HiWeigh NT User manual

1

Warning!

The power supply of NT-T16S printer is only DC 5V/2-3A.

Never use AC mains!

1. INTRODUCTION

NT-T16S is a new type of dot-matrix micro-printer. It is

small (123x165x66cm) in size and light (400g) in weight It is

very attractive in appearance and it has many features.

NT-T16S micro-printer has a serial RS-232C compatible. It

is competent as the output listing devices for many kinds of

intelligent instrument and microcomputer.

1.1 Interface

There is one interface mode in the NT-T16S: SERIAL

interface compatible with RS-232C standard. It is linked

with the master computer through a standard 25pin D type

connector and a cable. The serial connector is female. If the

master computer is furnished with a standard 25pin D type

connector, (IBM PC, or laptop computer etc), it can be linked

with the NT-T16S micro-printer through standard 25 wire

cable and connector. If not, the linkage can be realized

through reformation of the connector on the 25 wire cable.

For details please refer to section “Interface” of NT-T16S.

1.2 Character Codes

NT-T16S provides a font with 448 characters in the internal

ROM. The font includes, English, Greek, German, French,

Russian, Japanese and Chinese characters, a large amount of

math symbols, specific meaning symbols and tabulation

symbols. Characters are 5×7 dot matrix and graphics 6×8.32

special characters can also be defined with the print program.

NT-T16S provides bit image mode. The image mode can be

mixed with characters on the same line.

1.3 Print Commands

NT-T16S provides 35 print commands. Most of these are

compatible with the two most popular standards - IBM and

EPSON. Therefore, NT-T16S can be substituted for 9 pin

printer or even 24 pin printer, usually without modification.

Some new commands are added for special features. The

command for printing curves is an example. This is

convenient for plotting graphs.

1.4 Working Modes

NT-T16S has six working modes - dump, text, bit image,

self-test, on/off line and paper feed mode. The first three

modes are changed by control commands and the last three

are realized by pushing button switches.

1.5 “OFF-Line” Printing

The printing speed of some models, such as NT-T16S, is

slow. For some applications, particularly for industrial

control, a faster printing process is needed .To solve this

problem, a large buffer storage is provided in NT-T16S series.

The master computer transfers data to the buffer very fast.

Then the printer prints “off-line” and the computer can

proceed to other jobs without delay. There are three sizes of

printer buffer : 2K, 8K and 32kbytes. The printer buffer is set

by the manufacturer, and can not be modified by users

themselves.

1.6 Specifications

The general features of the NT-T16S series are listed as

follows:

(1) Interface --Serial

The serial interface is compatible with RS-232C standard.

The baud rate may be selected as 150, 300, 600, 1200, 2400,

4800, 9600 or 19200 bps. The transmission is asynchronous.

The form is handshaking is flag control or x-ON/X-OFF

protocol. The parity check can be selected as Even, Odd or

None by setting an internal dip switch. The signal level is

EIA standard.

(2) Indicators and Switches

There are two LED lamps, Power and SEL indicators. And

two push button switches, SEL select on/off line and LF line

feed switch.

(3) Power Supply - Single DC 5 Volt voltage only. The

current requirement is 2A for NT-T16S.

(4) Ribbon life time is 10,000 lines. (ERC-05)

(5) Printing Paper - plain white paper. The paper width is

44.5 ± 0.5mm. Thickness is 0.07mm. The outer diameter of

paper roll must not be more than 50mm and the paper roll is

placed inside the printer.

2. Installation

2.1 Model Checking

The appearance of the NT-T16S printer is shown as Figure

2-1. Please check the model No. on the label of the printer.

Read all instructions about this model in the manual.

