-7-

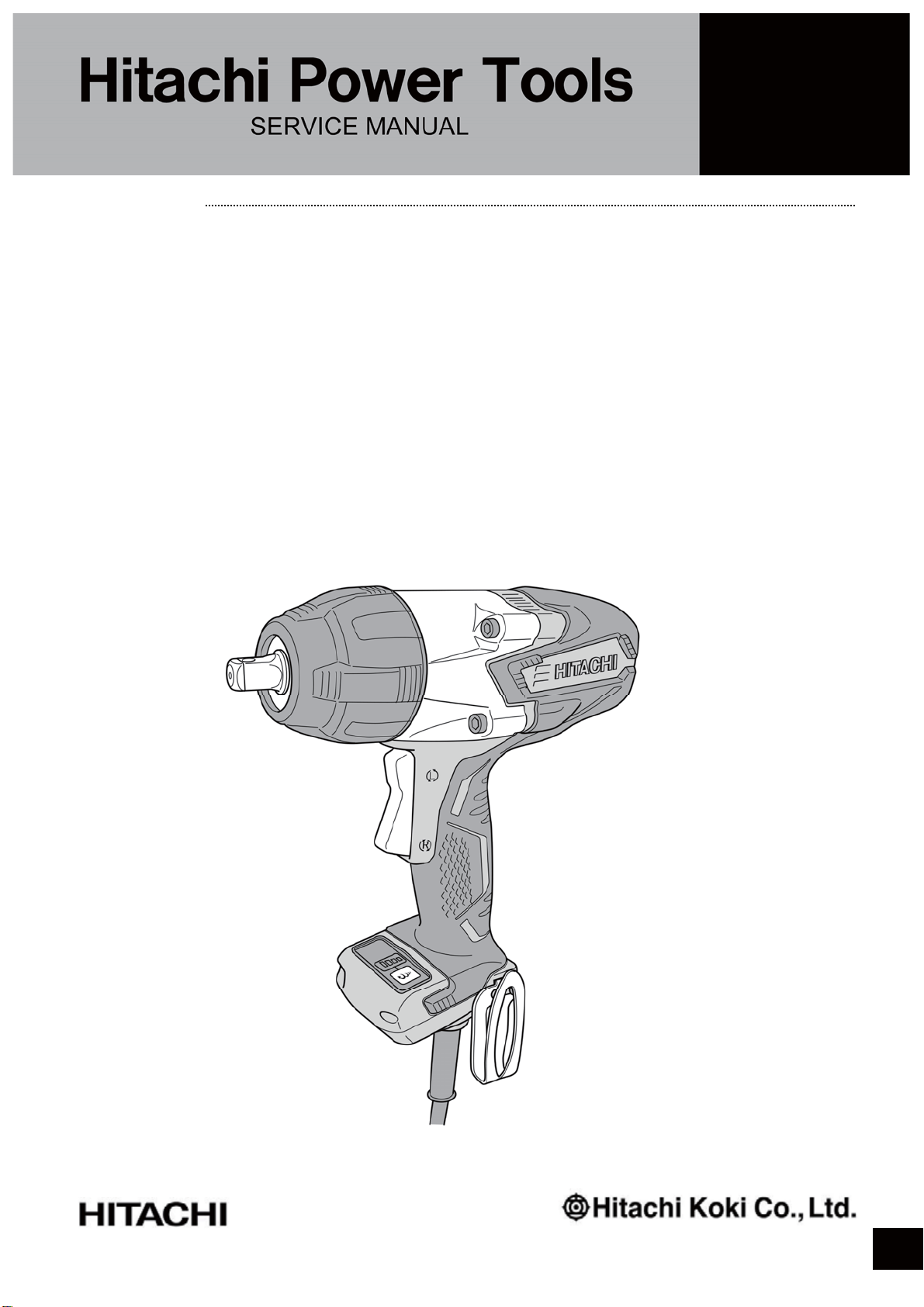

2. Reassembly of the impact mechanism components

(1) Mount two Washers (B) [12], Hammer Spring (A) [13], Washer (A) [14], and Spindle (A) [17] in this

order on Hammer (A) [8], which contains the twenth-nine Steel Balls D3.97 [9].

(2) Match the peak of the cam groove of Spindle (A) [17] with the steel ball insertion groove of Hammer

(A) [8]. Use a hand press or similar tool to press the end pawl portion of Hammer (A) [8] so as to

compress Hammer Spring (A) [13] until it contacts Spindle (A) [17], and then hold it there.

