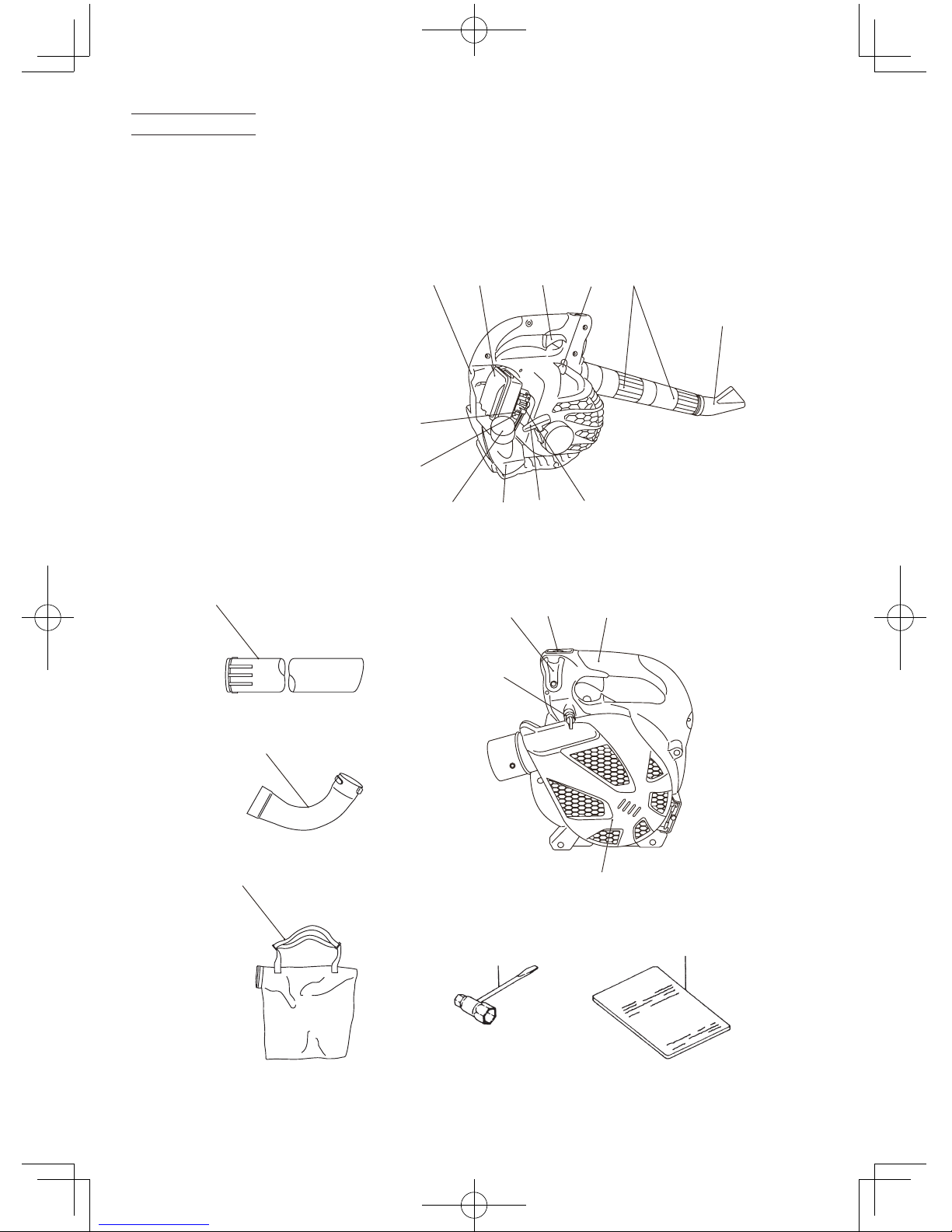

Assembly procedures

WARNING

Make sure the engine is turned off/stopped and not hot before

assembly.

NOTE ; Safety future

If you try to open the dust cover (5) when engine is running, it will

automatically stop the engine. (Fig.3)

But never try to open the dust cover (5) when engine is running

even with this future, otherwise serious personal injury may occur.

