HIRD GLASS Wienold GML800+ User manual

Northern (Head Office)

Tel: +44 (0)1482 227333

Central

Tel: +44 (0)1302 341659

Southern

Tel: +44 (0)203 174 0658

DISCLAIMER - ALL INSTRUCTIONS ARE SUPPLIED FROM MANUFACTURER AND WHERE CORRECT AT TIME OF PRINT

www.hird.co.ukwww.hird.co.uk

OPERATOR MANUAL

WIENOLD

GML800+

Sept 2019

PRE1307

Daily Pre-Use Checklist

Counterbalance Floor Crane

Northern (Head Office) Tel: +44 (0)1482 227333

Central Tel: +44 (0)1302 341659

Southern Tel: +44 (0)203 174 0658

www.hird.co.uk

Machine Model: Site Name:

Date Week Commencing: Fleet No: Address:

Inspected by:

Wienold GML 800+

Result of Inspections: List defects or state “No Defects”

Signature: Name: Date:

Daily Pre-use Checks M T W T F S S COMMENTS

1Are all operators manuals present and readable

2Is the Report of Thorough Examination (LOLER) in date

3Complete a visual walk around / Inspection for any noticeable defects

4Are all safety information decals present and readable

Check the following components or areas for damage, or missing parts & unauthorised modifications:

5Cators are free from defects

6Footbrake(s) is operational

7Chassis is in good condition with no major defects

8Nut, bolts & other fasteners

9Push handle has no major defects

10 Counterweights are free from defects

11 Counterweights are all fitted correctly

12 Forklift points are free from damage

13 Boom sections are secure and free from defects

14 All boom extension pins are present

15 Gauges and switches

16 Electrical components, wiring, connectors,

17 Vacuum mounting is correct and secure (when fitted)

18 Air hoses are free from defects (when fitted)

19 Vacuum pads are secure and free from defects (when fitted)

20 Vacuum pumps engage when switched on (when fitted)

21 Vacuum gauges are operational (when fitted)

22 Extendable crane boom is in serviceable condition (when fitted)

23 Extendable Forks are serviceable (when fitted)

24 Electric telescopic boom is servicable (when fitted)

25 Carry out full function test

YES YES YES YES YES YES YES

NO NO NO NO NO NO NO

Operator’s Initials

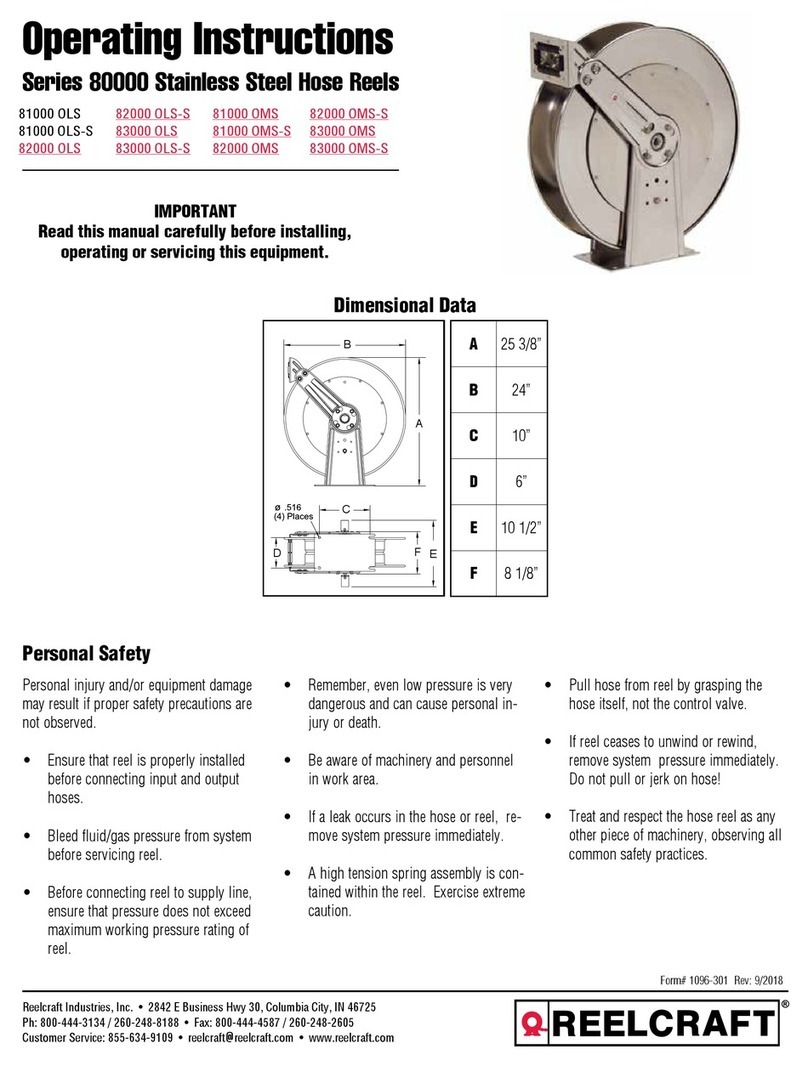

Glass and Material Lift GML 800+

Contents Page

Basic procedures

General description

GML Series typ overview

COMPONENTS VIEW

GML800+/Std M

GML800+/K M

GML800+/K AC

GML800+/K DC

Electrical components

Safety instructions

Pre-operation inspection

Working area inspection

Function tests

Operating instructions

INSTALLATIONS

GML800+/Std

GML800+/K (M+AC)

GML800+/DC

Lateral outrigger

Mast safety hook

Loading devices

Load preparation

RAISING/LOWERING LOADS

by manual winch

by electric winch (AC Series, 220/110V)

by electric winch (DC Series, 24V)

Charging batteries at DC models

Loading/Transportation

Technical data

Declaration of conformity

3

4

5

6

7

8

9

11

13

19

21

22

25

26

29

34

35

36

37

38

40

41

42

43

44

49

50

Contents

Operation Manual

GML 800+

2

Glass and Material Lift GML 800+

.de

-

Tel.: +49 5903 - 9394-0

Fax: +49 5903 - 9394-50

info@wienold-lifte.de

This lift fulfils the current CE regulations and norms, EN

ISO 12100, as well as the machinery directive 2006/42/EG,

when used and operated according to the manufacturer‘s

recommendations.

