IMPORTANT SAFETY INFORMATION .............................. 3

MEANINGS OF SIGNAL WORDS ....................................... 3

SAFETY ......................................................................................... 4

IMPORTANT SAFETY INSTRUCTIONS FOR

USING ALL POWER TOOLS ........................................... 4

REPLACEMENT PARTS ....................................................... 8

USE PROPER EXTENSION CORD ....................................... 8

DOUBLE INSULATION FOR SAFER OPERATION ............ 9

OPERATION AND MAINTENANCE ........................................ 10

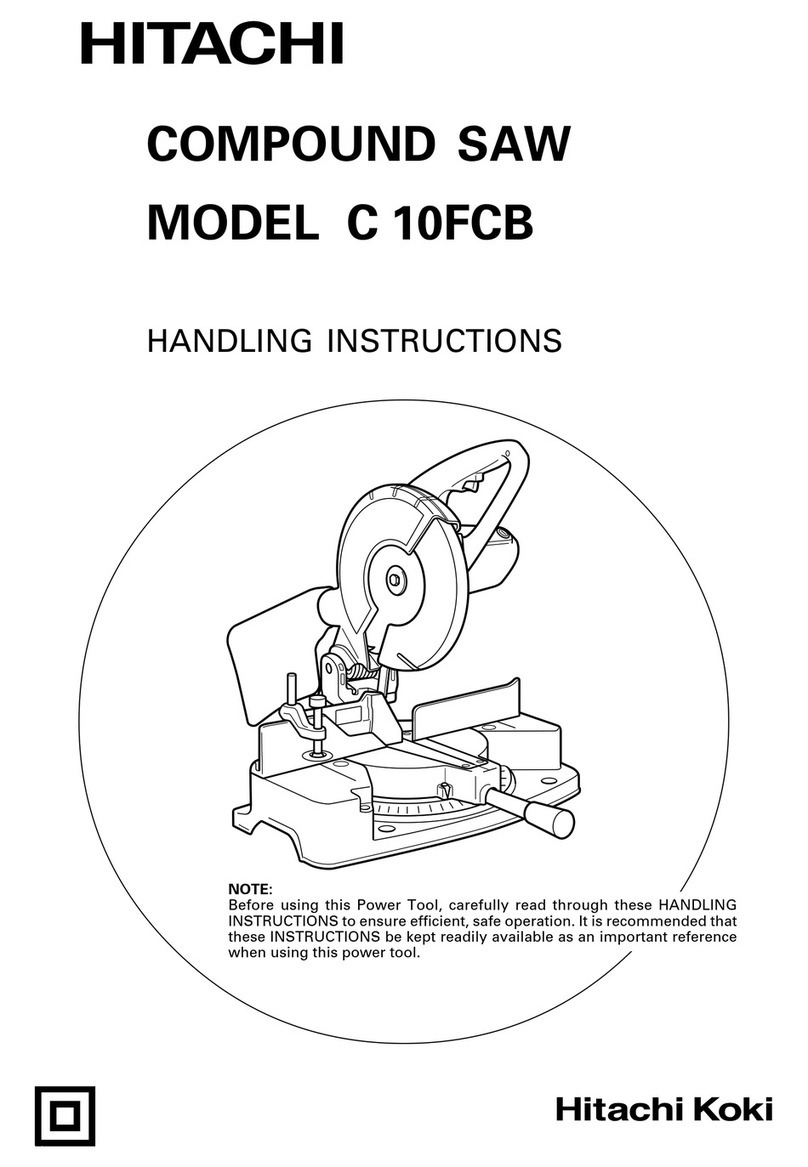

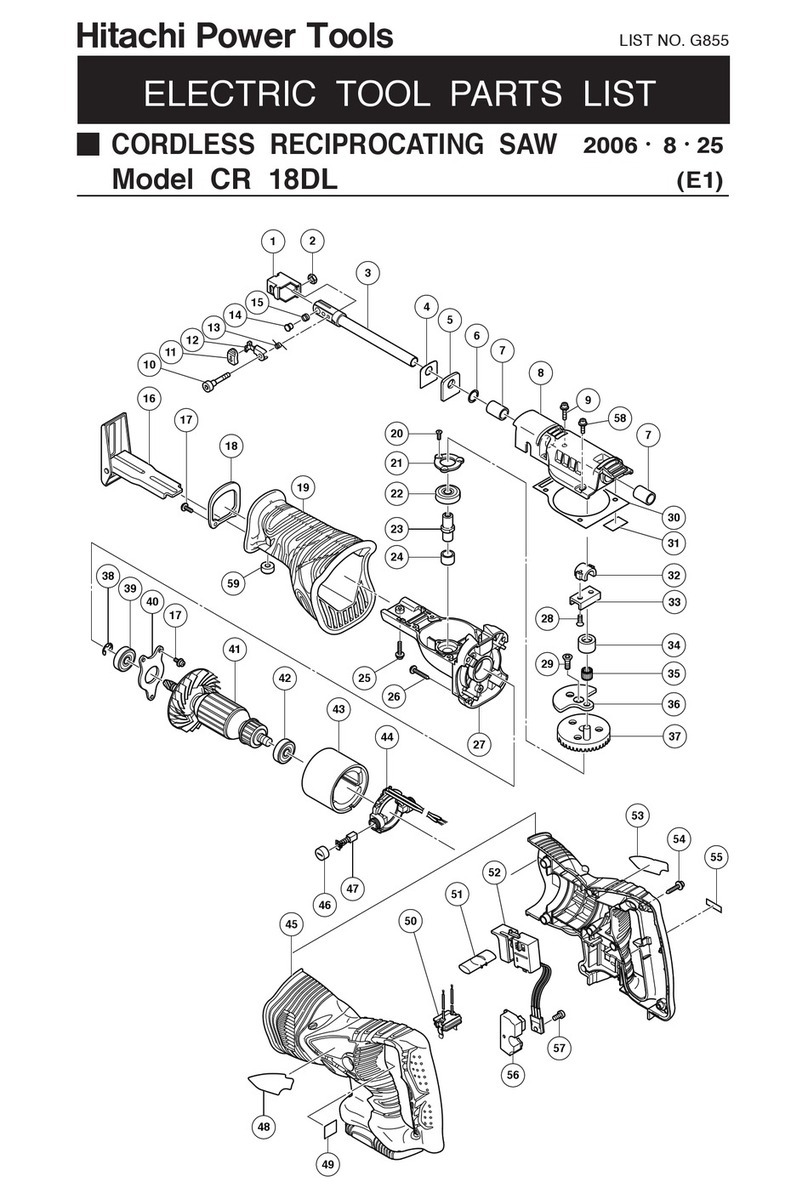

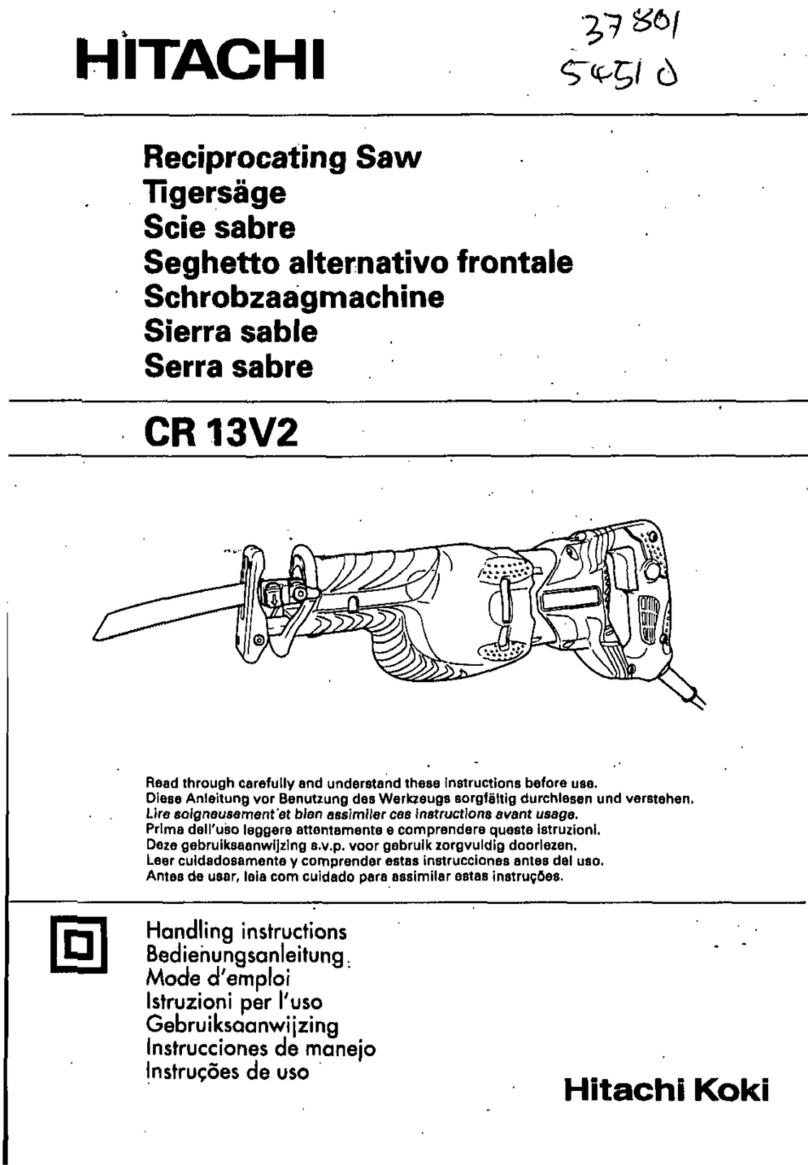

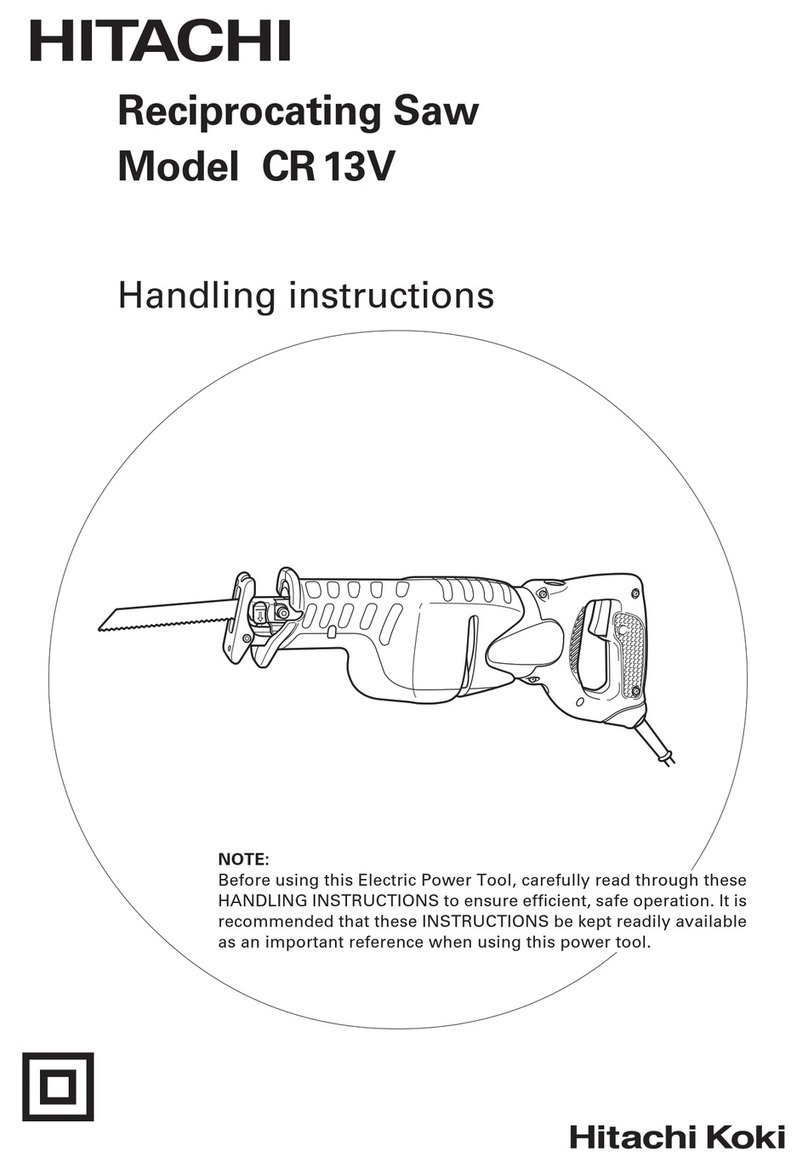

NAME OF PARTS ............................................................... 10

SPECIFICATIONS ............................................................... 12

CONTENTS

English

PAGE PAGE

ACCESSORIES .................................................................... 13

APPLICATIONS .................................................................. 14

PREPARATION BEFORE OPERATION ............................. 14