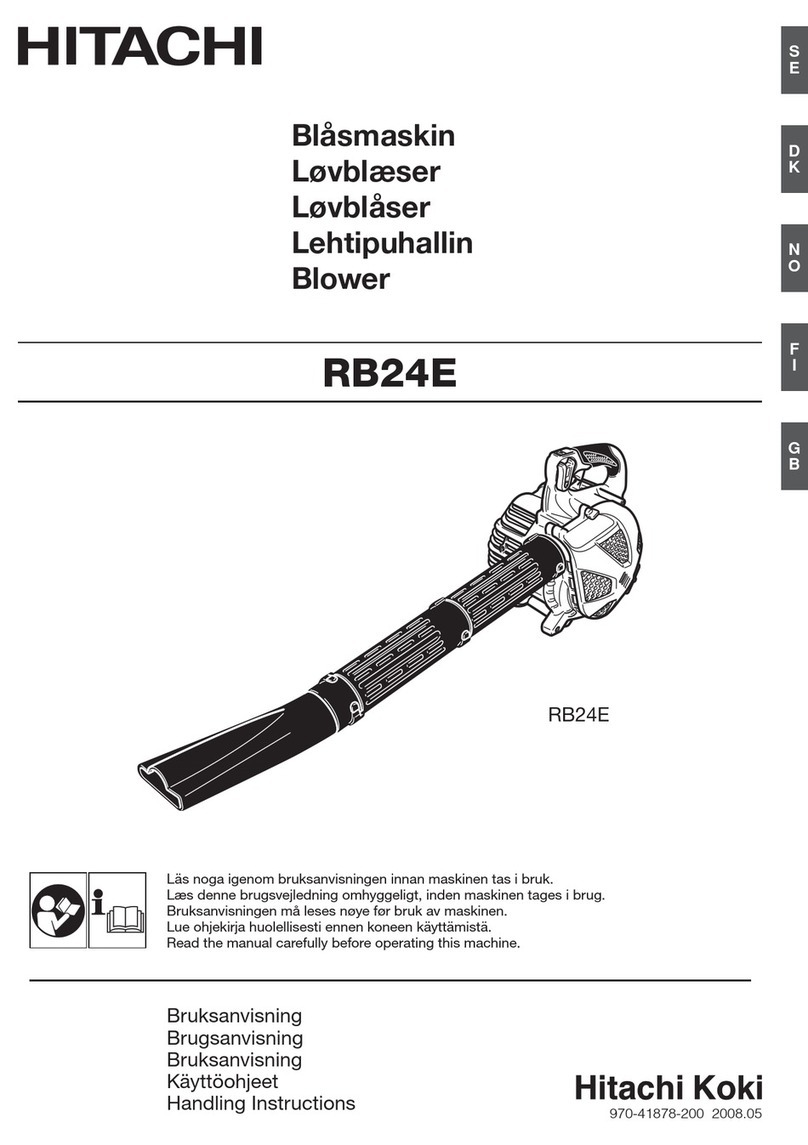

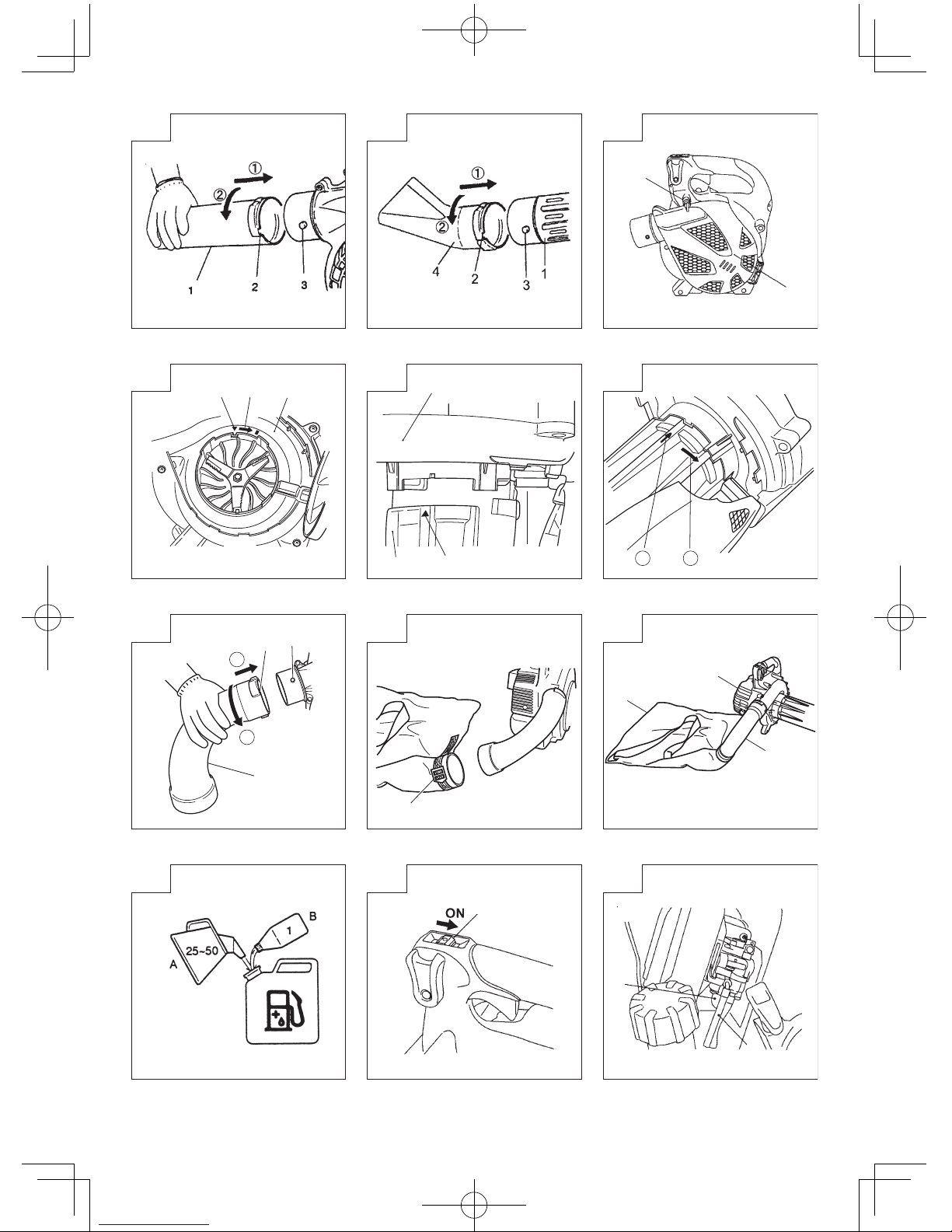

1. Blower assembly

Blow pipes to main body (Fig. 1)

Inspect the main body and accessories.

Connect straight pipe (1) and other pipe(s) securely. (See page 1 )

Align groove (2) in straight pipe with projection (3) on blower

housing (or another pipe) and slide the pipe onto the blower

housing (or another pipe).

Rotate the pipe clockwise to lock it into place.

Fan headed pipe to straight pipe (Fig. 2)

• Align groove (2) on the fan headed pipe (4) and projection (3) on

2nd straight pipe (1) and rotate the fan head in place.

2. Vacuum assembly

Vacuum pipe to main body (Fig. 5)

• Loosen knob bolt (5). (Fig. 3)

• Align the arrow(11) on the vacuum pipe (10) and the arrow (8) on

the fan case (7) as shown Fig. 4. (Fig. 4, 5)

• Slide( ①) the vacuum pipe into the fan case, and then rotate( ②)

the vacuum pipe clockwise(9) as shown Fig. 4 until it clicks.(Fig. 4)

Bent pipe and dust bag to main body

• Connect bent pipe (12), Align groove (13) in bent pipe with

projection (3) on blower housing and slide the pipe onto the

blower housing. Rotate the pipe clockwise to lock it into place.

(Fig. 7)

• Connect the dust bag to the installed bent pipe by inserting the

thinner part of the pipe into the opening of the bag. Fasten the

adjuster (14) securely by taping the end of the sawn strap. (Fig. 8)

WARNING

Always connect dust bag (16) to bent pipe (12).

