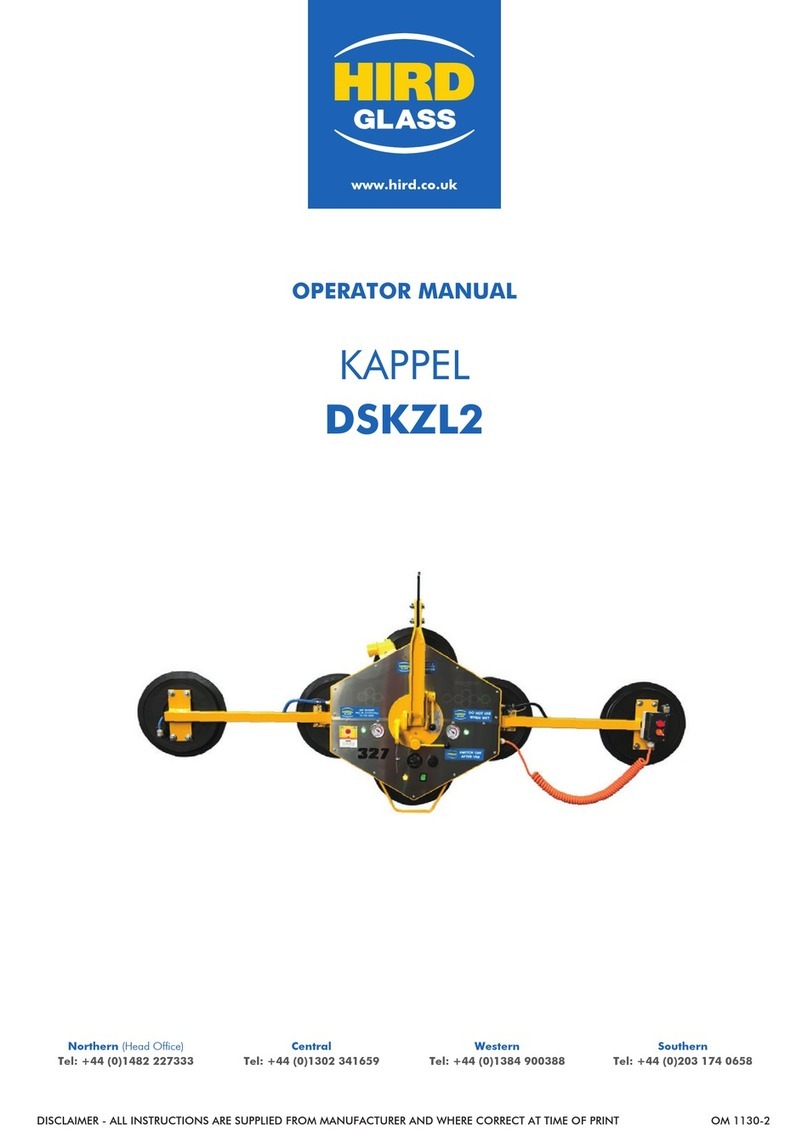

OPERATOR MANUAL | HYDR

www.hird.co.uk

OPERATION

6. Check the test plate of the lifter for:

a. Safe Working Load (SWL), this will always show the

maximum SWL. The current Report of Thorough

Examination must be consulted to confirm the SWL in the

configuration being used.

b. Serial number of the lifter, and that it matches the serial

number on the accompanying Report for Thorough

Examination.

c. The last examination date matches that on the Report of

Thorough Examination and that the current date is within

6 months of the last Thorough Examination.

7. Ensure all pad shut off valves are in the ‘OFF’ position, i.e. not in line with

the pipe. Press both vacuum activation buttons on the remote control and

turn the power switch to ‘ON’

8. Ensure that all warning lights and sirens are on during vacuum build up.

9. Ensure vacuum reaches correct level on both circuits before pump turns off.

10. Using the remote control buttons, check that the lifter tilts from O to 90° and

back again freely.

11. Holding the rotation release handle ensure that the lifter turns 270° freely.

Repeat this operation, this time checking that it will lock every 90°.

12. Turn the power switch to ‘OFF’ and pull both the vacuum actuation valves to

release the vacuum and ensure the vacuum gauges drop to 0.

13. Ensure all pad isolation valves are turned on, i.e. in line with the pipes

14. Apply the lifter to a glass unit, turn the power ‘ON’, press both the vacuum

application buttons until they click. When the correct vacuum levels are

reached and all warnings are extinguished, record the vacuum levels, leave

the lifter applied and wait for a period of 10 minutes. Inspect the gauges

again and check whether the levels have dropped 5% or more from the

recorded values. If so do not use go to step 15.

15. Remove the lifter, clean the load and pads thoroughly. Repeat step 15. If

the lifter is still loosing more than 5% over the 10 minute period from either

circuit, remove the lifter from service and label it ‘Out of Service’ and ring

Hird Ltd Service and Maintenance.

Safety Note 1.

When using the extension arms it is imperative that the pipes from the pads

are correctly connected to the quick release fittings prior to vacuum being

applied. Failure to do so will isolate the relevant pad from the vacuum

system. If the above condition is seen , return load to safe position before

trying to rectify, as any attempt to connect the pipe after the vacuum is

applied may lead

DSH2 VARIANTS HYDRAULICA VACUUM LIFTER

OPERATING AND MAINTENANCE MANUAL