Figure 2-1. Appearance of NT-T16S printer

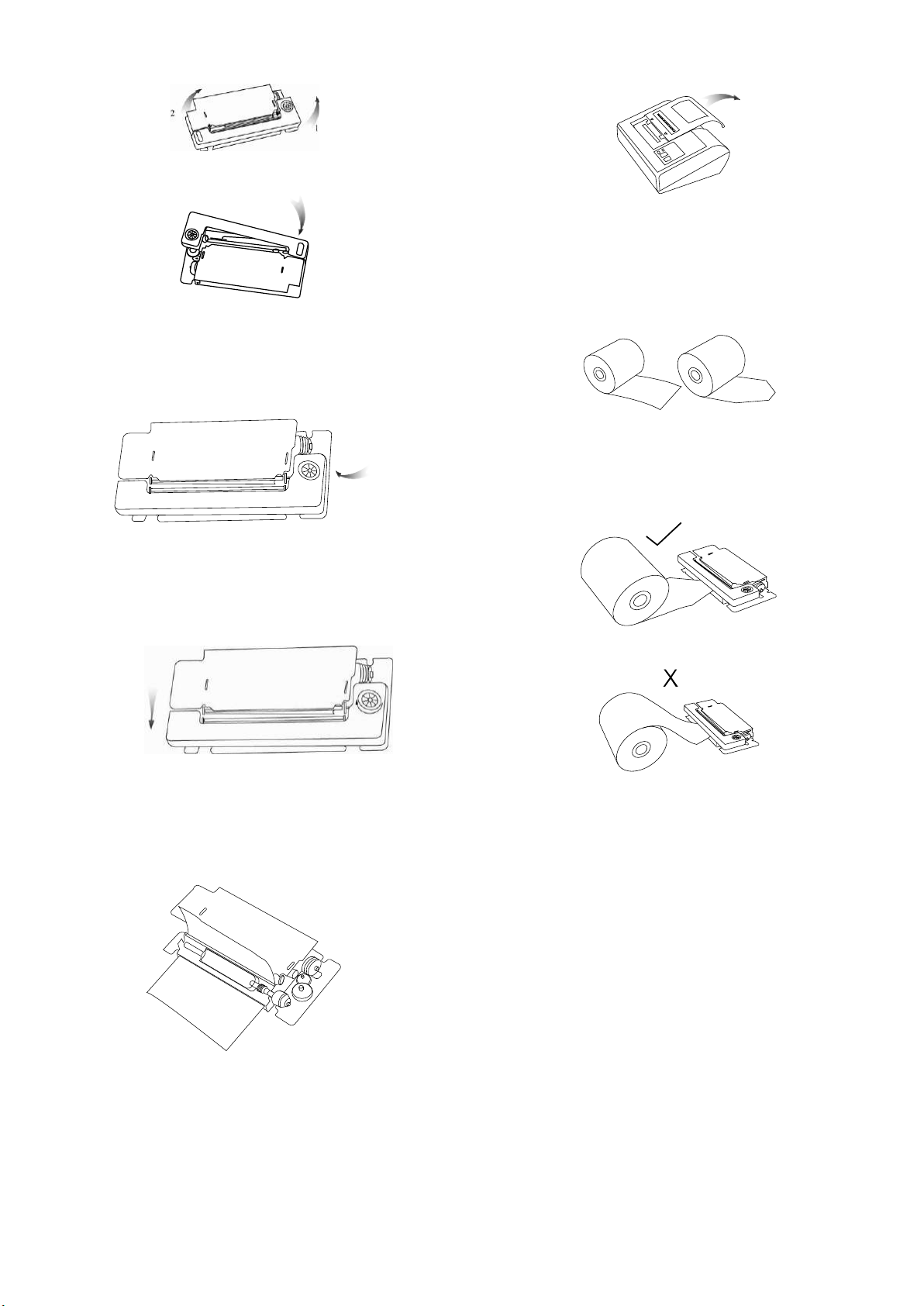

2.2 Ribbon cassette –Loading

Ribbon cassette has been put inside the printer before

packing. When the printing becomes faint after long use, put

in a new ribbon as follows:

(1) Push forward the removable cover plate with both

thumbs. (Note the arrow on cover plate. See Figure 2-2)

Then take off cover plate carefully.

Figure 2-2. Shows the correct action

(2) Hold the left end of the ribbon cassette with your left

hand. Hold right end in right hand. Right thumb is on top and

forefinger below (Figure 2–4). Lift the right end of the

cassette with the right forefinger. Then lift the left end. The

ribbon cassette will come off easily. Caution –Never lift left

2

end first. This may damage ribbon and printer head.

Figure 2-4. Ribbon Cassette –Unloading

Figure 2-5. Keep right end of cassette up

(3) Take a new ribbon. Hold the cassette as in step 2. Put the

left end on the axle of the gear on the left end of the printer

head. Keep the right end of the cassette up as shown in

Figure 2-5.

Figure 2-6 .Turn the gear as indicated by the arrow

If it is difficult to push the left end down, raise it again. Hold

the cassette with right hand. Press the gear on the cassette

with left thumb. Then rotate slightly as indicated. See arrow

on the cassette cover (Figure 2-6)

Figure 2-7. Press down the right end with thumb.

