Stratus SAE-P48 Guide

Model No. SAE-P48

4 post Parking Lift

Single Point Manual Release

Lifting Capacity 8,000 lbs

Installation & Operation &

Maintenance Instructions

Important Note

1. This equipment can not be installed, operated or repaired without reading instructions.

2. Electricity must be hooked up by certified electrician.

3. Do not use this equipment beyond its rated capacity.

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

2

TABLE OF CONTENTS

1. Packing, transport and storage .......................................................................................................................................5

1.1 Packing..............................................................................................................................................................................5

1.2 Transport...........................................................................................................................................................................5

1.3 Storage..............................................................................................................................................................................5

2. Description of the machine...............................................................................................................................................6

3. Technical specifications....................................................................................................................................................7

4. Safety......................................................................................................................................................................................9

4.1 General warnings.............................................................................................................................................................9

4.2 Risks for people...............................................................................................................................................................9

4.3 Personnel crushing risks................................................................................................................................................9

4.4 Risk of the vehicle falling from lift..................................................................................................................................9

4.5 Slipping risks..................................................................................................................................................................10

4.6 Electrocution risks .........................................................................................................................................................10

4.7 Risks resulting from improper lighting........................................................................................................................10

4.8 Risks of breaking component during operation.........................................................................................................10

4.9 Risks for unauthorized uses.........................................................................................................................................10

4.10 Risks during vehicle lifting and working...................................................................................................................10

5. Installation...........................................................................................................................................................................11

5.1 Tool required...................................................................................................................................................................11

5.2 Checking for room suitability........................................................................................................................................12

5.3 Lighting.......................................................................................................................................................................12

5.4 Installation surface.........................................................................................................................................................12

5.5 Site layout..................................................................................................................................................................12

5.6 Connect the platforms and beams..............................................................................................................................13

5.7 Mount on the top post plate and fix safety ratchets..................................................................................................14

5.8 Mount on lifting platforms.............................................................................................................................................14

5.9 Fix transfer bar...............................................................................................................................................................16

5.10 Routing steel cable......................................................................................................................................................17

5.11 Installation of power unit.............................................................................................................................................17

5.12 Connection of hydraulic hoses..................................................................................................................................18

5.13 Lock system assembly................................................................................................................................................18

5.14 Make electrical hookup to power unit.......................................................................................................................19

5.15 Oil filling and bleeding.................................................................................................................................................20

5.16 Final installation...........................................................................................................................................................20

5.16.1 Runway leveling adjustment...........................................................................................................................20

5.16.2 Locking position adjustment..........................................................................................................................21

5.16.3 Accessory installation......................................................................................................................................21

5.16.4 Caster kit installation........................................................................................................................................21

5.17 Anchoring columns......................................................................................................................................................21

5.18 Check before start-up.................................................................................................................................................22

5.18.1 General checks...................................................................................................................................................22

5.18.2 Steel cable for proper installation.................................................................................................................22

5.18.3 Safety lock for proper installation.................................................................................................................22

5.18.4 Hydraulic system for proper operation........................................................................................................22

5.19 Check with load ...........................................................................................................................................................22

6. Operation and use.............................................................................................................................................................23

6.1 Controls of lift .................................................................................................................................................................23

6.1.1 Lifting......................................................................................................................................................................23

6.1.2 Standing .................................................................................................................................................................24

6.1.3 Lowering.................................................................................................................................................................24

6.2 Moving with caster kit ..............................................................................................................................................24

7. Maintenance........................................................................................................................................................................25

7.1 Ordinary maintenance...................................................................................................................................................25

7.2 Periodic maintenance....................................................................................................................................................25

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

3

8. Troubleshooting.................................................................................................................................................................26

9. Parts list...............................................................................................................................................................................27

9.1 Explode drawing and parts list.....................................................................................................................................27

9.2 Transverse beam and parts list...................................................................................................................................29

9.3 Power-side runway and parts list................................................................................................................................31

9.4 Hydraulic line and parts list..........................................................................................................................................33

10. Special notes....................................................................................................................................................................34

10.1 Environmental damage...............................................................................................................................................34

10.2 Dismantling...................................................................................................................................................................34

10.3 Disposal........................................................................................................................................................................34

10.4 Noise declaration.........................................................................................................................................................35

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

4

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide sufficient instruction for the

safe operation of the product. The information is provided clearly and concisely. The chapters are arranged by

letter and the pages are numbered continuously.