(3) Put the two Steel Balls D6.35 [7] in the steel ball insertion groove. Confirm that Steel Balls D6.35 [7]

are in the cam groove, and then release the hand press.

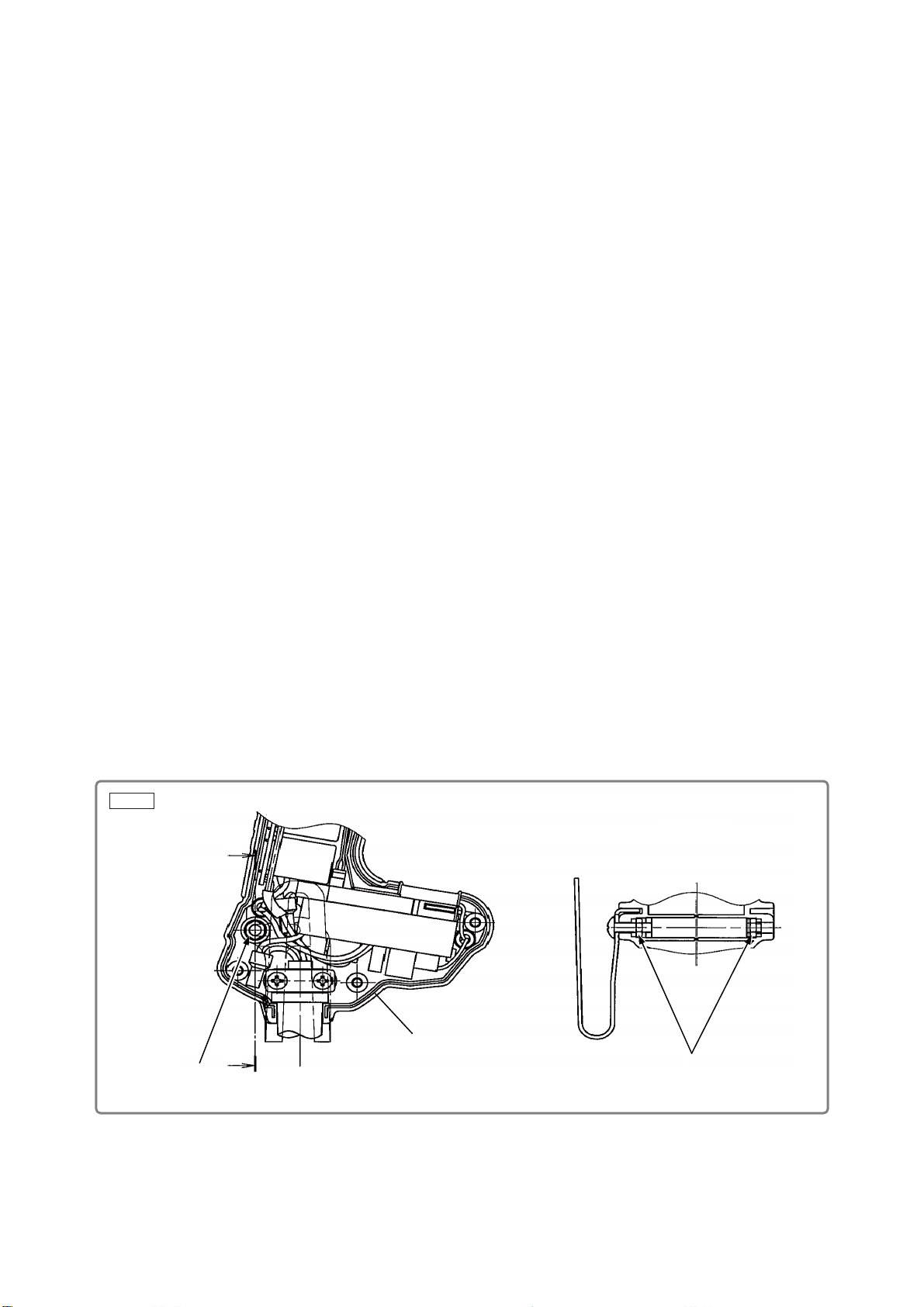

(4) Set the hammer ass’y on the J-364 washer (A) cradle (dedicated tool, Code No. 334413), use a hand

press or similar tool to press the end of Spindle (A) [17] so as to compress Hammer Spring (A) [13], fit

Stopper (A) [15] to the spindle shaft, and then release the hand press.