Secure the cassette on the printer head. The procedure may

be repeated several times until it is easy to push the left end

of the cassette onto the axle of the gear. Then press down the

right end of the cassette with the right thumb as shown in

Figure 2-7.

Figure 2-8. Part of the ribbon rides up over the printer head

Sometimes, the cassette is put in correctly but part of the

ribbon rides up over the printer head as shown in Figure 2-8.

This may be caused by two reasons:

i). The paper has been loaded before the ribbon. Remove

paper and try again.

ii). The ribbon is a used one. Replace with new cassette.

(4) Put on the removable cover plate.

Place the plate on the glide slot. Push into place gently as in

Figure 2-9.

Figure 2-9. Put on cover plate.

2.3 Loading Paper

(1). The removable cover plate must be taken off for loading

paper.

(2). Cut the paper roll as shown in Figure 2-10.

Figure 2-10. Cut the paper roll

The paper roll may be placed inside or outside of the printer

case. When the paper roll is placed inside, the end should be

underneath as Figure 2-11, Caution- Don’t load as in Figure

2-12.

Figure 2-11. Correct paper roll loading End is underneath.

Figure 2-12. Wrong paper roll loading

(3). Switch on 5V/2-3A power supply.

(4). The SEL (Select) button in an ON/OFF toggle. Press

“OFF” the SEL indicator off. Then printer head begins to run.

Feed in paper. The paper enters the printer head and comes

out from the top of the printer head. To stop paper feeding,

press and release LF of SEL button.

(5). Switch off the power supply.

(6). Feed the paper through the slot on the removable cover

plate. Then push the plate back on the printer as before. (See

Section 2.2 Step 4).

2.4 Power Supply

The NT-T16S printer uses a 5V/2-3A DC power supply. A

power supply is specially made for this series and is

recommended. Insert the output plug of the power supply

into the jack (Φ2.5mm) on the back of the printer. When

using other models of power supply, please pay attention to

the voltage and current limits. If the voltage is higher than

DC 5.5V/2-3A or lower than DC 4.5 V, or the maximum

current is less than 2A the printer will not work normally,

and the printer head may be damaged.

Pay attention to the polarity of the power supply. The central

pin of the power jack on the printer is positive. The spring

3

plate in the side of the jack is negative.

Caution: Never connect AC mains directly!