It is the duty and responsibility of each operator to obey all

regional rules and regulations concerning the safe usage

of this lift.

Please read carefully and follow all of the safety

instructions for this appliance before

maintenance, repair or operation.

This is in compliance with all the manufacturer‘s

recommendations and all of the legal guidelines as

required by the government and local authorities.

In order to allow for a safe and appropriate use of this

lift,it may only be used by persons who have been

instructed by authorised specialists and who have been

granted operative authorisation.

Repairs and maintenance of this lift are only to be

undertaken by qualified and trained personnel without

exception.

Waldstr. 35a

D-48488 Emsbüren

Germany

This lift is subject to an annual UVV-inspection by an

authorised tester. Without a current UVV-test seal this lift

must not be operated.

The owners and anyone hiring/borrowing this lift should

have all construction parts undergo a complete inspection.

All of the lift‘s functions must be thoroughly examined

and inspected before sale or lease takes place. Damaged

and malfunctioning parts must be repaired or replaced.

This operating manual is an essential requirement

for all operators of this equipment. For this reason

it must always remain in its appropriate place on

the lift and always be readily available.

Norbert Wienold GmbH is constantly developing and

improving this and other Wienold products.

For this reason our appliances and products may be

subject to modification without prior notice.

If you have any questions or queries, or if you notice any

mistakes and/or deviations concerning the contents of this

operating manual, please do not hesitate to contact us.

The manufacturer‘s instructions and safety regulations.

The operating and safety instructions for this lift.

The inscriptions, labels and warning signs on this lift.

The safety instructions and operating instructions at the job site.

The current, local and legal safety regulations.

Basic Procedures

Please read and comply with:

Contact:

Copyright © Norbert Wienold GmbH 2015. All rights reserved.

3

Glass and Material Lift GML 800+

The GML800+ consists of a chassis and a mast element

system. The lifting height is defined by the number of mast

elements. The loading capacity is defined by both the model

and the required lifting height.

There are various models with different lifting heights. All

models extend the mast elements sequentially until the

required working height is reached.

The various mast elements drive systems and their

corresponding models are listed below:

a) per Manual Winch (M Series)

b) per 230V Electric Winch (AC Series)

c) per 24V Winch(DC Sries)

The 24V Model includes a battery pack and a battery charger.

GML800+ Wienold Glass and Material Lift

On AC and DC models, an automatic mast limit switch

ensures an automatic deactivation of the lifting movement

when the maximum lifting height has been reached and

this switch also controls the cable tension when lowering.

The GML800+ is equipped with frontal outriggers which,

depending on the model, may also be deployed as rear

outriggers when used in combination with counterweights.

Different loading accessories are employed to raise, lower,

hold and load up to the Safe Working Load (SWL).

A lifting fork or a crane outrigger are generally available as

loading accessories. These can be easily substituted.

Minor positioning of the lift during operation must always be

done manually.

Transportation of persons with the lift is strictly prohibited!

Do not operate the lift in areas where an explosion hazard

exists.

General Description

BEFORE USE ALWAYS please read and understand:

The safe working load (SWL) of all components must be checked before use.

The lowest SWL is always relevant!

Example 1: Example 2:

Lift: 800 kg SWL max. Lift: 800 kg SWL max.

Boom: 450 kg SWL max. Boom: 450 kg SWL max.

Suction Cups: 450 kg SWL max. S

uction Cups: 250 kg SWL max.

= 450 kg SWL max. = 250 kg SWL max.

Always follow the instructions of the load capacity chart!

Copyright © Norbert Wienold GmbH 2015. All rights reserved.

