HITROL HLC-200 Series User manual

HLC-200 Series

HITROL CO., LTD. 1

HITROL CO., LTD.

HEAD OFFICE.FACTORY.R&D INSTITUDE

HITROL CO., LTD. 141, Palhakgol-gil, Jori-eup

Paju-si, Gyeonggi-do, Korea

TEL. : (+82)-31-950-9700

FAX. : (+82)-31-943-5600

www.hitrol.com

INSTRUCTION MANUAL

LEVEL CONTROLLER & ALARM UNIT

HLC-200 Series

Doc. no. : HLC200_IM_Eng_Rev.0

Issue date: 2020. 09

HLC-200 Series

HITROL CO., LTD. 2

You should be careful where CAUTION is marked to carry

outthework.

You should be well-informed of the contents where

WARNING is marked before carrying out the work.

.

You should be aware of where NOTICE is marked to carry

outthework.

Table of Contents

Overview ··························3

Characteristics ·······················3

Operating Principle and Composition ········3

Specifications ······················4

HLC-200A ·······························4

HLC-200F ·······························4

Dimensions ························4

Installation and Wiring ···············5

Installation ···························5

HLC-200A Wiring ·························5

HLC-200F Wiring ·······················6

Sensitivity Adjustment and Recommended

Tool (HLC-200A) ····················7

Precautions for Removal ·············8

Precautions for Installation ············8

Safety and Environment ·············8

Failure Check and Solution ··············8

Marking ·······················9

Warranty and Contact ··············9

HLC-200 Series

HITROL CO., LTD. 3

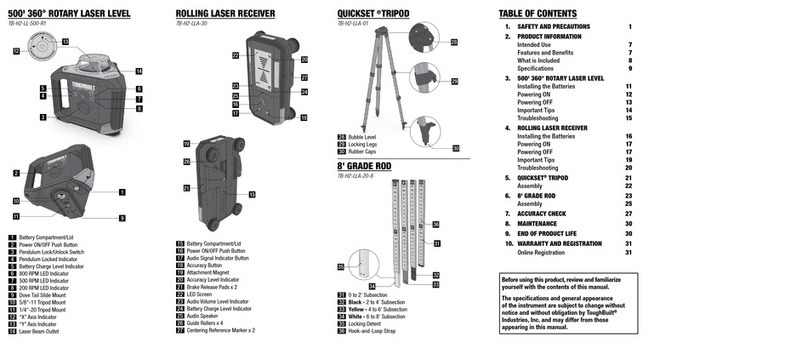

The image above is from HLC-200A.

Overview

Characteristics

Operating

Principle and

Composition

When the level switch connected to HLC-200 Series detects a liquid in the tank, a

leakage current flow and it is sensed by leakage current sensing circuit, and transistor is

activated. Accordingly, relay contact is changed and it can be used for alarm and/or

control signal.

■Easy to install (DIN Rail Type)

■Compact size

■Socket structure type for freely detachment

■Operating can be checked through LED lamp (High: Red, Low: Green)

■Sensitivity can be adjusted at the site if the sensor is too much sensitive to the conductivity

or foam of the liquid. (HLC-200A)

HLC-200 Series is a Level Control & Alarm Unit that controls and alarms by combining

with the level sensor (HE, HQ, HR Type) of the storage of tank. The signal of the level

sensor can control the upper and lower alarm of liquid and automatic supply of liquid

through HLC-200 Series, and the product can be installed inside the control panel.

HLC-200 Series Socket

DIN-Rail Mounting Button

Socket Locker

Serial No.

HLC-200 Series Body

HLC-200 Series

HITROL CO., LTD. 4

HLC-200 Series

HLC-200 Series

Actual product may have a tolerance slightly.

The image above is from HLC-200A.

Specifications

Dimensions

Model

HLC-200A

HLC-200F

Mounting

Panel Inside (DIN Rail or Bolting)

Ambient Temperature

-20℃~ +70℃

Power Source

AC 110V or 220V

@ 50/60Hz

DC +24V

@ DC +21V ~ DC+30V

Standby Power Consumption

AC 110V @ 0.5W /

AC 220V @ 0.8W

DC +24V @ 0.48W

Active Power Consumption

AC 110V @ 1.4W /

AC 220V @ 2W

DC +24V @ 1.1W

Output Voltage

AC 14V

DC +22V

Relay Contact

1-SPDT

Contact Load Capacity

AC 250V, 5A / DC 30V, 5A Max.

