8.1 Homing Operation..........................................................................................................................................8-1

8.1.1 Desirable Homing.............................................................................................................................8-2

8.1.2 Low Speed Homing...........................................................................................................................8-2

8.1.3 High Seed Homing1 ( Off edge ).....................................................................................................8-4

8.1.4 High Seed Homing2 ( Marker stop ).............................................................................................8-7

8.1.5 Home position of Absolute Encoder..............................................................................................8-9

8.2 Manual Operation..........................................................................................................................................8-10

8.2.1 Manual Operation1 ( Control Mode by External Input ).........................................................8-10

8.2.2 Manual Operation2 ( Command Control Mode )......................................................................8-11

8.3Automatic Operation.....................................................................................................................................8-13

8.3.1 Automatic Operation1 ( One Step Operation )..........................................................................8-14

8.3.2 Automatic Operation2 ( Single cycle Operation )......................................................................8-16

8.3.3 Automatic Operation3 ( Continuous Cycle Operation )...........................................................8-17

Chapter 9 Positioning Module Installation 9-1 to 9-6

9.1 Loading the Positioning module..................................................................................................................9-1

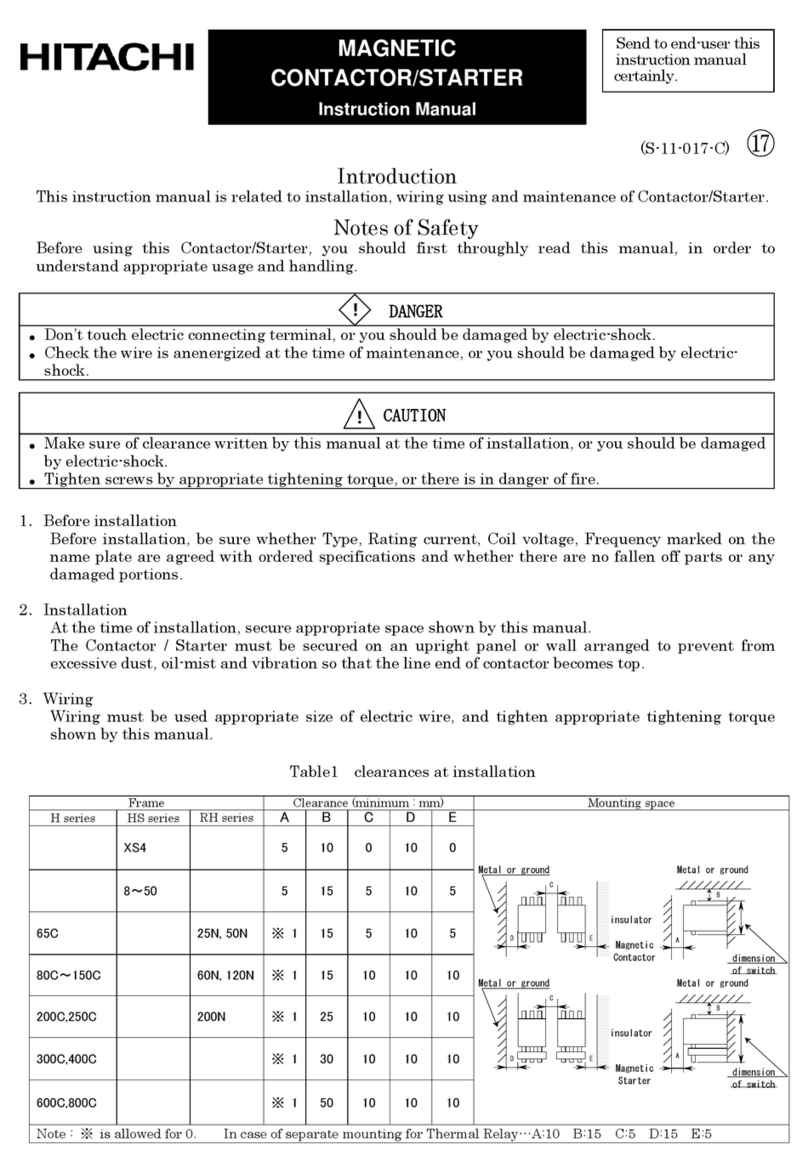

9.2Wiring to the Power supply module............................................................................................................9-2

9.3Wiring to the Positioning module...............................................................................................................9-2

9.3.1 Output wiring....................................................................................................................................9-2

9.3.2 Caution of Input / output wiring....................................................................................................9-3

9.4Example of wiring with a Servo Amplifier................................................................................................9-4

9.4.1 Example of wiring with Hitachi AD series (increment)...........................................................9-4

9.4.2 Example of wiring with Hitachi AD series (absolute)..............................................................9-5

9.4.3 Example of wiring with YasukawaΣII series (absolute)........................................................9-6

Chapter 10 Error code list 10-1 to 10-3

Chapter 11 Trouble shooting 11-1 to 11-4

11.1 Error indication of LED.................................................................................................................................11-1

11.1.1 Trouble shooting procedure for WDTE LED on. ( Module abnormal )...................................11-2

11.1.2 Trouble shooting procedure for O.R lamp on ( Overrun error )................................................11-3

11.2 Error indication of LED.................................................................................................................................11-4

11.3Error display atPositoner ( Option )..........................................................................................................11-4

11.4Error display on EH-CPU.............................................................................................................................11-4

11.5Abnormal operation of Motor......................................................................................................................11-4

Chapter 12 Comparison with POSIT-2H 12-1 to 12-2

12.1 Comparison with POSIT-2H........................................................................................................................12-1

12.2 Command Comparison with POSIT-2H....................................................................................................12-2

Chapter 13 Programming example 13-1 to 13-11

13.1 Caution on programming..............................................................................................................................13-1

13.2 Communication program..............................................................................................................................13-1

13.3Operation program.........................................................................................................................................13-5

13.4Data readout program...................................................................................................................................13-6

13.5Example of simple program and operation...............................................................................................13-7

13.5.1 Configuration.....................................................................................................................................13-7

13.5.2 Explanation of Execution...............................................................................................................13-7

13.5.3 Program..............................................................................................................................................13-8

13.5.4 Operation example...........................................................................................................................13-11

Chapter 14 ChapterPositioner ( option ) Operation 14-1 to 14-14

14.1 Structure and operation keys.......................................................................................................................14-1