4

Not Aus Not Aus

GML Series

Operation Manual

GML 800+

Glass and Material Lift GML 800+

GML800+ /Std M

Standard with manual winch GML800+ /K M

with Counterweights and manual winch

GML800+ /K AC

with counterweights and 230/110V winch GML800+ /K DC

with counterweights and 12V winch

5

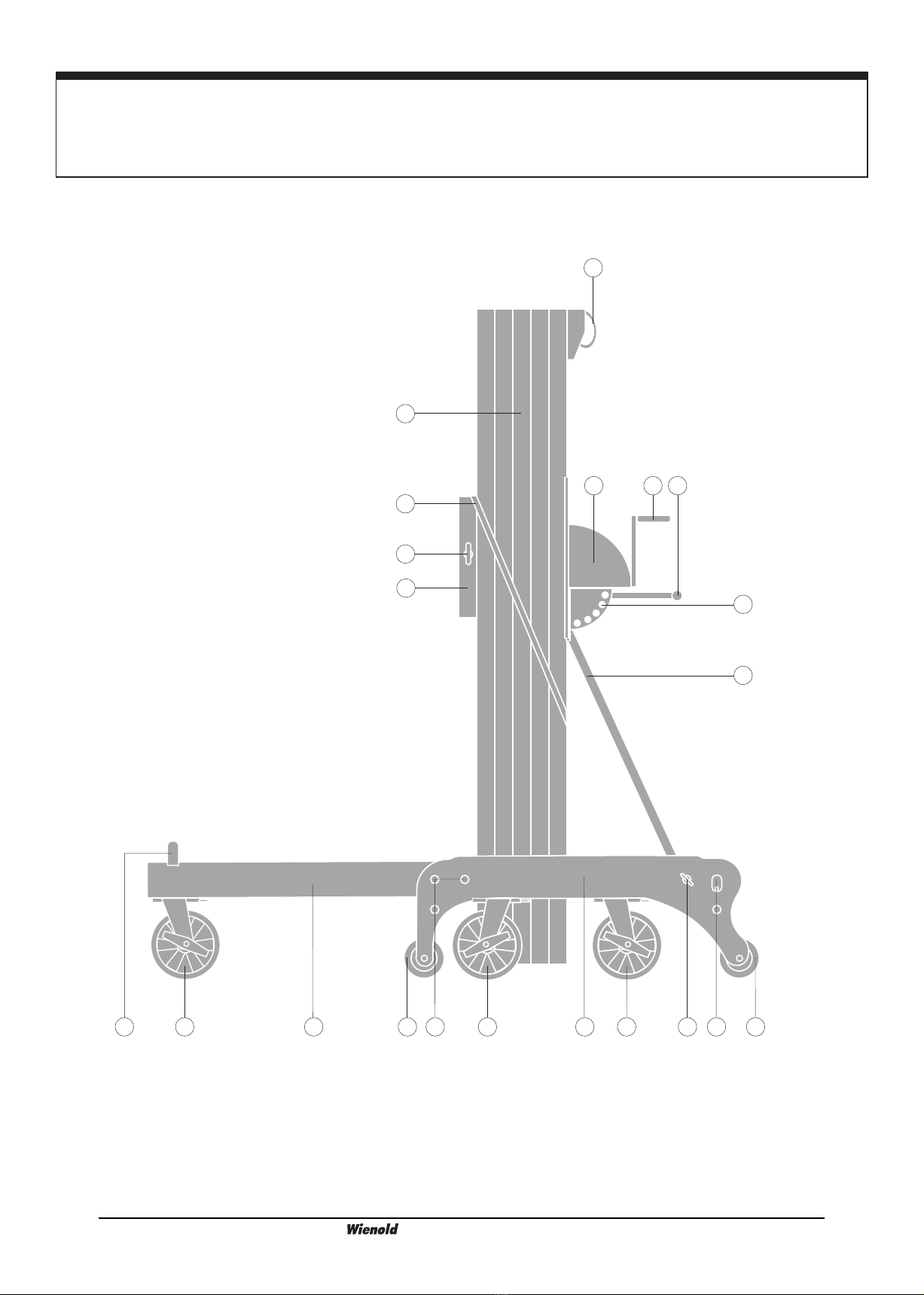

Components GML/Std M (Types GML /10 und /15)

Standard (Std) with maual worm winch (M).

Types GML /10 und /15 without lateral outriggers (as option available)

Types GML /20 und /25 are equiped with lateral outriggers (standard).

(ref. „Componets GML/K M“)

1211 1413 15 1716

1

2

5

3

4

6 7 8

9

10

12 12 1418

1) Carriage

2) Bolt to secure attachments

3) Hold down bar (for transportations)

4) Mast System

5) Lifting eye

6) Worm gear winch

7) Worm winch crank

8) Push bar

9) Adjustment holes for push bar

10) Stabilizer

11) Securing pin for weight box

12) Swivel caster with brake

13) Outrigger

14) Support wheel

15) Holes for outrigger

16) Chassis

17) Securing pin

18) Bolt with nut

Operation Manual

GML 800+

Glass and Material Lift GML 800+

6

1

2

5

3

4

6 7 8

9

11

13

14

19 20 21 2122 1923 24

10 15 16 17 18

212625

12

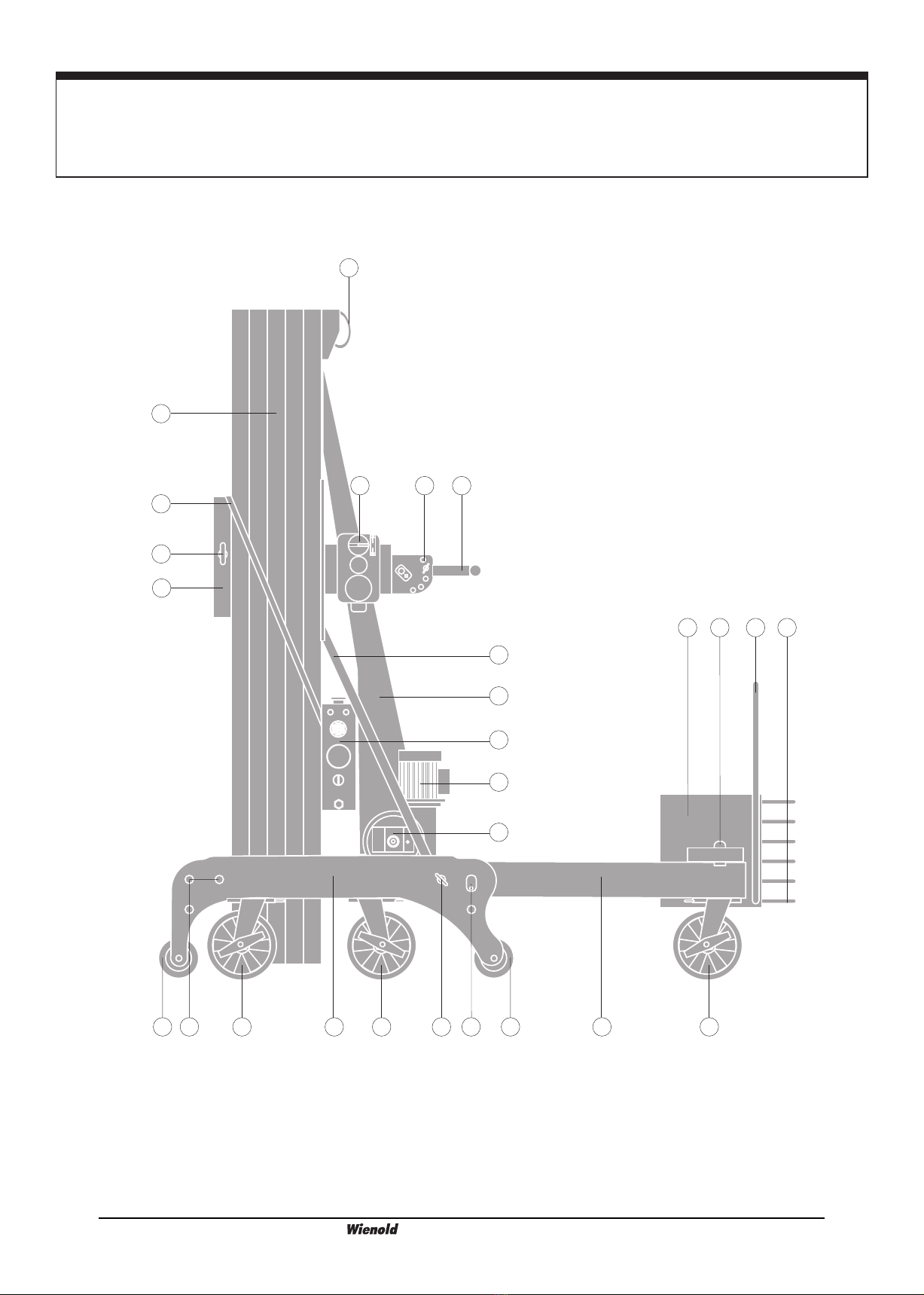

10) Lateral outrigger (Pair)

11) Lateral outrigger brake plate

12) Stabilizer

13) Lateral outrigger lock pin

14) Lateral outrigger adjustment plate

15) Counterweight box

16) Counterweight securing pin

17) Steering arm

18) Counterweights (2x 6 pcs.)