Our products are subject to ongoing development. Our company reserves the right to alter the design,

equipment and technical features of the system. No guarantee of particular features of the product should

therefore be assumed from the present operating instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following graphics:

Indicates an extremely hazardous situation. Failure to comply with this instruction will result in

severe irreparable injury and even death.

Indicates an extremely hazardous situation. Failure to comply with this instruction may result in

severe irreparable injury and even death.

Indicates a hazardous situation. Failure to comply with this instruction may result in

slight to medium injury.

Indicates a material hazard. Failure to comply with this instruction may result in material damage.

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

5

1. Packing, transport and storage

All packing, lifting, handling, transport and unpacking operations are to be performed exclusively by expert

personnel with knowledge of the lift and the contents of this manual.

1.1 Packing

The packing of the lift is delivered in following components:

•1 base unit packed in a steel frame, wrapped up in non-scratch material, including all the accessories.

•1 power unit packed in a carton box.

1.2 Transport

See Fig 1, packing can be lifted or moved by lift trucks, cranes or bridge cranes. In case of slinging, a second

person must always take care of the load, in order to avoid dangerous oscillations.

During loading and unloading operation, goods must be handled by vehicles or ships.

At the arrival of the goods, verify that all items specified in the delivery notes are included. In case of missing parts,

possible defects or damage due to transport operations.

If finding missing parts, possible defects or damage due to transport, one should examine damaged cartons

according to <<Packing List.>> to verify the condition of damaged goods and missing parts, also the person in

charge or the carrier must be immediately informed.

The machine is heavy goods! Don’t take manpower load and unload and transporting way into consideration, the

safety of working is important.

Furthermore, during loading and unloading operation goods must be handled as shown in the picture. (Fig 1)

Fig 1

1.3 Storage

The machine equipment should be stocked in the warehouse, if stocked outside should do the disposal well of

waterproof.

Use box truck in the process of transport, use container storage when shipping.

The control box should be placed perpendicularly during the transport; and prevent other goods from extrusion.

The temperature for machine storage: -10ºC -- 40ºC

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

6

2. Description of the machine

The lift is suitable for lifting motor vehicles having maximum weight as described in the nameplate on the power

side column of the lift. The electro hydraulic operation is described in detail in chapter 8.

This chapter describes the lift’s principal elements, allowing the user to be familiar with the machine. As shown in

figure 2, the lift is composed of four columns: 1 power-side column (1), 3 off-side columns (2), two platforms: the

power-side platform (3) and the off-side platform (4), and two transverse beams (5), anchored to the ground by

means of the column base plates.

Raising motion is carried out by pushing the lifting button on the power unit (6) to operate a power unit delivering

the hydraulic fluid to cylinders to act on cable lifting system. Lowering motion is controlled by pressing the lowering

lever on the power unit and carried out under the weight of the load lifted.

The automatic back-up lock holds on the lift in the elevated position, can be released by pressing the latch release

lever (7). The slack cable lock in each end of transverse beam can hold on the lift in event of cable slackening

and/or failure. The caster kit (8) can be ordered as an option to move the lift.

Fig. 2

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

7

3. Technical specifications

CAPACITY

8,000 lbs (3,600kg)

Max. lifting height with no pad extension

86 15/16”(2209mm)

Min. adaptor height

4 15/16” (125mm)

Overall height

96 1/16”(2440mm)

Overall width

113 3/4”(2890mm)

Lifting time

≤60

S

Lowering time

30-40

S

Noise level

<85 dB(A)/1m

Working temperature

41°F - 104°F

Voltage

110V/60Hz/1PH

Power

2.2KW /3HP

Breaker

30A

Hydraulic Fluid Requirement

3-5 Gallons AW32/AW46

Average weight of package

1587 lbs (720kg)

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

8

Fig.5 Layout

Fig. 3

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

9

4. Safety

Read this chapter carefully and completely because it contains important information for the safety of the operator

and the person in charge of maintenance.

The lift has been designed and built for lifting vehicles and making them stand above level in a closed area,

any other use is forbidden.

The manufacturer is not liable for possible damages to people, vehicles, or objects resulting from an

improper or unauthorized use of the lift.