Never try to connect directly to main body (15), otherwise dust bag

might approach near exhaust of mufer and it might cause res or

injuries. (Fig. 9)

Operating procedures

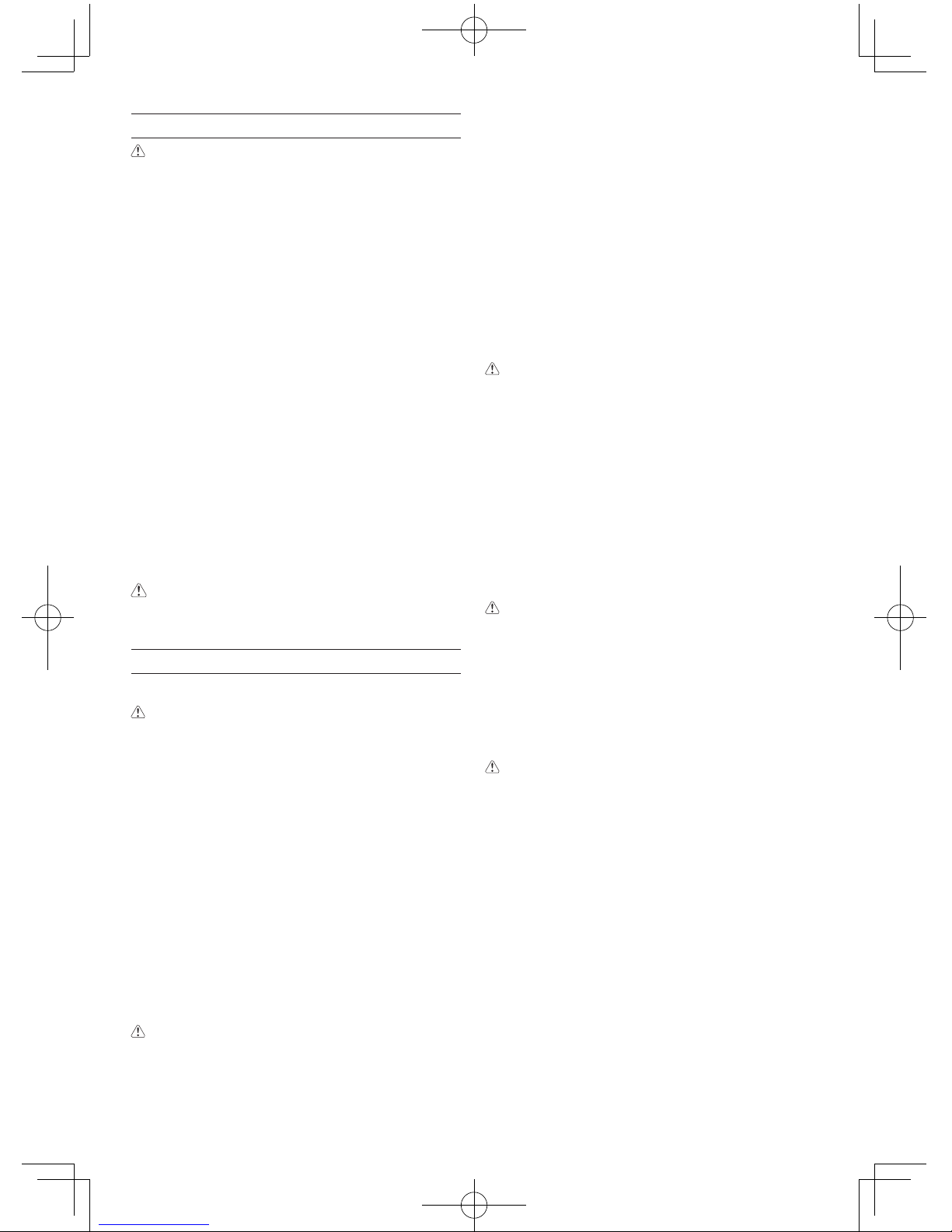

Fuel (Fig. 10)

WARNING

• This unit is equipped with a two-stroke engine. Always run

the engine on fuel, which is mixed with oil. Provide good

ventilation, when fueling or handling fuel.

• Fuel contains highly ammable and it is possible to get the

serious personal injury when inhaling or spilling on your body.

Always pay attention when handling fuel. Always have good

ventilation when handling fuel inside building.

Fuel

• Always use branded 89 octane unleaded gasoline.

• Use genuine two-cycle oil or use a mix between 25:1 to 50:1,

please consult the oil bottle for the ratio or Hitachi Authorized

Service Centers.