3. Operation

3.1 Serial Interface Connection

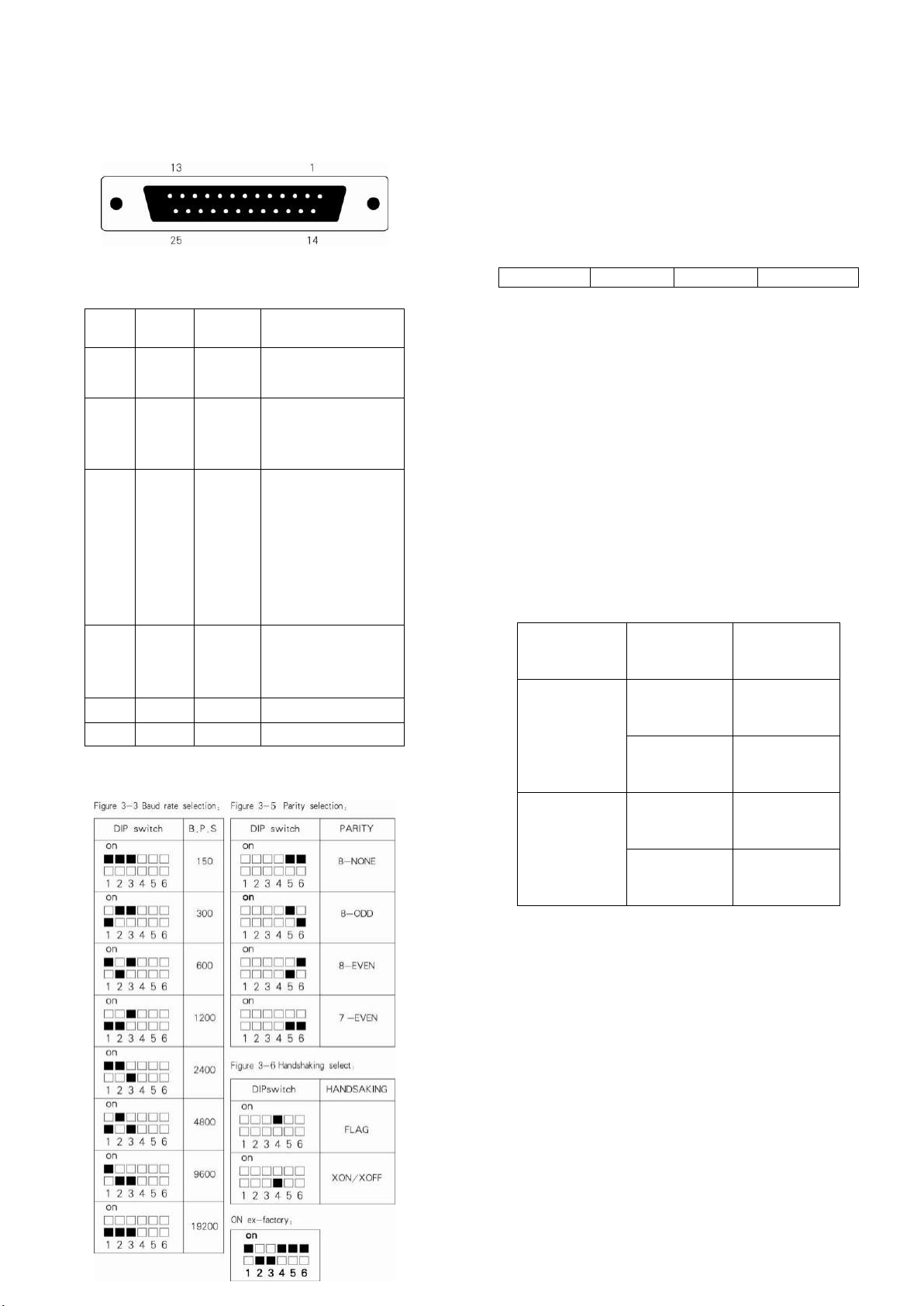

The 25 pin connector at the back of the VMP-T series printer

is shown in Figure 3-1.

Figure 3-1. Pin order of the connector of serial interface

The serial interface is standard RS-232C compatible. The pin

signal is shown in Figure 3-2.

Pin

N o

Signal

Source

Description

2

R×D

Printer

Printer receives

data format host

computer

3

T×D

Host

Printer transmits

data when uses the

hand-shaking of

x-ON/ X-OFF.

5

CTS

Printer

Signal set

“MARK” state to

Indicate the printer

is BUSY and can

not accept data,

and “SPACE” state

to indicate the

printer is READY

and can accept

data.

6

DSR

Printer

Signal

set ”SPACE” to

indicate the printer

is ON-LINE

7

GND

Signal ground.

8

DCD

Printer

Same as CTS.

Figure 3-2. The pin signals of serial interface

Signal level is compatible with EIA standard.

The baud rate of serial Interface can be selected as 150, 300,

600, 1200, 2400, 4800, 9600 or 19200bps. To set the baud

rate, take off the re-movable cover and the upper case of the

printer; you will see the DIP switch in the upper right corner

of the PCB. Baud rate can be selected as in Figure 3-3.

Switch near the white mark is K1. The ex-factory baud rate

setting is K1 On, K2 OFF and K3 OFF, which is 9600 bps.

The format of serial interface is asynchronous, shown as in

Figure 3-4.

Start bit (0)

Data bits

Parity bit

Stop bit(1)

1 bit 8 bits 1bit 1bit

Figure 3-4 Asynchronous transmitting format.

START and STOP bits are one bit signals. These signals

come at the beginning and end of a computer message. The

computer message, the DATA, has eight bits, plus a Parity

Check bit. The Parity Check can be set with K5 and K6 DIP

switches as in Figure 3-5. These are set at No Parity

ex-factory, k5 ON, K6 ON.

The signal polarity of serial RS-232C is:

Mark=Logic “1” (EIA low level, -3V to –27V)

Space= Logic “0” (EIA low level, +3V to +27V)

There are two kinds of handshaking to be selected. First is

the flag control. The other is the X-ON/X-OFF protocol. It is

selected with K4 as in Figure 3-6. The K4 is set to ON

ex-factory.

Handshaking select:

Two kinds of handshaking are listed in Figure 3-7

Handshaking

Data

Direction

RS-232C

Interface’s

Signal

Flag Control

Can accept

data

Line 5 &8

are SPACE

state

Can’t accept

data

Line 5 &8

are MARK

state

X-ON/X-DFF

control

Can accept

data

Send X-ON

code (11H)

on line 3

Can’t accept

data

Send X-OFF

code (13H)

on line 3

Figure3-7.Two kinds of handshaking

The operation procedure of serial interface is shown as

follows:

(1) Select baud rate with DIP switches K1- K3.