For operator and people safety, a safety area at least 3 feet away from the lift must be vacated during lifting and

lowering. The lift must be operated only from the operator’s control site in this safety area.

Operator’s presence under the vehicle, during working, is only admitted when the vehicle is lifted and the safety

lock is engaged.

Never use the lift when safety devices are off-line. People, the lift and the vehicles lifted can be seriously

damaged if these instructions are not followed.

4.1 General warnings

The operator and the person in charge of maintenance must follow accident-prevention laws and rules in force in

the country where the lift is installed.

Any use of the lift other than that herein specified can cause serious accidents to people in close proximity

of the machine.

They also must carry out the following:

•Neither remove nor disconnect hydraulic, electric or other safety devices;

•Carefully follow the safety indications applied on the machine and included in the manual;

•Observe the safety area during lifting;

•Be sure the motor of the vehicle is off, the gear engaged and the parking brake put on;

•Be sure only authorized vehicles are lifted without exceeding the maximum lifting capacity;

•Verify that no one is on the runways during lifting or standing.

4.2 Risks for people

All risks the personnel could run, due to an improper use of the lift, are described in this section.

4.3 Personnel crushing risks

During lowering of runways and vehicles, personnel must not be within the area covered by the lowering trajectory.

The operator must be sure no one is in danger before operating the lift.

Fig. 4

4.4 Risk of the vehicle falling from lift

Vehicle falling from the lift can be caused when the vehicle is improperly placed on platforms, and when its

dimensions are incompatible with the lift or by excessive movement of the vehicle.

In this case, keep immediately away from the working area.

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

10

Fig. 5

4.5 Slipping risks

The risk of slipping can be caused by oil or dirt on the floor near the lift.

Keep the area under and around the lift clean. Remove all oil spills.

4.6 Electrocution risks

Avoid use of water, steam, and solvent, varnish jets in the lift area where electric

cables are placed and, in particular, next to the electric panel.

Fig. 6

4.7 Risks resulting from improper lighting

Make sure all areas next to the lift are well and uniformly lit, according to local regulations.

4.8 Risks of breaking component during operation

Materials and procedures, suitable for the designed parameters of the lift, have been

used by the manufacturer to build a safe and reliable product. Operate the lift only for

the use it has been designed for and follow the maintenance schedule shown in the

chapter “Maintenance”.

Fig. 7

4.9 Risks for unauthorized uses

The presence of unauthorized persons next to the lift and on the platforms is strictly

forbidden during lifting as well as when the vehicle has been already lifted

Fig. 8

4.10 Risks during vehicle lifting and working

To avoid overloading and possible breaking during lifting and working, the following safety devices have been used:

•A pressure valve placed inside the hydraulic unit to prevent excessive weight.

•Automatic mechanical back-up safety holds on the lift in the elevated position.

•Slack safety in event of cable slackening and/or failure.

The maximum pressure valve has been preset by the manufacturer to a proper pressure. DO NOT try to

adjust it to overrun the rated lifting capacity.

It is strictly forbidden to modify any safety device. Always ensure the safety device for proper operation

during the service.

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

11

5. Installation

Only skilled technicians, appointed by the manufacturer, or by authorized dealers, must be allowed to carry

out installation. Serious damage to people and to the lift can be caused if installations are made by

unskilled personnel.

Always refer to the exploded views attached during installation.

5.1 Tool required

Rotary Hammer Drill D.20

Carpenter’s Chalk

Hammer

Screw Sets

Level Bar

Tape Measure (7.5m)

English Spanner (12")

Pliers

Ratchet Spanner With Socket (28#)

Socket Head Wrench (3#, 5#, 8#)

Wrench set

(10#, 13#, 14#, 15#, 17#, 19#, 24#, 27#, 30#)

Lock Wrench

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

12

5.2 Checking for room suitability

The lift has been designed to be used in covered and sheltered places free of overhead obstructions.

The place of installation must not be next to washing areas, painting workbenches, solvent or varnish deposits. The

installation near to rooms, where a dangerous situation of explosion can occur, is strictly forbidden. The relevant

standards of the local Health and Safety at Work regulations, for instance, with respect to minimum distance to wall

or other equipment, escapes and the like, must be observed.

5.3Lighting

Lighting must be carried out according to the effective regulations of the place of installation. All areas next to the lift

must be well and uniformly lit.