Weight

Body: 200g / Socket: 70g /

Total: 270g

Body: 120g / Socket: 70g /

Total: 190g

Housing

Body: ABS-Flame Resisting / Socket: PBT Glass

Approvals

KC

-

Unit: mm

<HLC-200 Series Socket>

<Assembly>

HLC-200 Series

HITROL CO., LTD. 5

HLC-200 Series

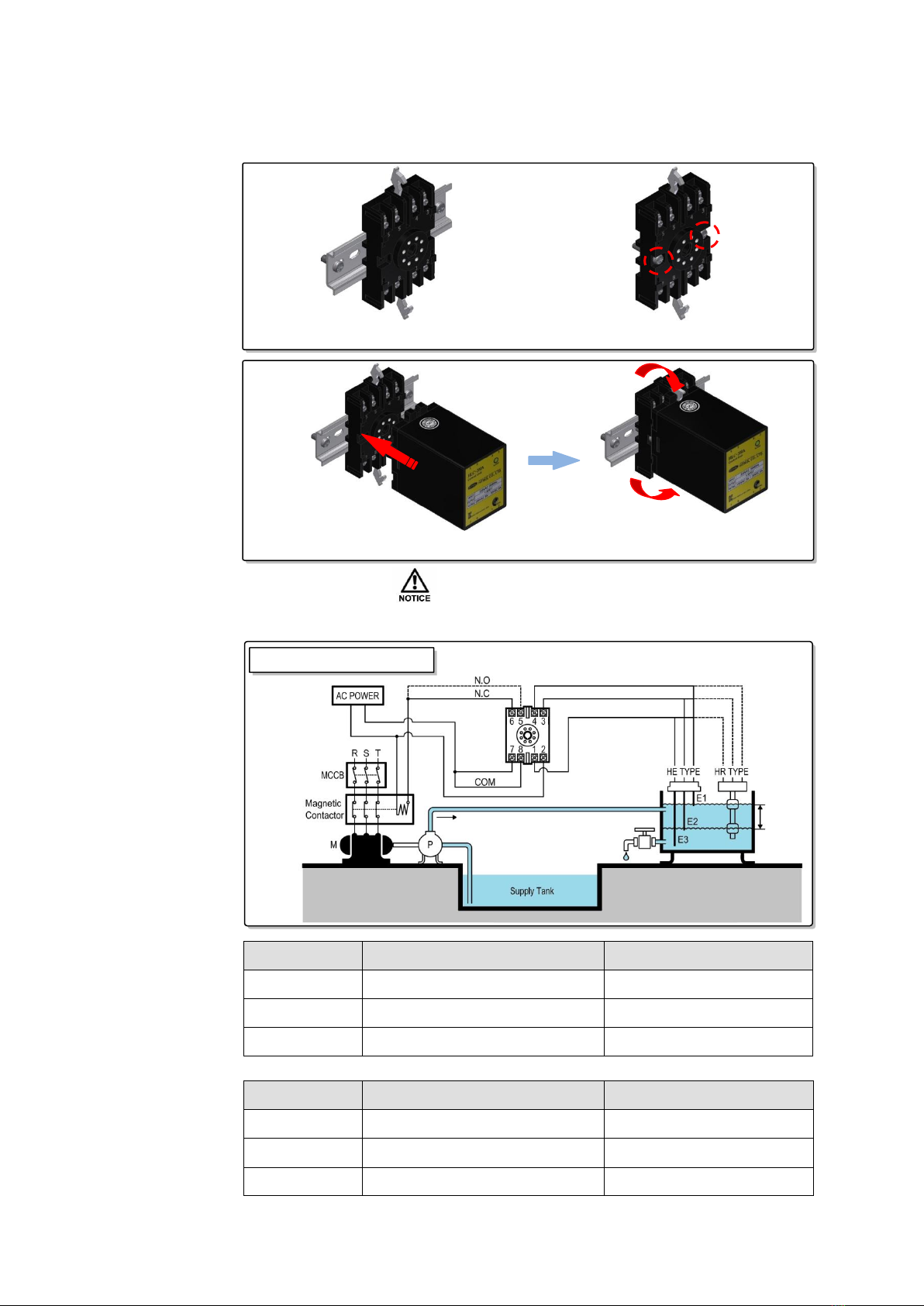

■Installation

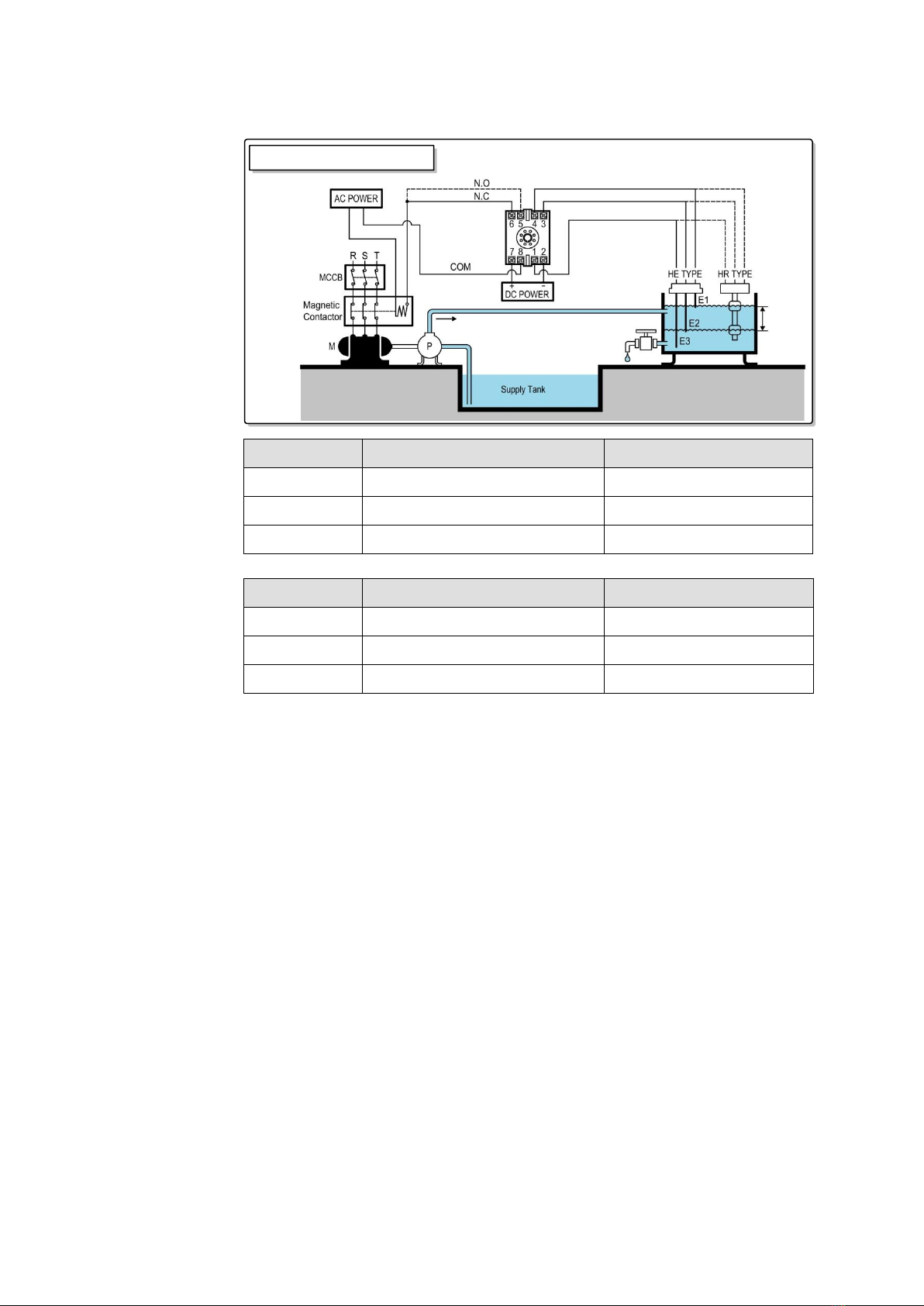

■HLC-200A Wiring

The image above is from HLC-200A.