(2) Select parity with DIP switches K5 and K6.

(3) Select handshaking with DIP switch K4.

(4) When only 32 bytes free space is left in the printer buffer,

signal DCD (line8) and CTS (line 5) are both set to “busy”,

i.e. Mark status, by printer. Otherwise set to “ready”, i.e,

Space status.

(5) Under X-ON/X-OFF control handshaking, the printer

sends X-OFF code (13 in Hex.) when ready. Under Flag

control handshaking, host computer sends data to printer

when both DCD and CTS are ready.

3.2 Indicators and Switches Operation

4

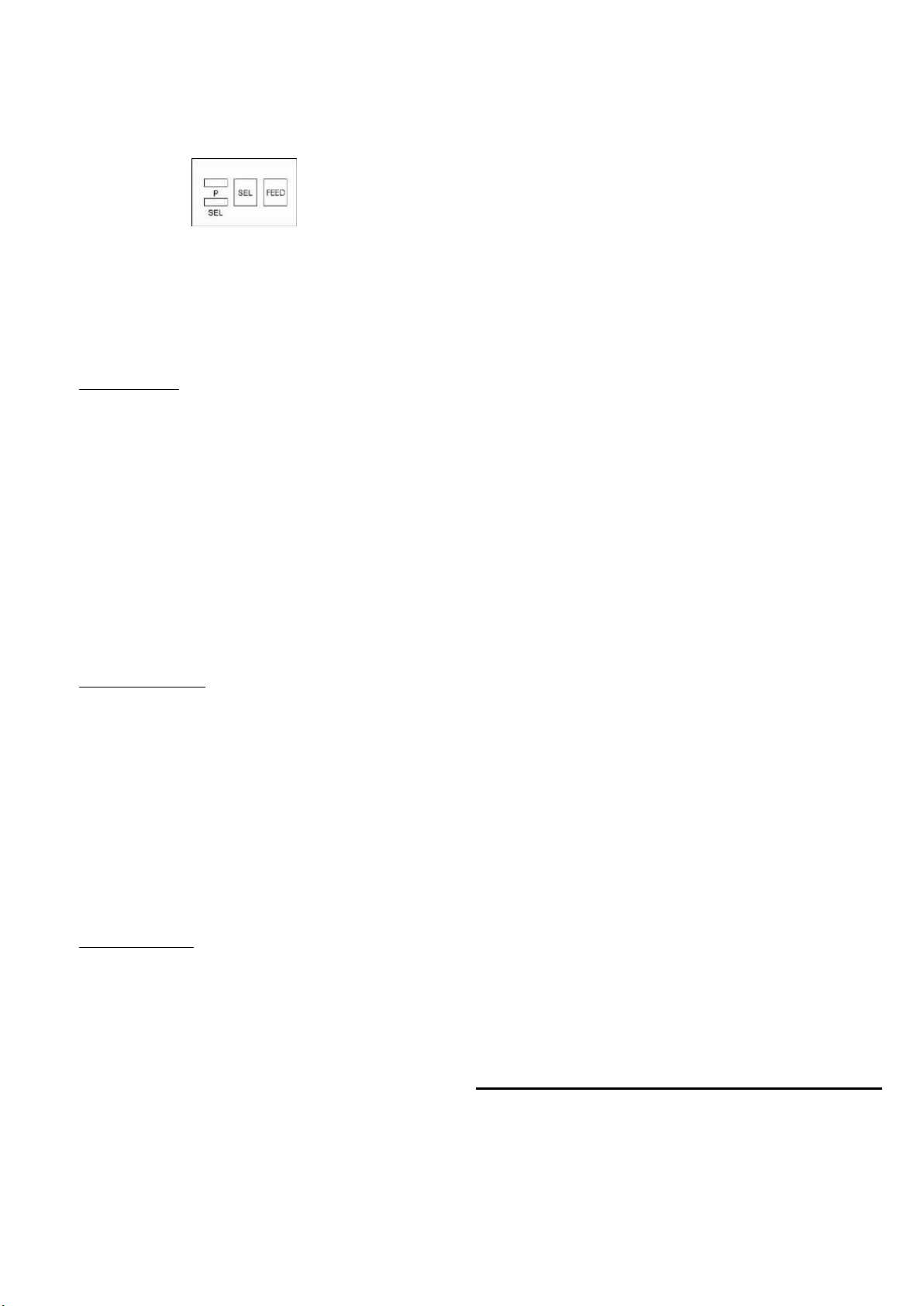

There are two indicators and two button switches on the

panel of the printer. The power indicator is labeled “P”. The

other is the SEL indicator. A button switch is labeled “SEL”

for selecting ON/OFF line. Another is labeled “FEED” for

paper line feeding. (See Figure 3-8.)