5.4 Installation surface

The lift does not require to be anchored to floor. But, despite if it is anchored or not, a level floor is suggested.Any

major slope change will affect the level lifting performance. If a floor is of questionable slope (more than 3 degrees),

considering to pour the new concrete slab. The new concrete slab must be adequately cured by at least 21 days.

If the lift is chosen to be anchored to floor, the concrete slab should have the compression strength of at

least 3000 PSI and the minimum thickness 6” with an extension of at least 4 feet from anchoring point.

5.5Site layout

•Determine which end of the lift will be approach side.

•Determine which side the power-side runway (with the hydraulic cylinder attached) will be located on.

Remember that the power-side runway must be installed on the same side as the power-side column.

Fig. 9

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

13

5.6 Connect the platforms and beams

•Place the two columns face to face with a distance of 102 15/16” and then push in the crossbeam from the top

of the posts.

•Erect the posts after both crossbeams was connected.

Fig. 10

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

14

5.7 Mount on the top post plate and fix safety ratchets

•Fix ratchet with the top post plate with M20 hex nut and flat washer. Ensue the four safety ratchets are of the

same height from the ground, this could be checked by measuring the distance of the lowest square hole

reserved on the ratchet and the floor.

•Fix the top post plate with the post using M12*25 hex head screw, spring washer and flat washer.

Fig. 11

①Top post plate ;② M12*25 hex screw ;③ φ12 spring washer;④ φ12 flat washer ⑤safety ratchet

⑥M20 nut ⑦φ20 flat washer

5.8 Mount on lifting platforms

1. Raise both crossbeams to the first locking points.

Fig. 12

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

15

2. Lift the platform with proper lifting equipment and place it onto the crossbeams. Fix the lifting platform and the

crossbeam with M12*25 hex socket flat head screw.

①Hex socket flat head screw M12*25

Fig. 13

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

16

3. Fix the installation plate for drive-on ramps

Fig. 14

①Installation plate for drive-on ramp ②M16*25 hex head screw ③Flat washer

5.9 Fix transfer bar

Insert the two section of the transfer bar respectively to the swing shaft assemblies in both crossbeams. Connect

the two sections into a whole with screws.

Fig. 15

①Transfer bar; ②Connection tube; ③Main swing shaft; ④Secondary swing shaft

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

17

5.10 Routing steel cable

Each cable must be routed through the column hole toward to the lift center. The lift cannot work properly

and thus damage the cable if failure to do so.

•Slide the cables from the end of power-side runway and route the cables though the pulleys in transverse

beams referring to the routing diagram (fig. 16). Make sure that the cables are not twisted during routing and

are in the proper pulley grooves. Make sure the cables are routed correctly on the slack cable rollers;

•Insert the thread end of steel cable through the top plate of the column and fi t two M20 nuts on the thread end,

then tighten them.

Fig. 16

5.11 Installation of power unit

•Attach the power unit onto the bracket on the power side column;

•Secure it using M8X20 screws, M10 nuts and the washers;

•Make sure to keep the power unit clean.

Fig. 17

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

18

5.12 Connection of hydraulic hoses

When routing the hydraulic hose, make sure that the hose is clear of any moving part, make sure to keep

the hose and fittings clean from dust.

•Clean the hoses and fittings;

•Inspect all threads for damage and make sure that all hose fittings are in good condition;

•Route the hydraulic hoses from the power unit to the cylinder as shown through the 90°bulkhead fitting fitted in

the power-side runway;

•Route the risen hose from the power unit to the cylinder as shown through the hole on the power-side runway;

•Tighten the hose fittings thoroughly. Make sure not to over-tighten the hose fittings so as to result in oil leakage.

Fig. 18

5.13 Lock system assembly

The single point safety lock is a system of connecting rods and linkage that disengage the four lock latches that

secure the lift to each column.

•Locate the parts in the package and preassembled in the lift referring to the figure 19 and the sheet below;

•Assemble the lock system referring to the figure 19 and tighten the respective screws and nuts;

•Make sure that all four latches can be released by depressing the lock release lever.