Installation

and Wiring

Control

Drain

Pump

LED Color

Red

Green

Input

1, 3, 4

1, 3, 4

Output

8, 5

8, 6

Alarm

H. A

L. A

LED Color

Red

Green

Input

1, 4

1, 4

Output

8, 5

8, 6

(1) Install the socket DIN Rail (2) Fix it using bolts

- After assembling the HLC-200 Series body on the socket, lift the locker to fix the body.

Connection Diagram

HLC-200 Series

HITROL CO., LTD. 6

■HLC-200F Wiring

Control

Drain

Pump

LED Color

Red

Green

Input

1, 3, 4

1, 3, 4

Output

8, 5

8, 6

Alarm

H. A

L. A

LED Color

Red

Green

Input

1, 4

1, 4

Output

8, 5

8, 6

Connection Diagram

HLC-200 Series

HITROL CO., LTD. 7

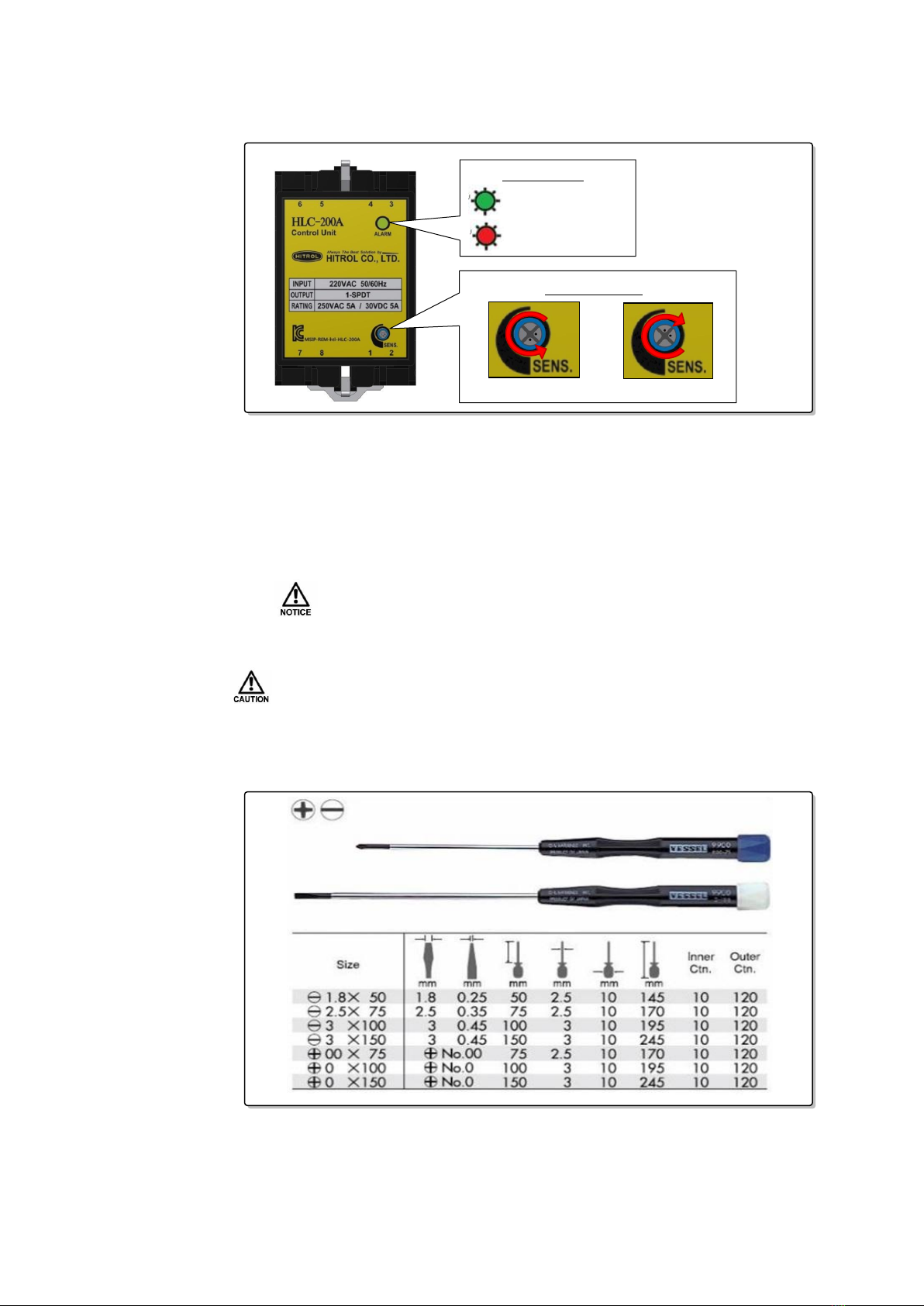

■Sensitivity Adjustment

Use only with electrode sensors.