• Only for the state of California at 50:1.

• If genuine oil is not available, use an anti-oxidant added quality

oil expressly labeled for air-cooled 2-cycle engine use (JASO FC

GRADE OIL or ISO EGC GRADE). Do not use BIA or TCW (2-stroke

water-cooling type) mixed oil.

• Never use multi-grade oil (10 W/30) or waste oil.

• Always mix fuel and oil in a separate clean container.

Always start by lling half the amount of fuel, which is to be used.

Then add the whole amount of oil. Mix (shake) the fuel mixture.

Add the remaining amount of fuel.

Mix (shake) the fuel-mix thoroughly before lling the fuel tank.

Fueling

WARNING

• Always shut off the engine and let it cool for a few minutes

before refueling.

• Slowly open the fuel tank, when lling up with fuel, so that

possible over-pressure disappears.

• Tighten the fuel cap carefully, after fueling.

• Always move the unit at least 3 m (10 ft.) from the fueling area

before starting.

• Do not smoke and/or allow ames or sparks near fuel when

handling or lling fuel.

•

Always wash any spilled fuel from clothing immediately with soap.

• Be sure to check for any fuel leaking after refueling.

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

Starting the cold engine

CAUTION

Do not start if the pipe and dust cover are obstructed by the ground

or any other object.

1. Set ignition switch (17) to ON position. (Fig. 11)

*Push priming bulb (18) several times so that fuel ows through

the bulb or return pipe. (19) (Fig. 12)

2. Set choke lever to CLOSED position. (Fig. 13)

3. Pull recoil starter briskly, taking care to keep the handle in your

grasp and not allowing it to snap back. (Fig. 14)

4. When you hear the engine want to start, return choke lever to

RUN position (open). Then pull recoil starter briskly again.

WARNING

•

Never start or run the engine inside a closed room or building and/

or near the inammable liquid. Breathing exhaust fumes can kill.

•

Do not allow the rope to snap back in and always hold the unit rmly.

NOTE

If engine does not start, repeat procedures from 2 to 4.

5. After starting engine, allow the engine about 2-3 minutes to

warm up before subjecting it to any load.

Starting the warm engine

Use only 1 and 3 of the starting procedure for cold engine.

If the engine dose not start, use the same starting procedure

as for a cold engine.

Operating blower (Fig. 15)

• A low speed should be used to blow leaves and dry grass.

• A medium speed should be used to clean wet leaves and grass.

• A high speed should be used when moving gravel, dirt or other

heavy materials.

WARNING

• Do not direct discharge of air toward people or pet.

• The unit should be operated in a well ventilated area.

• Never perform assembly or disassembly procedures with

engine running or serious personal injury may result.

• Never touch mufer, spark plug, or other metallic parts while

engine is in running or immediately after shutting off engine.

CAUTION

This blower has been designed and adjusted to be used with all

blowing pipes attached (See page 1). It must never be operated

without the straight pipe, and fan headed pipe.

Operating vacuum (Fig. 16)

WARNING

Do not vacuum bottles, cans or any other hard materials, which

may cause damage or serious injuries.

• Do not use a bag with holes or tears in it. Even a small hole can

cause a lot of dust to come out. Repair or replace it immediately.

• Make sure zipper of the bag is completely closed.

• Wear shoulder strap over right or left shoulder.

• Make sure bevel at end of suction pipe faces downward.

• The unit should be operated In a well ventilated area.

• Use rakes and brooms to loosen debris before vacuuming.

•

A low speed should be used to vacuum small leaves and dry grass.

•

A medium speed should be used to vacuum large leaves and grass.

•

A high speed should be used to vacuum larger or wet leaves and grass.

• Dispose of debris in the bag more frequently in dusty condition.

NOTE

When you hear or feel strange sound or vibration, stop engine

immediately and check if anything blocks fans or pipes, If so,

remove it and check for damage.

Stopping (Fig. 17)

Decrease engine speed and run at an idle for a few minutes, then

turn off ignition switch.

NOTE

If the engine dose not stop, it can be forced to stop by setting

the choke lever to CLOSED position.

Before restarting the engine, ask Hitachi Authorized Service Centers

for repairs.