19) Support wheel

20) Holes for outrigger

21) Swivel caster with brake

22) Chassis

23) Securing pin

24) Bolt with nut

25) Forklift pockets (Option)

26) Outrigger

Components GML/K M (Types GML /20 und /25 with lateral outrigger)

Series with counterweights (K) and maual worm winch (M).

- Fork lift pockets optional available for all models. -

Types GML /10 und /15 without lateral outriggers (as option available)

All Types GML /20 und /25 are equiped with lateral outriggers (standard).

Forlift Pockets 25 as option

Operation Manual

GML 800+

1) Carriage

2) Bolt to secure attachments

3) Hold down bar (for transportations)

4) Mast System

5) Lifting eye

6) Worm winch

7) Worm winch crank

8) Push bar

9) Adjustment holes for push bar

Glass and Material Lift GML 800+

7

Not Aus

1

2

5

9) Stabilizer

10) Cable cover

11) Electric control box

12) Electric motor

13) Winch unit

14) Counterweight box

15) Counterweight securing pin

16) Steering arm

3

4

6 7 8

9

11

12

13

14 15 16 17

18 19 20 2021 201822 23 24

10

Components GML/K AC (Types GML /10 und /15)

With counterweights (K) and electrical 220/110V winch (AC).

Types GML /10 und /15 without lateral outriggers (as option available)

All Types GML /20 und /25 are equiped with lateral outriggers (standard).

(ref. „Componets GML/K M“)

Operation Manual

GML 800+

1) Carriage

2) Bolt to secure attachments

3) Hold down bar (for transportations)

4) Mast System

5) Lifting eye

6) Worm winch

7) Worm winch crank

8) Push bar

17) Counterweights (2x 6 pcs.)

18) Support wheel

19) Holes for outrigger

20) Swivel caster with brake

21) Chassis

22) Securing pin

23) Bolt with nut

24) Outrigger

Glass and Material Lift GML 800+

8

Battery Cart description: next page.

Components GML/K DC (Tyxpes GML /10 und /15)

With counterweights (K) and electrical 24V winch (DC).

Not Aus

1

2

5

3

4

6 7 8

9

11

12

13

16 17 18 1819 1619 20 21

10

14

15

18

9) Stabilizer

10) Cable cover

11) Electric control box

12) Electric motor

13) Winch unit

14) Power supply

15) Slip-On for battery cart

16) Support wheel

17) Holes for outrigger

18) Swivel caster with brake

19) Chassis

20) Securing pin

21) Outrigger

Operation Manual

GML 800+

Types GML /10 und /15 without lateral outriggers (as option available)

All Types GML /20 und /25 are equiped with lateral outriggers (standard).

(ref. „Componets GML/K M“)

1) Carriage

2) Bolt to secure attachments

3) Hold down bar (for transportations)

4) Mast System

5) Lifting eye

6) Cable remote control

7) Push bar adjustment holes

8) Push bar

Glass and Material Lift GML 800+

9

1) Push bar

2) Battery pack locking

3) Battery pack

4) Counterweights (3 pcs. each side)

5) Counterweight box (screwed)

6) Slip-On eye for Securing pin

7) Slip-On securing pin

8) Caster

9) Swivel caster with brake

10) Battery access

18 32

20 28

24

-+

-+

100% -+

11 10

1

8

9

Left side: Right side:

Both sides:

11) Battey supply

Left side:

12) Power switch

13) Voltmeter

14) Charger with charge indicator

15) Charger supply

Right side:

8

12 13 14 15

6

5

4

3

7

9

Battery Cart GML/K DC (Tyxpes GML /10, 15, 20, 25)

With counterweights (K) and electrical 24V winch (DC).

Operation Manual

GML 800+

Battery Cart includes batteries, charger, voltmeter, power switch, counterweights.

10

2

Glass and Material Lift GML 800+

10

Emergency

Stop

Electric Components AC-Series

Control box and cable remote control.

1) Green LED: ready to operate

2) Red LED: electrical interference

3) 24V socket for electrical attachments

4) Emergency Stop

5) Power switch (On/Off)

6) Cable remote control supply

Emergency

Stop

1 2

7

4

5

6

Control box left side: Control box right side:

000000

8

9

7) Hour meter

8) Fuse

9) 230/110V supply

Control box buttom side:

10 11 12

10) Limit switch supply

11) Emergency descent

12) Winch supply

Cable remote control:

13

14

15

16

13) Switch UP/DOWN

14) Accessory control

15) Emergency Stop

16) Control box supply

4

Operation Manual

GML 800+

Glass and Material Lift GML 800+

11

Electric Components DC-Series

Control box and cable remote control.

Emergency

Stop

1) Green LED: ready to operate

2) Red LED: electrical interference

3) 24V socket for electrical attachments

4) Emergency Stop

5) Power switch (On/Off)

6) Cable remote control supply

Emergency

Stop

1 2

7

4

5

6

Control box left side: Control box right side:

000000

8

9

7) Hour meter

8) Fuse

9) Battery supply

Control box buttom side:

10 11 12

10) Limit switch supply

11) Emergency descent

12) Winch supply

Cable remote control:

13

14

15

16

13) Switch UP/DOWN

14) Accessory control

15) Emergency Stop

16) Control box supply

4

Operation Manual

GML 800+

Glass and Material Lift GML 800+

12

OFF

ON

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the lift.

c) the inscriptions, labels and warning signs on the lift.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

Warning!

Failure to obey the instructions and safety regulations in this manual

may result in death or serious injury.

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the lift.

3. Inspect the working area thoroughly before

using the lift.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the lift as per the operating instructions.

Any deviations are not acceptable. In case,you

must always contact the owner of the equipment.

Safety Instructions

Operation Manual

GML 800+

Glass and Material Lift GML 800+

Do Not Operate Unless:

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the lift.

3. Inspect the working area thoroughly before

using the lift.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the lift as per the operating instructions.

Any deviations are not acceptable. In case,you

must always contact the owner of the equipment.