Note that factory standard setting is for high sensitivity.

Sensitivity

Adjustment &

Recommended

Tool (HLC-200A)

■Recommended Tool

- When adjusting

SENS.

(Sensitivity), use the driver (-) 2.5x75 or less or (+) 00x75.

- Alarm Lamp: The red light is on when the liquid is detected, and the green light is on

when the liquid is not detected.

- Sensitivity Dial: It is a function to adjust the sensitivity in condition that it is too

sensitive to the conductivity of the medium or foam. Turning counter-clockwise is for

higher sensitivity and clockwise is for lower sensitivity.

Sensitivity Dial

High Sensitivity

Low Sensitivity

Default Status

Detector Status

Alarm Lamp

Maximum available adjustment range of potentiometer using for the sensitivity

dial is approximately 260°. (±130°based on 9 o’clock direction)

Pay attention to use it because it can be damaged if it is adjusted over the range.

HLC-200 Series

HITROL CO., LTD. 8

Precautions

for Removal

Precautions

for Installation

Safety and

Environment

Failure Check

and Solution

■Precautions for Use

- Do not disconnect the cable during use.

- Do not disconnect the product from the socket during use.

- Do not apply high impact to the product.

■Precautions for Wiring

- Make sure to wire contacts correctly. (Refer to Wiring)

- Wire and supply the power to the product after checking the specifications.

- Incorrect power voltage may cause damage to the product.

- Pay attention to prevent electric shock.

■Disposal of Product

- Make sure to separate the PCB and main unit from housing before disposing the products.

No part (ex. Mercury Switch) has influence on the environment, so no special attention is

required.

■Remove it with the power disconnected.

■Remove in reverse order of installation. (Power off Release the Locker Body

Disconnection Wiring Disconnection Socket Disconnection)

■It is recommended to use washers to prevent a loosening when the product is fixed

using bolts.

■Wiring shall be performed after checking of wiring diagram described in the manual or sticker.

■Make sure that the power source whether it is AC 110V, AC 220V, or DC +24V.

■It is recommended to use AWG 13 or 14 cable between the controller and level sensor, and

use shield cable in case that the distance between the controller and level sensor is quite long

(several hundred meters ~ 500m) and for low conductivity medium. (Non-recommendation

cables may result in some differences in operating and level sensing distances.)

■Check the LED color after applying of power. (High: Red, Low: Green)

■Power shall be applied after completing of installation.

■Relay contact does not work

- Check whether the LED lamp is on/off.

- Check the cable connection.

- Check the input voltage.

- Check the connection between the body and the socket.

- Check the level sensor wiring cable.

HLC-200 Series

HITROL CO., LTD. 9

DC voltage (HLC-200F) can cause sensor corrosion due to electrolysis.