(5) Mount the Idle Gear Set (2 pcs.) [18] and the two Needle Rollers [16] on Spindle (A) [17].

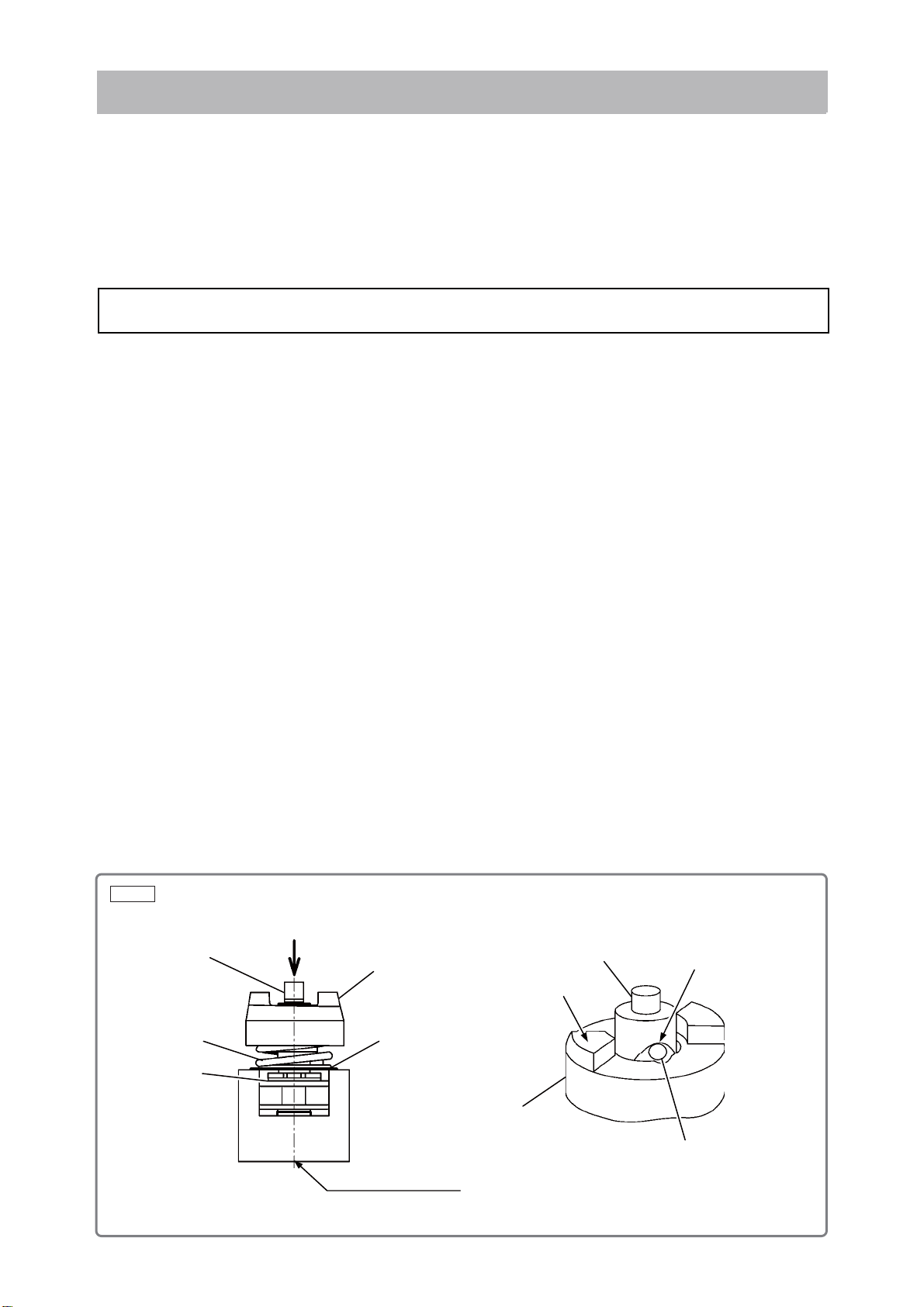

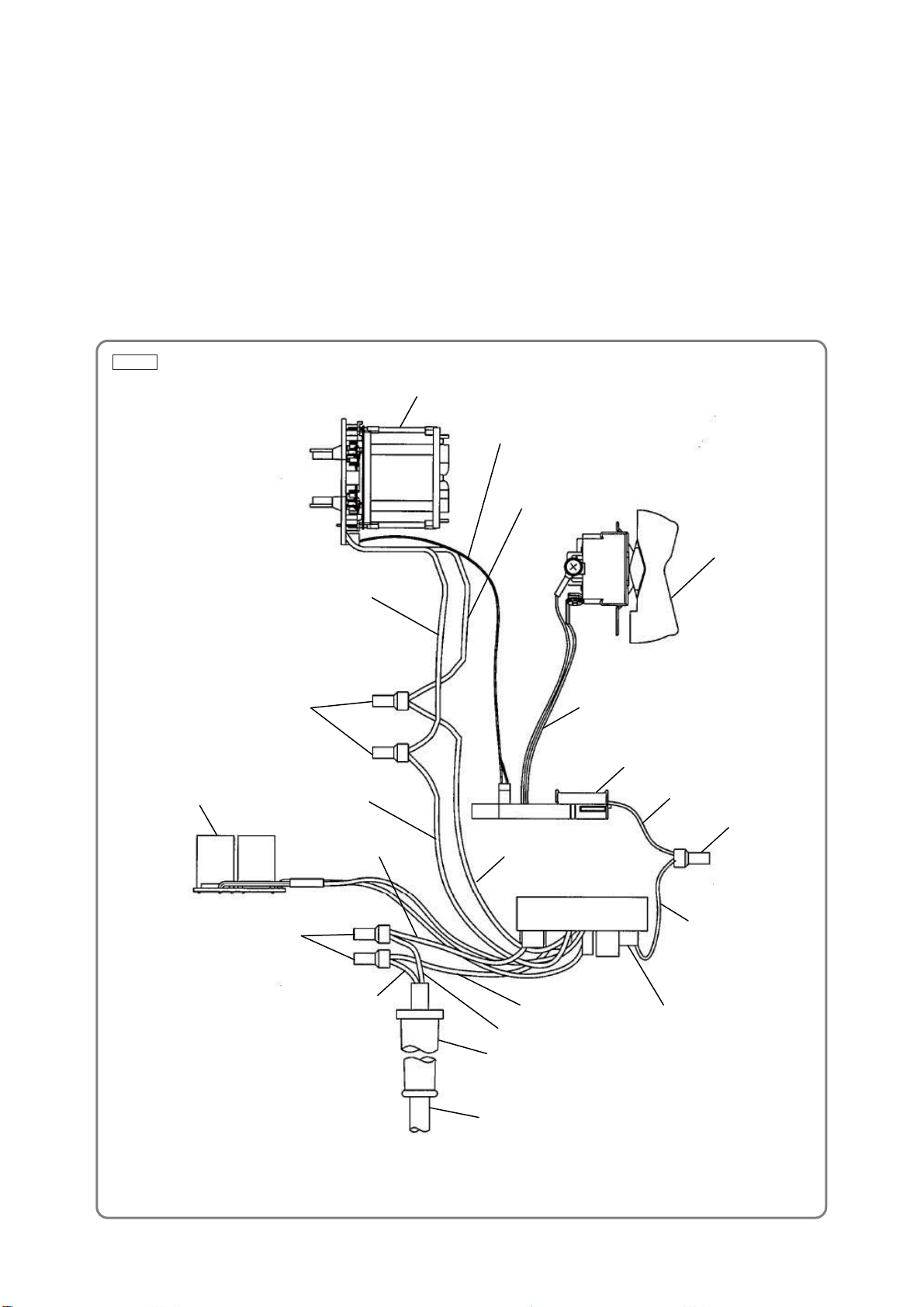

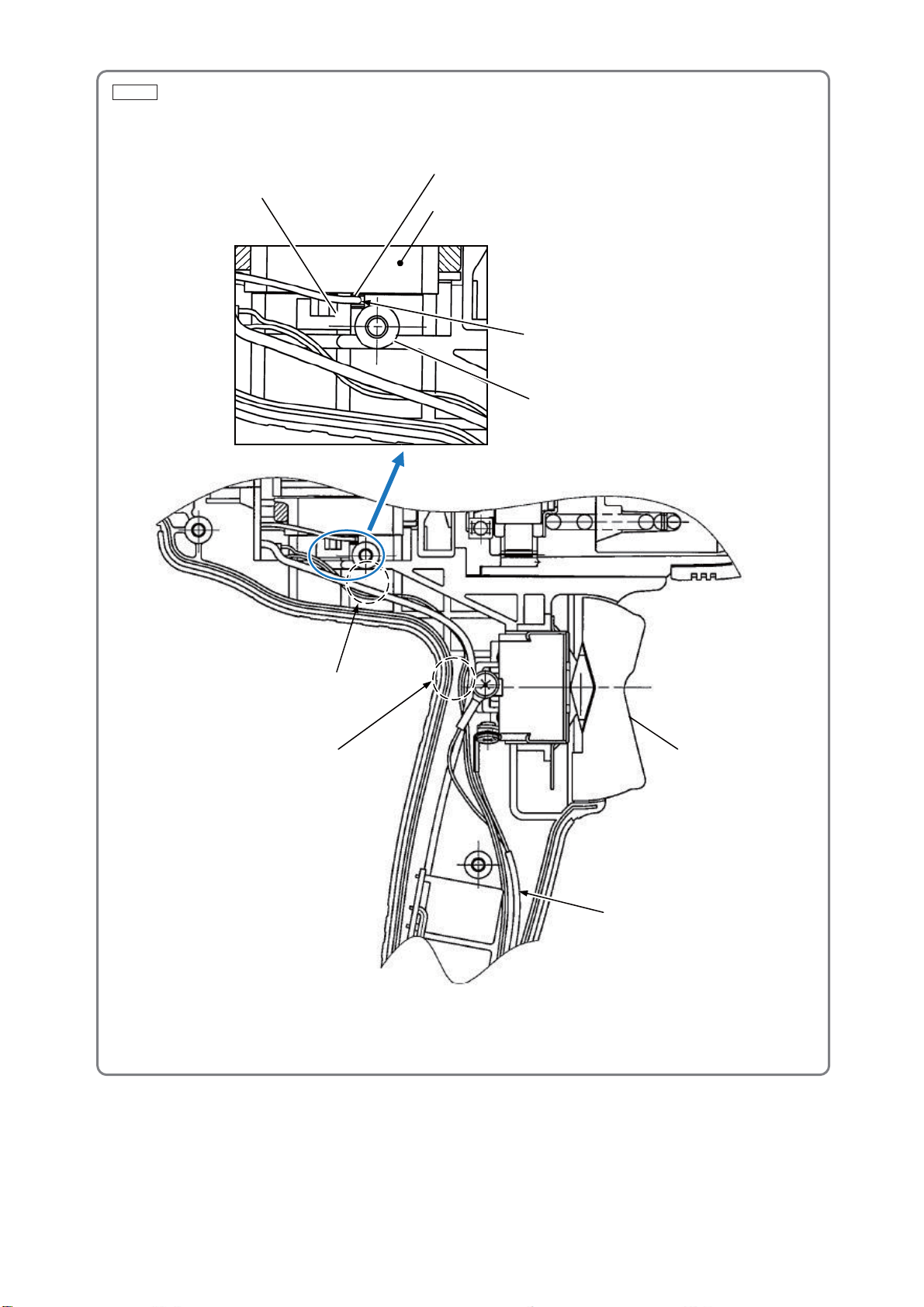

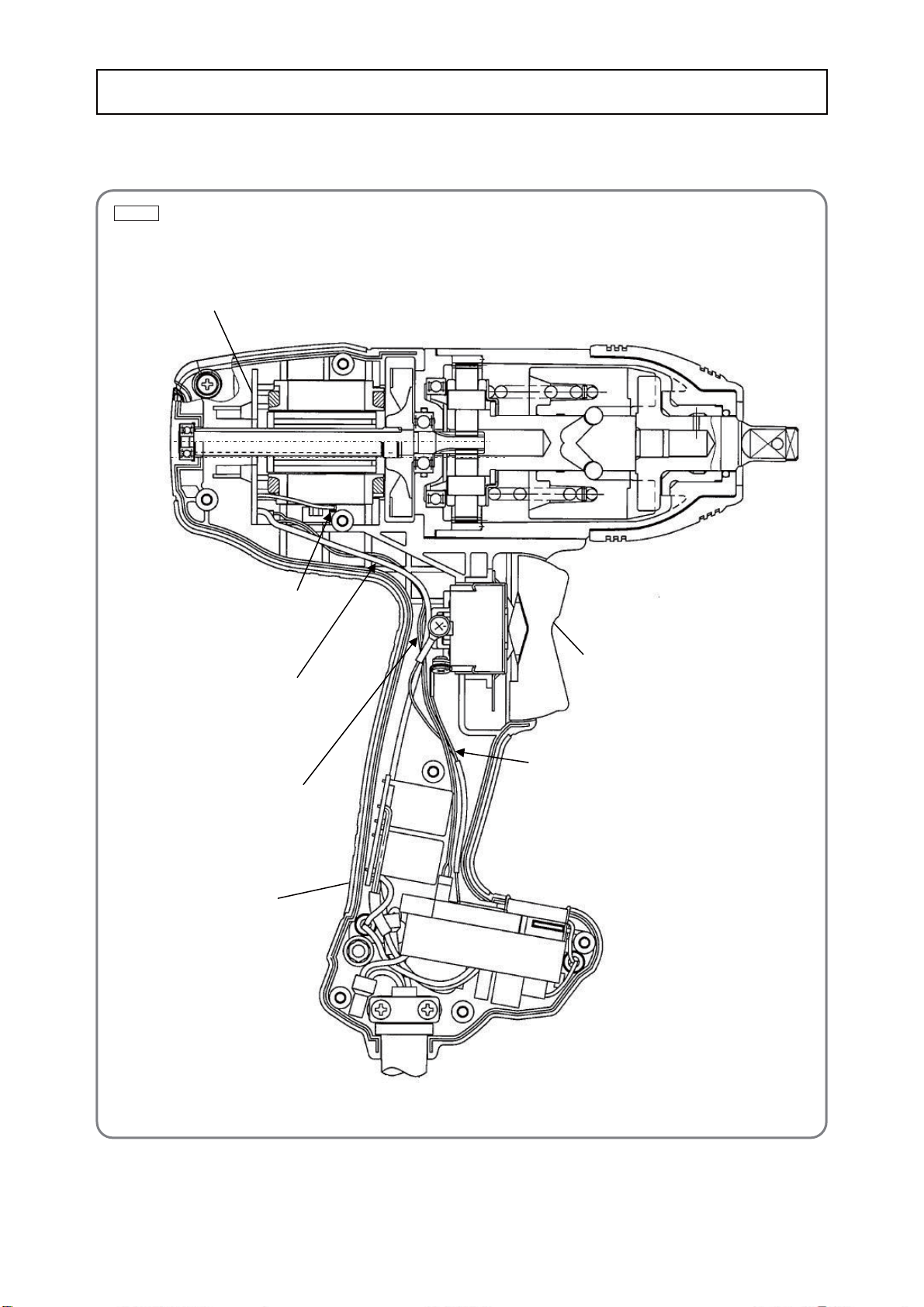

3. Reassembly of the body

(1) Mount a set comprised of Inner Cover (A) [23] (including the Rotor Ass'y [25]) and the power supply