BEFORE USING ................................................................... 15

BEFORE CUTTING .............................................................. 17

PRACTICAL APPLICATIONS ............................................ 25

SAW BLADE MOUNTING AND

DISMOUNTING ............................................................. 38

MAINTENANCE AND INSPECTION ................................ 40

SERVICE AND REPAIRS .................................................... 42

TABLE DES MATIERES

Français

PAGE PAGE

INFORMATIONS IMPORTANTES

DE SÉCURITÉ ................................................................. 43

SIGNIFICATION DES MOTS

D’AVERTISSEMENT ..................................................... 43

SECURITE ................................................................................... 44

CONSIGNES DE SECURITE RELATIVES AUX

OUTILS ÉLECTRIQUES ................................................. 44

PIECES DE RECHANGE ..................................................... 48

UTILISER LE CORDON DE

RALLONGE APPROPRIÉ .............................................. 49

DOUBLE ISOLATION POUR UN

FONCTIONNEMENT PLUS SUR ................................. 49

UTILISATION ET ENTRETIEN ................................................. 51

NOM DES PIÈCES .............................................................. 51

SPÉCIFICATIONS ............................................................... 53

ACCESSOIRES .................................................................... 54

APPLICATIONS .................................................................. 55

PRÉPARATION AVANT L’UTILISATION ......................... 55

AVANT L’UTILISATION ..................................................... 56

AVANT LA COUPE .............................................................. 58

APPLICATIONS PRATIQUES ............................................ 66

INSTALLATION ET RETRAIT DE LA LAME ..................... 80

ENTRETIEN ET INSPECTION ............................................ 82

SERVICE APRÈS-VENTE ET RÉPARATIONS .................. 84

ÍNDICE

Español

PÁGINA PÁGINA

INFORMACIÓN IMPORTANTE SOBRE

SEGURIDAD ................................................................... 85

SIGNIFICADO DE LAS PALABRAS DE SEÑALIZACIÓN .... 85

SEGURIDAD ............................................................................... 86

NORMAS DE SEGURIDAD PARA LAS

HERRAMIENTAS ELÉCTRICAS ................................... 86

PIEZAS DE REEMPLAZO ................................................... 90

UTILICE EL CABLE PROLONGADOR

ADECUADO .................................................................... 91

AISLAMIENTO DOBLE PARA OFRECER UNA

OPERACIÓN MÁS SEGURA ........................................ 91

OPERACIÓN Y MANTENIMIENTO ......................................... 93

NOMENCLATURA DE PARTES ........................................ 93

ESPECIFICACIONES .......................................................... 95

ACCESORIOS ...................................................................... 96

APLICACIONES .................................................................. 97

PREPARATIVOS PREVIOS A LA OPERACIÓN ............... 97

ANTES DE LA UTILIZACIÓN ............................................. 98

ANTES DEL CORTE .......................................................... 100

APLICACIONES PRÁCTICAS .......................................... 108

MONTAJE Y DESMONTAJE DE LA

HOJA DE SIERRA ........................................................ 122

MANTENIMIENTO E INSPECCIÓN ............................... 124

SERVICIO Y REPARACIONES ......................................... 127