed, press the F1 switch to move to the next setting.

•When all settings have been completed, press the F1 switch for 1 second or more. The

- 15 -

➜

buzzer will sound twice, and the setting mode will close.

6) Settings for the Count Set

•Change to the Count Setting Mode (F1 Display " ") and set the number of screws to

be tightened for the particular work piece using the x10, x1 switches (Setting range is

from 1 to 99 screws)

•When settings have been completed, press the F1 switch to move to the next setting.

•When all settings have been completed, press the F1 switch for 1 second or more. The

buzzer will sound twice, and the setting mode will close.

7) System Settings

•Change to the System Settings mode (F1 Display " ") and set the system settings us-

ing the x10, x1 switches.

•Settings for the following features are available.

a) DSP (Controls the display of remaining number of screws: ON=display, OFF=not

displayed)

b) BUZZ (Controls the buzzer sound: ON=buzzer noise, OFF=no buzzer noise)

c) RCN-T (Controls the reverse count: ON=on, OFF=off) for BLOP-STC 3

d) EVERON (Controls the normal counter operating mode: ON=on, OFF=off)

e) TUP BUZZ (Controls the buzzer sound during torque-up: ON=on, OFF=off)

f) COUNTER OFF (Stops all counting features: power supply only)

•See page 13.

•When settings have been completed, press the F1 switch to move to the next setting.

•When all settings have been completed, press the F1 switch for 1 second or more. The

buzzer will sound twice, and the setting mode will close.

<Caution>

•Press the Reset switch if you wish to cancel the process at any time. All changes will

be lost.

This completes the initial settings. Next, determine the operating mode for the actual work

and proceed according to the operator's manual.

- 16 -

■Quick installation

1. Normal power mode

✽When performing tightening of screws using the equipment as a normal power supply for

an electric screwdriver without using the external device control or counter function.

■Connections

1) Connect the connector for the screwdriver cord to the metal connector of this equip-

ment.

2) Connect the power supply cord for this device to a power supply that supplies the rated

power (AC outlet), and connect to ground.

■Setup and work instructions

1) Set 80 in the System Setting Mode (F1 Display " ").

2) Exit the Setting Mode by pressing the F1 switch for longer than 1 second.

3) After work preparations are complete, tighten screws as normal.

2. Continuous counter mode

✽When the external device control function of this equipment is not used and only the

counting function is used for performing work.

Thismodeisforcaseswhereworkpiecesarenotxedandforuseofatargetcountto

prevent careless mistakes.

■Connections

1) Connect the connector for the screwdriver cord to the metal connector of this equip-

ment.

2) Connect the power supply cord for this device to a power supply that supplies the rated

power (AC outlet), and connect to ground.

■Setup instructions

1) Set F3 "2" (Do not use torque-up buzzer) in System Setting Mode (F1 Display " "), or

F3 "3" (Use torque-up buzzer).

Set F2 "0

-

7" depending on conditions of use.

2) Set the number of screws to be tightened using the Count Setting Mode (F1 Display " ").

3) Set the Counter Timer operating time using the CN-T Setting Mode (F1 Display " ")

switch(rangeof0.01secondto0.99second)whileperformingconrmationtightening.

4) Exit the Setting Mode by pressing the F1 switch for longer than 1 second.

5) Preparation settings are now complete.

- 17 -

■Work instructions

1) Turn on the main power switch.

2) Tightentherstscrew.The number of screws display is lowered by one.

3) Aftertighteningthesetnumberofscrews,tighteningofscrewsisnished.

•The number of screws display reaches “00” and the complete buzzer sounds.

•Afterwards, it is automatically reset and the initial setting for the number of screws to

tighten is displayed.

•This work can be repeated.

3. Counter mode

✽ Usethismodewhencontrollinganelectricscrewdriverforeachpieceofworkandxing

of work piece using the external device function.

✽The total number of work pieces completed can be counted by connecting a commercially

available total counter.

■Connections

1) Connect the connector for the screwdriver cord to the metal connector of this equip-

ment.

2) Connect the power supply cord for this device to a power supply that supplies the rated

power (AC outlet) and connect to ground.

3) Make connections for each control signal with reference to Fig. 1.

■Setup instructions

1) Turn on the main power switch.

2) Set 00 in the System Setting Mode (F1 Display " ").

3) Set the number of screws to be tightened using the Count Setting Mode (F1 Display

"").

4) Set the Work Set Timer operating time to suit the work piece using the WS-T Setting

Mode (F1 Display " ") switch (range from 0 second to 3.9 seconds).

5) Set the Counter Timer operating time using the CN-T Setting Mode (F1 Display " ")

switch(rangeof0.01secondto0.99second)whileperformingconrmationtightening.

6) Set the Work Reset Timer operating time to suit the work piece using the WR-T Setting

Mode (F1 Display " ") switch (range from 0 second to 3.9 seconds).

7) Exit the Setting Mode by pressing the F1 switch for longer than 1 second.

8) Preparation settings are now complete.

- 18 -

■Work instructions

1) Turn on the main power switch.

2) Input the set signal

•The work set timer starts operation.

•The work set timer stops operation.

•The valve signal is generated at the same time.

•Simultaneously, the operating display LED (DRV) is turned on and electric screwdriver

operation is permitted.

3) Finishingoftighteningoftherstscrew.

• Tightentherstscrew.The number of screws display is lowered by one.

4) Aftertighteningthesetnumberofscrews,tighteningofscrewsisnished.

•The number of screws display changes to “00” and the work reset timer operation

starts.

•Next the work reset timer operation stops.

•The valve signal output stops at the same time.

•Simultaneously, the operating display LED (DRV) is turned off and electric screwdriver

operation is prevented.

•The completion buzzer turns off at the same time.

•The COMP signal is generated for 0.1 second.

5) Next, the unit changes to standby until the set signal is input.

6) The above is repeated.

7) Work is completed.

- 19 -

This manual suits for next models

1

Table of contents

Other HIOS Power Tools manuals

Popular Power Tools manuals by other brands

Wacker Neuson

Wacker Neuson BPS1030A Operator's manual

Titan

Titan Pro V55 owner's manual

EINHELL

EINHELL TE-MG 300 EQ Original operating instructions

Makita

Makita HR001G instruction manual

BlackJack SolderWerks

BlackJack SolderWerks BK4000 instruction manual

Windsor

Windsor DOUBLE DRY DDH 86000000 operating instructions