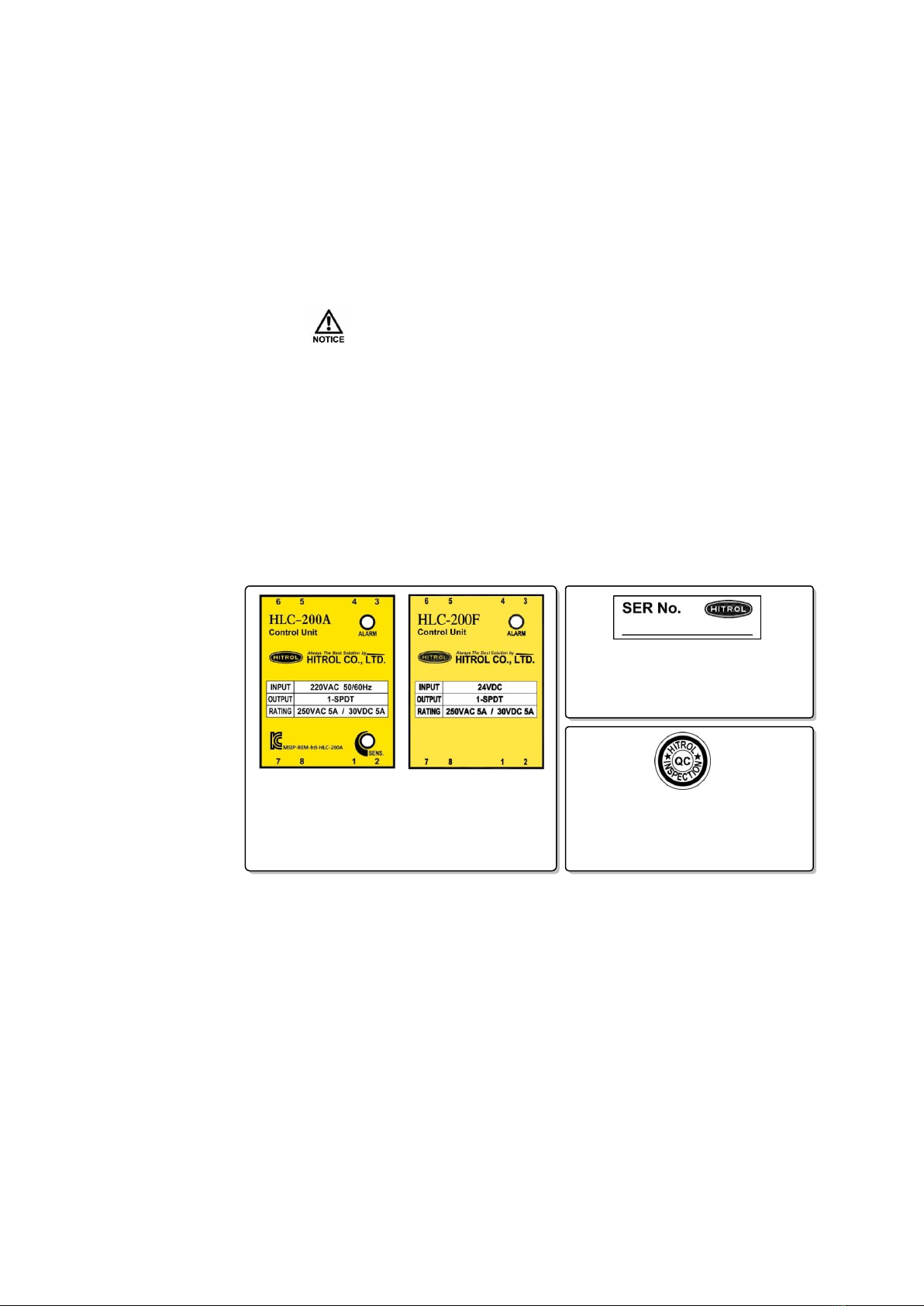

Marking

Warranty

and Contact

■Warranty and Service

This product is subject to the warranty for 2 years of shipment and unpaid service

will be provided for any damage found under normal operating conditions. If it is

not about the failure of product, the service charge will be payable.

You can request A/S at our website or by contacting our headquarters.

■Headquarters ․Factory ․Laboratory Contact

ADDRESS:

HITROL CO., LTD 141, Palhakgol-gil, Jori-eup, Paju-si, Gyeonggi-do, Korea

T E L : 031-950-9700 (Headquarters & A/S)

F A X : 031-943-5600 (Headquarters & A/S)

