Advantage Controls MegaTrom XSi User manual

Table of contents

Other Advantage Controls Controllers manuals

Advantage Controls

Advantage Controls MegatronXS Quick start guide

Advantage Controls

Advantage Controls MegaTron User manual

Advantage Controls

Advantage Controls MINI-TROL IF User manual

Advantage Controls

Advantage Controls MegaTronMT User manual

Advantage Controls

Advantage Controls 200 Series User manual

Advantage Controls

Advantage Controls NanoTron Nano-P Series Operating instructions

Advantage Controls

Advantage Controls MegatronXS User manual

Advantage Controls

Advantage Controls 75 Series User manual

Advantage Controls

Advantage Controls MegatronXS Operating instructions

Advantage Controls

Advantage Controls MICROtron MICRO-C User manual

Popular Controllers manuals by other brands

Sollae Systems

Sollae Systems CIE-H10 Update manual

Full Gauge Controls

Full Gauge Controls MT-512 E 2HP quick start guide

Chicago Pneumatic

Chicago Pneumatic CS7000 Hardware overview manual

SOMFY

SOMFY INIS UNO installation guide

HGLRC

HGLRC FD413 Stack manual

Door Controls

Door Controls DC-ONE V3 Getting Started and Troubleshooting Guide

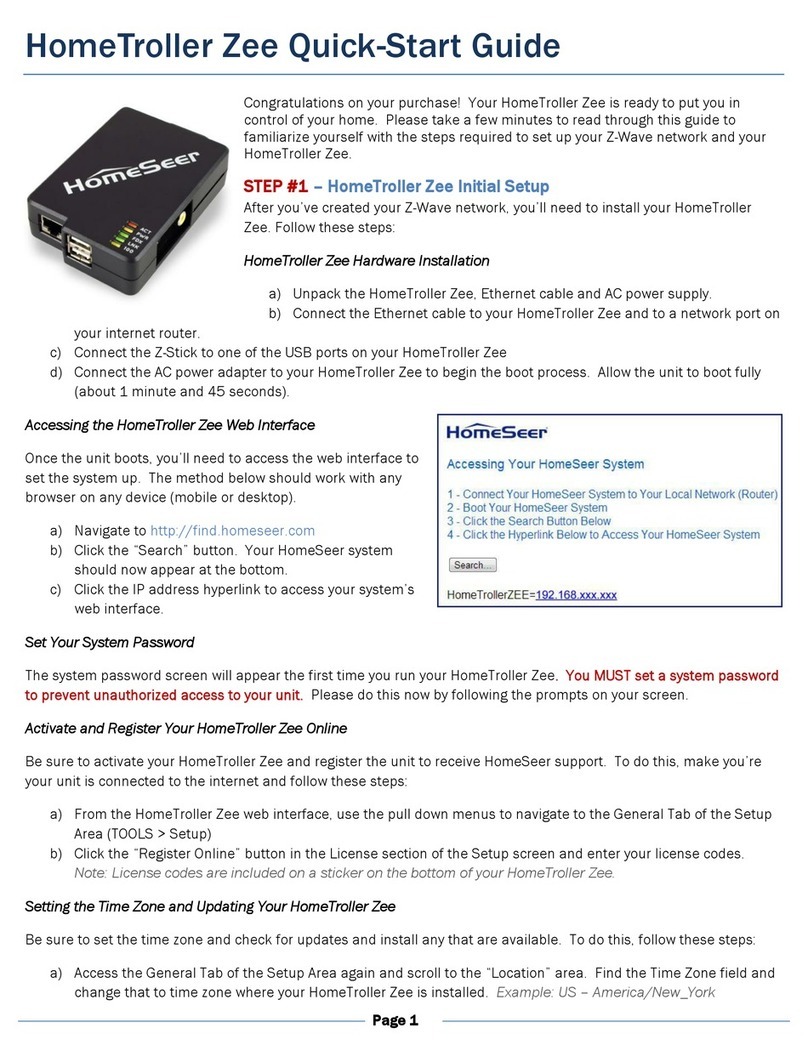

HomeSeer Technologies

HomeSeer Technologies HomeTroller Zee quick start guide

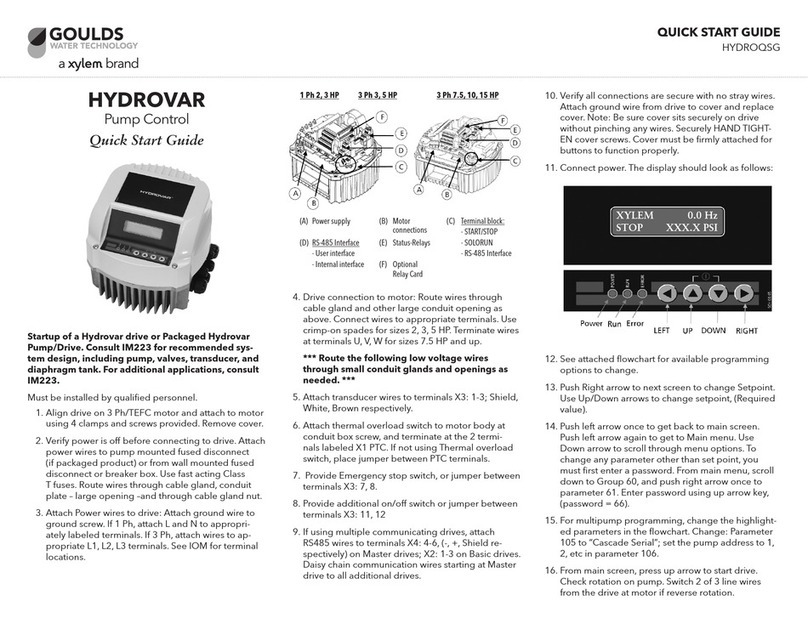

Goulds Pumps

Goulds Pumps HYDROVAR Quick start guides

Intelligent lighting

Intelligent lighting DMX-240A, DMX-240B user manual

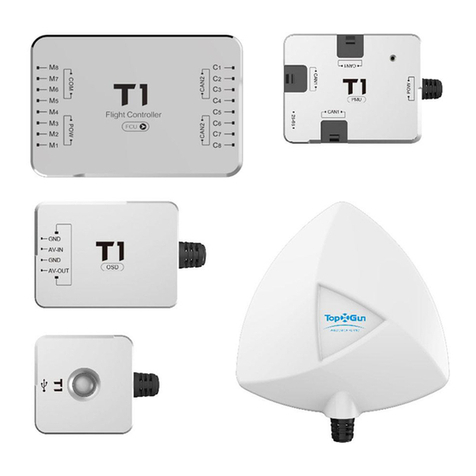

TopXGun

TopXGun T1-A user manual

Seneca

Seneca Z-PC SERIES installation manual

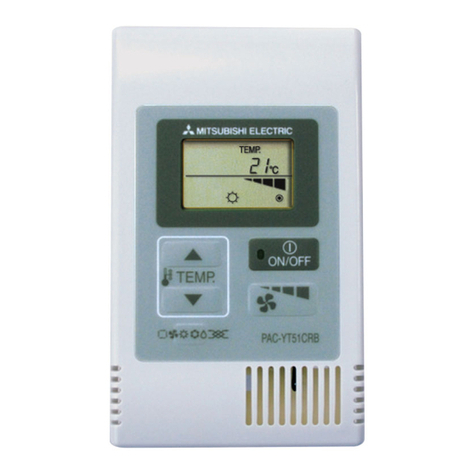

Mitsubishi Electric

Mitsubishi Electric SIMPLE MA PAC-YT51CRB Operation manual