GML 800+

13

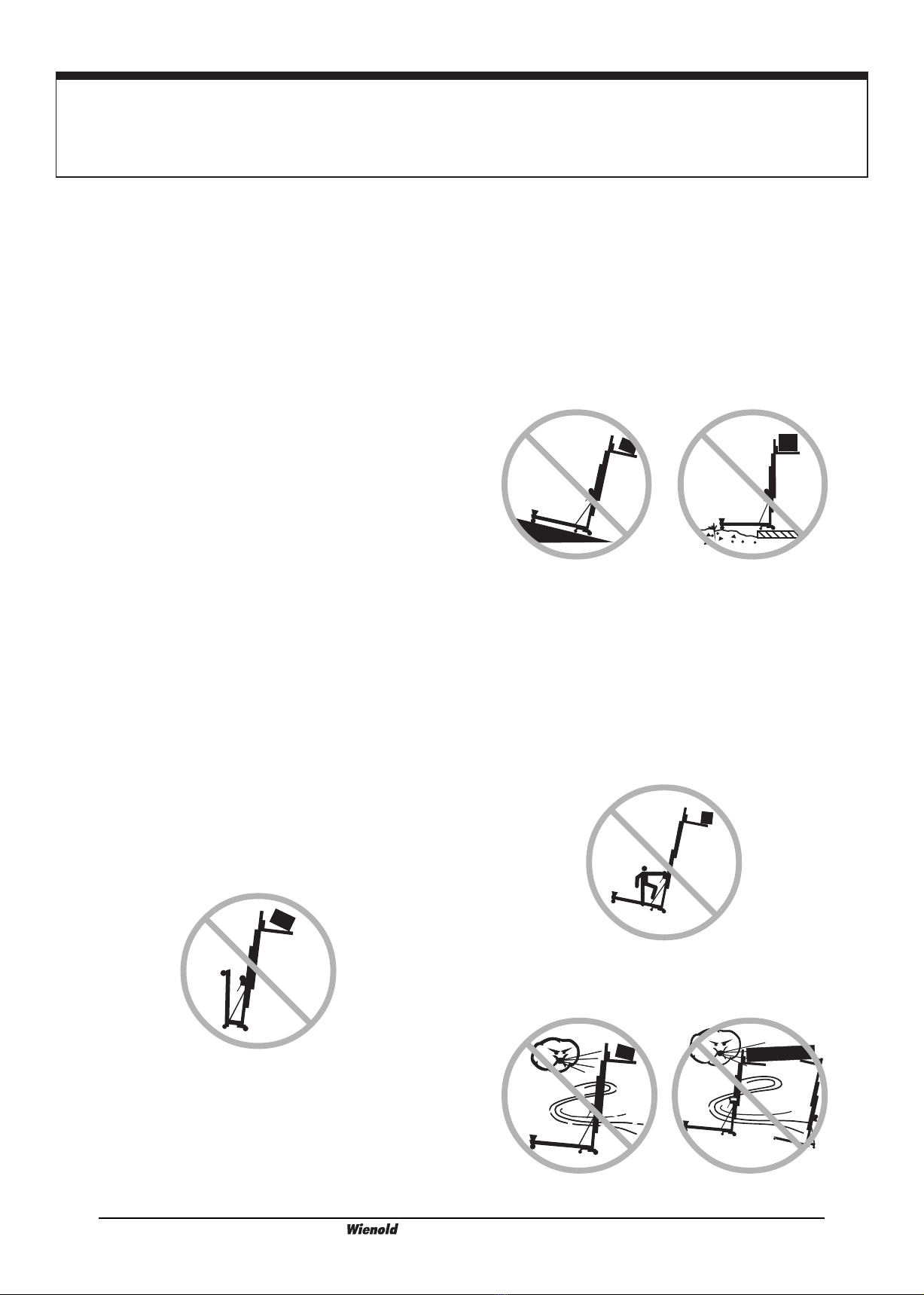

Prior to use, check the working area for steep slopes &

drop-offs, holes and debris. Also check for instable, slippery

or icy surfaces and other possible sources of danger.

Do not raise the load unless the loading accessories

are correctly secured to the lift.

Do not use any blocks, stones, planks or any other items

to balance the lift.

Do not move the lift with a raised load except for very

minor positioning.

Never operate the lift if it is iced.

Never operate the lift in strong or gusty wind conditions.

An increase in the load surface area will decrease lift

stability when operating in windy conditions.

Never leave a load in a raised position when windy

conditions may occur unless the lift is correctly tag lined.

Always ensure, when raising or lowering secured or

overhanging loads, that no obstructions can interfere

with the safe operation of the lift.

Safety Instructions

Wear Appropriate Personal Protective

Equipment (PPE)

Always wear PPE before operating the lift including:

1. Safety helmets

2. Safety goggles

3. Safety shoes

Always check which PPE is required at each particular

job site. Do not use the lift and do not execute any

function tests without wearing the appropriate PPE.

Keep loose clothes, jewelry, hair etc. away from any moving

parts and ensure appropriate PPE is worn whilst operating

the unit. Keep hands and feet within the areas acceptable

to operate the winch safely to raise or lower the unit.