portion to housing (A).

(2) Mount the Cord Clip [36] with its protrusion facing the cord, and then secure it with the two Tapping

Screws D4 x 16 [37].

(3) Insert Lock Nut M4 [35] into Housing (A).(B) Set [29], mount housing (B), and then tighten the eight

Tapping Screws D4 x 20 [42].

(4) Mount the hammer ass’y (reassembled in “2. Reassembly of the impact mechanism components”

above) to Housing (A).(B) Set [29], while paying attention to the engagement of the Idle Gear Set (2

pcs.) [18], Ring Gear [19], and pinion of the Rotor Ass’y [25]. At this time, the protrusion of the Ring

Gear [19] must contact the Hammer Case Ass’y [3]. Confirm that Washer (C) [20] is fitted to Spindle

(A) [17]. After reassembly, confirm that the Rotor Ass'y [25] rotates smoothly. If not, the gears may not

be properly engaged. Check and correct the gear engagement.

(5) Insert Anvil (L) [6] into the end of Spindle (A) [17] of the hammer ass’y, and then place the Hammer

Case Ass'y [3] over it. Tighten the four Bolts M5 x 35 [2]. Confirm that Packing (A) [22] is inserted

between the Hammer CaseAss’y [3] and Inner Cover (A) [23].

(6) Place Bumper (A) [1] over the Hammer Case Ass'y [3].

Fig. 6

Housing (A)

[35] C

CC - C

[35]