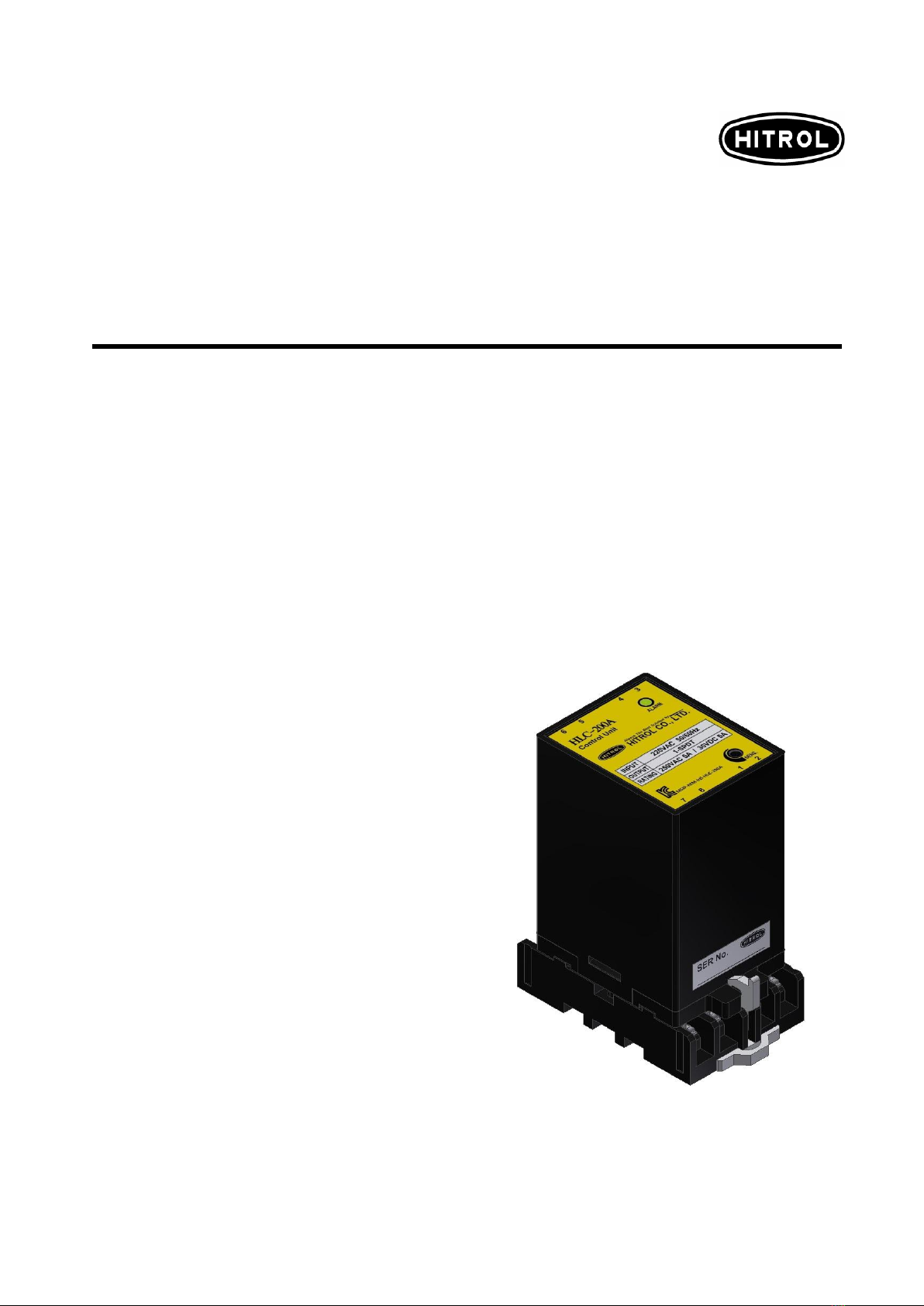

■Product Identification

- The product identification mark is attached onto housing and shows the model

name, serial number, and matters regarding input/output. The serial number is a

unique manufacturing number for the identification of products.

■Controller is normal, but not working

1) Electrode Type Level Switch

- If there is foreign matter or sediment such as lime on the bottom of tank, it may cause malfunction.

- Too low liquid conductivity can cause malfunction. (ex. Distilled Water)

- When wiring between controller and electrode is far apart, it may cause malfunction.

- Please refer to the cable recommendations between the controller and the sensor for

installation precautions (Page 9).

2) Float Type Level Switch

- Check that the float floats normally.

- Check the signal when the float operates normally.

- It is attached to the front of the product and the

model name and input/output information are

indicated.

- It is attached to the bottom of the product

and the serial number is indicated.

- It is attached to the top of the product and

means it has passed the internal quality

system.

This manual suits for next models

2

Table of contents

Other HITROL Laser Level manuals