Fall Hazards

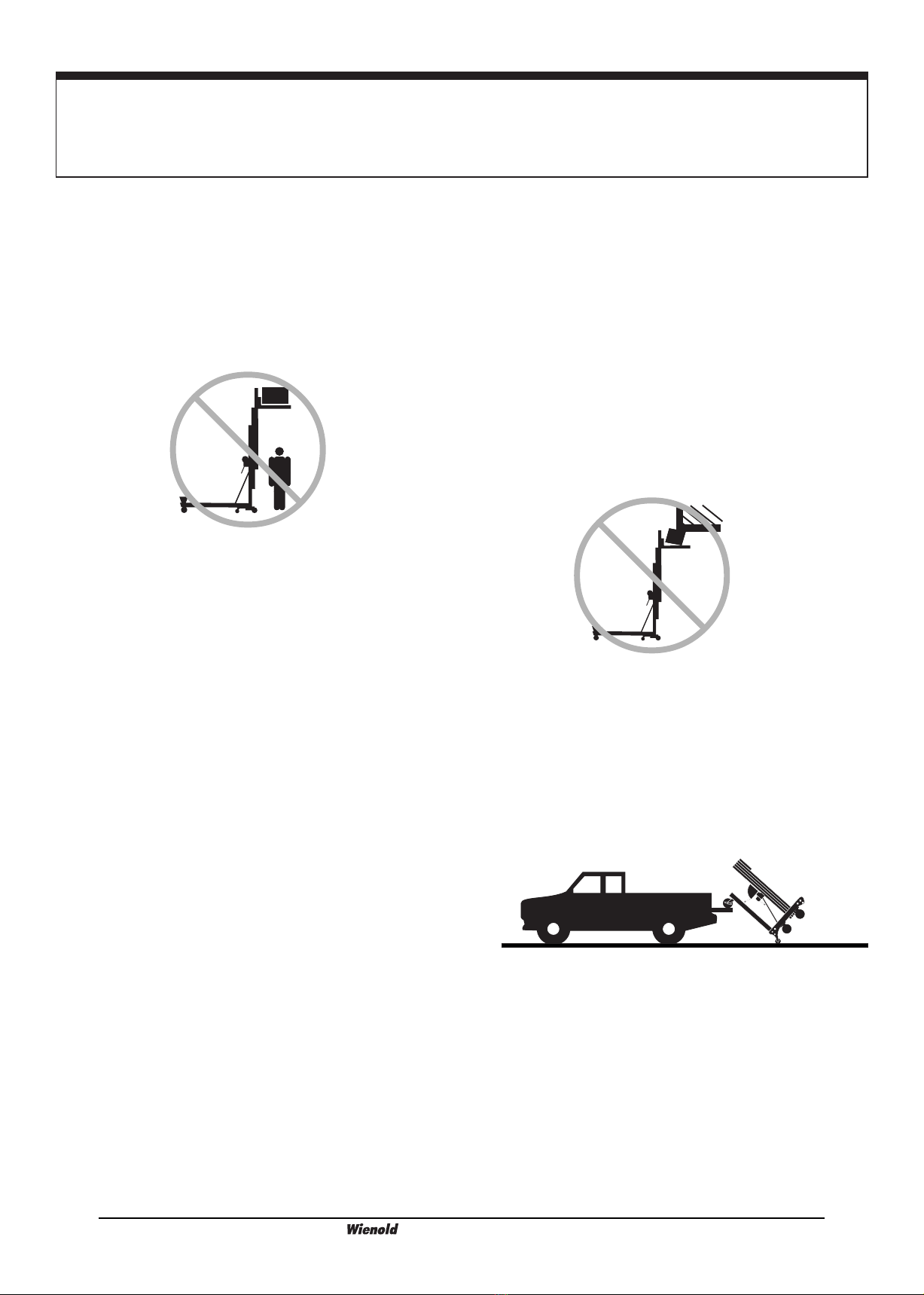

Do not use this lift as a personnel lifting platform or step.

Do not stand on the loading accessories (e.g. lifting fork

etc.).Do not climb on the mast, the chassis or other

components.

Tip-over hazards

Always ensure before either loading or lifting that the lift is

positioned on a secure, solid, flat and horizontal subsurface.

Do not raise the load until all the available stabilisers and

legs have been fully lowered and secured and the casters

are in full contact with the work surface.

Do not raise the load until all outriggers are extended and

the appropriate leg retainer pins are properly inserted into

the chassis.

When using models with counterweights, only raise the load

when the weight box has been completely filled with the

specified counterweights.

A fixed and secured outrigger must not be re-adjusted

as long as the lift is loaded or is in a raised position.

Operation Manual

GML 800+

Glass and Material Lift GML 800+

GML 800+

14

Electrocution Hazards - Danger to Life

This lift is not electrically insulated and will not provide

protection from contact with or proximity to electrical current.

Keep away from the lift if it contacts electrical power cables.

Personnel must not touch or operate the lift until the power

conductors have been switched off.

Maintain safe distances away from electrical power conductors

and appliances.

Please take into account the relevant current legal regulations

and the following chart:

Do not lean any ladders or scaffolding against the lift or

the load.

Do not operate the lift on a movable/mobile surface or

on a motor vehicle.

The Safe Working Load (SWL) must not be exceeded

under any circumstances. Aways refer to the load charts

on the unit.

Avoid moving the lift with closed outriggers over debris or

uneven ground.

Never replace lift parts that are important for stability

or construction with parts with different weights and

specifications. Only use original replacement parts.

If the equipment is damaged or operating incorrectly

you must contact the hirer immediately.

Only use the approved loading accessories with this lift.

Lifting Hazards

Always use the correct lifting techniques when loading or

tilting the lift. Personnel should be trained and competent

to use the unit correctly.

Always use the correct lifting techniques when installing

and de-installing the loading accessories.

Operating the Lift

Ensure that the safety brakes are engaged prior to operating

the lift in order to avoid rolling.

Do not ever stand or allow others to stand under the loading

accessories.

Always remain behind the winch when raising or lowering.

Do not stand on the chassis, the outriggers or any other

components.

VOLTAGE

Phase-to-Phase

0 - 300 V

300 V - 50 kV

50 kV - 200 kV

200 kV - 350 kV

350 kV - 500 kV

500 kV - 7550 kV

750 kV - 1000 kV

Allow for mast movement and possible swaying and sagging

of electrical cables. Be especially careful in strong or gusty

wind conditions!

The unit is not to be used in conjunction with welding units

fitted to the forks under any circumstances..

Injury Hazard

Do not hold on the winch cable and do not grasp into the winch

itself.

Avoid Contact

3,1 m

4,6 m

6,1 m

7,6 m

10,7 m

13,7 m

MINIMUM SAFETY DISTANCE

Meters

Safety Instructions

Glass and Material Lift GML 800+

15

Operation Manual

GML 800+ GML 800+

Crushing Hazards

Do not raise if the load is not

1. correctly centred on the loading accessory.

2. correctly secured to the loading accessory.

Never stand under the load as it is being raised or lowered

or suspended. Do not allow others to stand in the lifting area

when the unit is being operated.

Standing under the load is prohibited.

The load may fall from between 30 and 91 cm before

the safety brake mechanism activates the locking of

the mast elements.

Do not lower the load unless the area below is clear

of personnel and obstructions.

Keep hands and fingers away from the winch, the folding

outriggers, loading accessories and any other potential

pinch points.