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

19

Fig. 19

Item

Description

Qty

Item

Description

Qty

1

Latch release rod B

1

9

Knob M10X33

1

2

Latch release rod A

1

10

Nut M12

2

3

Coupler

1

11

Nut M8 –left handed

4

4

Spacer

2

12

Nut M8

4

5

Long stud

2

13

Self-locking nut M8

8

6

Short stud

2

14

Screw M8X30

4

7

Bearing M8 –left handed

4

15

Right latch

2

8

bearing M8

4

16

Left latch

2

5.14 Make electrical hookup to power unit

The hookup work must be carried out by a qualified electrician. Make sure that the power supply is right.

Make sure the connection of the phases is right. The power unit must be kept dry.

•Make the electric hookup to the hydraulic power unit referring to the wiring diagram;

•Make sure to install a proper circuit breaker on the circuit (DZ47-63/ D32A/2P is suggested for single phase

110V);

•Make sure the lift is grounded well.

STRATUS 4 post parking Lift Installation & Operation & Maintenance Instructions

20

5.15 Oil filling and bleeding

DO NOT run power unit without oil. Damage to pump can occur. If motor gets hot or sounds peculiar, stop

immediately and recheck the electric connection.

If the vented cap is lost or broken, order the replacement. The oil tank must be vented well.

Add about 2.5 gallons of hydraulic oil to the hydraulic fluid reservoir, AW32 during winter time (cold weather), and

AW46 during summer time (hot weather).

Make sure there is no oil leak.

Repeatedly raise and lower the lift to bleed trapped air from the cylinders.

Power unit testing (Fig 20)

Fig 20

**Important Information**

7 Pressure Valve: Clockwise adjustment increases pressure to make the power unit to have more power,

counterclockwise adjustment decreases pressure to make the power unit to have less power.

8 Hydraulic oil Flow Valve: Clockwise adjustment to speed up, counterclockwise adjustment to slow down.

5.16 Final installation

5.16.1 Runway leveling adjustment

Runways must be leveled side to side, front to rear. The maximum tolerance cannot be over 1/8”.

•Raise the lift off all latches until the cables are supporting the lift and check that all cables are adjusted in the

same tension;

•Verify if both the runways are leveled horizontally by means of a water gauge or a leveling instrument. If not

make the adjustment referring to the figure 16.