Figure 3-8. Indicators and switches

The SEL button can change the SEL indicator’s status. When

the SEL indicator is on, the printer is On- Line.

The printer working mode can be changed with button SEL

and FEED among three modes –self-test, on/off line and

paper feed.

<1>. Self-Test Mode

There are two ways to enter the self-test mode.

(1) Press SEL button when power on the printer. After few

seconds then release, The SEL indicator then turns off and

the printer prints out the self-test sample.

(2) To enter the self-test mode when the printer is on already.

With printer in Off-Line status, press FEED button then press

SEL button. Release both buttons, the printer will enter

self-test mode.

There also are two ways to exit the self-test mode.

(1) The printer will exit self-test mode automatically after

finishing the self-test sample print out.

(2) When the self-test sample is being printed, it can be

terminated by pressing the SEL button. The printer will exit

self-test mode.

<2>. On/ Off Line Mode

After switching on the printer or being in the Self-test mode,

the printer enters On-Line mode. The SEL indicator lights up.

Press the SEL button, SEL indicator lights up. Press the SEL

button, SEL indicator lights off, Printer enters the Off-Line

mode. When printer is in Off-Line mode, it can not receive

data. Press SEL again, Printer re-enters the On-Line mode.

SEL has another function –to interrupt the printout. If SEL is

pressed and then released during a printout, the printer will

stop after completing the current line. At this point you can

load more paper. To complete the printout, press and release

the SEL button again. The printer will run again at the point

printout was interrupted.

<3>. Paper Feed Mode

When print procedure is interrupted, SEL off, the printer

enters Off-Line mode. If paper has to be replaced, press LF

button, then release. Printer will feed paper without printing.

Re-press LF, then release. Printer will stop paper feed.

Printer can also re-enter On-Line mode in the Paper Feed

procedure by pressing the SEL button.

3.3 Self-Test

Self-Test checks condition of printer. If the printer prints out

the Self-Test sample correctly, the printer is working

normally. Other faults will be caused by the interface or

master computer. If there’s a problem with the Self-Test, the

printer or power supply needs repairing.

Self-Test prints out all characters in the fonts. Then print the

messages about interface type and printer head model.

After Self-Test the printer enters On-Line mode. It can then

receive data from the master computer.

3.4 Printer Initialization

Initialization includes default values settings. Default values

are: 3 dot lines spacing, 40 lines form length, 0 values of

vertical tab and horizontal tab, 0 values of right margin and

left margin, normal alphanumeric and graphic character size

(i.e. enlarge factor to receive commands and data)

There are three ways to realize initialization. First is to run

the initialization software on master computer. Master

computer sends initialization commands (ESC@ commands)

to printer.

Second is through self-test procedure.

Third is power on initialization.

3.5 Command Set Selection

There is one command set in NT-T16S: ESC control codes,

other setting –ESC control codes ex-factory.

4. Printing Commands

Summary

NT-T16S provides up to 35 printing commands.

These commands specify the functions of the printer:

(1) Define formatting.

(2) Enlarge or condense characters.

(3) Print image graphics.

(4) Select font.

(5) Define special characters.

(6) Other

Some of these commands are one byte control codes. Some

are ESC code sequences. These sequences start with “ESC”

code, followed by alphanumeric characters.

Printer’s control codes (especially ESC control codes) are

not standardized. Every printer manufacturer has its own

code system. Control codes for the NT-T16S were designed

with reference to the popular IBM and EPSON printers.

Hence, they are compatible with most printers.

5. Operating Note

( 1) Do not dismantle printer head!

( 2) Do not leave power on when not is use for a long period.

( 3)Switch off, if printer does not work normally.

( 4)Power supply must match requirement. See Section 2.5.

( 5) Do not lubricate the printer head.

( 6) Fluff and dust from paper are harmful to printer head.

Check and clear the head when replacing paper roll.

( 7) When replacing ribbon, do not press the cassette too hard.

Otherwise the plastic wheel on the head may be damaged.

( 8) Keep the main circuit board clean.

( 9) Do not remove the IC chips in the main board.

(10) Never use ribbon oil. It may damage printer head.

Other HiWeigh Printer manuals