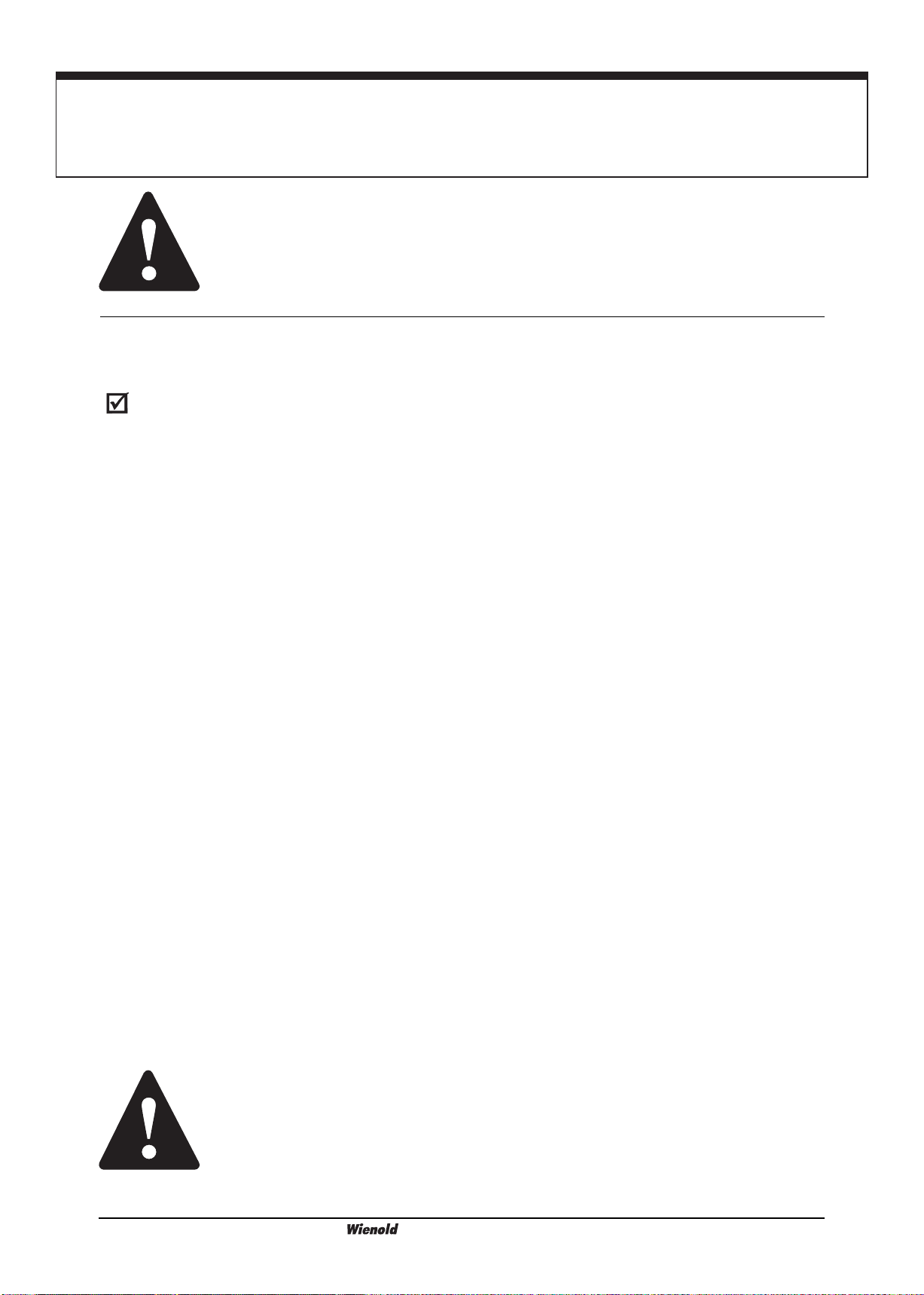

Maintain a firm grasp on the loading accessory when the safety

bolt is removed. Otherwise the loading accessory will fall.

Maintain a firm grasp on the outrigger when the safety bolt

is removed. Otherwise the outrigger will fall.

Maintain a firm grasp on the winch crank handle. The winch

brakes engage automatically when you stop winding.

The crank handle must not move when you stop winding.

Standard Forks

Only use appropriate loading accessories when lifting a

load. Always ensure before loading that the loading accessory

used is suitable for the load and is correctly secured.

Only raise the load when the loading accessory has been

correctly installed and the load has been correctly aligned and

secured. Always take into account the relation between lifting

height and load center .

Collision Hazards

Check the working area for overhead obstructions or other

potential sources of danger.

Always plan your route if transporting a load on site using the unit.

Avoid sharp turns, inclines or voids in the ground. Only move the lift

when in transport position!