Table of contents

Other Stratus Lifting System manuals

Stratus

Stratus SAE-P410 User manual

Stratus

Stratus SAE-F10S Installation instructions

Stratus

Stratus SAE-C10C Guide

Stratus

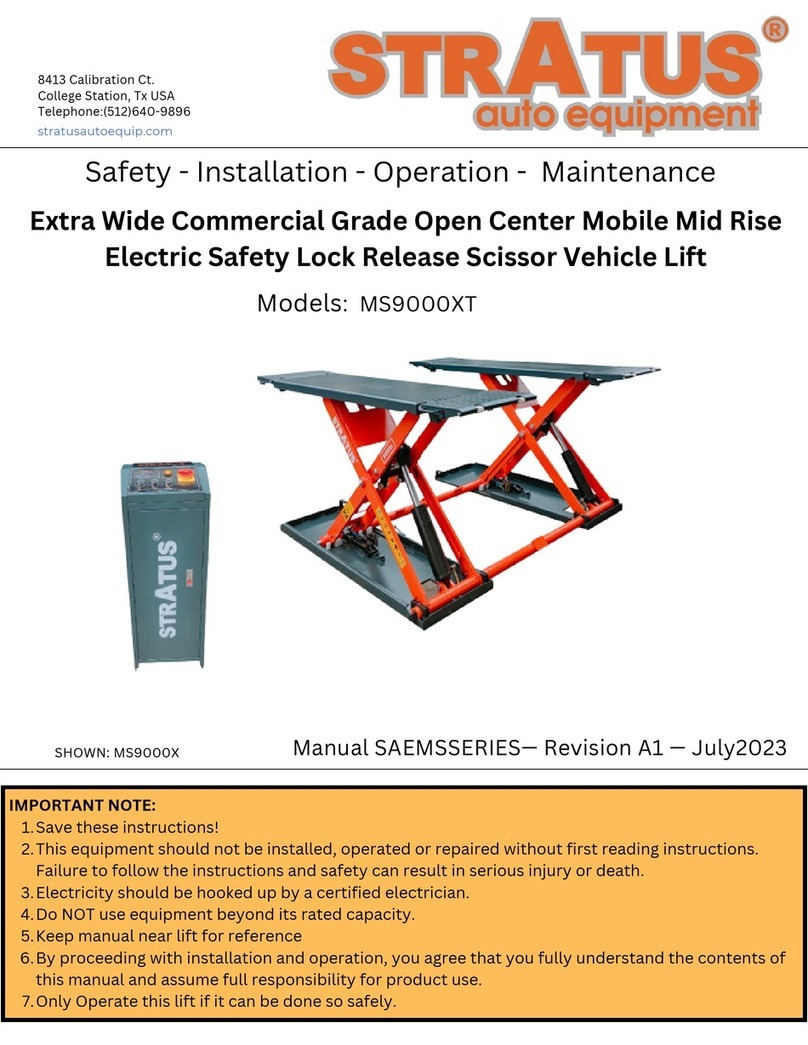

Stratus MS9000XT User manual

Stratus

Stratus SAE-C10P Guide

Stratus

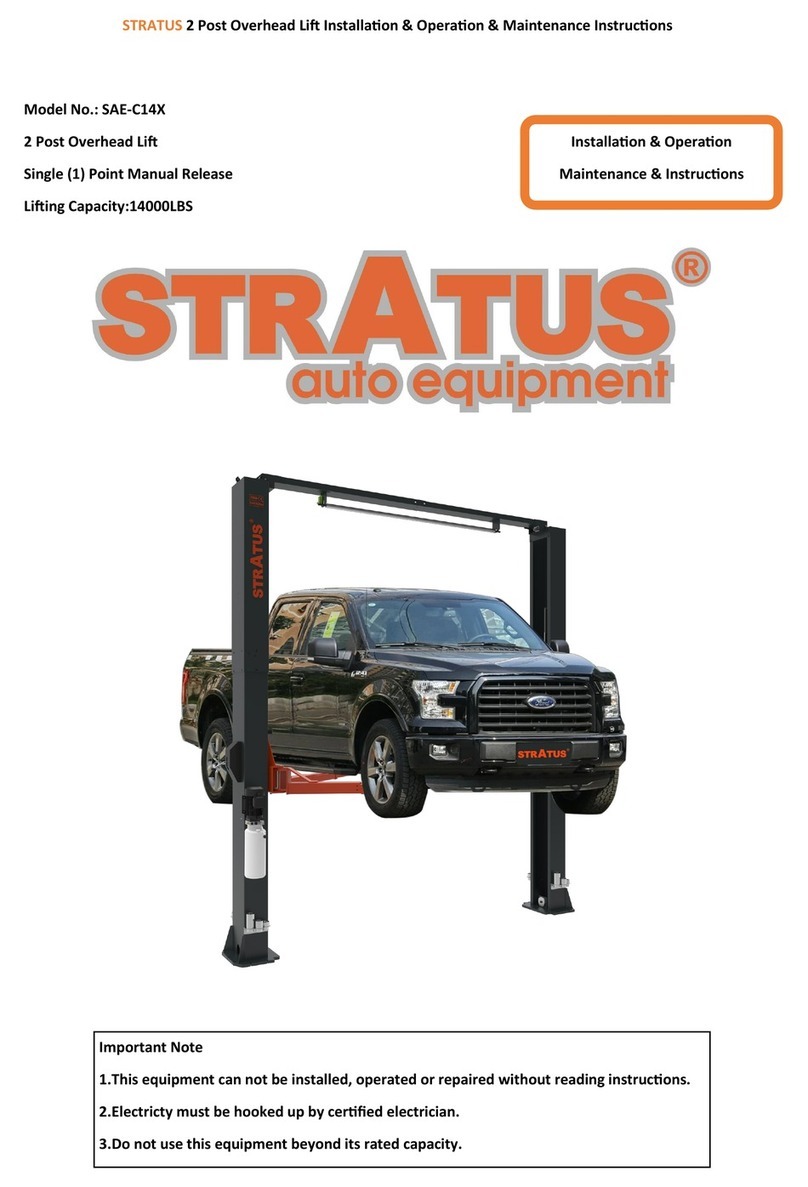

Stratus SAE-C14X Guide

Stratus

Stratus SAE-C10XE Guide

Stratus

Stratus SAE-UT8000 Guide

Stratus

Stratus SAE-P166M Guide

Stratus

Stratus SAE-C12X Guide