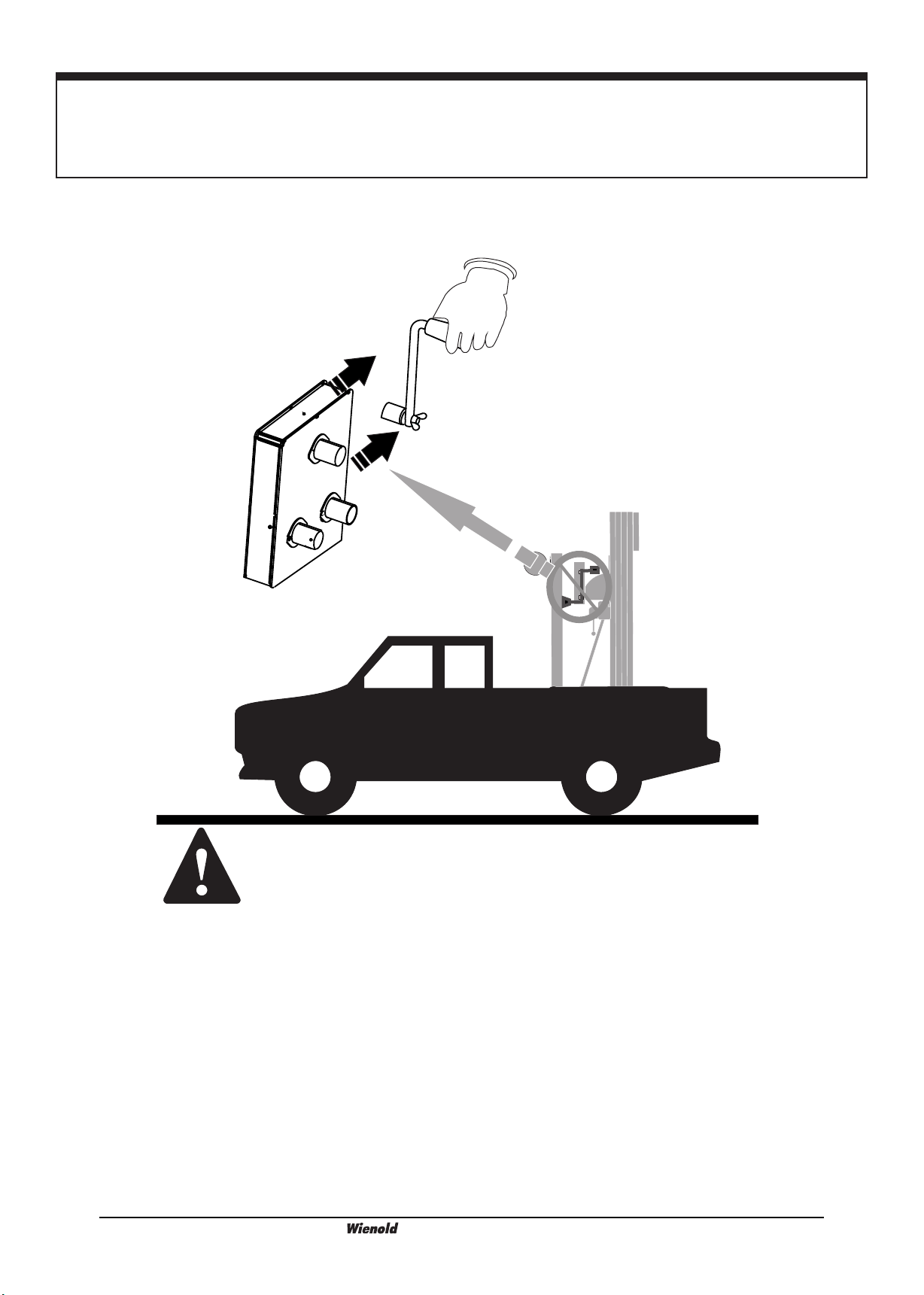

Loading

When loading the lift (for transport), always ensure that the lift

and the transport vehicle are on an even subsurface.

Always use the correct lifting techniques and always use the snap

hook on top of the lift when using a crane or the forklift receptors

when loading with a forklift.

Safety Instructions

Glass and Material Lift GML 800+

16

Operation Manual

GML 800+ GML 800+

Safety Instructions

Glass and Material Lift GML 800+

17

Operation Manual

GML 800+ GML 800+

RISK OF FALLING DOWN

Dismount the handle for transportation by road, sea or air

and store it in your vehicle. Otherwise there is a risk that the handle may come loose and fall down.

Only move the lift with the handle stored on the 3-step drill kit when there is no risk that the falling handle

could impute loss of life, physical injury or damage to health.

Legend - Warning Signs

Wienold lifts, appliances & machines use symbols,

colour codes and signal words to identify the following:

Damaged Lift Hazards

Do not operate a damaged or malfunctioning lift.

Do not use a lift with a worn,

frayed, kinked or damaged cable.

Do not use a lift with less than 4 layers

of cable on the winch drum when the

loading accessory is fully lowered.

Always conduct a thorough pre-operation inspection

prior to each use.

Any damage, faults or failure of the unit must be assessed

by a competent person trained to identify such matters

and instructed for repair work on this lift.

Non appliance to this rule may lead to serious injury and

possible danger to life.

Always ensure that all warning signs are legible and

in place.

Always ensure that the operating manual is complete, legible

and placed in the storage container installed on the lift.

Maintain proper lubrication on the winch. Do not allow oil or grease

on the brake surfaces or on the mast elements.

Only use silicon spray when lubricating the mast elements

(no oil or grease). Avoid spraying onto the brake surfaces.

Hazard due to improper use

Never leave a loaded lift unattended or suspended. Unauthorised

personnel may attempt to operate the lift without having been

correctly briefed and thereby create an unsafe situation.

Glass and Material Lift GML 800+

Safety Alert Symbol:

This is used to alert personnel to

potential injury hazards.

Obey all safety messages that

follow this symbol to avoid

possible injury or death.

RED = DANGER

This is used to indicate the presence

of an imminently hazardous

situation which, if not avoided,

will result in death or serious injury.

.

ORANGE = WARNING

This is used to indicate the presence

of a potentially hazardous situation

which, if not avoided, could result

in death or serious injury.

YELLOW = CAUTION

This is used to indicate the presence

of a potentially hazardous situation

which, if not avoided, may cause

property damage or could result

in death or serious injury..

Safety Instructions

18

Operation Manual

GML 800+ GML 800+

Fundamentals

The pre-operation inspection is a visual inspection which must

always be performed by the operator prior to each work

assignment.

This inspection is designed to identify and avoid possible

malfunctions of the lift before the operator tests it.

Check the lift for modifications, damages and loose or

missing parts.

A malfunctioning or modified lift must not be operated under

any circumstances.

If any damage or unauthorised deviation from factory delivered

condition is discovered, the lift must be removed from service

and appropriately tagged. Additionally, the owner of the

equipment must be informed.

Repairs to the lift may only be undertaken by a qualified service

technician in compliance with the manufacturer‘s specifications.

The operator must perform a new pre-operation

inspection after any repairs are completed, before going on to

the function tests.

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the lift.

c) the inscriptions, labels and warning signs on the lift.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

Non compliance with the instructions and safety rules in this

operating manual may result in serious injury or accidents

including death!

Glass and Material Lift GML 800+

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the lift.

3. Inspect the working area thoroughly before

using the lift.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the lift as per the operating instructions.

Any deviations are not acceptable. In case,you

must always contact the owner of the equipment.

Do not operate the lift unless :

Pre-operation Inspection

19

Operation Manual

GML 800+ GML 800+

Table of contents

Other HIRD GLASS Lifting System manuals

Popular Lifting System manuals by other brands

Paragon Pro

Paragon Pro Telpro PanelLift 460 Operator's manual

Presto Lifts

Presto Lifts ECOA DXS Series Installation, operation and service manual

Atlas Equipment

Atlas Equipment Atlas BP9000X Installation & operation manual

Omega Lift

Omega Lift 23225 user manual

BIG RED JACKS

BIG RED JACKS TORIN T83002 owner's manual

Grainger

Grainger 12R538 instruction manual